Silent Sentinel Jaeger User manual

JAEGER INSTALLATION GUIDE

Commercial in Confidence 2/26

Silent Sentinel Limited reserves all the right. All in this manual including texts, pictures, diagrams, and

other contents belong to Silent Sentinel Limited. Without the written permission, no one shall copy,

photocopy, translate or disseminate all or part of this manual.

This manual is used as a guide. The photos, graphics, diagrams, and illustrations provided in the

manual are only used for explanation, which may be different from the specific product. Please refer

to the actual product. We try our best to make sure all the contents in this manual are accurate. We

do not provide any representations or warranties in this manual.

If you need the latest version of this manual, please contact us. Silent Sentinel recommends that you

use this manual under the guidance of professionals.

Version Control

Version

Author

Approver

Date

0.1

Matthew Short

Matthew Short

21/07/2021

1.0

Matthew Short

Matthew Short

06/08/2021

JAEGER INSTALLATION GUIDE

Commercial in Confidence 3/26

Contents

System Overview ...............................................................................................................................................5

Overivew ........................................................................................................................................................5

Power / Interface Requirements ...................................................................................................................5

System Orientation........................................................................................................................................5

Mechanical Installation......................................................................................................................................6

Overview ........................................................................................................................................................7

Fixtures and Fittings;......................................................................................................................................7

Mouting the Jaeger PTU ................................................................................................................................8

Attaching the Top Mount...............................................................................................................................9

Attaching the Side Payloads ........................................................................................................................10

Wiper Assembly Installation ............................................................................................................................12

Overview......................................................................................................................................................12

Fixtures and Fittings.....................................................................................................................................12

Cable Information ............................................................................................................................................15

Cable Overview ............................................................................................................................................18

Cable Pin Out ...............................................................................................................................................18

Physical Connectors.........................................................................................................................................19

Jaeger Base Connector.................................................................................................................................19

Side Payload Mounting Connector. .............................................................................................................20

Top Payload Mounting Connector...............................................................................................................21

JAEGER INSTALLATION GUIDE

Commercial in Confidence 4/26

INSTALLATION SHOULD BE CARRIED OUT BY QUALIFIED PERSONNEL ONLY IN ACCORDANCE WITH THE

APPLICABLE LOCAL CODES.

THE MANUFACTURER CAN ACCEPT NO LIABILITY FOR ANY DAMAGES OR LOSSES CAUSED DUE TO

INCORRECT OR IMPROPER INSTALLATION.

Safety Information

Before installing the equipment, please read this guide carefully.

Installation of this product should only be carried out by a competent and suitably qualified

engineer. If you are in doubt, you should refer the installation to a suitably qualified person.

To prevent electrical shock hazards, disconnect the power from electrical sources before working

on the equipment.

Make all connections with the power turned off. Do not make or remove connections when the

power is turned on. Before using the product ensure that all cables are correctly connected and

that the power cables are not damaged.

Ensure that the product is secured correctly in all situations. Do not place the equipment on to a

trolley, table desk or other platform that is not stable; to avoid the product from falling over.

Ensure that the power supply to be used is correct for the equipment and the correct input voltage

for your region. If unsure, contact your local power supply company. If the power supply or cables

are broken, do not use them. Contact a qualified electrical services technician or your retailer.

1. Do not use any equipment that appears damaged or incomplete. If you detect damage,

contact your dealer immediately.

2. Do not allow connectors to be exposed to long-term water immersion.

3. Do not allow electrical contacts or leads to be exposed to dust, humidity or moisture. Do not

allow electrical contacts or cable-ends to become wet.

4. The equipment must be firmly secured using appropriate fixings and fastening as

appropriate to the mounting surface that the unit is being affixed to.

Notes:

1. Do not open the camera unit, doing so invalidates the unit’s warranty.

2. Do not back-drive the pan or tilt axis of the camera. To do so will damage the motor drive

mechanism and will invalidate the warranty.

3. Do not use caustic or abrasive cleaning products on the unit.

4. In situations where there could be a risk of injury should any part of the assembly become

detached for any reason and fall, normal safety precautions should be employed.

5. Use only the power source types indicated in this user guide or provided with the unit.

6. All power supplies should be appropriately fused.

7. Take extra care lifting or moving units due to their weight.

8. The central PT unit should be installed by itself with no payloads attached. The

camera/sensor and Radar payloads fitted individually, after it has been secured.

9. Take care to allow space around the unit for Pan and Tilt motion.

10.Take care to avoid striking persons or objects when the camera is in motion.

11. Not fitting the provided sun shields will invalidate the systems warranty.

12.This guide only concerns itself with the Mechanical Installtion of the System.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 5/26

System Overview

Overivew

The Jaeger PT system generally comprises of;

1. The Jaeger PT Unit

2. QTY1 EO (Daylight Camera)

3. QTY1 Ti (Thermal Camera)

However, as the Jaeger is a highly modular platform the number and nature of payloads may vary

from unit to unit. This Installation Documention only considers the standard system as noted

above. If there is ANY uncertainy brought about by other combinations of payloads then Silent

Sentinel should be consulted prior to any installation efforts.

Power / Interface Requirements

Votlage Input: 48 VDC

Power Draw (PT Only): 100W (Max 150W)

These figures do not include the requirements of any large payloads, optional heating or cooling

devices added within the camera enclosures, nor optional infra-red lighting systems. Please consult

Silent Sentinel for further guidance.

Top mounted (fixed) payloads are powered separately from the PTZ system.

System Orientation

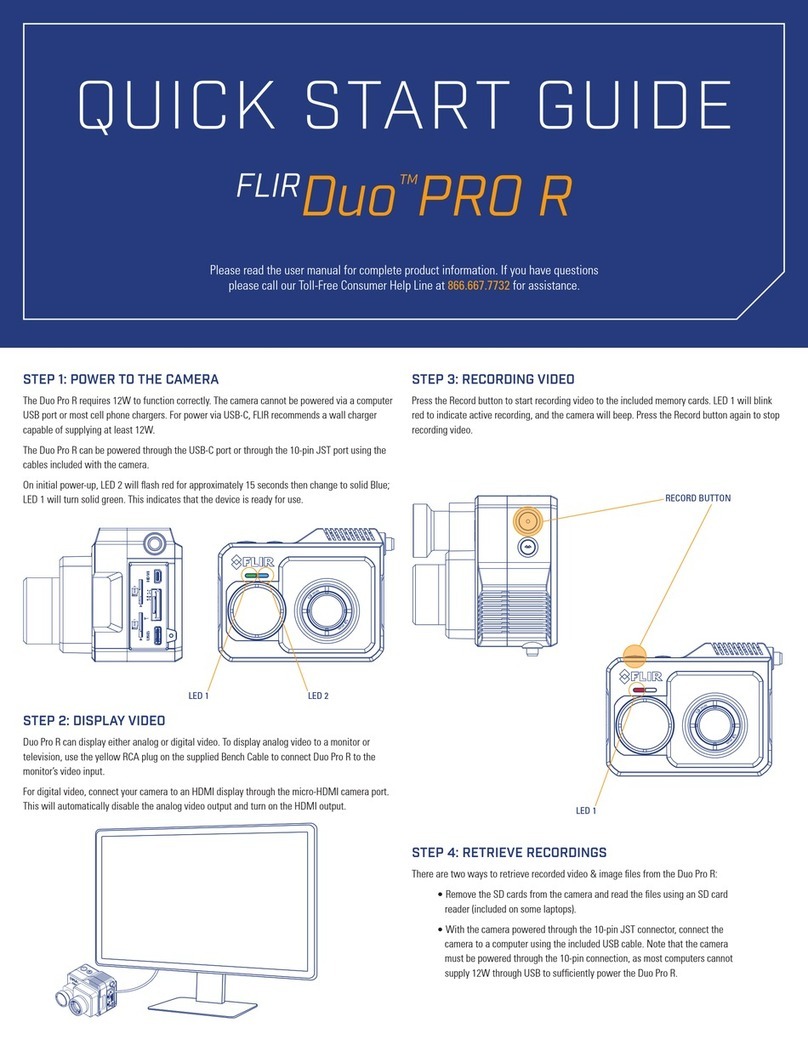

The image on the top left (Figure 1) shows a ‘MK2’ Jaeger with the additional spacer fitted. This

spacer can be used to identify the ‘Back’ and ‘Front’ of the PT Unit. If you face the rear of the unit,

Figure 2

Figure 1

JAEGER INSTALLATION GUIDE

Commercial in Confidence 6/26

the Daylight attachment point is on the left, the themral on the right. Therefore, the side connector

shown in this image is the Dayligth Connector. This is demonstrated further in Figure 2.

PLEASE NOTE: THE ACTUAL INPUT VOLTAGE OF THE UNIT MAY VARY SHOULD

ADDITIONAL / DIFFERING MODULES BE USED. ALWAYS CONSULT THE TEST REPORTS

DELIVERED WITH THE UNIT. DEPENING ON THE MODULES PROVIDED THE INSTALLATION

LOCATIONS MAY ALSO VARY. IF THE SYSTEM HAS MORE THAN TWO PAYLOADS PLEASE

REFER TO SILENT SENTINEL FOR GUIDANCE.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 7/26

Mechanical Installation

Overview

The system should be installed in the following order;

1. Pan / Tilt securely mounted to the Mast / Installation Location

2. RADAR / Top Mount Device securely installed

3. Side Payloads

4. Cable / PSU

Note: The system should not be powered on when any of the payloads / top mounts are attached.

Fixtures and Fittings;

The followings fittings are providing with the Jaeger System.

Figure 3 Jaeger Fittings

1. Sun Shield Fixings;

a. QTY4 –M4x10

b. QTY4 –M4 Nylon Washers

2. Top Mount Fittings;

a. QTY4 –M6x35

3. Side Payload Fittings;

a. QTY8 –M5x10

i. QTY4 for each Payload

4. Main Jaeger Fittings

a. QTY4 –M8x60

b. QTY4 –Spring Washers

c. QTY4 –M8 Nyloc Nuts

5. Duralac

a. To be used on all threads

Figure 4 - Duralac

JAEGER INSTALLATION GUIDE

Commercial in Confidence 10/26

Attaching the Side Payloads

Note: please ensure you are attaching the payloads to the correct side. Please refer to the Ssytem

Overview section for further information.

Step

Detail

1

Protective caps are fitted to the ends of the shafts

to prevent moisture and impact damage to the

electrical connections.

Remove the three securing screws from the tilt

cover cap and remove the cap from the tilt shaft.

Note: The IP67 protection of the unit is

compromsied whilst this cap is removed and the

payload is unattached.

2

Securely hold the tube and offer it up so that the

alignment holes engage on the ends of the rods.

Level the tube so that the connector faces are

parallel with no leaning in any direction.

Push the tube inwards, along the alignment rods

such that the connector assembly engages.

Care should be taken to keep the tube level so as

to reduce the risk of damage to the electrical plug

assembly.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 11/26

3

Once the tube is fully located on the shaft the top

securing screw should be inserted and partially

tightened – not all the way.

The remaining two screws should be inserted in to

their respective holes and, once in place, all three

tightened fully.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 12/26

Wiper Assembly Installation

Overview

This guide details the steps involved to install the wiper assembly onto a RHT camera housing.

Fixtures and Fittings

1. Wiper Assembly

2. Wiper Blade

3. O-Ring

4. Fixings

Step

Detail

1

Power down the camera unit and remove the

bottom cover at the front of the camera housing.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 13/26

2

Insert the supplied O-Ring into the groove on the

wiper box.

3

Align the wiper assembly holes with camera house

jack plug holes

3

Screw the supplied M4x 50 screws into the QTY4

fixing holes. Ensure that the O’ring is seated

properly when screwing together

3

Insert the spring into the wiper assembely shaft.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 14/26

3

Fit the wiper onto the shaft, locate the wiper at the

desired park position and tighten.

Note: the wiper ‘wipes’ anti-clockwise as you look

at the face of the tube. Therefore, the park position

should be to the right of the window and outside of

the FOV of the camera.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 15/26

Boresight Guide

Overview

As standard Silent Sentinel factory boresights the cameras ‘paralell’ at full tele. Therefore, the

separate between FOV should never be any greater than the seperation of the payloads.

However, should it be desired the boresight postion can be adjusted externally as detailed below.

Please note, boresight adjsutment is carried out on the Daylight camera. The Thermal is fixed

relative to the camersa housing.

It is recommended that the boresight adjustment is carried out at full zoom (full tele).

Horizontal Adjustment

Step

Detail

1

Remove the cover plate from the rear

(Horizontal) adjustment mechanism

to reveal the adjustment wheel and

locking screws.

The cover is secured by four screws

requiring an M3 Allen key tool.

2

Using an M2.5 Allen key, loosen (do

not remove) the two locking grub

screws that are located in the recess

holes either side of the adjustment

wheel.

3

The horizontal action can now be

made by turning the adjustment

wheel using a chisel-tip (slot) screw

driver.

Turn the wheel until the centre-line of

the picture corresponds to the centre

of the target.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 16/26

Vertical Adjustment

Step

Detail

1

The cover is secured by four screws

requiring an M3 Allen key tool.

2

Using an M3 Allen key, loosen (do

not remove) the locking screw that is

located beside the adjustment wheel.

3

The vertical action can now be made

by turning the adjustment wheel using

achisel-tip (slot) screw driver.

Turn the wheel until the centre-line of

the picture corresponds to the centre

of the target.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 17/26

ANNEX 1 –Galvanic Kit

Galvanic Kit

Provided with the Galvanic Kit:

1. 4 x M8x20 aluminium bolts

2. Rubber matting for underneath base

3. Aluminium lanyard

4. 4x Nylon Shoulder Washers

The galvanic kit prevents galvanic corrosion from happening on the base on the unit. It isolates the

metal of the unit from the metal of the mast or platform it’s secured on.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 18/26

ANNEX 2 - Cable Information

Cable Overview

The JCM cable supplied with the Jaeger can come in various lengths (up to 50m) and in two

different formats;

1. Double ended;

a. Each end of the Jaeger cable is terminated with a MIL38K Connector

i. This is typically the case is a pre-terminated PSU is purchased.

2. Bare Ended

a. The Jaeger end is terminated with the MIL38K Connector

b. The PSU end of the Cable is left as ‘flying leads’ with only the RJ45 and BNC

conductors terminated.

Cable Pin Out

Multiway Cable Conductor Assignments.

Conductor

Function

Conductor

Function

Red

PTZ Power + (Pos) [26-32VDC]

Green/Yellow

Earth (Chassis)

Black

PTZ Power - (Neg)

Grey (Drain wire)

Cable screen – overall multicore shield.

Orange

Aux / Washer Relay Pos – (Specific models only)

Coaxial 1

Composite Video 1 - miniRG59

White

Aux / Washer Relay Neg – (Specific models only)

Coaxial 2

Composite Video 2 - miniRG59

Brown

Pass-through Power Pos

Blue

Pass-through Power Neg

Yellow (UTP)

UTP - RS485 (Data +)

Cat5e - Grey

Net 1 (A) – Ethernet network – PTZ/Side camera

payloads

Blue (UTP)

UTP - RS485 (Data -)

Cat5e - Blue

Net 2 (B) – Ethernet network – Passthrough to top

payload

Netwok connection leads.

Cat5/8P8C pinout configuration –10/100BASET

(TIA568B)

Network connectors.

Pin Function

1 Tx D+

2 Tx D -

3 Rx D+

6 Rx D -

JAEGER INSTALLATION GUIDE

Commercial in Confidence 19/26

ANNEX 3 - Physical Connectors

Jaeger Base Connector

IL38K

View in to Socket face.

Amphenol TV-Series/ (D38999 ).

Base Socket: Amphenol TVP00ZN21-29P

Cable Connector: Amphenol TV06ZN-21-29SN

Contact arrangement: 21-29.

Contacts No.20 and No.25 are Coaxial types for Video transmission.

Installation cable - Contact assignments and conductors (CA-JCM cable).

(MIL38K)

Pi

n

Function

Conductor

Pin

Function

Conductor

1

Ethernet B 1 (Pass-thru')

(Net2 Blue) - Cat5e Brown

15

Ethernet A 4 (PTZ Data)

(Net1 Grey) - Cat5 White/Green

2

Ethernet B 2 (Pass-thru')

(Net2 Blue) - Cat5e White/Brown

16

Ethernet A 5 (PTZ Data)

(Net1 Grey) - Cat5 Blue

3

Ethernet B 3 (Pass-thru')

(Net2 Blue) - Cat5e Green

17

Ethernet A 6 (PTZ Data)

(Net1 Grey) - Cat5 White/Blue

4

Ethernet B 4 (Pass-thru')

(Net2 Blue) - Cat5e White/Green

18

Ethernet A 7 (PTZ Data)

(Net1 Grey) - Cat5 Orange

5

Ethernet B 5 (Pass-thru')

(Net2 Blue) - Cat5e Blue

19

Ethernet A 8 (PTZ Data)

(Net1 Grey) - Cat5 White/Orange

6

Ethernet B 6 (Pass-thru')

(Net2 Blue) - Cat5e White/Blue

20

Video 1 (CVBS) (Coax Contact)

Coax 1 (Black)

7

Ethernet B 7 (Pass-thru')

(Net2 Blue) - Cat5e Orange

21

Aux Power DC Positive

Orange

8

Ethernet B 8 (Pass-thru')

(Net2 Blue) - Cat5e White/Orange

22

Power DC Positive (Through)

Brown

9

Telemetry (+)

UTP Yellow

23

Power DC Negative (Through)

Blue

10

Telemetry (-)

UTP Blue

24

Aux Power DC Negative

White

11

Earth / Chassis

Green/Yellow Stripe

25

Video 2 (Coax Contact)

Coax 2

12

Ethernet A 1 (PTZ Data)

(Net1 Grey) - Cat5 Brown

26

Power Positive (PTZ) 28VDC

Red

13

Ethernet A 2 (PTZ Data)

(Net1 Grey) - Cat5 White/Brown

27

Power Negative (PTZ) 28VDC

Black

14

Ethernet A 3 (PTZ Data)

Net1 Grey) - Cat5 Green

Indicated conductor colours applicable to CA-MIL38K / CA-JCM cable assemblies.

Available functionality will depend on the installed PT unit and payload configurations.

JAEGER INSTALLATION GUIDE

Commercial in Confidence 20/26

Side Payload Mounting Connector.

MIL-D38999 G39

View in to Socket face.

Amphenol D38999 Series-III / TV.

PTZ Hub Socket: Amphenol D38999/20FG39SN

.

(Connector on payload: Amphenol D38999/26FG39PN – For attached equipment)

Contact arrangement: G39 / 21-99 - [G39T].

Contact “r” is a Coaxial type for Video transmission on HD-SDI models.

(available on limited pan models only).

Block 2

Pin

(G39A)

Function

Note

Pin

Function

Note

A

Power Positive

12VDC (4A)

c

Ethernet 1 (Rx-)

TIA-568B Gn 6

B

Power Negative / Ground

0V (4A)

d

Ethernet 2 (Rx+)

TIA-568B W/Gn 3

C

Serial 1 (D -) (INV)

Ti side Camera (RS485) (P1)

g

Ethernet 3 (Tx-)

TIA-568B Or 2

D

Serial 1 (D+) (NON)

Ti side Camera (RS485) (P1)

h

Ethernet 4 (Tx+)

TIA-568B W/Or 1

K

Serial 4 (D+)

Aux Comms (IP RS485 +)

i

P2 Comm switcher

(Not Fitted)

L

Serial 4 (D -)

Aux Comms (IP RS485 -)

j

Return-video Signal

For IP encoder cameras

S

Serial 2 (TMU Rx)

Day side Lens/Cam (RS232) (P2)

k

Return-video Ground

For IP encoder cameras

T

Serial 2 (TMU Tx)

Day side Lens/Cam (RS232) (P2)

n

Video CVBS Signal

X

Serial 3 (TMU Rx)

Ti side Lens (RS232) (P0)

p

Wiper Trigger

Y

Serial 3 (TMU Tx)

Ti side Lens (RS232) (P0)

q

Video CVBS Ground

r*

Video HD-SDi

Coaxial contact

(Not Fitted to all types)

Contact identity letters are case sensitive. (* Wide/Coaxial contact)

Table of contents

Other Silent Sentinel Thermal Camera manuals