INDEX

USE OF THE MANUAL.............................................................................................................................................1

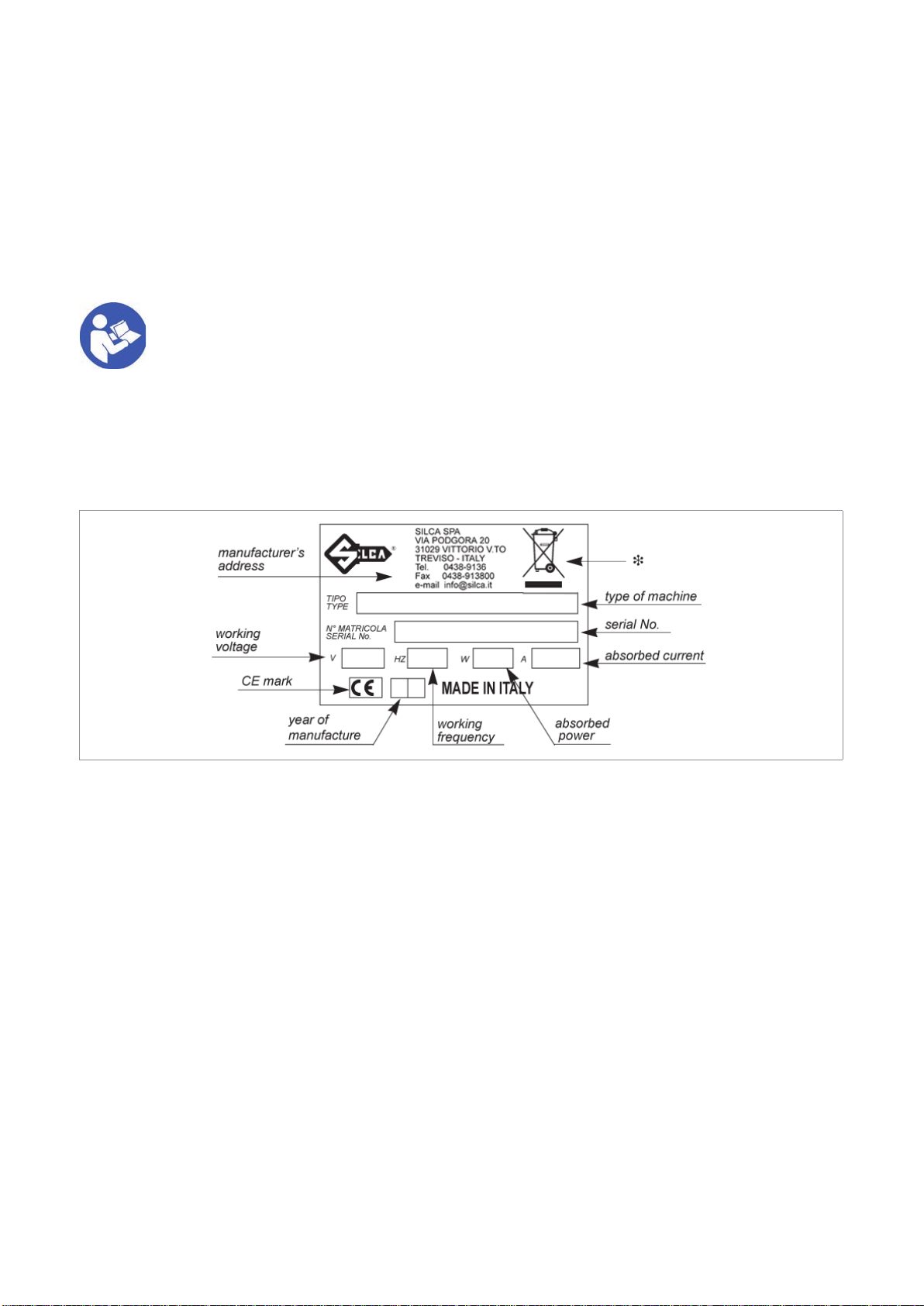

GENERAL WARNINGS.............................................................................................................................................3

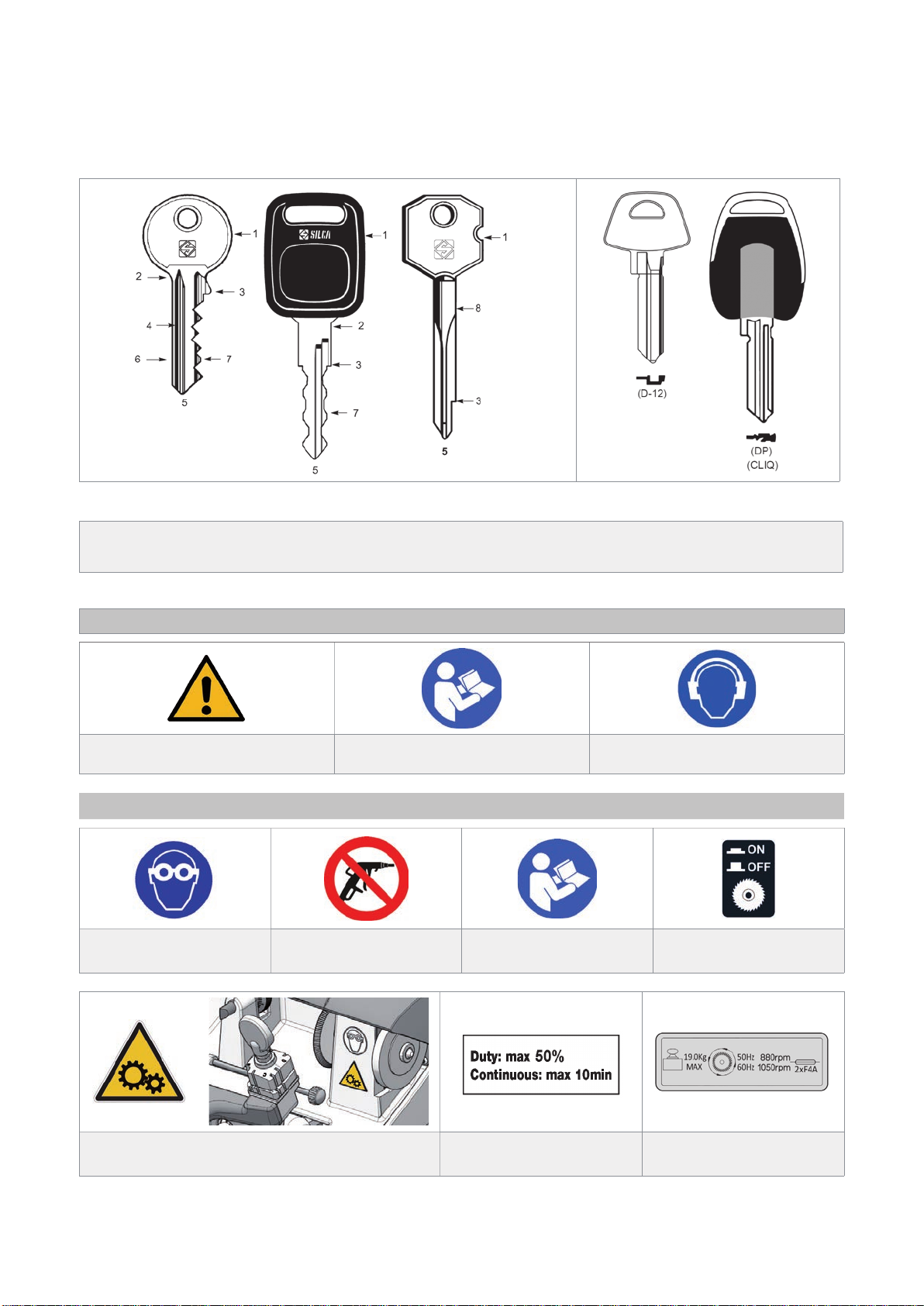

1 MAIN WORKING PARTS..................................................................................................................................4

2 MACHINE DESCRIPTION................................................................................................................................5

2.1 Further Risks ..................................................................................................................................................6

2.2 Technical Data.................................................................................................................................................6

2.3 Electric circuit..................................................................................................................................................7

2.4 Accessories provided......................................................................................................................................8

3 TRANSPORT....................................................................................................................................................9

3.1 Packing............................................................................................................................................................9

3.2 Unpacking .......................................................................................................................................................9

3.3 Handling the machine......................................................................................................................................9

4 MACHINE INSTALLATION AND PREPARATION...........................................................................................10

4.1 Checking for damage....................................................................................................................................10

4.2 Environmental conditions..............................................................................................................................10

4.3 Positioning

....................................................................................................................................................10

4.4 Separate parts ...............................................................................................................................................11

4.4.1 Carriage lever handle ...................................................................................................................................11

4.4.2 Power cable ..................................................................................................................................................11

4.5 Connection to the mains.................................................................................................................................11

4.6 Description of work station ...........................................................................................................................12

5 MACHINE REGULATION AND UTILIZATION ................................................................................................13

5.1 Checking and calibration...............................................................................................................................13

5.2 Calibration.....................................................................................................................................................13

6 CUTTING OPERATIONS ...............................................................................................................................16

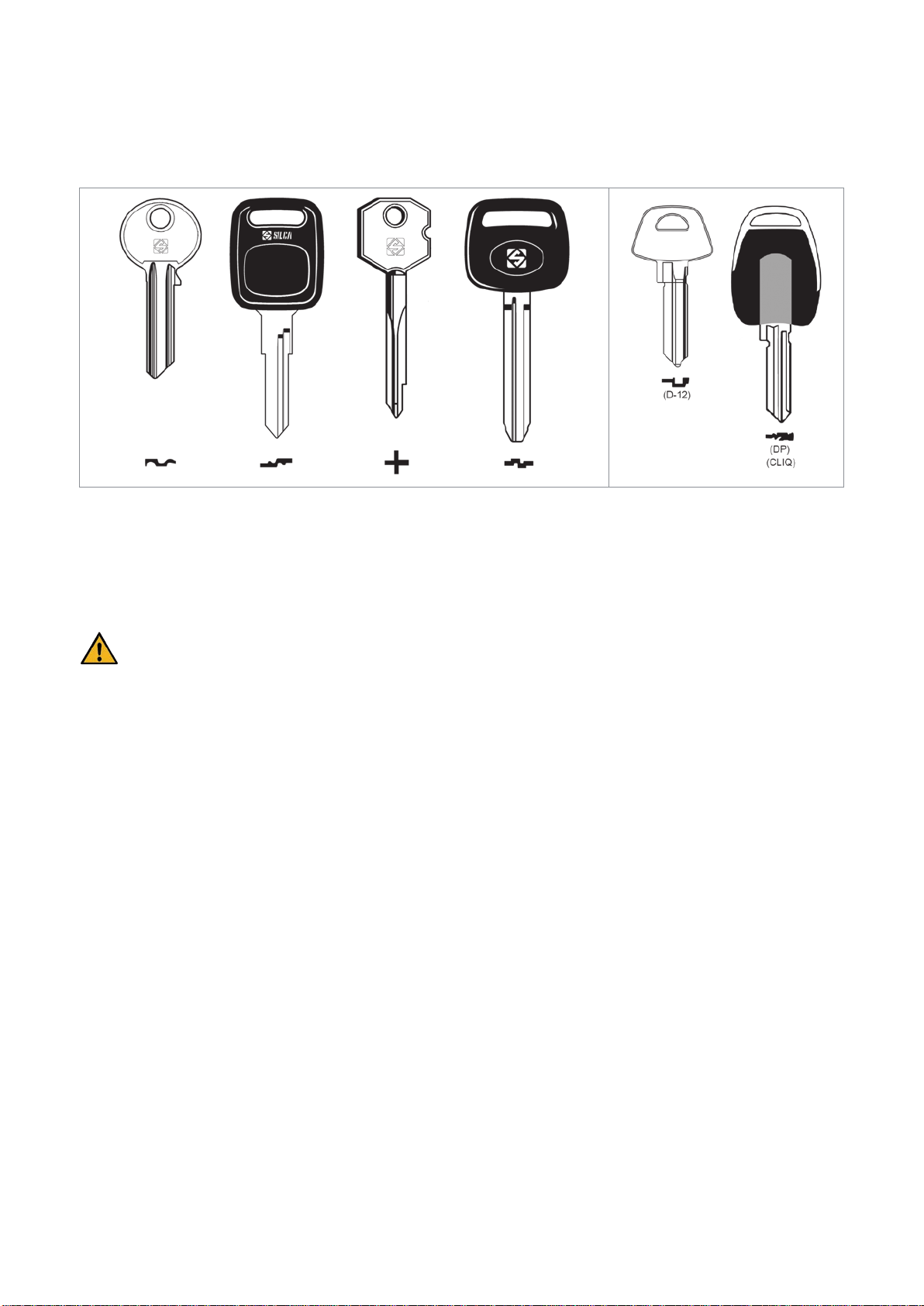

6.1 Key cutting.....................................................................................................................................................16

6.1.1 Clamp rotation .............................................................................................................................................17

6.1.2 Securing the keys in the clamps.................................................................................................................. 18

6.1.3 Key cutting ...................................................................................................................................................18

6.2 Using the accessories...................................................................................................................................19

7 MAINTENANCE..............................................................................................................................................21

7.1 Replacing the brush ......................................................................................................................................21

7.2 Replacing the cutting tool..............................................................................................................................22

7.3 Replacing the tracer point ............................................................................................................................23

7.4 Access to the lower compartment.................................................................................................................24

7.5 Replacing lamp feed (transformer)................................................................................................................25

7.6 Replacing lamp set/lamp protection..............................................................................................................26

7.7 Replacing the fuses.......................................................................................................................................27

7.8 Regulating carriage depth.............................................................................................................................27

7.9 Replacing the main switch.............................................................................................................................28

7.10 Replacing the cutter motor start push-button................................................................................................28

7.11 Sostituzione e/o tensionamento della cinghia...............................................................................................29

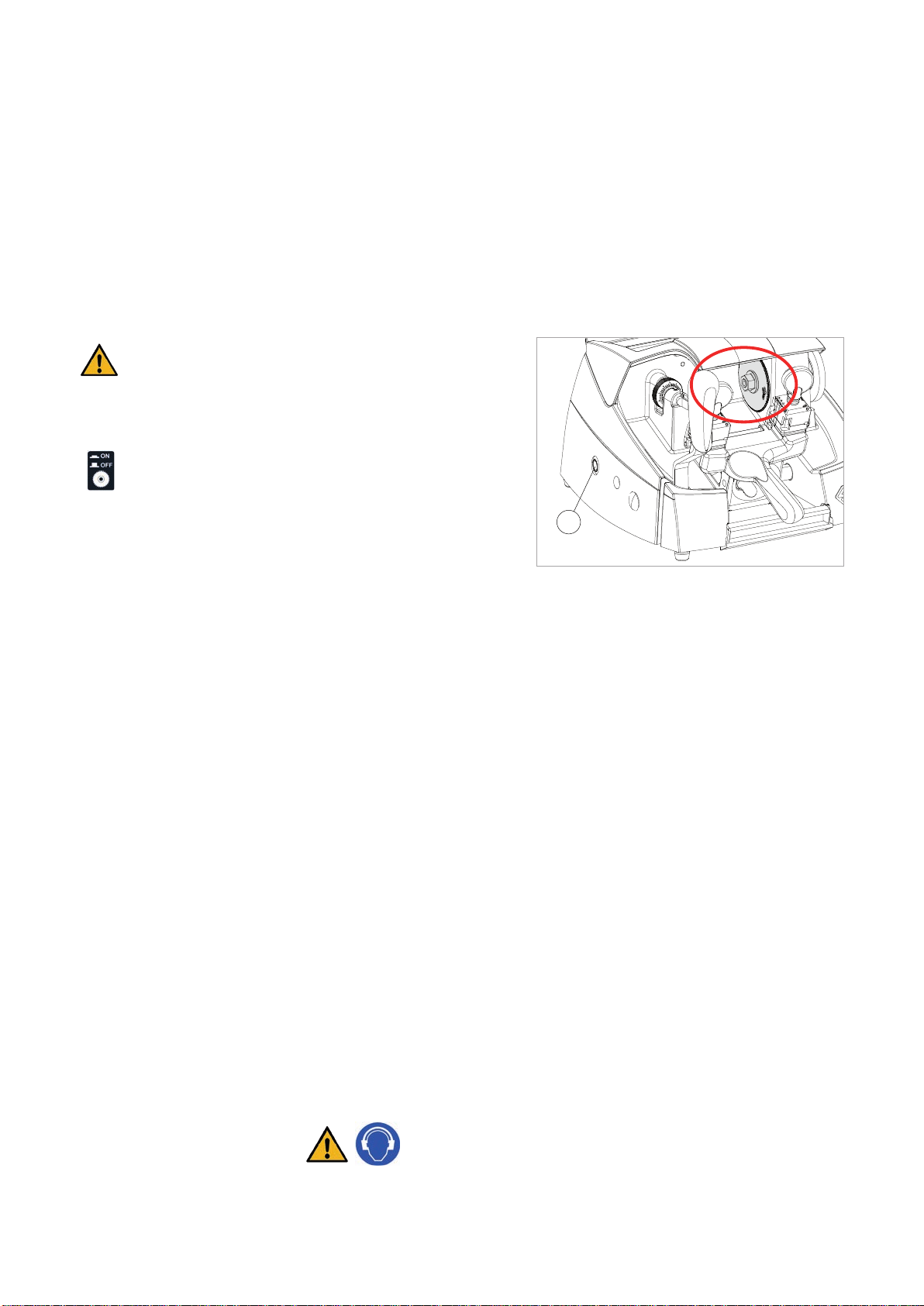

7.12 Replacing motor/condenser ..........................................................................................................................31

7.12.1 Replacing motor.........................................................................................................................................31

7.12.2 Replacing condenser ................................................................................................................................31

7.13 Replacing the microswitch.............................................................................................................................33

8 DISPOSAL......................................................................................................................................................34

9 ASSISTANCE..................................................................................................................................................35

9.1 How to request service..................................................................................................................................35