Signet 8550-1 User manual

page 1 of 8‡ SIGNET 8550-1 Flow Transmitter

CAUTION!

• Remove power to unit before wiring

input and output connections.

• Follow instructions carefully to avoid

personal in ury.

‡ SIGNET 8550-1 Flow Transmitter ENGLISH

Contents

1. Installation

2. Specifications

3. Electrical Connections

4. Menu Functions

• Max loop impedance: 50 Ω max. @ 12 V

325 Ω max. @ 18 V

600 Ω max. @ 24V

• Update rate: 100 ms

• Accuracy: ±0.03 mA

Open-collector output, optically isolated:

• 50 mA max. sink, 30 VDC maximum pull-up voltage.

• Programmable for:

• High or Low setpoint with ad ustable hysteresis

• Pulse operation (max rate: 300 pulses/min).

En ironmental

• Operating temperature: -10 to 70°C (14 to 158°F)

• Storage temperature: -15 to 80°C (5 to 176°F)

• Relative humidity: 0 to 95%, non-condensing

• Maximum altitude: 2000 m (6562 ft)

• Insulation category: II

• Pollution degree: 2

Standards and Appro als

• CSA, CE, UL listed

• Immunity: EN50082-2

• Emissions: EN55011

• Safety: EN61010

• Manufactured under ISO 9001 and ISO 14001

2 . Specifications

General

Compatibility: +GF+ SIGNET Flow Sensors (w/freq out)

Accuracy: ±0.5 Hz

Enclosure:

• Rating: NEMA 4X/IP65 front

• Case: PBT

• Panel case gasket: Neoprene

• Window: Polyurethane coated polycarbonate

• Keypad: Sealed 4-key silicone rubber

• Weight: Approx. 325g (12 oz.)

Display:

• Alphanumeric 2 x 16 LCD

• Update rate: 1 second

• Contrast: User selected, 5 levels

Electrical

• Power: 12 to 24 VDC ±10%, regulated, 61 mA max current

Sensor Input:

• Range: 0.5 to 1500 Hz

• Sensor power: 2-wire: 1.5 mA @ 5 VDC ± 1%

3 or 4 wire: 20 mA @ 5 VDC ± 1%

• Optically isolated from current loop

• Short circuit protected

Current output:

• 4 to 20 mA, isolated, fully ad ustable and reversible

Flow

Flow 6.25 GPM

Total 1234567.8>

ENTER

3-8550.090-1

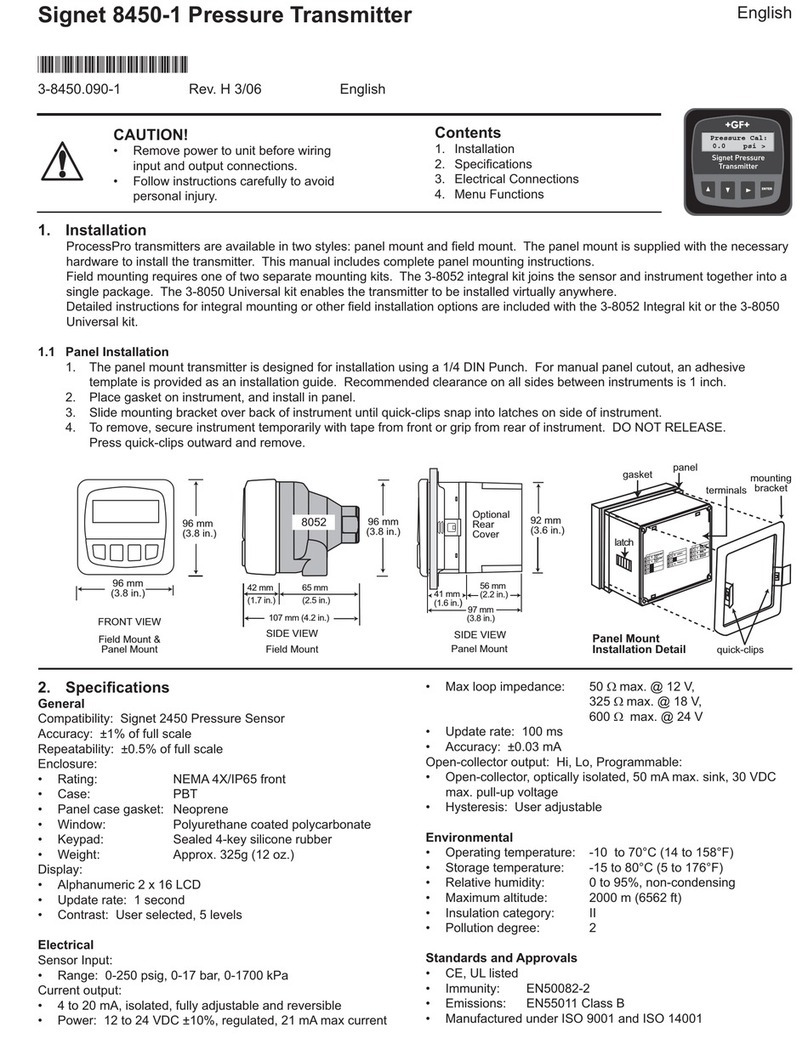

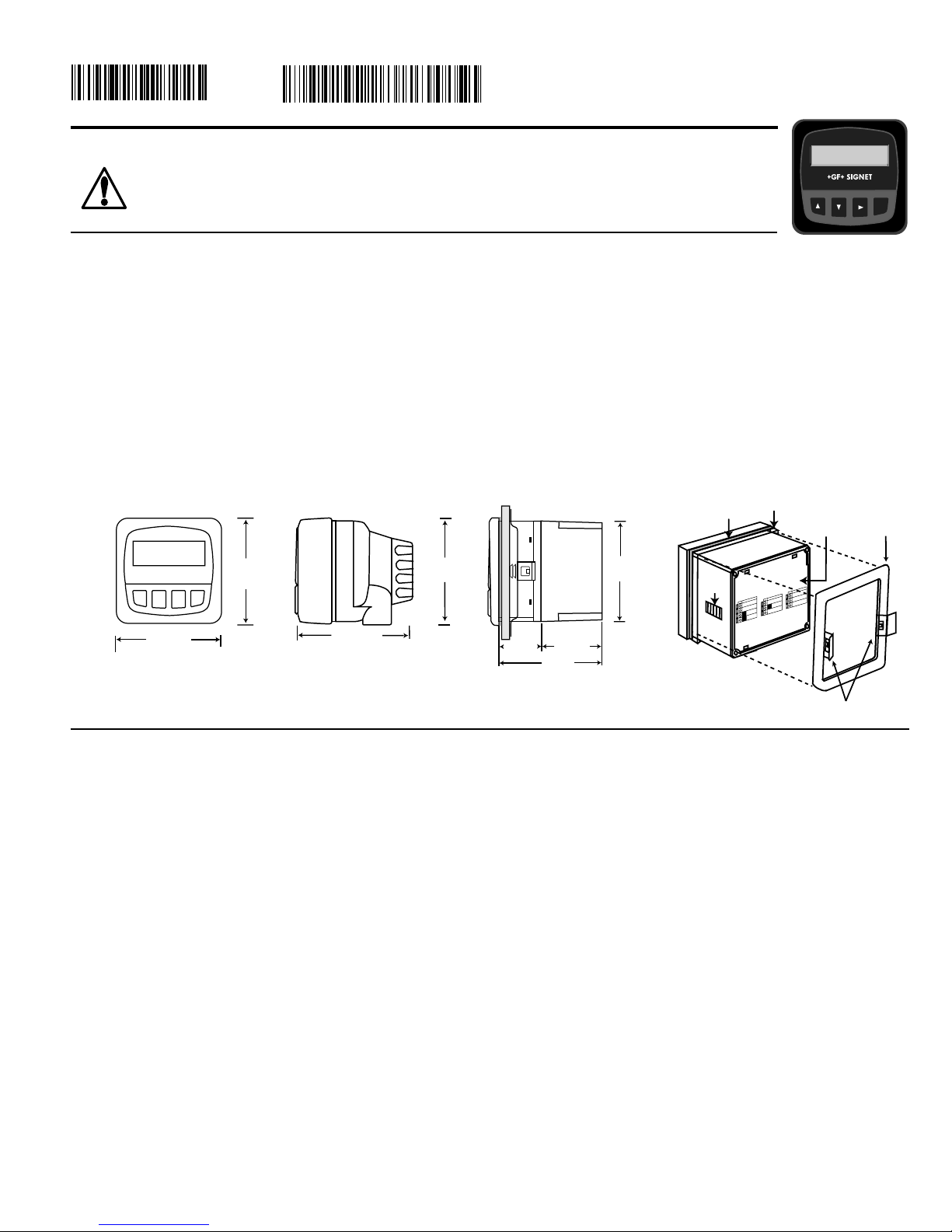

1. Installation

ProcessPro transmitters are available in two styles: panel mount and field mount. The panel mount is supplied with the necessary

hardware to install the transmitter. This manual includes complete panel mounting instructions.

Field mounting requires one of two separate mounting kits. The 3-8051 integral kit oins the sensor and instrument together into a

single package. The 3-8050 Universal kit enables the transmitter to be installed virtually anywhere.

Detailed instructions for integral mounting or other field installation options are included with the 3-8051 Integral kit or the 3-8050

Universal kit.

1.1 Panel Installation

1. The panel mount transmitter is designed for installation using a 1/4 DIN Punch. For manual panel cutout, an adhesive

template is provided as an installation guide. Recommended clearance on all sides between instruments is 1 inch.

2. Place gasket on instrument, and install in panel.

3. Slide mounting bracket over back of instrument until quick-clips snap into latches on side of instrument.

4. To remove, secure instrument temporarily with tape from front or grip from rear of instrument. DO NOT RELEASE.

Press quick-clips outward and remove.

SIDE VIEW

92 mm

(3.6 in.)

97 mm

(3.8 in.)

56 mm

(2.2 in.)

41 mm

(1.6 in.

)

Optional

Rear

Cover

Field Mount Panel Mount

FRONT VIEW

96 mm

(3.8 in.)

96 mm

(3.8 in.)

102 mm

(4.0 in.)

96 mm

(3.8 in.)

quick-clips

gasket panel

terminals mounting

bracket

latch

Output -

Output +

System Pwr

Loop -

System Pwr

Loop +

2

14

3

Sensr Gnd

(SHIELD)

Sensr IN

(RED)

Sensr V+

(BLACK)

7

6

5

SIDE VIEW

Field Mount &

Panel Mount

Panel Mount

Installation Detail

C-3/01 English

page 2 of 8 ‡ SIGNET 8550-1 Flow Transmitter

Output -

Output +

System Pwr

Loop -

System Pwr

Loop +

AUX

Power -

AUX

Power +

4

3

2

1

6

5

Sensr Gnd

(SHIELD)

Sensr IN

(RED)

Sensr V+

(BLACK)

9

8

7

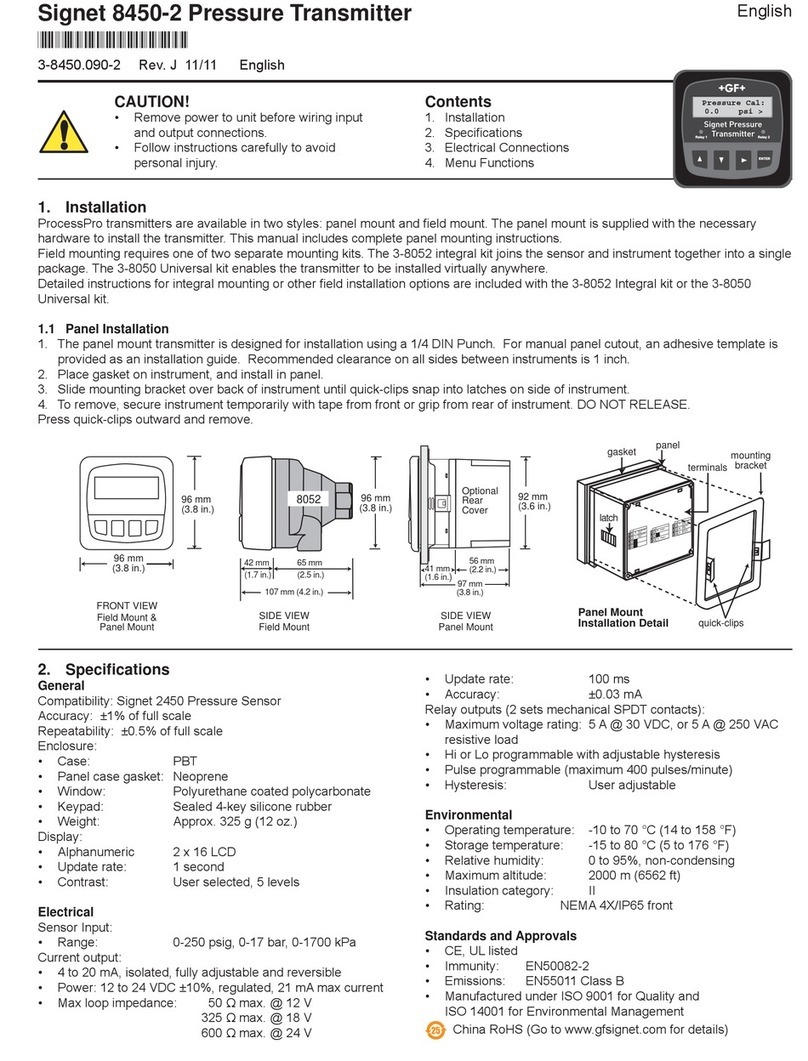

3. Electrical Connections

Caution: Failure to fully open terminal aws before removing wire may permanently damage instrument.

Wiring Procedure

1. Remove 0.5 - 0.625 in. (13-16 mm) of insulation from wire end.

2. Press the orange terminal lever downward with a small screwdriver to open terminal aws.

3. Insert exposed (non-insulated) wire end in terminal hole until it bottoms out.

4. Release orange terminal lever to secure wire in place. Gently pull on each wire to ensure a good connection.

Wiring Removal Procedure

1. Press the orange terminal lever downward with a small screwdriver to open terminal aws.

2. When fully open, remove wire from terminal.

2

1

Terminals 5 and 6: Open-collector Output

A transistor output, programmable (see CALIBRATE menu) as:

• High or Low setpoint with ad ustable hysteresis

• Volumetric pulse

• Frequency based on flow rate

• May be disabled (Off) if not used.

Terminals 3 and 4: Loop Power

12-24 VDC ±10% system power

and current loop output.

Max. loop impedance:

50 Ω max. @ 12 V

325 Ω max. @ 18 V

600 Ω max. @ 24 V

Terminals 7-9: Flow sensor input

Internal open-collector

output circuit

Output --

Output +

Isolation

15Ω

S

D

Terminals 1 and 2: AUXILIARY power

Used only if the flow sensor requires

more than 1.5 mA current. For Signet

sensors this is limited to the following

products:

• 2000 • 2507

• 2530 • 2535

• 2540 if mfg. prior to Jan 1999

page 3 of 8‡ SIGNET 8550-1 Flow Transmitter

3.1 System Power/Loop Connections

3.2 Sensor Input Connections

Wiring Tips:

• Do not route sensor cable in conduit containing AC power wiring. Electrical noise may interfere with sensor signal.

• Routing sensor cable in grounded metal conduit will help prevent electrical noise and mechanical damage.

• Seal cable entry points to prevent moisture damage.

• Only one wire should be inserted into a terminal. Splice double wires outside the terminal.

Transmitter

≤ 200 ft. (61 m)

Transmitter

≤ 1000 ft. (300 m)

Maximum cable length is 200 ft. for 515/8510-XX, 525 , 2517 and

any sinusoidal flow signal.

Maximum cable length is 1000 ft. for 2536/8512-XX, 2540, vortex,

and any square wave flow signal.

Stand-alone application, no current loop used

Transmitter

Terminals

4

3

2

1

Sys. Pwr.

Loop -

Sys. Pwr.

Loop +

AUX

Power -

AUX

Power +

Power Supply

DC 12 - 24 V

Power

Supply

Power

Supply

Connection to a PLC with built-in power supply

PLC

Terminals

Power Supply

Ground

Power

Supply

Loop Input

4-20 mA

Loop Input

4-20 mA

Internal PLC

Connection

Connection to a PLC/Recorder, separate supply

PLC or Recorder

Loop Input

4-20 mA in

Loop Input

4-20 mA in

DC 12 - 24 V

Power

Supply

Power

Supply

Example: Two transmitters connected to PLC/Recorder

with separate power supply

Transmitter 2

4

3

2

1

DC 12 - 24 V

Power

Supply

Power

Supply

Transmitter 1

4

3

2

1

Transmitter

Terminals

4

3

2

1

Sys. Pwr.

Loop -

Sys. Pwr.

Loop +

AUX

Power -

AUX

Power +

Transmitter

Terminals

4

3

2

1

Sys. Pwr.

Loop -

Sys. Pwr.

Loop +

AUX

Power -

AUX

Power +

Sys. Pwr.

Loop -

Sys. Pwr.

Loop +

AUX

Power -

AUX

Power +

Sys. Pwr.

Loop -

Sys. Pwr.

Loop +

AUX

Power -

AUX

Power +

PLC or Recorder

Channel 1

4-20 mA in

Channel 1

4-20 mA in

Channel 2

4-20 mA in

Channel 2

4-20 mA in

* See AUX POWER Note

* See AUX POWER Note

* See AUX POWER Note

* See AUX POWER Note

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

Auxiliary Power note:

AUXILIARY power is used only if the flow sensor requires more

than 1.5 mA current. For Signet sensors this is limited to the

following products:

• 2000 • 2507

• 2530 • 2535

• 2540 if mfg. prior to Jan 1999

No Aux Power

515

525

2100

2517

2536

2540

3-8510-XX

3-8512-XX

Aux Power

2000

2507

2530

2535

2540 (mfg prior to Jan 1999)

Terminals

Sensr Gnd

(SHIELD)

Sensr IN

(RED)

Sensr V+

(BLACK)

9

8

7

page 4 of 8 ‡ SIGNET 8550-1 Flow Transmitter

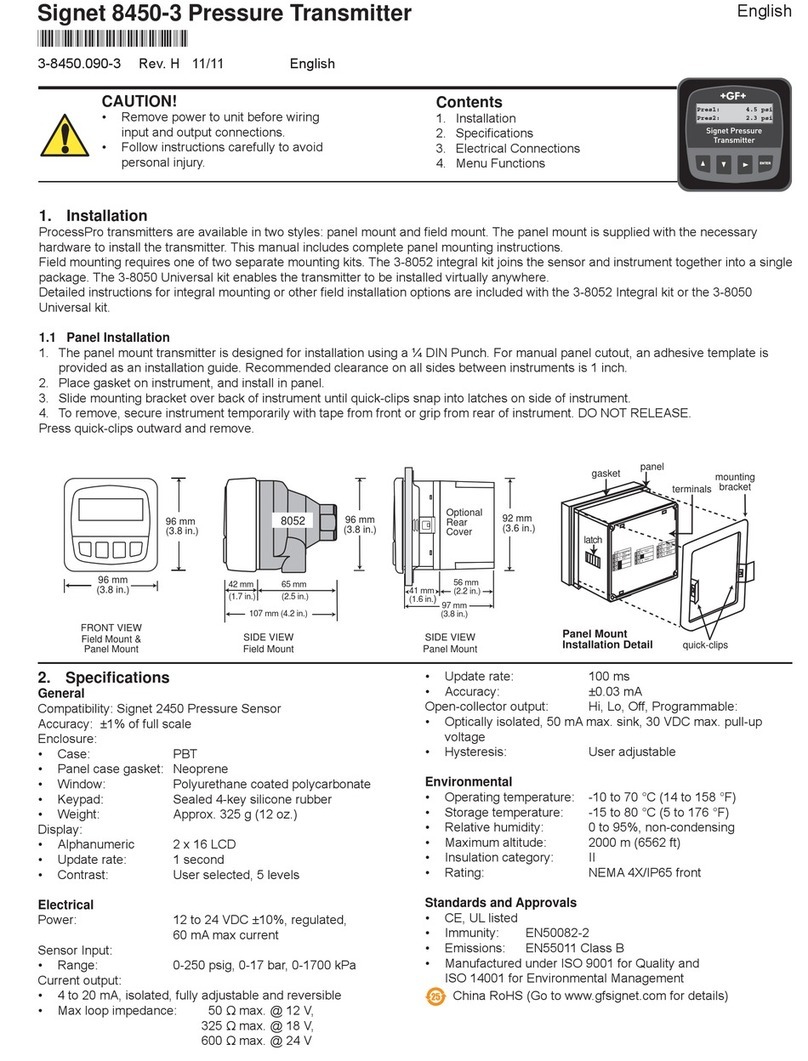

Monitor the Permanent Totalizer value.

Monitor the 4-20 mA Loop output.

Monitor date for scheduled maintenance or date of last calibration. (See

description in Calibrate Menu.)

Hysteresis

Time

Low Setpoint

Process

Hysteresis

Output acti e

Output inacti e

Time

High Setpoint

Process

Flow

Flow 6.25 GPM

Total 1234567.8>

ENTER

VIEW menu

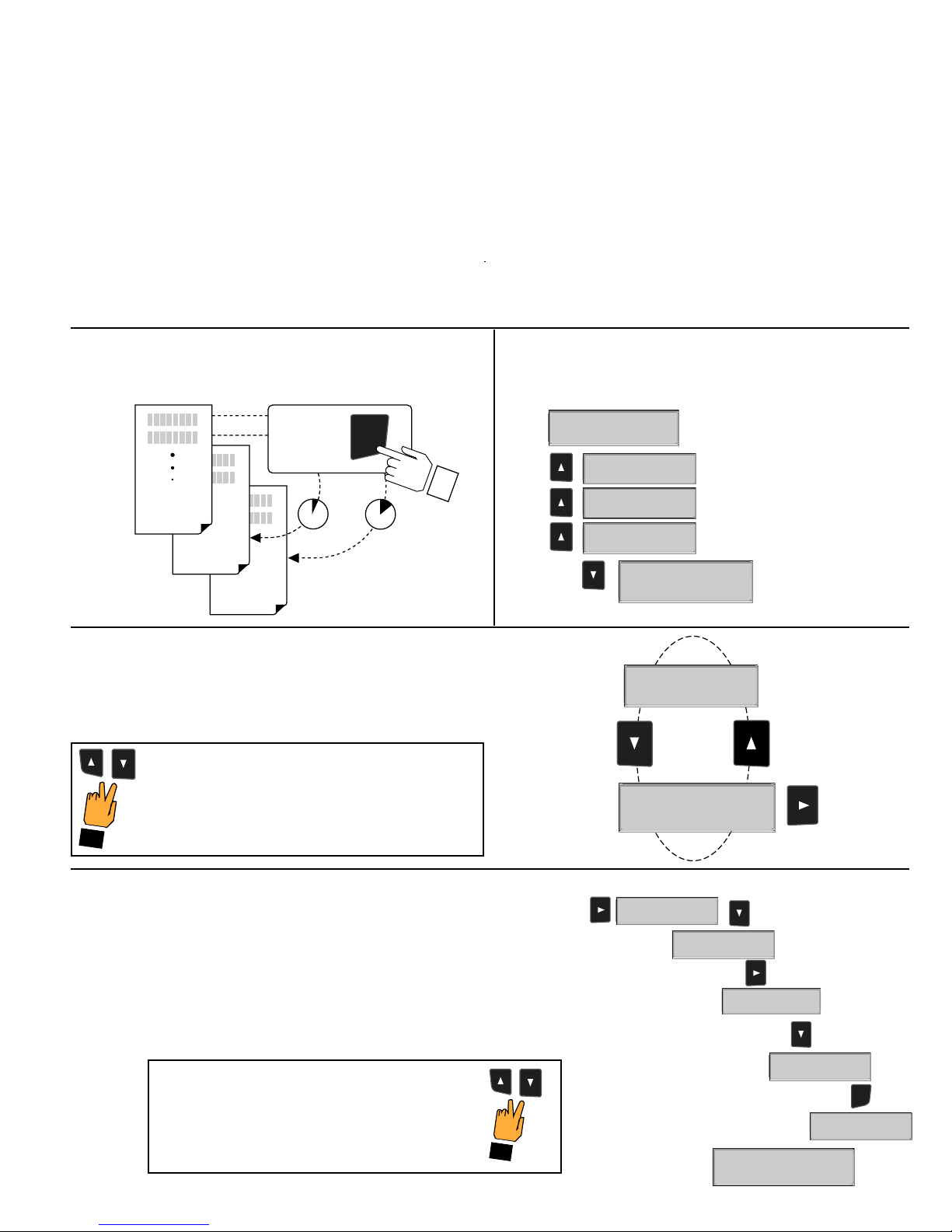

• During normal operation, the ProcessPro displays the VIEW menu.

• When using the CALIBRATE or OPTIONS menus, the ProcessPro will return to the VIEW menu if no activity

occurs for 10 minutes.

• To select the item you want displayed, press the UP or DOWN arrow keys. The items will scroll in a

continuous loop. Changing the display selection does not interrupt system operations.

• No key code is necessary to change display selection.

• Output settings cannot be edited from the VIEW menu.

The Open collector output can be used as a switch that responds

when the flow rate moves above or below a setpoint, or it can be

used to generate a pulse that is relative to the flow volume or to

the flow rate.

•Low

Output triggers when the flow rate is less than the setpoint.

The output will relax when the flow rate moves above the setpoint

plus the hysteresis value.

•High

Output triggers when the flow rate is greater than the setpoint.

The output will relax when the flow rate drops below the setpoint

plus the hysteresis value.

•Frequency

Output is a pulse stream that is based on the input flow sensor

signal. Set for 1 (input frequency = output frequency). Set for

even numbers (2, 4, 6, 8 . . . . 254 maximum) to scale output

frequency.

•Pulse

Output is a pulse based on the volume of fluid that passes the

sensor. Set any value from 0.0001 to 99999.

The output may be disabled (Off) if not used.

View Menu

Display Description

0.0 GPM

Total: 12345678 >

Perm: 12345678

Gallons

Loop Output:

12.00 mA

Last CAL:

06-30-01

Monitor the flow rate and the resettable totalizer. Press the RIGHT ARROW

key to reset the totalizer. If the Reset is locked, you will need to enter the Key

Code first. Lock or Unlock the totalizer in the OPTIONS menu. This is the

permanent View display.

All of the displays below are temporary. After ten minutes the display will return to the permanent display.

page 5 of 8‡ SIGNET 8550-1 Flow Transmitter

Notes on Steps 5 and 6:

• All output functions remain active during editing.

• Only the flashing element can be edited.

• RIGHT ARROW key advances the flashing element in a continuous loop.

• Edited value is effective immediately after pressing ENTER key.

• If no key is pressed for 10 minutes unit will restore the last saved value and return to step 3.

• Step 6 (pressing ENTER key) always returns you to Step 3.

• Repeat steps 3-6 until all editing is completed.

Notes on Step 2:

If no key is pressed for 5 minutes while display is showing "Enter

Key Code", the display will return to the VIEW menu.

Notes on Steps 3 and 4:

• Refer to pages 6 and 7 for complete listing of menu items and their use.

• From the Step 3 display, pressing the UP and DOWN keys simultaneously will

return the display to the VIEW menu.

• If no key is pressed for 10 minutes, display will also return to the VIEW menu.

ProcessPro Editing Procedure:

Step 1. Press and hold ENTER key:

• 2 seconds to select the CALIBRATE menu

• 5 seconds to select the OPTIONS menu.

Step 2. The Key Code is UP-UP-UP-DOWN keys in sequence.

• After entering the Key Code, the display will show the first item in the selected menu.

Step 3. Scroll menu with UP or DOWN arrow keys.

Step 4. Press RIGHT ARROW key to select menu item to be edited.

• The first display element will begin flashing.

Step 5. Press UP or DOWN keys to edit the flashing element.

• RIGHT ARROW key advances the flashing element.

Step 6. Press ENTER key to sa e the new setting and return to Step 3.

OPTIONS

CALIBRATE

VIEW

2s 5s

Press &

hold for

access:

ENTER

Step 5

Step 6

Notes on Step 1:

• The View Menu is normally displayed.

• The CALIBRATE and OPTIONS menus require a KEY CODE.

Step 4

First item in

CALIBRATE menu

Step 3

Step 3: Finished Editing?

Press the UP and DOWN keys simultaneously after

saving the last setting to return to normal operation.

Press the UP and DOWN keys simultaneously

while any element is flashing. This will recall the

last saved value of the item being edited and

return you to Step 3.

Step 5: Made an Error?

Output Setpnt:

2

0.00 GPM

Output Setpnt:

1

0.00 GPM

ENTER

Output Setpnt:

10.00

GPM

Output Setpnt:

1

9

.00 GPM

Output Setpnt:

Saving

Output Setpnt:

19.00 GPM >

20.0 GPM >

Output Setpnt:

GPM >

Flow Units:

CALIBRATE: ----

Enter Key Code

CALIBRATE: *---

Enter Key Code

CALIBRATE: **--

Enter Key Code

CALIBRATE: ***-

Enter Key Code

GPM >

Flow Units:

Table of contents

Other Signet Transmitter manuals

Popular Transmitter manuals by other brands

Geo

Geo Web Pack quick start guide

Inovonics

Inovonics EchoStream EN1210W installation instructions

IKONNIK

IKONNIK KA-6 quick start guide

Rohde & Schwarz

Rohde & Schwarz SR8000 Series System manual

Audio Technica

Audio Technica UniPak ATW-T93 Installation and operation

NIVELCO

NIVELCO EasyTREK SCA-300 Series Programming manual