ENGLISH

3

2. When using a single compressor

refrigeration unit that is installed in a remote

location, ensure that it is adequately

protectedagainstlow ambienttemperatures

(capacity controls/crankcase heating), oil

returnwheretheicemakerisbelowtheheight

of the compressor (suction risers/oil traps/

oil separators) and liquid refrigerant return

where the icemaker is above the height of

the compressor (suction accumulator).

Always check the compressor

manufacturer’sguidelines.

3. An electrical link/connection between the

icemaker and compressor system is NOT

necessary. Where a multi compressor rack

system is used, the icemaker’s internal

controls will close the electrically operated

solenoid valves to stop ice production.

Where a single remote compressor is used,

thismust be fittedwith a low pressuresafety

switch to stop the compressor at approx.

0.5 bar suction pressure as the solenoid

valve’s closing will result in the compressor

pumpingdown.

8) After completing all the refrigeration tubing

connections, the pipe work should be leak tested,

evacuatedand vapour charged with R404A.

9) Open the ball valve to ensure the ice production

capacity when the compressor refrigeration

capacity is less than 1.6kW at an evaporating

temperature of -18°C, condensing temperature

43°C, return gas temperature 5°C, liquid

temperature43°Candambienttemperature35°C.

Close the ball valve to protect the icemaker when

the compressor refrigeration capacity is 1.6kW

or more.

10) The refrigeration connections are now complete.

Proceedto sections 4 and 5to continue withother

serviceconnectionrequirementsbeforecompleting

section 6, the start-up procedure.

11) Refit the Side and Top Panels in their correct

positions.

4. ELECTRICAL CONNECTIONS

WARNING

THIS APPLIANCE MUST BE EARTHED

This icemaker requires an earth that meets the

national and local electrical code requirements.

To prevent possible severe electrical shock to

individuals or extensive damage to equipment,

install a proper earth wire to the icemaker.

Disconnect the main power supply before any

maintenance, repairs or cleaning is undertaken.

* This icemaker should not be installed:

a) Where the power supply is not within the range

of 220 - 240V.

b) Wheretheicemakercannotbeconnecteddirectly

into its own power supply without using an

extension cord or sharing a receptacle.

* Usually an electrical permit and services of a

licensed electrician are required.

* If the supply cord and/or the plug should need to be

replaced, it should only be done by a qualified

serviceengineer.

* In accordance with the requirement of the IEC

standard, the maximum permissible system

impedance(Zmax)attheinterfacepointofthepower

supply to be connected with this icemaker must be

0.17+j0.10 ohm (FM-600/FMN-440) or

0.2908+j0.18175 ohm (FM-481). Determine in

consultation with the supply authority, if necessary,

that the icemaker is connected only to a supply of

0.17+j0.10 ohm (FM-600/FMN-440) or

0.2908+j0.18175 ohm (FM-481) or less.

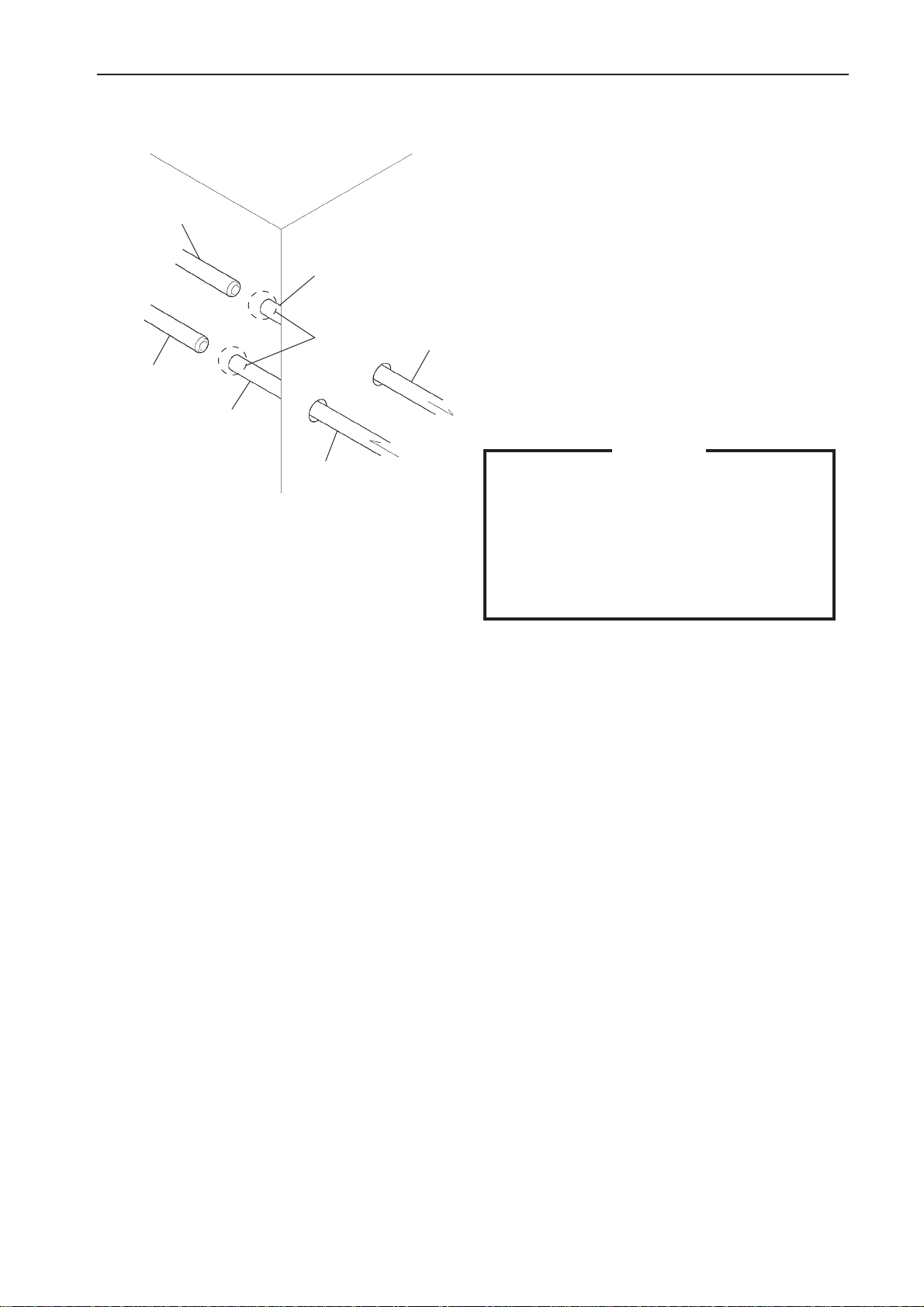

Fig. 6

1/2” ID

Suction Line

Liquid Line

1/4” ID

Expand

Suction Line

Liquid Line

Icemaker

pipe). Equivalent pipe lengths that exceed

20 m should be increased in size to 3/8”

OD liquid line and 5/8” OD suction line.