1

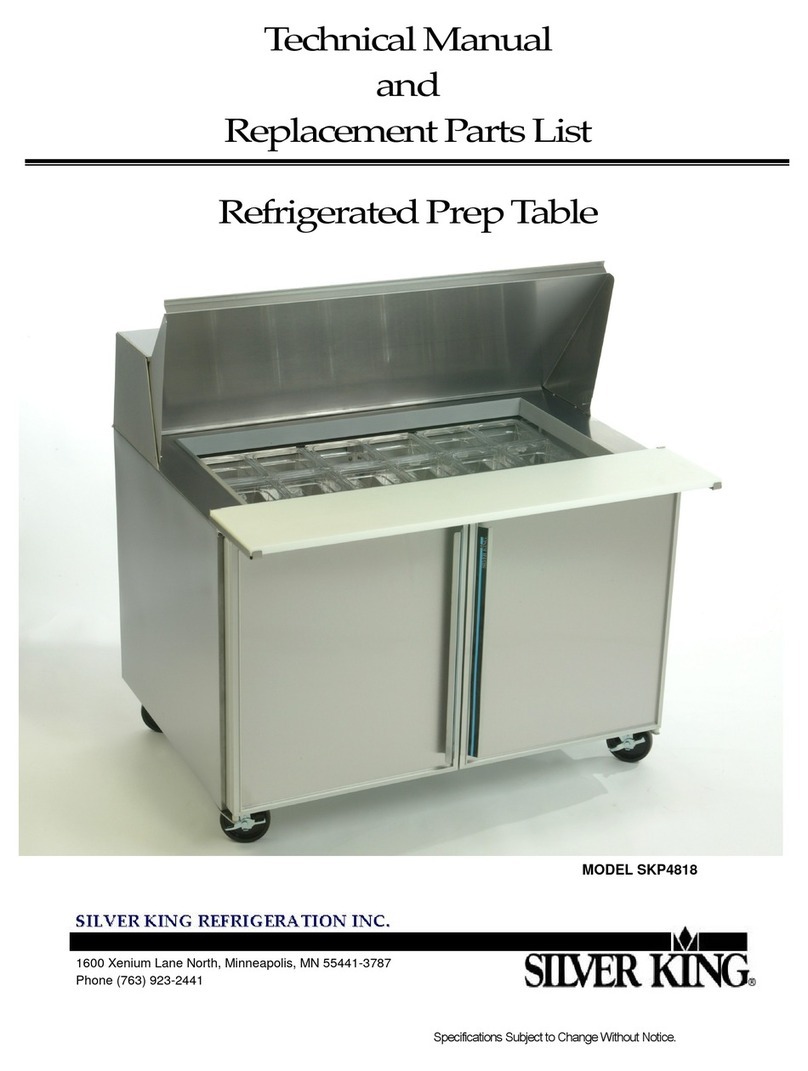

TECHNICAL MANUAL

SILVER KING PREPARATION TABLES

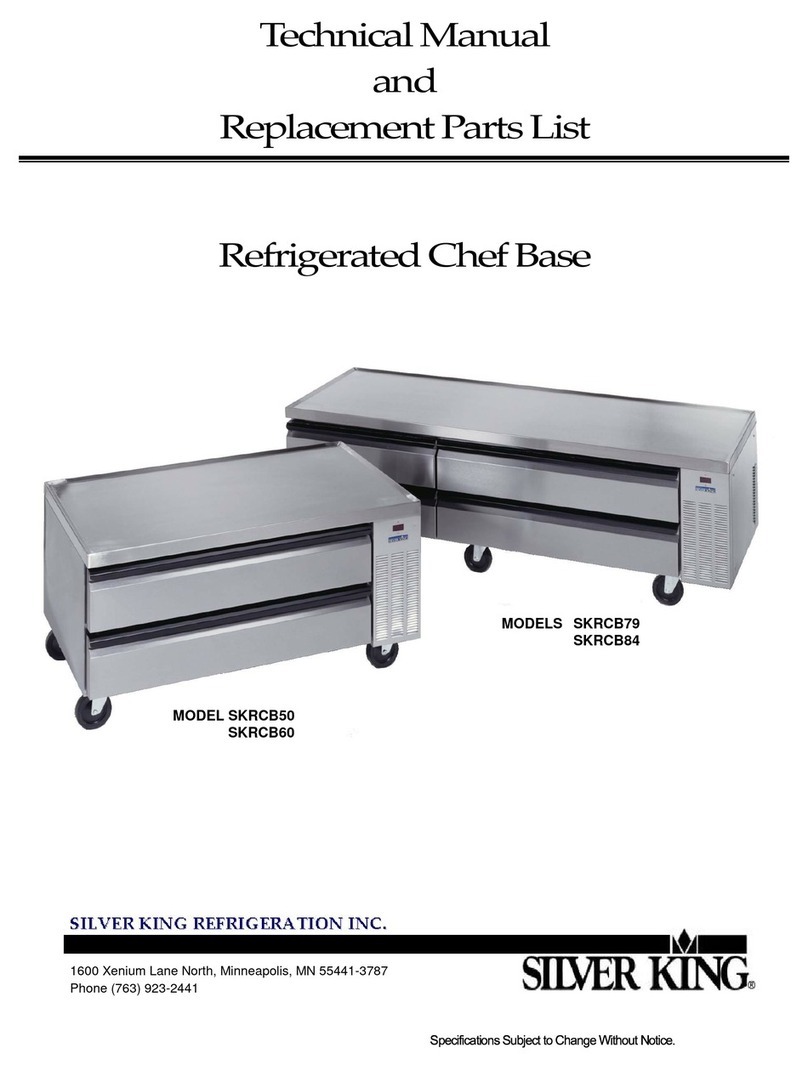

MODELS SKRCB50H, SKRCB60H, SKRCB79H, AND SKRCB84H

Thank you for purchasing Silver King food service equipment. Our goal is to provide our customers with the most reliable

equipment in the industry today. Please read this manual and the accompanying warranty information before operating your new

Silver King unit. Be sure to complete and mail the warranty card within 10 days of purchase to validate your warranty.

INSPECT FOR DAMAGE AND UNCRATE

Upon delivery of your new Silver King unit, uncrate at once to examine and test for possible damage following the instructions

printed on the exterior of the container. Report any damages to the carrier responsible for transportation and promptly present a

claim for any evidence of mishandling. Save all packaging materials if a claim must be filed.

INSTALLATION

The stainless steel exterior of the cabinet has been protected by a plastic covering during manufacturing and shipping. This

covering can be readily stripped before installation. After removing this covering, wash the interior and exterior surfaces using a

warm, mild soapy water solution and a sponge or soft cloth. Rinse afterward with clean water and wipe dry. Do not use chlorinated

cleaners.

Location

When locating your new Silver King unit, convenience and accessibility are important considerations, but the following installation

guidelines must be observed;

•When stacking cooking equipment on these units observe the following load limits: Models SKRCB50H and SKRCB60H have a

maximum load limit of 950 pounds and models SKRCB79H and SKRCB84H have a maximum limit of 1100 pounds of stacked

equipment.

•Stacked cooking equipment should not transfer excessive heat down onto the cabinet. When cabinet surface temperatures

exceed 150°F damage to cabinet insulation may occur.

•The unit must be level.

•Allow at least 2 inches of space on the right and back side, no space on the left side and leave the top open for proper air flow.

•All caster brakes should be set when the unit is positioned in its intended place.

Legs/Casters

The unit comes with legs or casters (four on models SKRCB50H and 60H and six on models SKRCB79H and 84H). To install

them, tip the unit on its back (remove the drawers first to lighten the unit) and locate the four hex-screw patterns on the base of the

unit. These hex screws are used to mount the plate casters. Remove the hex screws, align a plate caster over the four hole pattern

and re-install the hex screws tightly to mount the casters. The casters with brakes should be installed at the front of the cabinet.

Drawers

To remove drawers for cleaning, simply open them fully, lift up on the front of drawer, and pull drawer out. Replace drawers in the

same fashion.

With drawer removed the roller members can be removed by rocking the top of the roller member out when the roller member is

pushed all the way to the back of the cabinet.

The drawer system is rated for a maximum dynamic load of 275 pounds. The drawers are not designed or intended as a surface to

stand on. At no time should the drawers be extended and used as a platform for standing on to reach elevated equipment.