INDEX

1

TRANSPORT ..............................................................................................................3

1.1 Packing ............................................................................................................3

1.2 Transport .........................................................................................................3

1.3 Unpacking ........................................................................................................3

1.4 Machine handling .............................................................................................3

2

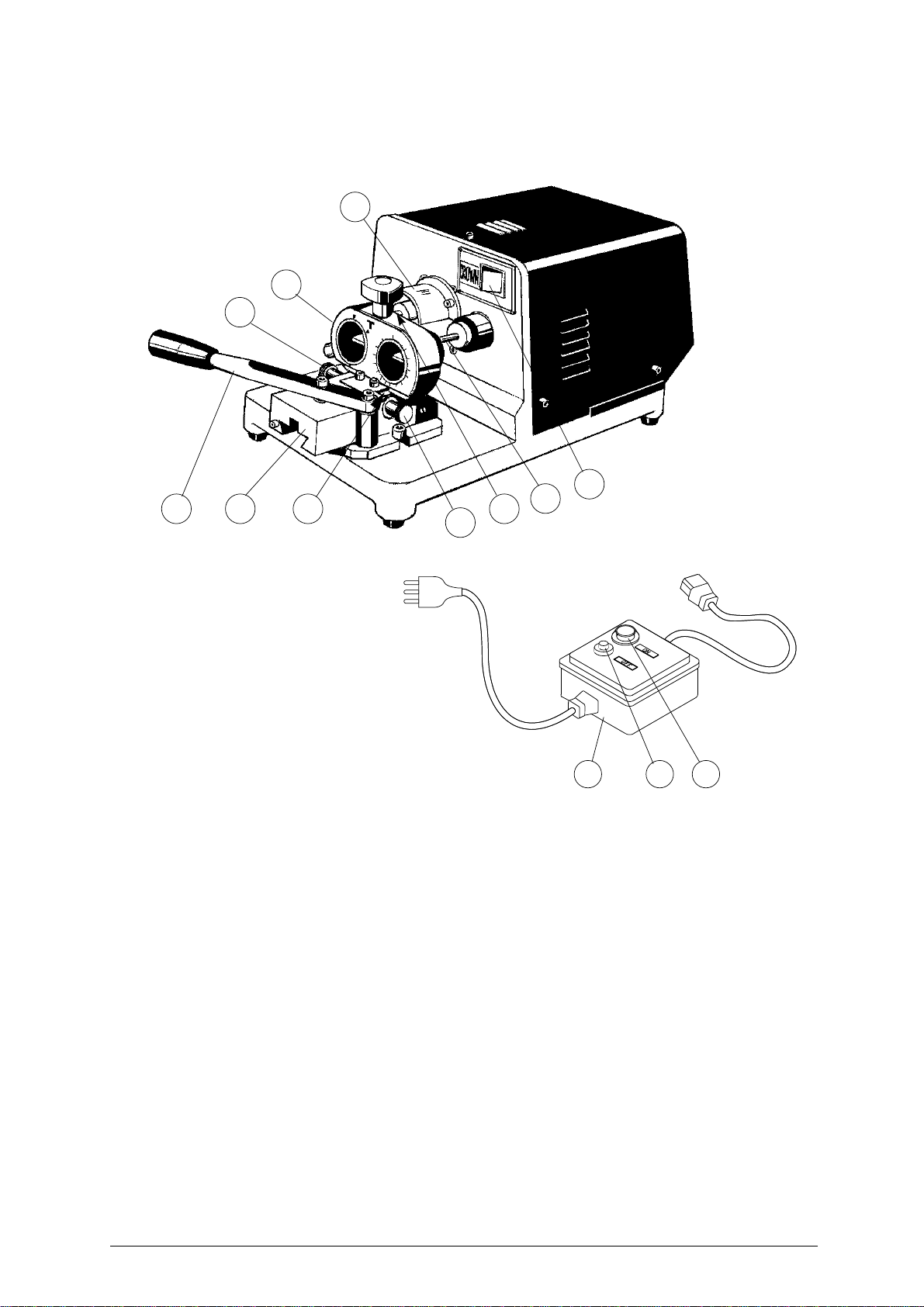

WORKING PARTS .....................................................................................................4

3

MACHINE DESCRIPTION ..........................................................................................5

3.1 Technical data .................................................................................................6

3.2 Electrical circuit ................................................................................................6

4

ACCESSORIES PROVIDED ......................................................................................7

5

MACHINE INSTALLATION AND PREPARATION ....................................................8

5.1 Checking for damage .......................................................................................8

5.2 Environmental conditions .................................................................................8

5.3 Positioning .......................................................................................................8

5.4 Description of work station ...............................................................................9

5.5 Separate parts .................................................................................................9

5.6 Connection to the mains ..................................................................................9

6

REGULATION AND USE OF THE MACHINE .........................................................10

6.1 Control and gauging ......................................................................................10

6.2 Gauging .........................................................................................................10

6.3 Cutting operations ..........................................................................................11

7

MAINTENANCE ........................................................................................................12

7.1 Cutter replacement ........................................................................................12

7.2 Tracer point replacement ...............................................................................12

7.3 Replacing the fuses .......................................................................................12

8

WASTE DISPOSAL ..................................................................................................13

9

ASSISTANCE ...........................................................................................................14

9.1 How to request service ..................................................................................14

10

SYNCHRONISED DEVICES ....................................................................................15

10.1 Devices T2 - T3 - T4 - T5 - T6 - T7 - T8 - T9 - T13 ........................................16

10.2 Self-Centering Device T10 .............................................................................17

10.3 Self-Centering Device T15 .............................................................................20

10.4 T14 synchronised device for cutting 5VP3 keys ............................................22

10.5 T17 Synchronised device ..............................................................................23