Silicon Laboratories EFM32 Instruction Manual

Other Silicon Laboratories Microcontroller manuals

Silicon Laboratories

Silicon Laboratories C8051F32x User manual

Silicon Laboratories

Silicon Laboratories C8051F00 DK Series User manual

Silicon Laboratories

Silicon Laboratories C8051F02x-DK User manual

Silicon Laboratories

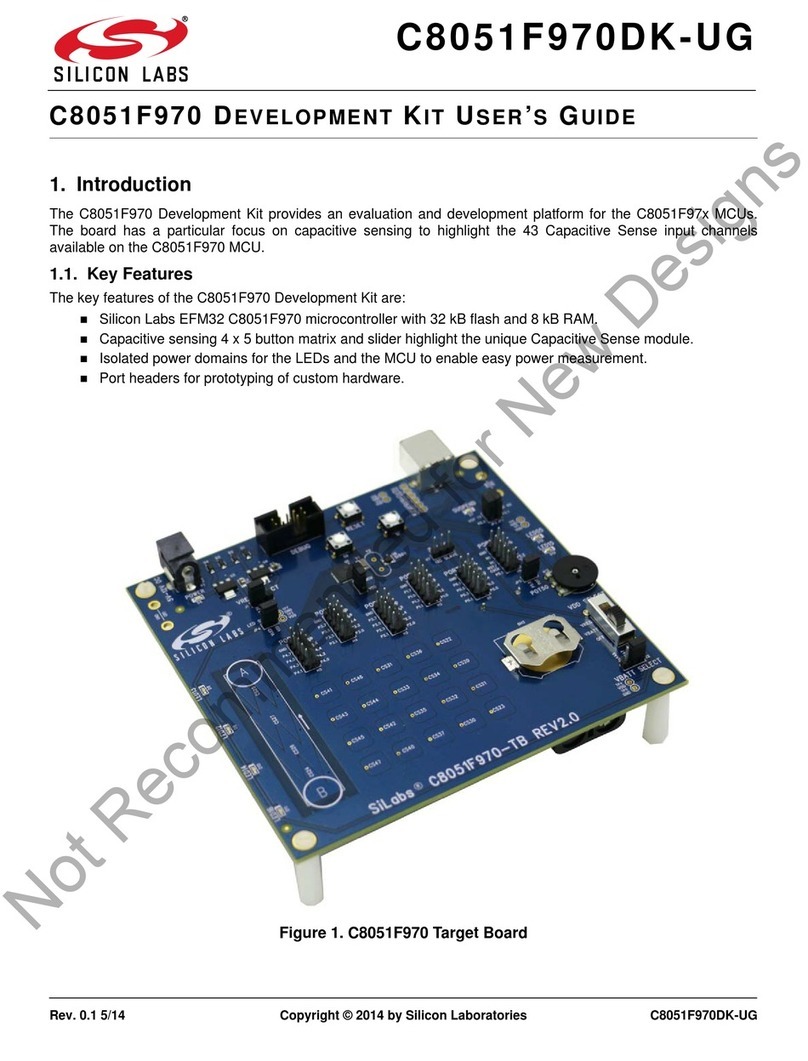

Silicon Laboratories C8051F970 User manual

Silicon Laboratories

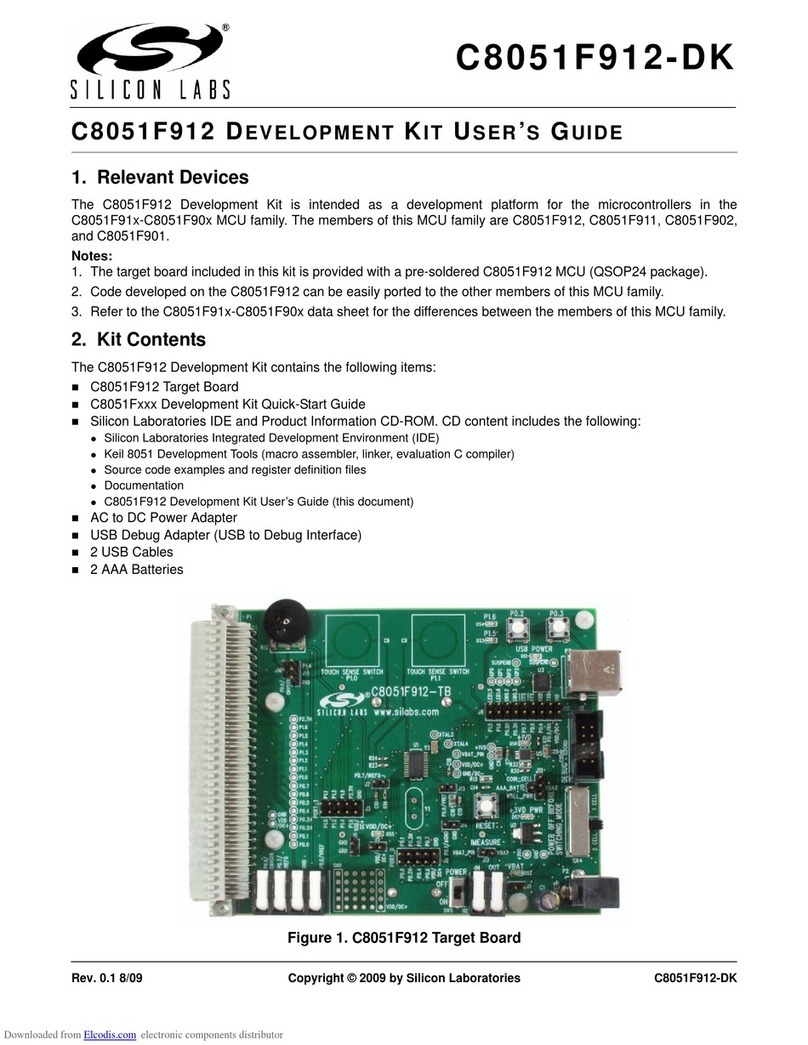

Silicon Laboratories C8051F912 User manual

Silicon Laboratories

Silicon Laboratories EFM8SB1-SLSTK2010A User manual

Silicon Laboratories

Silicon Laboratories C8051F31 Series User manual

Silicon Laboratories

Silicon Laboratories Telegesis ETRX357DVK User manual

Silicon Laboratories

Silicon Laboratories UG464 User manual

Silicon Laboratories

Silicon Laboratories C8051F310DK-T User manual

Silicon Laboratories

Silicon Laboratories C8051F91 Series User manual

Silicon Laboratories

Silicon Laboratories UG338 User manual

Silicon Laboratories

Silicon Laboratories EFM32TG User manual

Silicon Laboratories

Silicon Laboratories Z-Wave 800 Series User manual

Silicon Laboratories

Silicon Laboratories EFM8BB2-SLSTK2021A User manual

Silicon Laboratories

Silicon Laboratories C8051F34-DK Series User manual

Silicon Laboratories

Silicon Laboratories C8051F330DK User manual

Silicon Laboratories

Silicon Laboratories EFR32xG21 Wireless Gecko User manual

Silicon Laboratories

Silicon Laboratories SLWSTK6104A User manual

Silicon Laboratories

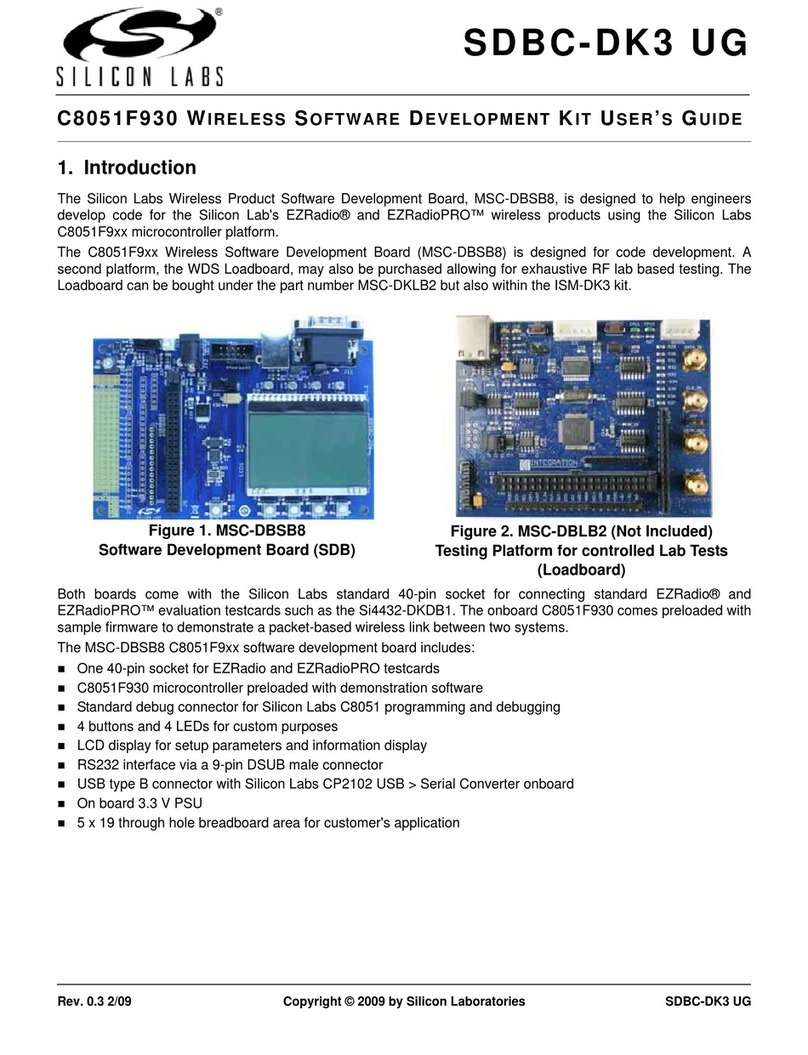

Silicon Laboratories C8051F930 User manual

Popular Microcontroller manuals by other brands

Novatek

Novatek NT6861 manual

Espressif Systems

Espressif Systems ESP8266 SDK AT Instruction Set

Nuvoton

Nuvoton ISD61S00 ChipCorder Design guide

STMicrolectronics

STMicrolectronics ST7 Assembler Linker user manual

Texas Instruments

Texas Instruments Chipcon CC2420DK user manual

Lantronix

Lantronix Intrinsyc Open-Q 865XR SOM user guide