INDEX

USE OF THE MANUAL....................................................................................................................... 1

GENERAL WARNINGS....................................................................................................................... 3

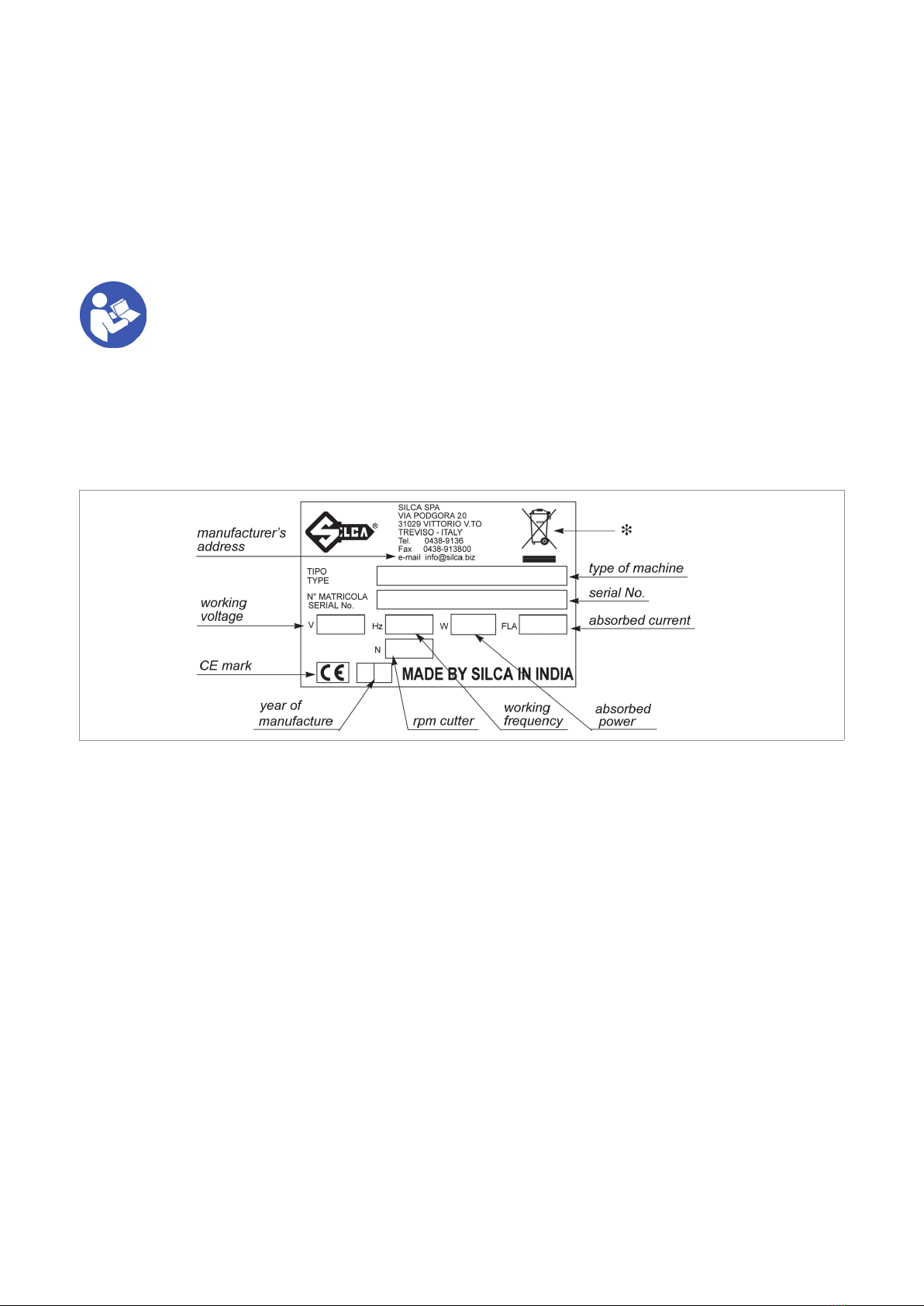

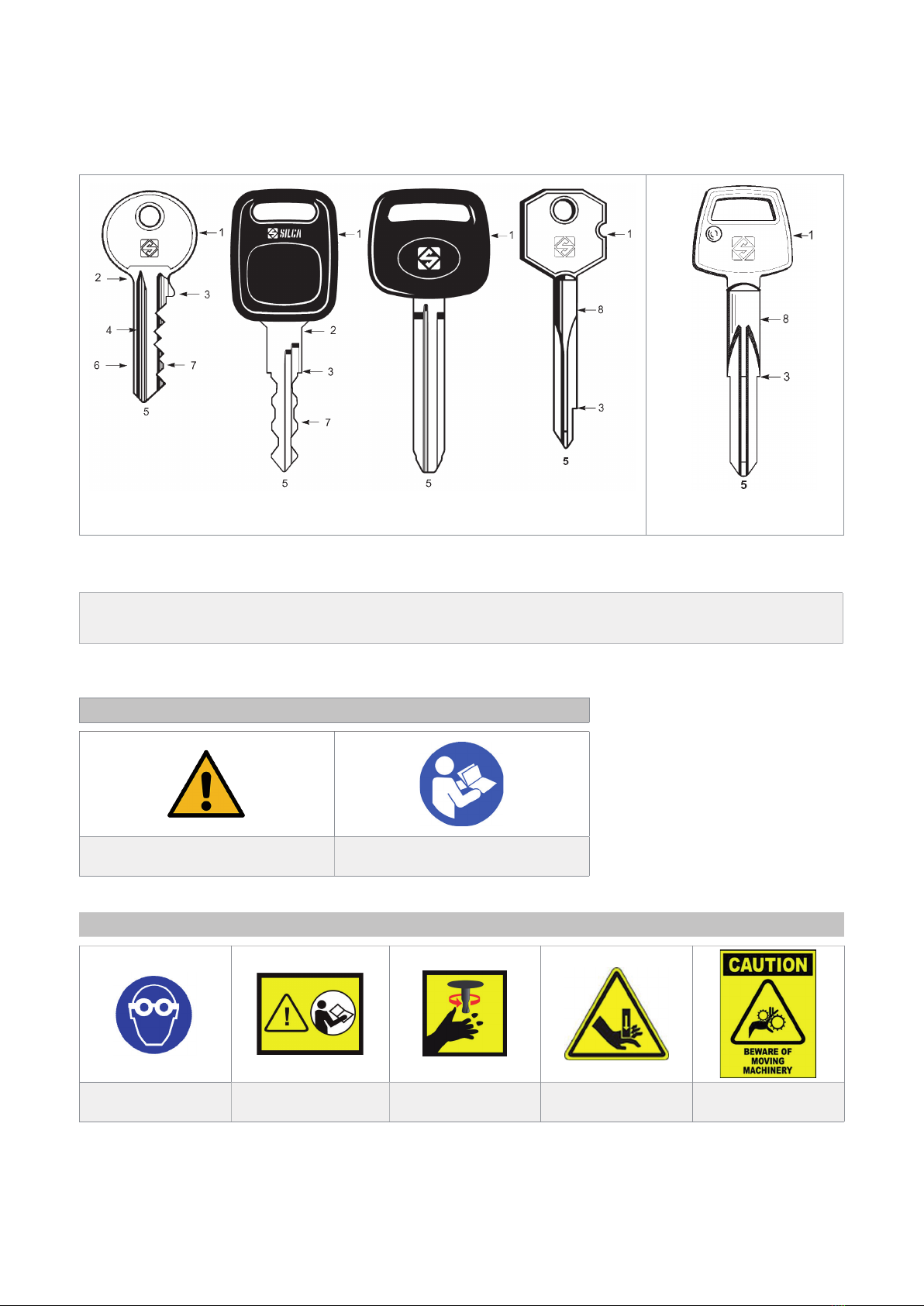

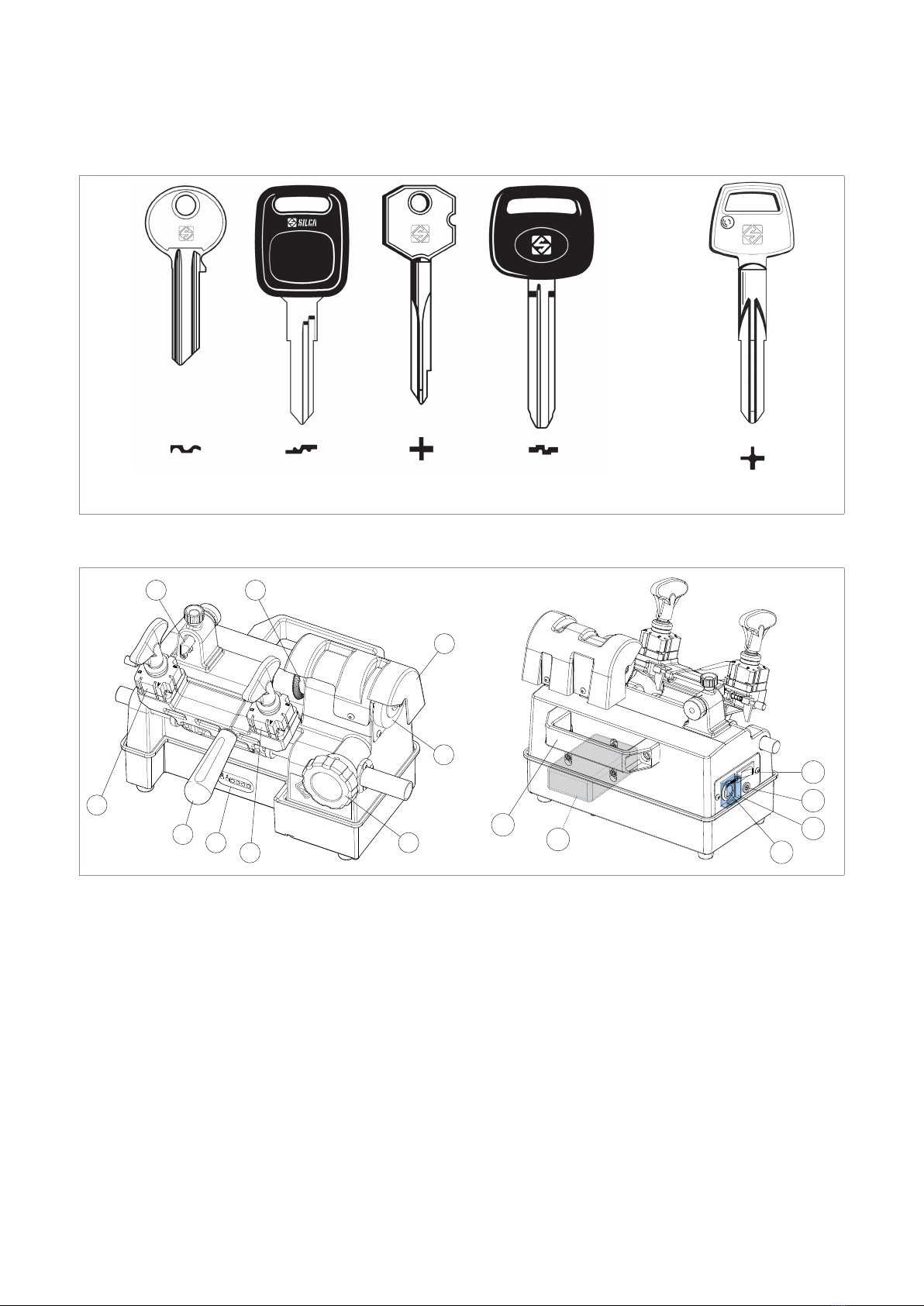

1 MACHINE DESCRIPTION....................................................................................................................4

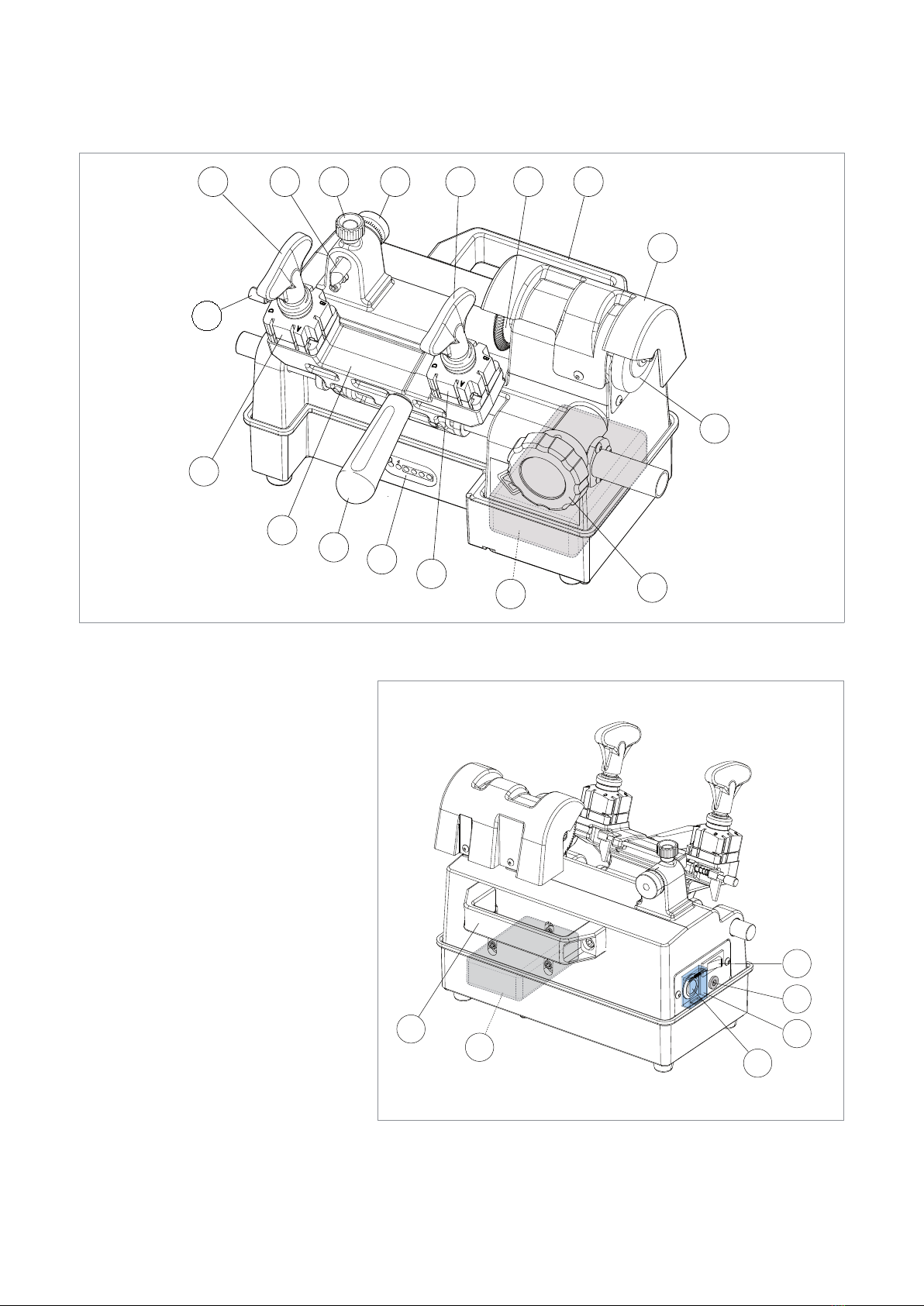

1.1 Main working parts......................................................................................................................6

1.2 Technical Data ............................................................................................................................7

1.3 Battery ........................................................................................................................................8

1.4 Electric circuit..............................................................................................................................9

1.5 Accessories provided................................................................................................................10

2 TRANSPORT......................................................................................................................................11

2.1 Packing .....................................................................................................................................11

2.2 Unpacking .................................................................................................................................11

2.3 Handling the machine ...............................................................................................................11

3 MACHINE INSTALLATION AND PREPARATION ..............................................................................12

3.1 Checking for damage................................................................................................................12

3.2 Environmental conditions..........................................................................................................12

3.3 Positioning ...............................................................................................................................12

3.4 Separate parts .........................................................................................................................12

3.4.1 Carriage handle ..............................................................................................................12

3.4.2 Fixing bracket..................................................................................................................13

3.5 Connection to external sources ................................................................................................14

4 MACHINE REGULATION AND UTILIZATION ....................................................................................15

4.1 Checking and calibration...........................................................................................................15

4.2 Calibration.................................................................................................................................15

5 CUTTING OPERATIONS .................................................................................................................18

5.1 Key cutting ................................................................................................................................18

5.1.1 Clamp rotation ................................................................................................................19

5.1.2 Securing the keys in the clamps .....................................................................................19

5.1.3 Key cutting ......................................................................................................................20

5.2 Using the accessories...............................................................................................................20

6 MAINTENANCE..................................................................................................................................22

6.1 Replacing the brush..................................................................................................................22

6.2 Replacing the cutting tool..........................................................................................................23

6.3 Replacing the tracer point ........................................................................................................23

6.4 Depth regulation (clamp protection)..........................................................................................24

6.5 Access to the lower compartment.............................................................................................24

6.6 Battery Replacement Instructions ............................................................................................25

6.7 Replacing the main switch ........................................................................................................26

6.8 Replacing the motor start switch...............................................................................................27

6.9 Replacing and/or adjusting tension on the belt.........................................................................28

7 DISPOSAL..........................................................................................................................................29

8 ASSISTANCE .....................................................................................................................................30

8.1 How to request service .............................................................................................................30

Operating manual FLASH MOBILE