Siko AP10 User manual

183/18

AP10

Absolute Position Indicator with RS485 /

SIKONETZ5 interface

User manual

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 2 of 50

Table of contents

1General Informaton ................................................................................................... 5

1.1 Dokumentation ........................................................................................................5

1.2 Definitions ..............................................................................................................5

2Intended use............................................................................................................. 5

2.1 Switching on the supply voltage.................................................................................6

3Display and control keys ............................................................................................ 6

3.1 General ...................................................................................................................6

3.2 LCD display..............................................................................................................6

3.2.1 Extended display range ..........................................................................................7

3.3 LED display..............................................................................................................7

3.4 Keys .......................................................................................................................7

4Functional Description ............................................................................................... 8

4.1 Operating modes ......................................................................................................8

4.1.1 Position-bound operating modes.............................................................................9

4.1.1.1 Positioning.......................................................................................................9

4.1.1.2 Loop positioning .............................................................................................10

4.1.2 Alpha-numeric display operating mode...................................................................11

4.2 Battery buffering....................................................................................................12

4.3 Parameterization of the position indicator .................................................................12

4.3.1 Manual parameterization......................................................................................12

4.3.1.1 Starting parameterization .................................................................................12

4.3.1.2 Value input.....................................................................................................12

4.3.1.3 Value selection................................................................................................13

4.3.1.4 Adjustable parameters......................................................................................13

4.3.2 Parameterization via interface ..............................................................................13

4.4 Warnings / Errors....................................................................................................13

4.4.1 Warnings ...........................................................................................................13

4.4.2 Errors ................................................................................................................14

4.5 System commands ..................................................................................................14

4.5.1 Calibration .........................................................................................................14

4.5.2 Restore factory settings .......................................................................................15

4.5.3 Read error memory ..............................................................................................15

4.5.4 Diagnosis of bus communication ...........................................................................15

4.5.4.1 General communication ....................................................................................16

4.5.4.2 Data scan .......................................................................................................18

4.5.4.3 Telegram scan.................................................................................................19

5Overview of parameters............................................................................................ 19

6Communication via SIKONETZ 5 ................................................................................ 21

6.1 Interface...............................................................................................................21

6.2 Data exchange .......................................................................................................21

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 3 of 50

6.3 Telegram setup.......................................................................................................22

6.3.1 Command...........................................................................................................22

6.3.2 Node address......................................................................................................22

6.3.3 Parameter address...............................................................................................22

6.3.4 Control word ......................................................................................................23

6.3.5 Status word........................................................................................................23

6.3.6 Data..................................................................................................................24

6.3.7 Check sum..........................................................................................................24

6.4 Synchronization .....................................................................................................25

6.5 Error telegram........................................................................................................25

6.5.1 SIKONETZ5 error codes.........................................................................................25

6.6 Communication errors .............................................................................................26

6.7 Communication monitoring ......................................................................................26

6.7.1 Bus-Timeout.......................................................................................................26

6.7.2 Programming interlock.........................................................................................26

6.8 Auto-ID.................................................................................................................27

6.9 Parameter description .............................................................................................29

6.9.1 00h: Node address...............................................................................................29

6.9.2 01h: Baud rate ...................................................................................................29

6.9.3 02h: Bus Timeout................................................................................................29

6.9.4 03h: Response parameter to a set point write access................................................30

6.9.5 04h: Keys enable time: Configuration start delay .....................................................30

6.9.6 05h: Key function enable1: Calibration enable.........................................................30

6.9.7 06h: LED flashing................................................................................................31

6.9.8 07h: LED3 (green right) .......................................................................................31

6.9.9 08h: LED2 (red left) ............................................................................................31

6.9.10 09h: LED1 (green left) .........................................................................................32

6.9.11 0Ah: Decimal places ............................................................................................32

6.9.12 0Bh: Display divisor (ADI) ....................................................................................32

6.9.13 0Ch: Direction indicators (CW, CCW).......................................................................33

6.9.14 0Dh: Display orientation ......................................................................................33

6.9.15 0Eh: Configuration programming mode...................................................................33

6.9.16 1Bh: Counting direction.......................................................................................34

6.9.17 1Ch: Resolution per revolution..............................................................................34

6.9.18 1Eh: Offset value ................................................................................................35

6.9.19 1Fh: Calibration value..........................................................................................35

6.9.20 20h: Target window1 (near field) ..........................................................................35

6.9.21 21h: Positioning type (loop type)..........................................................................36

6.9.22 22h: Loop length ................................................................................................36

6.9.23 28h: Operating mode...........................................................................................36

6.9.24 30h: Display in the 2nd row ...................................................................................37

6.9.25 31h: Target window2 (extended)...........................................................................37

6.9.26 32h: Target window2 visualization.........................................................................37

6.9.27 33h: Application of the display divisor (ADI application)..........................................38

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 4 of 50

6.9.28 34h: Formation of the differential value .................................................................38

6.9.29 35h: Key function enable2: Incremental measurement enable....................................39

6.9.30 39h: LED4 (red right)...........................................................................................39

6.9.31 3Ah: LCD backlight flashing..................................................................................39

6.9.32 3Bh: LCD backlight white .....................................................................................40

6.9.33 3Ch: LCD backlight red.........................................................................................40

6.9.34 3Dh: Key function enable3: Configuration enable via keyboard ..................................40

6.9.35 3Eh: Acknowledgement settings ............................................................................41

6.9.36 3Fh: Display factor ..............................................................................................41

6.9.37 63h: Battery voltage............................................................................................42

6.9.38 65h: Device identification ....................................................................................42

6.9.39 67h: Software version ..........................................................................................43

6.9.40 80h: Number of errors..........................................................................................43

6.9.41 81h until 8Ah: Errors ...........................................................................................43

6.9.42 96h: Input errors ................................................................................................44

6.9.43 A0h: System commands........................................................................................44

6.9.44 A7h: Calibration travel.........................................................................................45

6.9.45 A8h: Programming mode ......................................................................................45

6.9.46 AAh: Freeze actual value ......................................................................................45

6.9.47 C5h: ADC values of the sensor...............................................................................46

6.9.48 CFh: Period counter .............................................................................................46

6.9.49 D0h: Response delay............................................................................................46

6.9.50 D2h: Auto-ID assignment .....................................................................................47

6.9.51 FAh: Status word.................................................................................................47

6.9.52 FBh: Set point1 ..................................................................................................47

6.9.53 FCh: Differential value .........................................................................................48

6.9.54 FDh: Error telegram .............................................................................................48

6.9.55 FEh: Position value..............................................................................................48

6.9.56 FFh: Set point2...................................................................................................49

7Communication via Service Standard Protocol ............................................................ 49

7.1 General .................................................................................................................49

7.2 Error number encoding ............................................................................................49

7.3 Service protocol commands list.................................................................................49

General Informaton

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 5 of 50

1General Informaton

1.1 Dokumentation

The following documents describe this product:

The data sheet describes the technical data, the dimensions, the pin assignments, the

accessories and the order key.

The installation instructions describe the mechanical and electrical installation including

all safety-relevant requirements and the associated technical specification.

The user manual for commissioning and integrating the position indicator into a fieldbus

system.

These documents can also be downloaded at http://www.siko-global.com/p/ap10.

Additional information and support for this device can also be found there.

1.2 Definitions

If not explicitly indicated otherwise, decimal values are given as figures without addition (e.

g. 1234), binary values are labeled with b (e. g. 1011b), hexadecimal values are identified by

h (e. g. 280h) after the figures.

2Intended use

Absolute position indicator with hollow shaft suitable for direct shaft mounting. Actual and

target values are indicated via the backlit two-row LC display. A direction indicator (arrow) is

blended in if the actual value deviates from the target value including the adjustable target

window. The direction of the arrow indicates the direction of shaft movement necessary to

reach the target. Additionally, various visualization tasks can be realized by means of two bi-

color LEDs.

The device parameters can be adjusted by means of 3 keys. You can change the set point,

output the position value and adjust all device parameters via the integrated bus interface.

Scanning is magnetically-incremental. In the currentless state, scanning and saving of

changes of the position value are battery-supported.

The state of charge of the replaceable battery is monitored and signified.

Display and interface are active with external power supply only.

Display and control keys

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 6 of 50

2.1 Switching on the supply voltage

The AP10 will be initialized after switching on the supply voltage. A display test is executed

during initialization, the LEDs are lighted consecutively and the configutation parameters are

loaded from the non-volative memory into the RAM of the controller.

With the display still unconfigured all parameters are set to their default values. See to it that

the bus will be connected only after correct adjustment of baud rate and ID (see chapter 4.3:

Parameterization of the position indicator and 6.8: Auto-ID). The AP10 functions with the

data last parameterized.

AP10 is in the normal operating state. According to the requirements of the application, the

display can be parameterized via the SIKONETZ5 interface in this state.

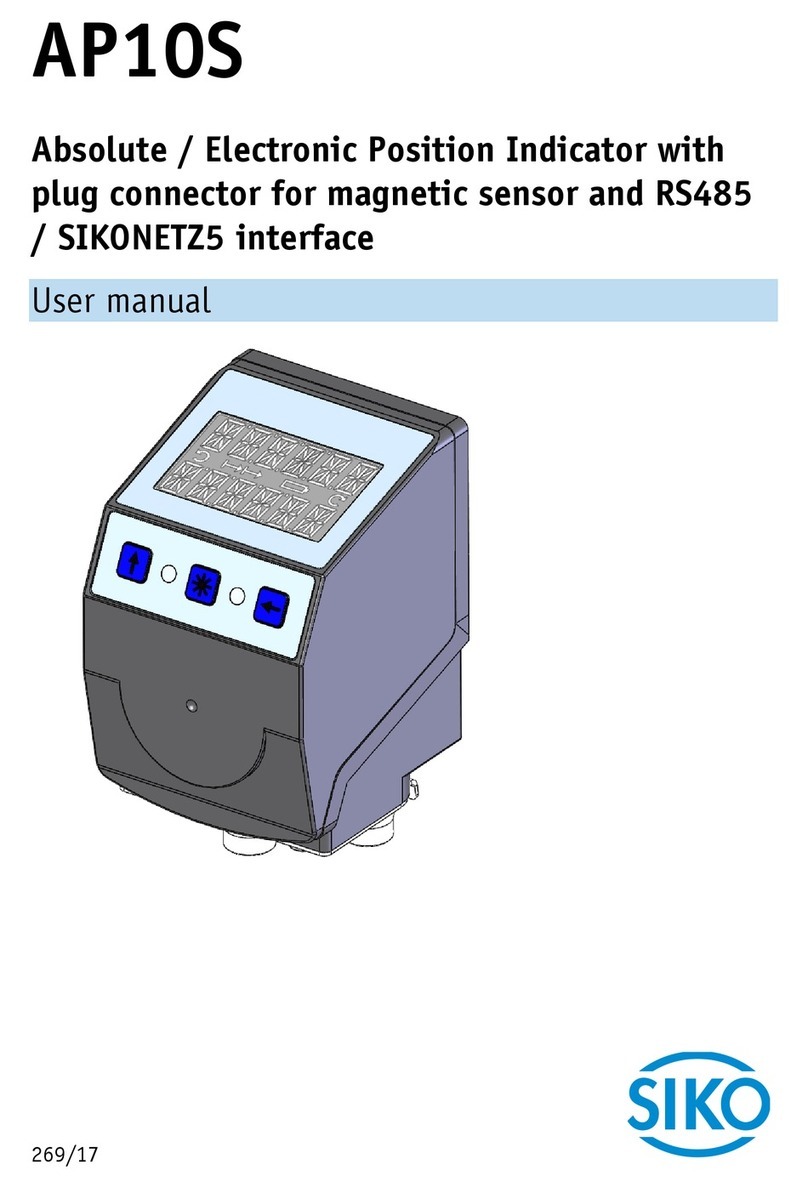

3Display and control keys

3.1 General

The position indicator has a two-line display with special characters and three control keys.

The keys serve for position indicator parameterization and control. Two LEDs (1) serve for

monitoring positioning.

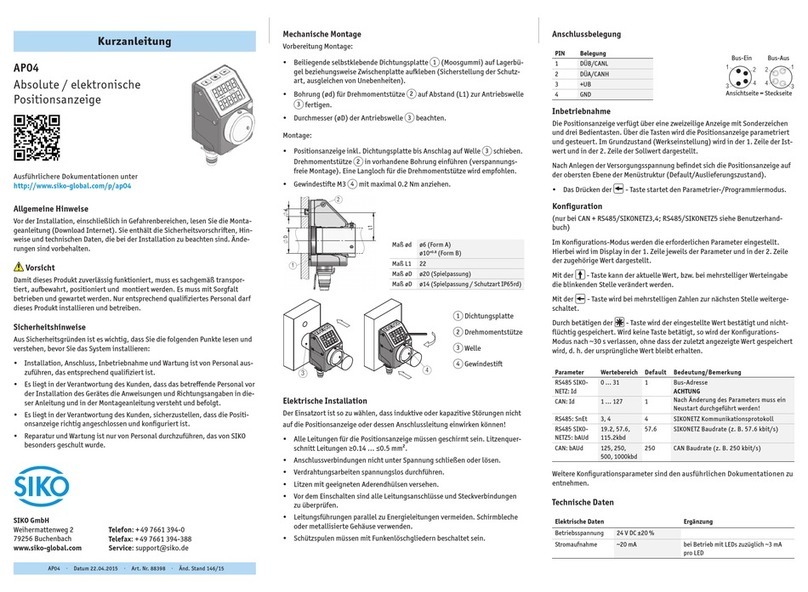

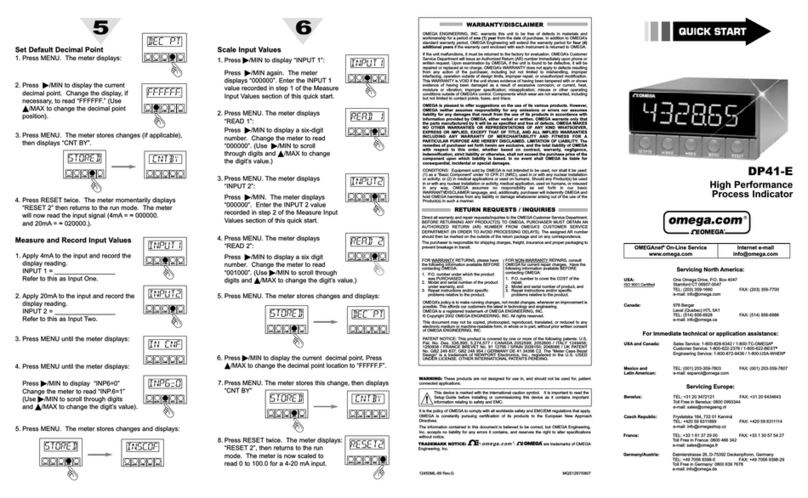

Fig. 1: Control elements

3.2 LCD display

The The display range is limited to -19999 … 99999. Values outside this

range are displayed with "".

With supply voltage applied to the position indicator with factory settings, the actual value

will be displayed in the 1st row and the set point in the 2nd row. If there is no valid set point,

"---" will be displayed in the 2nd row. The values displayed are determined by the operating

mode.

Direction indicators (arrows) support positioning.

The battery symbol is shown with a critical or insufficient battery status.

With incremental measurement function activated, the incremental measurement symbol

is shown.

LED1

Display and control keys

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 7 of 50

If battery voltage drops to a critical value, the battery symbol on the display will flash. If it

falls below the minimum value, the symbol will glow permanently.

Errors are signified by red characters.

3.2.1 Extended display range

Values up to -999999 can be displayed by means of the control word. If the relevant bit has

been set and the value to be displayed is between -199999 and -999999, then the negative

sign and the digit of the highest order will flash alternately. If the value range drops below -

999999, "" will be displayed.

3.3 LED display

In its basic state (factory setting) the LED display has different meanings depending on the

operating mode (see chapter 4.1: Operating modes).

With the basic function of the LEDs inactivated, every LED can be controlled independently via

the control word (see chapters 6.9.8 to 6.9.10 and 6.9.30: LEDs and chapter 6.3.4: Control

word).

3.4 Keys

Pressing the key enables or disables the incremental measurement function. With the

Auto-ID function, the new ID is adopted by actuating this key (see chapter 6.8: Auto-ID).

Pressing the key starts calibration (see chapter 4.5.1: Calibration) and acknowledges a

pending error (see chapter 4.4.2: Errors).

Pressing the key starts the parameterization mode (see chapter 4.3: Parameterization of

the position indicator).

In the "Alpha-numeric display" operating mode, the set points previously received (set point1

and set point2) are acknowledged via the respective buttons depending on the

acknowledgment settings (see chapter 6.9.35).

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 8 of 50

4Functional Description

4.1 Operating modes

The following position-dependent operating modes are differentiated: Absolute Position,

Differential Value, Modulo and the position-independent operating mode Alpha-numeric

Display.

Operating

mode

Absolute position

Differential value

Modulo

Alpha-numeric

Display

Line 1

Actual position

Actual position

Actual position

Set point1

Line 2

Set point2

Differential value

Set point2

Set point2

Table 1: Display with different operating modes

Absolute position:

Linear absolute position values are displayed.

Differential value display:

With factory setting: Differential value = actual position - set point2

Modulo display:

Position values ranging from 0° to 360° are displayed.

Using the parameter 0Ah: Decimal places the resolution and the modulo point of the

displayed values are set.

Decimal places

Display resolution

Value range

0

1°

0° …360°

1

1/10°

0.0° …360.0°

2

1/100°

0.00° …360.00°

3

1/1000°

0.000° …360.000°

4

1/10000°

0.0000° …360.0000°

Table 2: Modulo display

Alpha-numeric display:

Both rows can be written freely. Set point1 is received via the SIKONETZ5 parameter FBh "set

point1", set point2 via parameter FFh "set point2". The data identifier must be correctly set in

the relevant control word. The data identifier differentiates whether the data is interpreted

and displayed as figures or alpha-numeric characters (ASCII) (see chapter 6.3.4: Control

word).

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 9 of 50

4.1.1 Position-bound operating modes

4.1.1.1 Positioning

(see chapter 4.1.1.2: Loop positioning)

Arrows: (see parameter 0Ch: Direction indicators (CW, CCW))

Arrows are displayed to support the user with positioning as long as the current actual

position value is outside (see parameter 20h: Target window1 (near field)) target window1.

The direction of the arrow indicates the direction of shaft rotation in order to arrive at the set

point2.

LED display: (see e. g. parameter 09h: LED1 (green left))

With factory setting, the LED glows green as long as the actual position is within the

programmed window1. When leaving target window1, the LED glows red. The shaft must be

rotated in the direction of the glowing LED in order to arrive at the set point2. The red

glowing LED on the right means: clockwise (cw) rotation required. Red glowing LED on the

left: counter-clockwise (ccw) rotation required.

An additional target window (target window2) and an associated visualization can also be

configured (see parameter 31h: Target window2 (extended)).

With factory settings, the LED display has the following meaning:

Operating state

LED

Status

Meaning

There is no valid set

point2.

both

off

Positioning disabled.

There is a valid set

point2.

LED left

off

Target window not reached!

The shaft must be rotated clockwise (cw) in

order to reach the target.

red

Target window not reached!

The shaft must be rotated counter-clockwise

(ccw) in order to reach the target.

green

Target window reached.

LED right

off

Target window not reached!

The shaft must be rotated counter-clockwise

(ccw) in order to reach the target.

red

Target window not reached!

The shaft must be rotated clockwise (cw) in

order to reach the target.

green

Target window reached.

Table 3: LED display

Control word (see chapter 6.3.4: Control word):

The set point is not displayed and positioning not monitored unless the set point2 is marked

as valid in the control word.

Status word (see chapter 6.3.5: Status word):

Upon reaching target window1, the static and dynamic target-window-reached bits are set in

the status word. The dynamic bit is deleted when leaving target window1. The user must

acknowledge the static bit.

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 10 of 50

Example Position monitoring:

Parameterization: Factory setting

Additionally: Set point2 = 100

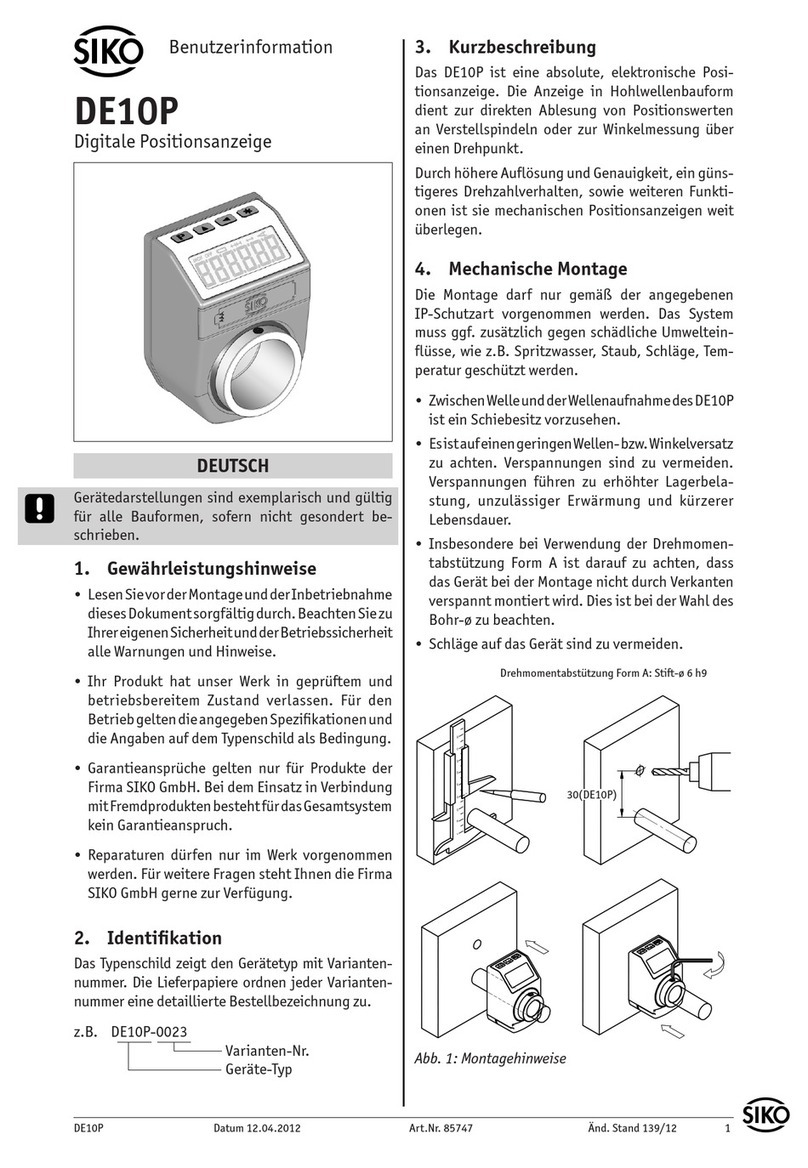

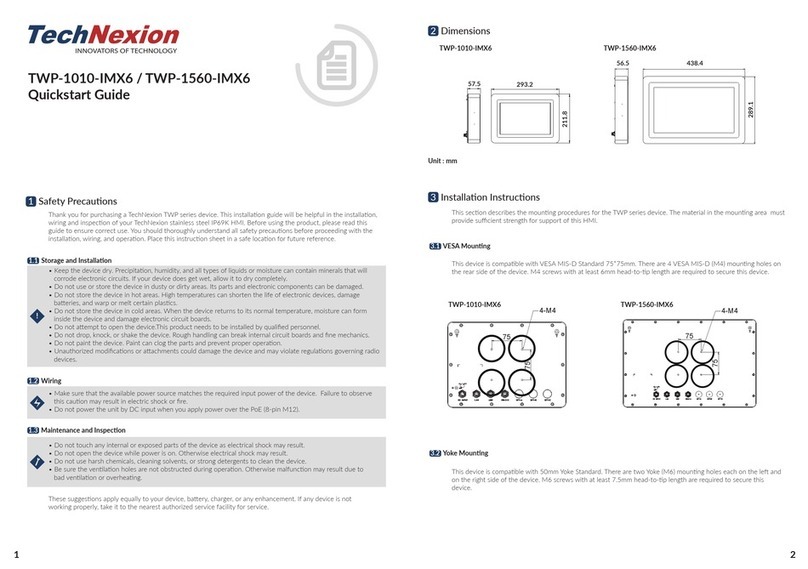

Fig. 2: Positioning monitoring

Example of position monitoring with additionally activated target window2 parameter:

Parameterization: Factory setting

Additionally: Target window 2 = 15

Visualization target window 2 = 1

Set point = 100

Fig. 3: Positioning monitoring with target window2

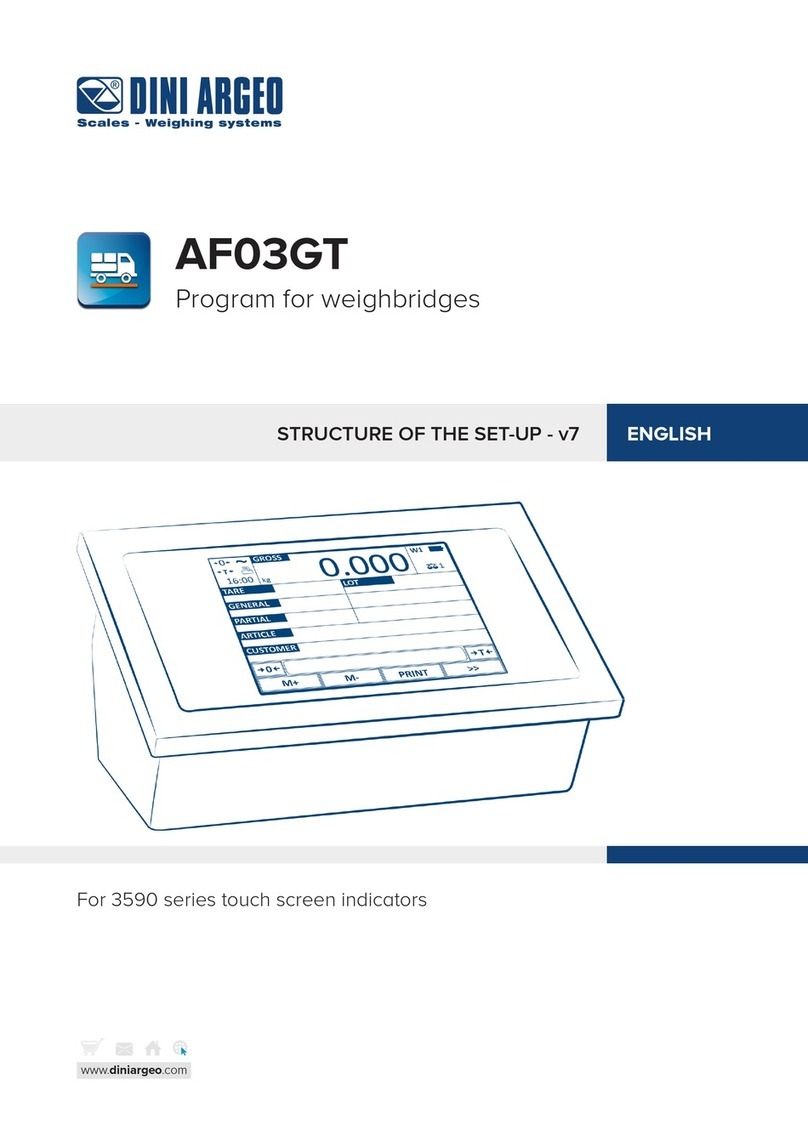

4.1.1.2 Loop positioning

Target window1 is also applied to the loop length.

If the position indicator is operated on a spindle or an additional gear, the spindle or external

gear backlash can be compensated by means of loop positioning. Therefore, movement

towards the set point is always in the same direction. This direction of approach can be

defined.

Example:

The direction from which every target position shall be driven to is positive.

Case 1 the new position is greater than actual position:

100

+

-

Target

window1

95

105

LED left

Positioning monitoring

LED right

+

-

Target

window1

Target window2

LED left

Positioning monitoring

85

115

LED right

100

95

105

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 11 of 50

Direct travel to the target position.

Case 2 the new position is smaller than actual position:

The position indicator's arrows show that the set point is to be overrun by the loop length.

Afterwards, the set point is approached in positive direction.

Fig. 4: Positioning Loop+

4.1.2 Alpha-numeric display operating mode

Two 6-digit set points can be displayed in this operating mode. With factory settings, the set

points are acknowledged by pressing the asterisk key (see chapter 3.4: Keys).

LCD display:

In the absence of a valid set point, the 1st row is displayed empty (blank). "---" appears in

the 2nd row.

A valid set point is displayed flashing until its receipt is acknowledged.

LED display:

With factory settings, the LED display works according to the following table.

Operating state

LED

Status

Meaning

There is no valid set

point.

both

off

There is a valid set

point.

LED left

red

Set point1 not acknowledged

green

Set point1 acknowledged

LED right

red

Set point2 not acknowledged

green

Set point2 acknowledged

Table 4: LED display in the alpha-numeric display operating mode

Control word:

In the control word, the relevant type (number or character string) and the validity of the set

point is transmitted to the display. As an additional option, the set point can be

acknowledged via the control word.

Set point

+

-

Positioning in positive

direction

Positioning in negative

direction

Positioning: loop +

Loop length

Target window1

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 12 of 50

Status word:

Type, validity and acknowledgement status of the set points are fed back in the status word.

4.2 Battery buffering

The battery makes possible the detection of currentless displacement. Battery life is approx. 5

years depending on the duration of battery operation (including storage) and frequency of

currentless adjustments. Battery voltage is checked at intervals of approx. 5 min. If battery

voltage drops below a specified value, the battery symbol will blink on the display. If

the battery voltage continues to drop, will be displayed permanently. The battery

should be replaced within approx. three months after the first appearance of the battery

symbol. The battery can be replaced by the SIKO distribution partners or at the SIKO main

factory. For battery replacement it is mandatory to follow the instructions of the installation

instructions.

Status word:

The charge status of the battery is signified in the status word. Bit 11 is set when the

charging voltage is critical and an error is signified with the additional bit 7 set when the

battery is empty.

4.3 Parameterization of the position indicator

The position indicator can be fully parameterized via the bus interface. You can configure

manually via keyboard the most significant bus parameters (node address, baud rate, protocol,

bus timeout and reponse delay).

4.3.1 Manual parameterization

4.3.1.1 Starting parameterization

After applying supply voltage and completion of initialization, the position indicator is on the

uppermost level of the menu structure (default/Factory settings).

By actuating the key, the set node address and baud rate is displayed. Parameterization

starts if it is actuated for the duration of the enable time (see parameter 04h: Keys enable

time: Configuration start delay and 3Dh: Key function enable3: Configuration enable via

keyboard).

4.3.1.2 Value input

Enter values via the key and the key. Confirm values entered by pressing the key.

- decimal place selection key

- value input key

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 13 of 50

4.3.1.3 Value selection

For some parameters you can select values from a list.

Direct value input is not possible there.

Pressing the key, the value can be selected from the list. By pressing the key, the

selection is confirmed.

4.3.1.4 Adjustable parameters

The following parameters can be adjusted.

Display

Parameter

Options

ID

Node-ID

1 … 127

KBAUD

Baud rate

19.2 kbaud

57.6 kbaud

115.2 kbaud

Protcl

Protocol

SIKONETZ5

Service-standard

BUS TO

Bus-Timeout

0 … 20

Inhibt

Response delay

0 … 20

CODE

System commands

Reset factory settings (see chapter 4.5.2)

Start diagnosis (see chapter 4.5.3)

Table 5: Manually adjustable parameters

4.3.2 Parameterization via interface

The position indicator can be completely parameterized in the RS485-SIKONETZ5 interface

(see chapter 6: Communication via SIKONETZ 5).

4.4 Warnings / Errors

4.4.1 Warnings

Warnings do not influence the acquisition of the absolute position value.

Warnings are deleted after removing the cause.

Possible warnings:

Battery voltage for absolute position detection is below limit immediately exchange

battery!

This warning is displayed with a blinking battery symbol . Warnings are issued through

the interface via the status word (see chapter 6.3.5:Status word, and chapter 4.5.3: Read

error memory).

Display

Bit assignment in the status word

Error

flashing

11

Low battery voltage

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 14 of 50

4.4.2 Errors

Errors are signified via the display (written in red or ) and via the interface.

The cause of error must be removed to enable resumption of normal operation (see Table 7:

Corrective actions). Afterwards you can acknowledge or delete the error message by pressing

the key or via the interface (see chapter 6.3.4: Control word).

(For signaling see chapter 6.3.5:Status word and chapter 4.5.3: Read error memory)

Display

Error code

SIKONETZ5

Bit assignment in

the status word

Error

permanent

0006h

11+7

Low battery voltage (empty)

SENBND

000Fh

12+7

Tape-sensor gap exceeded

noSENS

001Ah

12+7

No sensor connected

SPEED

0019h

12+7

Travel speed exceeded

CS bUS

0080h

7

Checksum SIKONETZ5

to bUS

0081h

7

Timeout SIKONETZ5

Table 6: Error messages

Display

Error

Possible effect

Corrective actions

permanent

Battery empty

Position value not

reliable

Battery change +

calibration travel

SPEED

Admissible speed

exceeded (see

installation instruction)

Position value not

reliable

Reduce speed +

calibration travel

Table 7: Corrective actions

4.5 System commands

4.5.1 Calibration

Two steps are required for executing calibration:

1. Write calibration value (see object 1Fh: Calibration value)

2. Execute calibration (reset) (see chapter 3.4: Keys or object 0Ah: Decimal places with the

data content 7 or object A7h: Calibration travel)

Since the measuring system is an absolute system, calibration is necessary only once with

commissioning. With calibration, the calibration value is adopted for calculation of the

position value. The following equation is applied in case of calibration:

Position value = 0 + calibration value + offset value

Calibration value (see object 1Fh: Calibration value)

Offset value (see object 1Eh: Offset value)

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 15 of 50

4.5.2 Restore factory settings

There are various options for restoring the factory settings of the device:

Access

Coding

Factory settings are restored

Manuell

11100

all parameters

11102

all except bus parameters

11105

only bus parameters

SIKONETZ5

(see parameter A0h:

System commands)

A0h

1

all parameters

2

all except bus parameters

5

only bus parameters

Table 8: Access to factory settings

The bus parameters are:

Display

Parameter address

Parameter

ID

00h

Node-ID

KBAUD

01h

Baud rate

Protcl

-

Protocol

BUS TO

02h

Bus-Timeout

-

03h

Response parameter to target value write access

-

0Eh

Configuration programming mode

Inhibt

D0h

Response delay

Table 9: Bus parameter

4.5.3 Read error memory

To receive a list of device errors that occurred switch the device to the diagnosis mode. Enter

CODE "200000" in parameterization (see chapter 4.3.1: Manual parameterization) and confirm

by pressing the key. Any errors occurring are output indicating the error number and total

of occurrences in the upper row. The type of error is shown in the lower row. Error number 1

contains the latest error. The oldest error is output with the highest error number.

4.5.4 Diagnosis of bus communication

By entering code CODE 300 00X, three different diagnostic modes can be called up:

Mode

Diagnostic parameters

to be specifie

Possible results of diagnosis

General

communication

Baud rate

There is genral bus communication.

Bus load

Addressed nodes

Connection or data quality, resp.

Node address

Data scan

Node address (ID) to be

checked

The data content of the set telegram last

received meets the expectation.

The set telegram is sent with the expected

quantity and time.

Access type (read/write)

Parameter address

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 16 of 50

Mode

Diagnostic parameters

to be specifie

Possible results of diagnosis

Telegram scan

Node address to be

checked

The expected telegram is sent or received,

resp.

Access type (read/write)

Parameter address

Data content

Table 10: Diagnostic modes

LED status

Meaning

All OFF

No messages are received (no bus traffic)

red

General bus traffic is detected, but not with the set telegram properties

green

The set node address is addressed, or the data contents correspond with

the set value, resp.

Table 11: Meaning of the LED

4.5.4.1 General communication

Start via input "CODE 300.000".

Display

Adjustment

Meaning

ID to be checked

Number of all telegrams received with this

ID, per second.

M/s = Message / second.

here: to ID 31: 63 telegrams/s

ID to be checked

Number of all telegrams received with this

ID, per second.

M/s = Message / second.

here: to ID 31: 0 telegrams/s

no telegrams with this ID (0M/s)

However, telegrams with a different ID are

received (indicated by the red LED)

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 17 of 50

Display

Adjustment

Meaning

ID to be checked

Number of all telegrams received with this

ID, per second.

M/s = Message / second.

here: to ID 31: 0 telegrams/s

no telegrams with this ID (0M/s)

no telegrams with a different ID (no

LED)

Possible causes:

wrong baud rate, disconnection, master

does not send, defective device driver

ID to be checked

acknowledged by

key

1st line

"FE" = Parameter address in hex

(here: actual value).

".0" = read command (see chapter 6.3.1)

"Nxx" = number of telegrams received (here:

63)

2nd line:

The data content of the message last heard

is displayed in decimal notation. (here: 0).

Consequently, the data content, e. g. of the

position value may alternate between "0"

and "x". The master sends "0" in its request,

the respective device responds with "x".

Messages sent by the device itself cannot be

displayed/recorded.

ID to be checked

acknowledged by

key

No telegram with this confirmed ID was

received, "no COM" will be displayed.

Functional Description

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 18 of 50

Display

Adjustment

Meaning

ID to be checked

again

acknowledged by

key

1st line:

Number of telegrams with checksum error

(with valid ID) in one second.

(here: 7)

2nd line:

Number of telegrams with CS error compared

with number of all telegrams. Expressed as a

percentage

(here: 99.99 %)

4.5.4.2 Data scan

With the data scan, the data content of a specific telegram is output.

Start via input "CODE 300.001".

Display

Adjustment

Meaning

ID to be checked

Telegrams directed to node address xx are

examined below.

(Annotation to the picture: LED off: no bus

traffic!)

Here: node address = 31

Command to be

checked (access

type)

The command is input in decimal notation

(lower line).

The command is displayed in hexadecimal

notation due to lack of place (upper line).

Here "0" = read command

Overview of parameters

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 19 of 50

Display

Adjustment

Meaning

Parameter to be

checked

The parameter address is input in decimal

notation (lower line).

The parameter address is displayed in

hexadecimal notation due to lack of place

(upper line).

Here parameter address = "0xFF" = set point

The ID, the access

type and the

parameter address

were input

The parameter address and the access type

are displayed in the upper line.

After the X, the number of these telegrams

received is indicated.

(The counter overruns at 0xFF)

In the lower line, the data content of the

message last received is displayed in

decimal notation.

Attention: The data content may alternate

between 0 (= question of the master) and x

(= response of the device).

4.5.4.3 Telegram scan

Start via input "CODE 300.002".

Here, node address, command, and parameter address are set as is the case with the data

scan. Additionally, the expected data content is set. If a telegram is received where all items

match exactly, the Received counter is increased, and the LED switched to green.

5Overview of parameters

Name

Description

see

page

00h: Node address

Node address

29

01h: Baud rate

Baud rate of the RS485 interface

29

02h: Bus Timeout

Indication of bus timeout in x100 ms

29

03h: Response parameter to a set

point write access

Defines the response to the command

"Write set point".

30

04h: Keys enable time:

Configuration start delay

Period of key actuation in order to start

configuration.

30

05h: Key function enable1:

Calibration enable

Enable calibration

30

06h: LED flashing

All LEDs flashing

31

Overview of parameters

AP10 Date: 16.05.2018 Art. No. 86855 Mod. status 183/18 Page 20 of 50

Name

Description

see

page

07h: LED3 (green right)

LED green right (LED3)

31

08h: LED2 (red left)

LED red left (LED2)

31

09h: LED1 (green left)

LED green left (LED1)

32

0Ah: Decimal places

Number of decimal places

32

0Bh: Display divisor (ADI)

ADI display divisor

32

0Ch: Direction indicators (CW, CCW)

Visualization of direction indicators

33

0Dh: Display orientation

Display orientation

33

0Eh: Configuration programming

mode

Basic setting of programming interlock

33

1Bh: Counting direction

Counting direction

34

1Ch: Resolution per revolution

Resolution of the measuring system.

34

1Eh: Offset value

Offset value

35

1Fh: Calibration value

Calibration value

35

20h: Target window1 (near field)

The set point has been reached when the

actual value is within the target window1

35

21h: Positioning type (loop type)

Travel towards set point in this direction

36

22h: Loop length

Loop length

36

28h: Operating mode

Operating mode

36

30h: Display in the 2nd row

Controls the display of the 2nd row of the

display

37

31h: Target window2 (extended)

Extended target window for easier positioning

37

32h: Target window2 visualization

Visualization of target window2

37

33h: Application of the display

divisor (ADI application)

ADI application

38

34h: Formation of the differential

value

Formation of the differential value

38

35h: Key function enable2:

Incremental measurement enable

Incremental measurement enable

39

39h: LED4 (red right)

LED red right (LED4)

39

3Ah: LCD backlight flashing

Flashing LCD backlight

39

3Bh: LCD backlight white

LCD backlight white

40

3Ch: LCD backlight red

LCD backlight red

40

3Dh: Key function enable3:

Configuration enable via keyboard

Configuration enable

40

3Eh: Acknowledgement settings

Acknowledgment settings (alpha-numeric

display)

41

3Fh: Display factor

Display factor (inch indication)

41

63h: Battery voltage

Battery state of charge

41

65h: Device identification

SIKONETZ5 device identification (AP10 = 8)

42

67h: Software version

Software version

43

80h: Number of errors

Number of error incidents

43

81h until 8Ah: Errors

Error list

43

Other manuals for AP10

3

Table of contents

Other Siko Touch Panel manuals