Silver Marine Calypso 330 WD User manual

Calypso 300 WD

Calypso 330 WD

Owner’s manual

www.silvermarine.com

1

CONTENTS

GENERAL INTRODUCTION......................................................................................................2

STRUCTURE TERMINOLOGY..................................................................................................3

TECHNICAL SPECIFICATIONS.................................................................................................3

PARTS TERMINOLOGY...........................................................................................................4

PACKING LIST........................................................................................................................5

INSTALLATION TIPS...............................................................................................................5

STEP ONE: UNFOLD THE HULL...........................................................................................5

STEP TWO: INFLATION.......................................................................................................6

STEP THREE: FLOORBOARD SEAT AND BENCH BAG ASSEMBLY.......................................7

STEP FOUR: OAR FITTING AND ASSEMBLY.......................................................................8

STEP FIVE: SELF-BAILING DRAIN VALVE...........................................................................8

MOTOR INSTALLATION...........................................................................................................9

DEFLATION AND DISASSEMBLY.............................................................................................9

PRESERVATION......................................................................................................................9

MAINTENANCE......................................................................................................................10

REPAIRING............................................................................................................................10

FOLDING & STORAGE...........................................................................................................11

OPERATION ON YOUR SILVER MARINE®..............................................................................12

Rowing..............................................................................................................................12

Motoring & Safety...............................................................................................................12

Towing.................................................................................................................................12

Stability and buoyancy.......................................................................................................12

TROUBLESHOOTING CHART.................................................................................................13

2

GENERAL INTRODUCTION FOR THE OWNER’S MANUAL

This manual has been compiled to help you operate your craft with safety and pleasure. It contains

details of the craft, the equipment supplied, and information on their operation. Please read it carefully

and familiarize yourself with the craft before using it.

This owner’s manual is not a course on boating safety or seamanship. If this is your first craft, or if you

are changing to a type of craft you are not familiar with, for your own comfort and safety, please ensure

that you obtain handling and operating experience before “assuming command” of the craft. Your dealer

or national sailing federation or yacht club will be pleased to advise you of local sea schools, or compe-

tent instructors.

Ensure that the anticipated wind and sea conditions will correspond to the design category of your craft,

and that you and your crew are able to handle the craft in these conditions.

Even when your boat is categorized for them, the sea and wind conditions corresponding to the design

categories A, B and C range from severe storm conditions for category A, to strong conditions for the top

of category C, open to the hazards of a freak wave or gust. These are therefore dangerous conditions,

where only a competent, fit and trained crew using a well maintained craft can satisfactorily operate.

This owner’s manual is not a detailed maintenance or trouble shooting guide. The boat builder cannot be

held responsible for modifications that he has not approved.

In some countries, a driving license or authorizations are required, or specific regulations are in force.

Always maintain your craft properly and make allowance for any deterioration that might occur in time

as a result of heavy use or misuse of the craft.

Any craft, no matter how strong it may be, can be severely damaged if not used properly. This is not

compatible with safe boating. Always adjust the speed and direction of the craft to sea conditions.

All persons should wear a suitable buoyancy aid (life jacket/personal floatation device) when on deck.

Note that, in some countries, it is a legal requirement to wear a buoyancy aid that complies with their

national regulations at all times.

PLEASE KEEP THIS MANUAL IN A SECURE PLACE, AND HAND IT OVER TO THE NEW OWNER

WHEN YOU SELL THE CRAFT.

Thank you for choosing Silver Marine® inflatables. They are carefully handcrafted with polyester fabric

coated with PVC on both sides, and include a transom and molded floorboard system for smart

performance. This manual has been compiled to help you achieve long term safe use, and pleasure from

your Silver Marine®. Please read it carefully and familiarize yourself with the craft before boating.

Designed for voyages in coastal waters, large bays, estuaries, lakes and rivers where conditions up to,

and including, wind force 6 and significant wave heights up to, and including, 2.0m may be experienced.

3

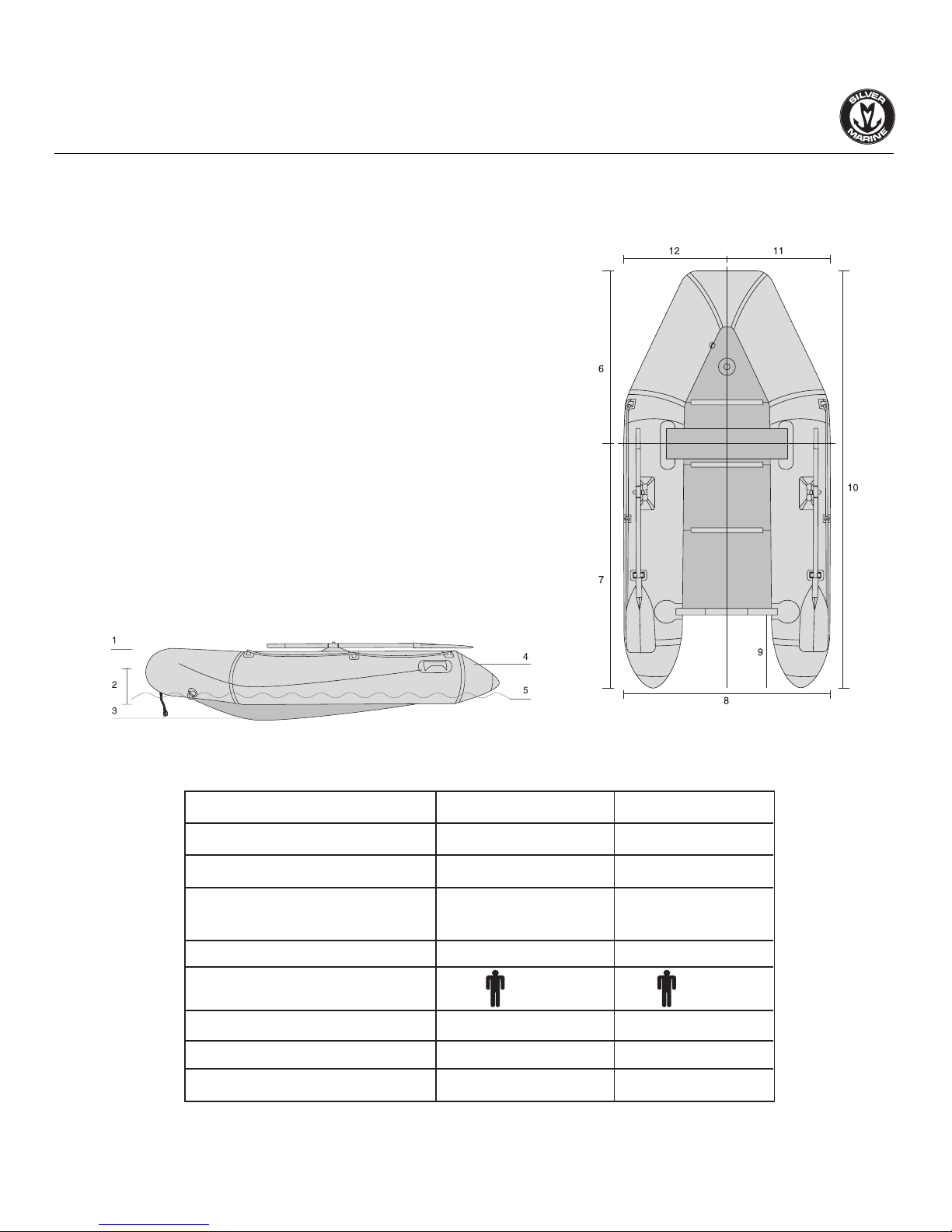

BOATING TERMINOLOGY

1. Bow

2. Freeboard

3. Keel

4. Stern

5. Water line

6. Forward

7. Aft

8. Beam

9. Transom

10. Length overall

11. Starboard side

12. Port side

STRUCTURE TERMINOLOGY

TECHNICAL SPECIFICATIONS

MODEL

STANDARD NO.

DESIGN CATEGORY

DIMENSIONS

(Inflated hull length x beam)

MAX. MOTOR POWER

MAX. PASSENGER CAPACITY

MAX. PAYLOAD

RECOMMENDED WORKING PRESSURE

WEIGHT

Calypso 300 WD

C, TYPE V

EN ISO6185-2:2001

2.94 x 1.53m

9.9HP (7.5kw)

4

794lbs (360kg)

0.25 bar*

88.2lbs (40kg)

Calypso 330 WD

C, TYPE V

EN ISO6185-2:2001

2.94 x 1.53m

9.9HP (7.5kw)

4

794lbs (360kg)

0.25 bar*

88.2lbs (40kg)

* Designed working pressure for each buoyancy chamber is 0.25 bar; must not to be less than 0.18 bar.

4

PARTS TERMINOLOGY

5

PACKING LIST

Calypso 300 WD & Calypso 330 WD:

Boat Hull, Oars, Foot Pump, Pressure Gauge, Wooden Seat, Docking Rope, Safety Grab Line, 4

Screw Valves + 1 Drain Valve, Repair Kit, Carry Bag, Boat Cover and Bench Bag.

4 pieces Floorboards; 3 pieces Stringer (66cm); 2 pieces Stringer (90cm).

INSTALLATION TIPS

Tip 1: Although the boat is designed to be assembled by one person, an additional person can make it

substantially easier.

Tip 2: Make sure to tuck the wood floor edge in correctly to the aluminium stringers.

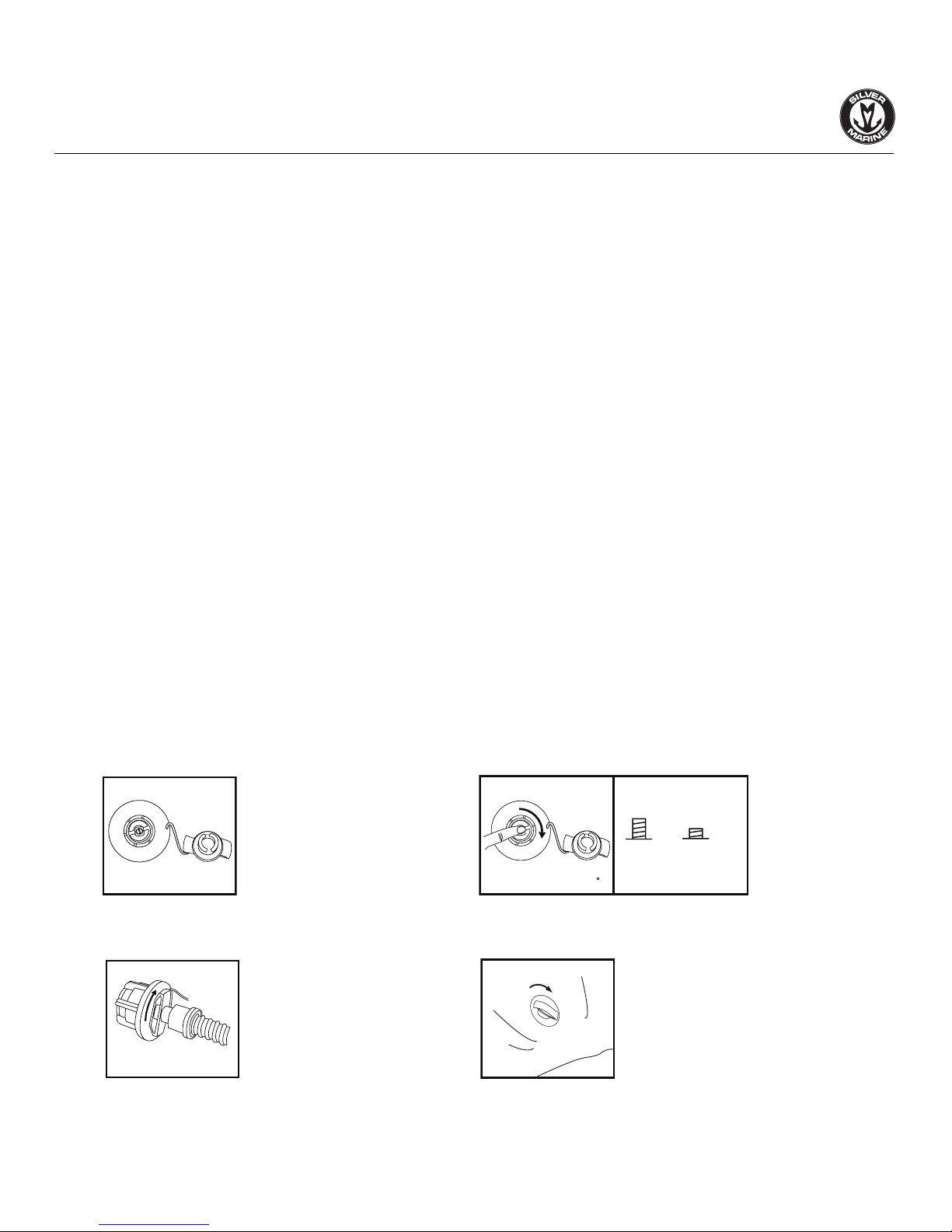

Tip 3: Make sure to press down and turn the pop-up spring valve 90 degrees before inflating. (The default

setting is for deflation.)

Tip 4: If using an electric pump, after tube inflation, use a foot pump to add a little more air to ensure

correct pressure.

Tip 5: In case the valve is loose, screw it tight with the black plastic wrench included in the accessories.

Tip 6: In case you find difficulty when installing the bench seat, put your knees on one of the inflated

tubes to add pressure to the bench.

HOW TO SET UP THE BOAT?

STEP ONE: STARTING UP

1. Unfold the hull

Clear a flat area (make sure it is clean and free of sharp objects). Remove the hull from box and take off

the plastic bag. Unroll the hull and lay it out flat.

2. Screw Valve Installation

1

2.2

UP DOWN

(A) INFLATE (B) DEFLATE

2.1

PRESS AND TURN 90

3

4

1. Take off the top of the valve. (The valve by

default is at deflation position)

3. Insert the inflation adapter to the valve. Secure

the adapter by turning it clockwise. Connect the

pressure gauge and pump to the adapter. Start

inflating until the pressure reach 0.25 bar.

2. Press down the spring switch and turn it clockwise by 90 degrees.

Make sure the switch is popped up. Note: To deflate, press the inner

button at the center and turn counterclockwise 90 degrees.

4. Remove the pressure gauge and pump. Put the cap on the valve.

6

2

1

2

3

1

Fit the metal joint strip (wider side up) to the end

of board 2 and slide floor board 3 against board 2

with modest pressure. Fit the front edge to the

metal stripe.

Start by fitting the back board to the rear end.

Lift the front edge a little to make space for the

last board.

3. Inflate the chambers slightly. We suggest first inflating the air chambers to about 10% (About 20 foot

pump compressions) of their capacity so that the floorboards can be easily inserted.

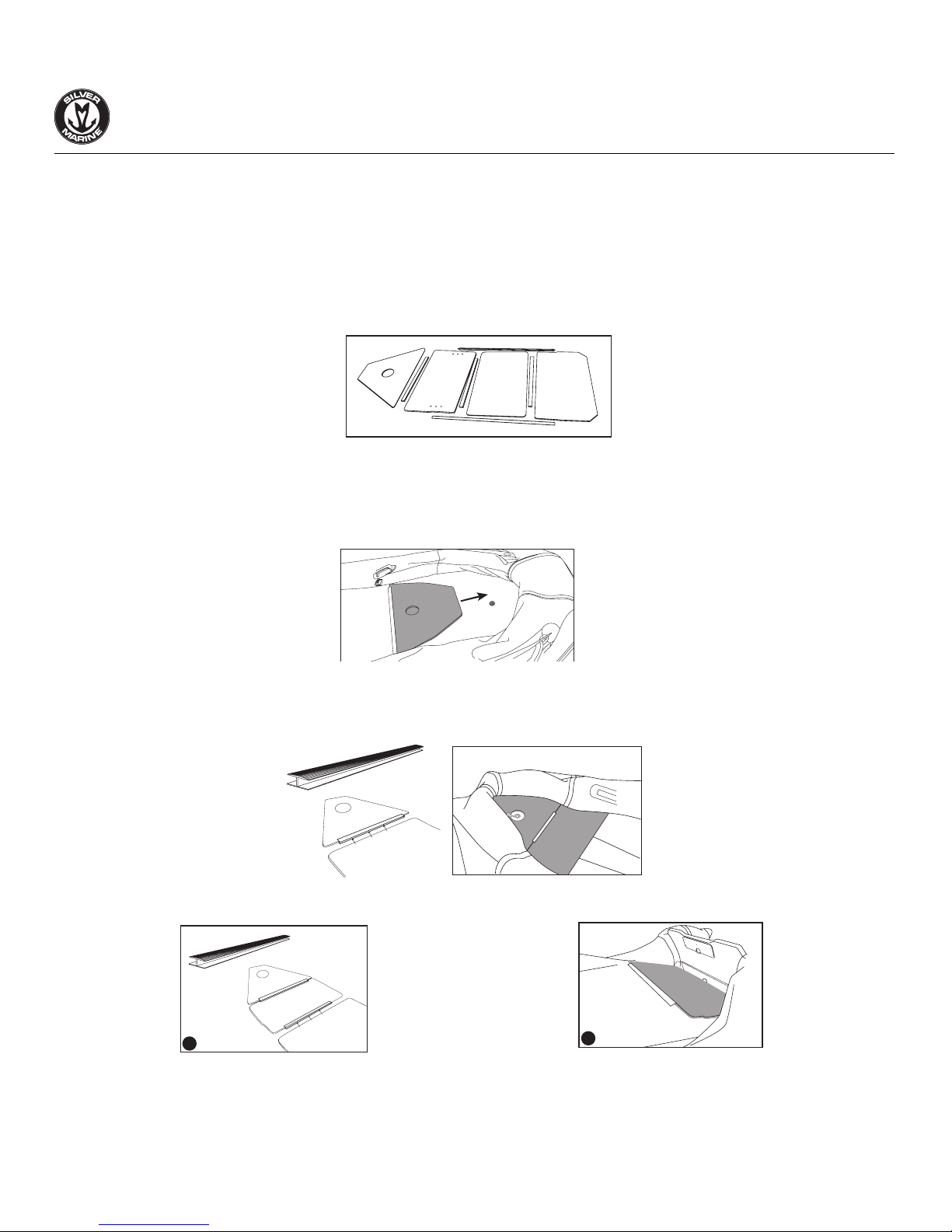

STEP TWO: FLOORBOARD AND SEAT ASSEMBLY

Calypso 300 WD&330 WD are equipped with an interlocking floorboard system which has 4 pieces

wooden floorboard.

1. Install Bow Floorboard

Start by fitting the wooden bow board, between air tubes and bottom. Slide and push it forward as far as

possible, until it has reached the top of the bow, and the air valve of the inflatable keel fits into the hole

of the bow board.

2. Install Floor Board 2

Fit the metal joint strip (wider side up) on the end of board 1 and, slide floor board 2 against board 1 with

modest pressure. Fit the front edge to the metal strip. Make sure the sides fit in between the tube and

floor.

3. Install the Rear Floorboards.

2

1

Calypso 300 WD & Calypso 330 WD

1

2

34

7

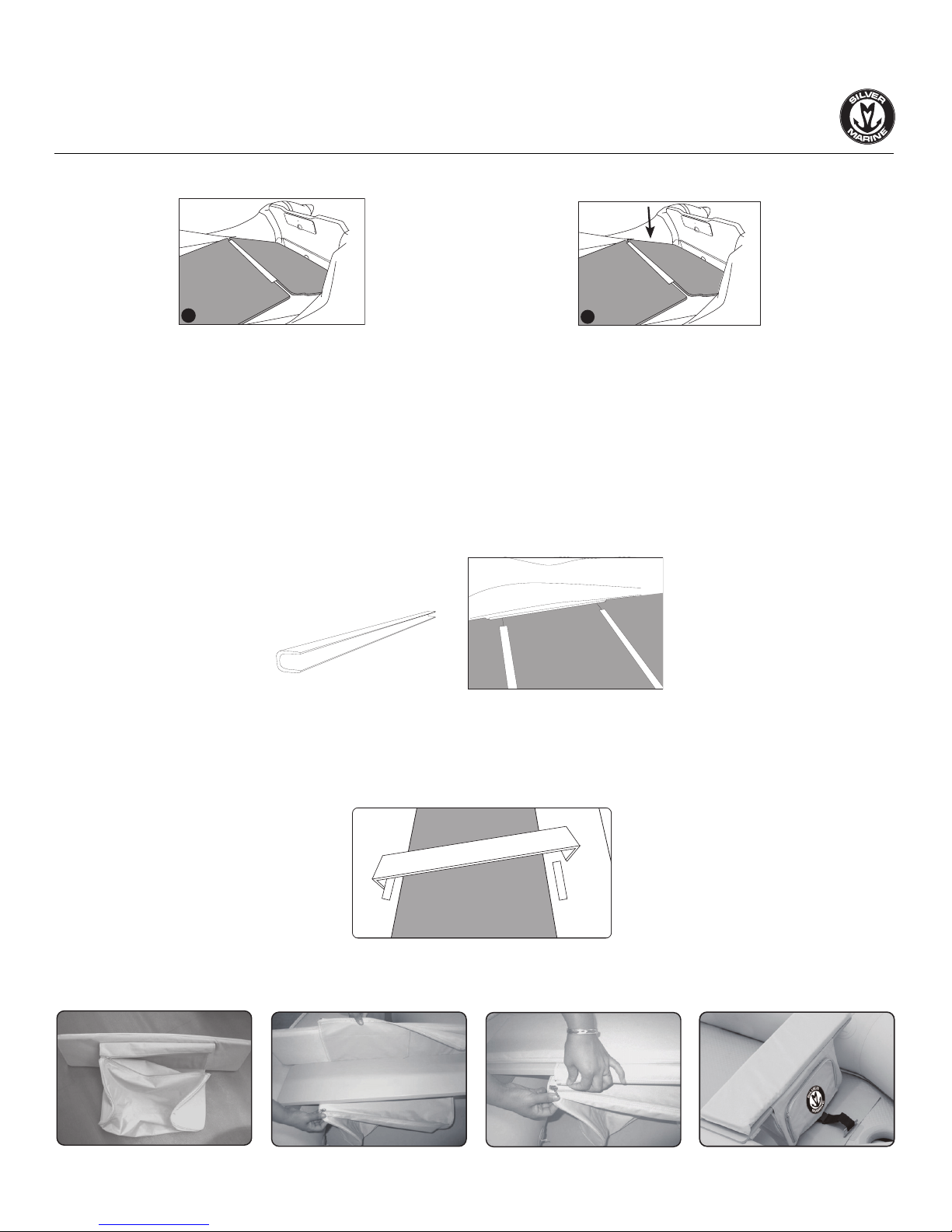

4. Side Stringers Assembly

There are two sturdy aluminum side stringers that serve to strengthen the structure of the boat and keep

the floorboards tight. Make sure the keel is slightly inflated, then insert the side stringers to fit in the

respective side positions.

5. Seat Installation

When the wood deck is in position, hook the plastic brackets at the bottom of the seat onto the PVC

straps on your Silver Marine® boat.

Connect the last board to the back of board 3

(per picture), lift and connect to the rear board’s

lifted side.

Push down the two boards at the joint.

4

3

6. Seat bag assembly

After the Seat Assembly, attach the bench seat bag onto the bench seat.

8

STEP FIVE: SELF-BAILING DRAIN VALVE

Push the plug into sleeve located in the transom.

Note: Always make sure the plug is secured into the valve before launching the boat and

do not open while afloat.

STEP THREE: FINISH INFLATION

After inflating the tubes, insert the barometer against the valve. Check if the pressure in the air chambers

reaches 0.25 bars, then remove the barometer and screw the cap on.

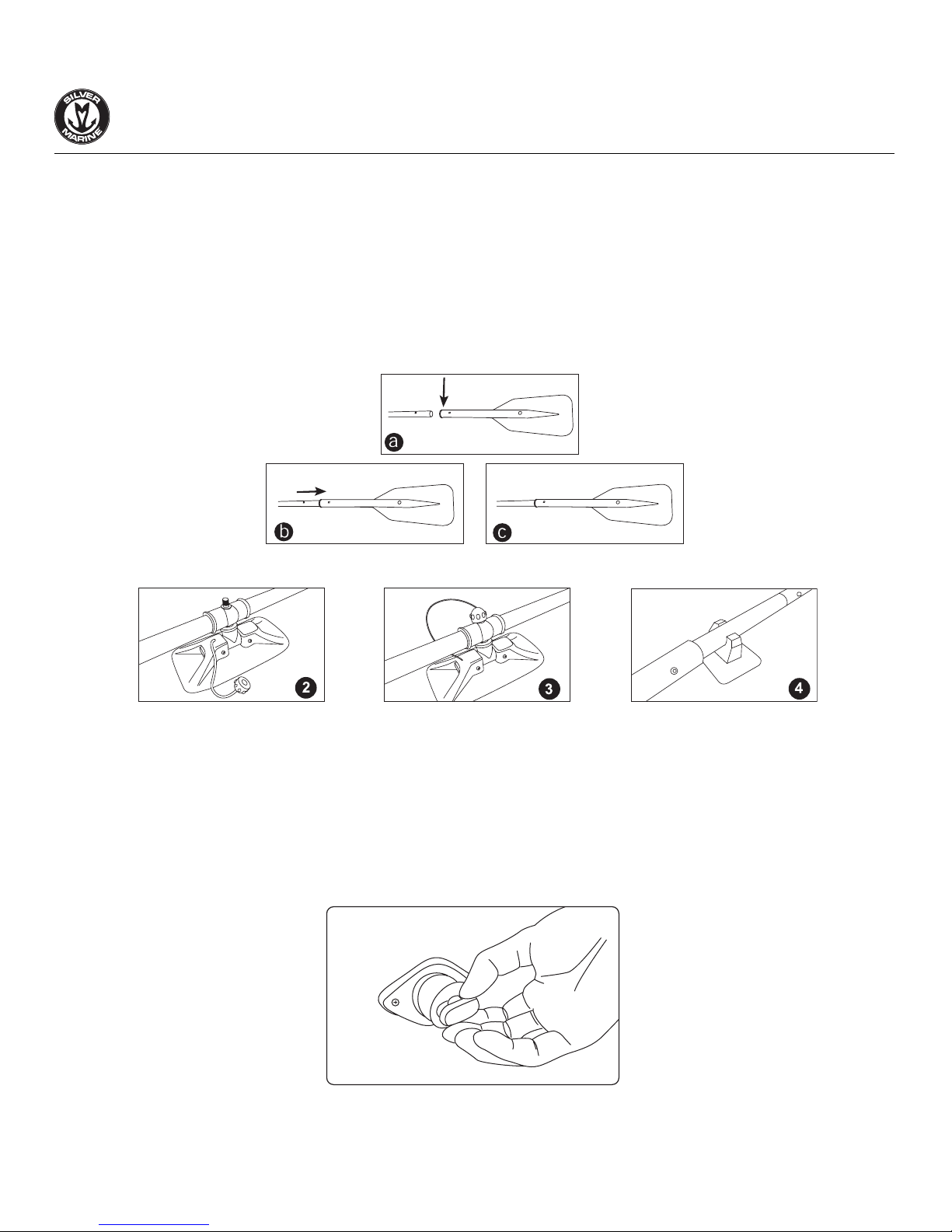

STEP FOUR: OARS FITTING AND ASSEMBLY

1. Press the clasp at one end of the oar, and insert it into blade end.

3. Screw the cap back to

lock the oar into position.

2. Press the screw on the

oarlock through the hole

on the oar.

4. Secure the blade end

in its clasp.

9

MOTOR INSTALLATION

Most outboard motors can be mounted directly onto the transom engine mounting plate. Read the

instruction manual supplied by separate outboard motor manufacturer. All outboards are slightly different,

and some require special installation procedures. Below is a general outline:

1. Set the motor on tilt and tilt the mounting bracket.

2. Place the motor in the center of the transom.

3. Screw the mounting brackets securely to the transom.

WARNING

1. Read the entire manual before mounting or operating the outboard motor.

2. Gasoline (Petrol) is highly flammable, and its vapors are flammable and explosive. Handle and store

gasoline (petrol) carefully. Make sure there are no gas fumes or leaking fuel before starting the engine.

3. Improper mounting of the outboard motor could result in hazards such as poor handling, loss of

control, or fire.

4. If any item in the pre-operation check is not working properly, have it inspected and repaired before

operating the outboard motor. Otherwise, accidents may occur.

DEFLATION AND DISASSEMBLY

You only need to turn the Joint Screw Gasket counterclockwise for easy deflation.

IMPORTANT: Do not deflate one chamber completely while keeping others fully inflated. This could

damage the bulkheads of your boat.

PRESERVATION

You should endeavour to keep your Silver Marine® in good condition. Preferably store it deflated. If you

leave it outside, raise it off the ground and cover it from the elements especially strong sunshine, or

heavy, cold, raining, conditions. If you leave it in the water, use a boat cover. If you store it in a closet,

basement or garage, we suggest you pick a cool and dry spot. Keep the boat clean and dry.

Every boat now includes a boat cover to keep it protected while not in use.

Take the cover

out of packaging.

Indentify the front

side of the cover.

(with Silver Marine

logo).

Assemble the boat cover front first,

then the back.

After assembly,

tighten clasp at

back.

Finish

THE PROCESS TO ASSEMBLE A BOAT COVER

10

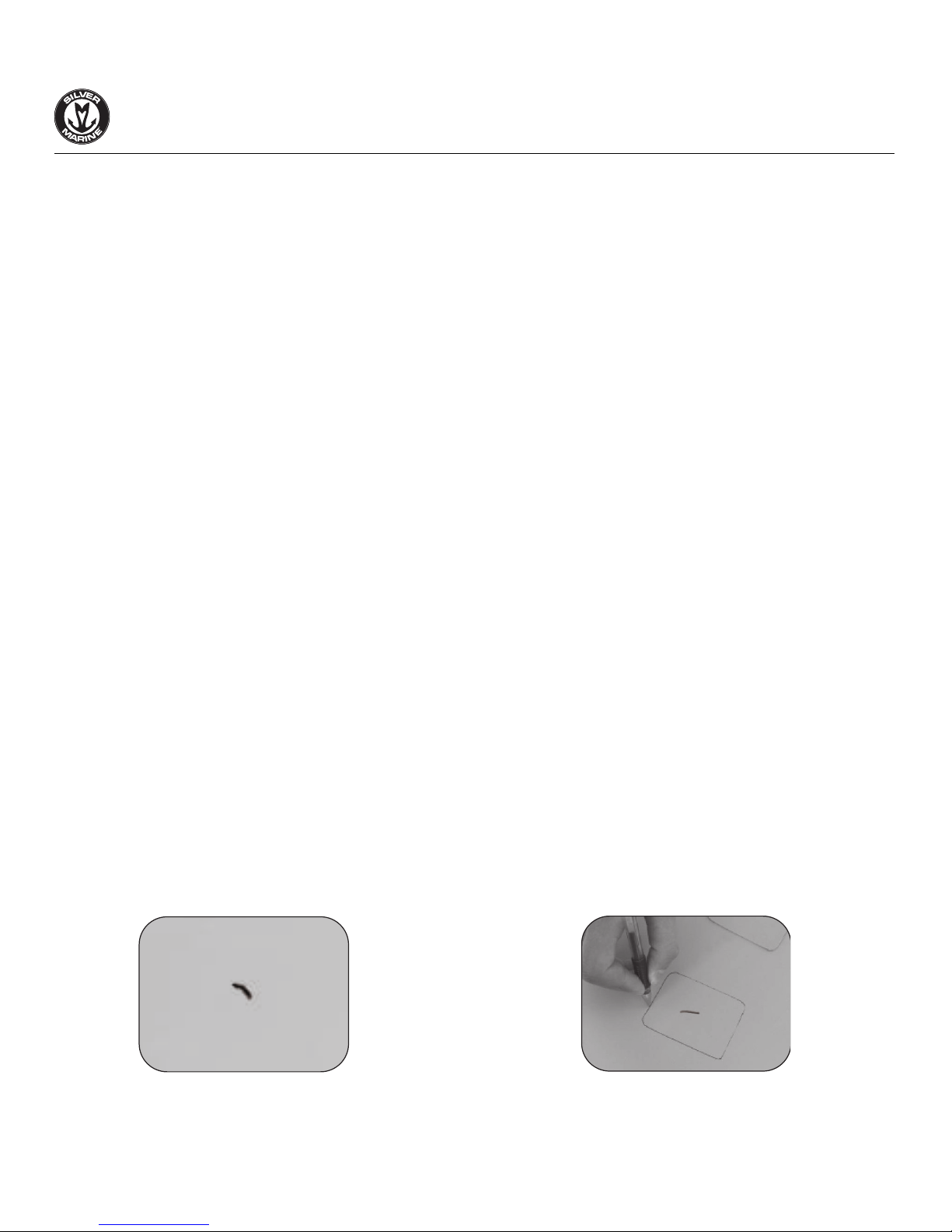

2. Cut a piece of repair material large enough to

overlap the damaged area by approximately 1/2

inch. Use a pencil to trace the outline of the patch.

1. Thoroughly clean the area surrounding the leak

to remove any dirt or grime.

MAINTENANCE

1. Inflate the boat up to working pressure. At this time you do not need to install the removable boards,

seat, oars and outboard engine.

2. If wet, leave the boat to dry, but avoid leaving it directly in the sun. Any quality problem occuring from

an extended time in the sun without using is not a product problem, and will not be covered by the

warranty.

3. When dry, vacuum order to get any sand, gravel, rubbish or debris off the bottom, pay extra attention

to the inflatable keel and in the gaps between the floor and tube.

4. Clean the boat all over with ordinary soap and water and rinse thoroughly with fresh water.

5. Check the inflation valves, clean them and remove any sand or debris.

REPAIRING

Your Silver Marine® boat comes with a repair kit for patching minor punctures. Most leaks only take a

few minutes to repair.

Air Leakage: If your boat appears a bit soft, it might not be because of a leak, since any change in

temperature can cause modifications 0.003 bar (0.045 psi) per Celsius degree (34F). If the boat was

inflated late in the day, that air might cool overnight. The cooler air exerts less pressure on the hull, so

it could appear soft the next morning.

If there has been no temperature variation, you need to first determine exactly where the air is leaking.

Please follow these instructions:

1. Check that there is no sand or debris within the air valve.

2. Make sure that the valve gasket is in place.

3. Inflate all chambers of the tube.

4. Close the cap on all the valves.

5. Rinse the boat with soapy water, including perimeter of the inflation valves.

6. Wherever bubbles appear, that is the location of the leak to be repaired.

Small Repairs: Deflate your boat. Thoroughly clean (you can use vinyl cleaner for this purpose) and dry

the area to be repaired. For a small puncture (less than 1/8 inch) apply a small drop of glue. Let dry for

12 hours.

Patches: Leaks larger than a pinhole can be patched. NOTE: Repairs should be carried out on deflated

boats.

11

4. Place the patch on the damaged area and press down firmly. Allow 12 hours for repair to dry. After

patch has dried, apply glue around the edges for a complete seal (dry for 4 hours).

FOLDING & STORAGE

1. Lie your inflatable boat on a clean flat surface, then deflate the buoyancy chambers.

2. Remove oars or paddles and removable rowing seat.

3. Fold the aft cones toward the transom.

4. Fold the buoyancy compartments inwards, i.e. towards the center of the boat.

5. Close the caps over the valves in order to avoid any damage to the hull material.

6. Fold the boat around the transom from the back.

7. Fold the bow section on top of the previously folded rear part of the boat.

Place the boat inside your Silver Marine® carry bag or protective coving. When storing your inflatable

boat, ensure protection against rodents and other vermin, as they feed on the fabric of the boat.

3. Apply adhesive to the underneath side of patch and around the area to be repaired. Coat the affected

area lightly but completely with glue. Let the glue sit for 2-4 minutes until it appears tacky.

12

OPERATION ON YOUR SILVER MARINE®

Rowing

Silver Marine® transom boats are great tenders and can be rowed easily. The oars are attached to the

swiveling oarlocks, which allow for easy rowing. Snap the rear blade section of the oar out of the clasp

and the oarlock will pivot out for instant use. You can remove the oar from the oarlock by unscrewing the

plastic nut on the oar.

Motoring & Safety

Silver Marine® transom boats are responsive and quick under power, and turn and track very well. All

boats have their maximum horsepower range, so take time to familiarize yourself with how your Silver

Marine® maneuvers in various conditions.

Basic seamanship is beyond the scope of this owner’s manual, but we would like to go over a few

fundamentals. It is your responsibility to be aware of and comply with all relevant safety regulations. In

all water sports you should have reasonable swimming ability. Always respect the water and weather,

both can change rapidly and have surprised even the most seasoned mariner. Always carry enough

approved personal floatation devices (Life jackets) for every passenger. We strongly suggest that all

boaters enroll in at least one of the excellent water safety courses.

Towing

Tie each end of a small line to the front side D-Rings on your boat to form a bridle. Tie your

towline to this bridle, and not to the carry handle in the front of the boat. Using the bridle

will distribute the force of towing across the hull.

Stability and buoyancy

a) Stability is reduced by any weight added high up;

b) Air tanks shall not be punctured;

c) Breaking waves are a serious stability hazard.

13

PROBLEM POSSIBLE REASONS POSSIBLE SOLUTION(S)

Buoyancy chamber

looses air

Rise or drop in temperature

Inflatable keel is not sufficiently inflated

Buoyancy collar is not sufficiently inflated

Aluminium stringers are not adequately

installed

Engine is incorrectly mounted

Load is not distributed correctly

Hull is full of water

Oar has been installed incorrectly

Plastic valve cap has not been fitted

Loose valve

Puncture

Floorboards not rigid

enough

Boat does not get

on plane

Oar slips out of the base

MAINTENANCE (P8)

MAINTENANCE (P8)

MAINTENANCE (P8)

REPAIRING (P9)

STEP TWO: AIR DECK

AND SEAT ASSEMBLY (P5)

MOTOR INSTALLATION (P8)

MOTOR INSTALLATION (P8)

SELF-BAILING DRAIN VALVE (P7)

STEP FOUR: OARS

FITTING AND ASSEMBLY (P7)

STEP ONE: STARTING UP (P4)

STEP ONE: STARTING UP (P4)

TROUBLESHOOTING CHART

Warning:

1. Please read the owner’s manual carefully before using.

2. Please retain owner’s manual for future reference.

3. Follow the instructions in the Owner’s Manual, including the data given on the capacity

plate. Uneven distribution of people or loads in the boat could result in danger.

4. Please refrain from using the boat at winds above 6-level and waves above 2 m.

5. Please pay attention to suspicious liquid such as leaking oil. It may lead to danger.

6. Always beware of offshore winds and currents.

7. Not for use in whitewater/ rapids.

8. Not a life saving device.

9. Not for use by children without adult supervision.

“WARNING – Do not exceed the maximum recommended number of persons.

Regardless of the number of persons on board, the total weight of persons and equipment

must never exceed the maximum recommended load. Always use the seats/seating spaces

provided.

“WARNING – When loading the craft, never exceed the maximum recommended load.

Always load the craft carefully and distribute loads appropriately to maintain design trim

(approximately level). Avoid placing heavy weights high up.”

D

S

U

14

15

Designed in USA by Silver Marine International Co., Ltd

©2008. All rights reserved.

www. silvermarine.com

This manual suits for next models

1

Table of contents

Other Silver Marine Boat manuals

Popular Boat manuals by other brands

ROCKSIDE

ROCKSIDE VULCAIN V335 user guide

Bavaria Yachts

Bavaria Yachts BAVARIA 38 manual

Silverline

Silverline S550LF user manual

Sea Eagle

Sea Eagle FastTrack Angler 385fta Instruction & owner's manual

Jeanneau

Jeanneau PRESTIGE 32 owner's manual

Banzai

Banzai 2-IN-1 SLIDE & BOUNCE COMBO PARK Assembly instructions