Simco-Ion Chargemaster VCM Series User manual

CHARGEMASTER VCM 5201067 Rev. B

Chargemaster

VCM30 and VCM60

Electrostatic Generating

Power Supplies

INSTALLATION AND OPERATING INSTRUCTIONS

CHARGEMASTER VCM 5201067 Rev. B

TABLE OF CONTENTS

1. DESCRIPTION...................................................................................................... 3

2. SAFETY ............................................................................................................... 3

3. FEATURES ........................................................................................................... 4

4. SPECIFICATIONS ................................................................................................. 5

5. INSTALLATION .................................................................................................... 7

6. OPERATION ....................................................................................................... 12

7. REMOTE OPERATION ........................................................................................ 18

8. MAINTENANCE.................................................................................................. 23

9. REPLACEMENT PARTS...................................................................................... 25

10. WARRANTY....................................................................................................... 26

3

CHARGEMASTER VCM 5201067 Rev. B

1. DESCRIPTION

Each Chargemaster VCM Electrostatic Generating Power Supply incorporates

high frequency switch-mode and power factor corrected technology within a

compact enclosure. Each unit is electronically current limited and arc protected.

The output voltage is adjustable from zero to full rated output at maximum rated

current. Refer to specifications for specific models.

The VCM30 and VCM60 power supplies are manufactured in either positive or

negative polarity, and feature remote ON/OFF capability. The output voltage can

also be controlled from a remote location via a 0-5V, 0-10V, 0-20mA or 4-20mA

voltage or current source. The power supplies also supply a 0-5V or 0-10V output

signal to remotely monitor the output voltage and current.

2. SAFETY

NOTE – Statements identified with a NOTE indicate precautions necessary

to avoid potential equipment failure.

CAUTION – Statements identified with a CAUTION indicate potential

safety hazards.

NOTE – This equipment must be correctly installed and maintained.

Adhere to the following notes for safe installation and operation:

a) The Chargemaster VCM high-voltage power supply is intended to

generate high voltages for charging bars and electrodes.

b) A skilled and qualified electrical engineer must carry out all work on this

equipment.

c) Disconnect the equipment prior to working on it.

d) Make sure that the equipment is properly grounded for correct and safe

operation.

CAUTION – Electrical Shock Hazard

High voltage is hazardous for people with a pacemaker

4

CHARGEMASTER VCM 5201067 Rev. B

3. FEATURES

• Operates in either Current Control or Voltage Control mode.

• Front panel orientation is factory selectable for bench top or wall

mounting.

• Flat panel with membrane switches.

• Mounting brackets for bottom or top mounting.

• No cooling fan.

• Short circuit protected output.

• Very stable electronically controlled output voltage.

• Remote output voltage control features.

• Keyboard lock to prevent unauthorized adjusting of the output voltage

setting.

• Remote monitoring of the output voltage, current and overload status.

• Large digital readout with backlight.

• Run feature for displaying preset voltage level during remote

operation.

5

CHARGEMASTER VCM 5201067 Rev. B

4. SPECIFICATIONS

Output Voltage: VCM30: 0-30 kV VCM60: 0-60kV

Output Current: VCM30: 0-5.0mA VCM60: 0-2.5mA

Max. Output Power: 150W

AC Input Voltage: 85 - 264 V

AC Input Frequency: 47-63 Hz

Fuse (Rear Panel): 3.15 AT

Output Connections: 4 Output Ports (Simco-Ion SLCC type)

Remote Control Connection: 25 Pin D-Sub Connector

Cooling: Convection

Polarity: N = Negative, P = Positive

Short-Circuit Protection: Output Electronically Protected at Max. Output Current

Input Power Connection: IEC-320 AC Receptacle (North American 115 and 230 Line

Cords are provided with each VCM unit)

Resolution Of Display: 0.2 kV, 0.05mA

Voltage Stabilization: 2% Of Max. Output Voltage With Input Voltage Between 85 and

264 V.

Load Stabilization: 2% of Maximum Output Voltage at Load Fluctuation between 0

and Maximum Rated Load.

Ripple, peak-peak: 10% of Maximum Output Voltage at Maximum Load

Remote ON / OFF: 0V = OFF, 12 V = ON (Typical)

Control Voltage Range:

10 V , 10 mA min.

30 V , 25 mA max.

Internal Power Supply: 12 V (± 20%), 20 mA (Uripple = 0.5Vtt max.) For

Remote On/Off And External Overload Signaling, If necessary

Remote programming: 0-5V, 0-10V, 0-20mA or 4-20mA

Ambient Temperature: 32°F - 131°F (0 - 55°C)

Operating Environment: Vibration-Free Installation

Remote Control Functions: • Switching High Voltage On/Off

• Output Voltage and Current Control via Standard Industry

Control Signals.

• Output Voltage and Current Monitoring

• Overload Indication Monitoring.

• Easy to configure via D-Sub connector

6

CHARGEMASTER VCM 5201067 Rev. B

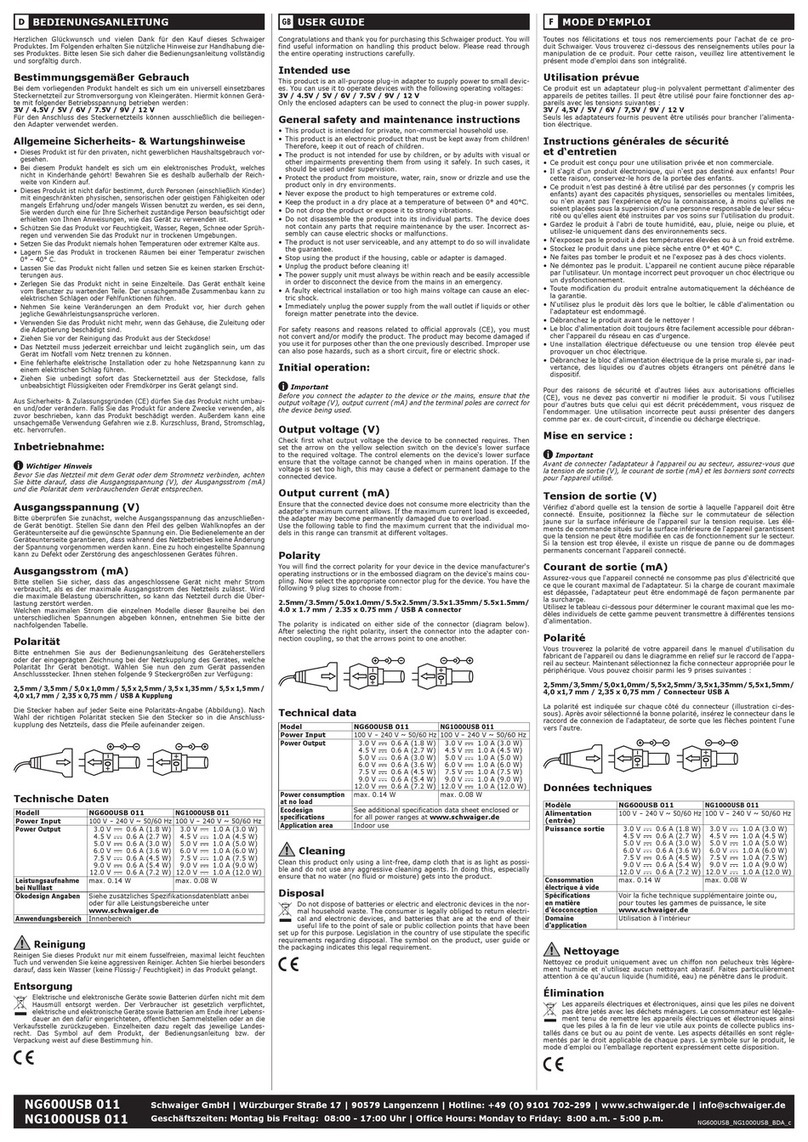

STANDARD

CHARGEMASTER VCM

VCM30-N, (Negative) P/N: 4012555

VCM30-P, (Positive) P/N: 4012557

VCM60-N, (Negative) P/N: 4012559

VCM60-P, (Positive) P/N: 4012561

WALL MOUNT CONFIGURATION

VCM30-N, (Negative) P/N: 4012556

VCM30-P, (Positive) P/N: 4012558

VCM60-N, (Negative) P/N: 4012560

VCM60-P, (Positive) P/N: 4012562

The display panel is rotated 180° to allow for

easy viewing when the generator is mounted

on a vertical wall. Wall mounting brackets

and hardware to affix the brackets to the

generator are supplied with the generator.

Note that this is only a factory installed

option on the initial order.

DUAL POLARITY CONFIGURATION

Reversing the mounting brackets on the

bottom power supply allows two standard

VCM units to be stacked together. Units

are supplied with mounting brackets and

hardware to affix the brackets to the power

supply.

Figure 1

7

CHARGEMASTER VCM 5201067 Rev. B

5. INSTALLATION

5.1 Unpacking

Carefully remove equipment from the carton and inspect the contents.

NOTE – If any damage has occurred during shipment, notify the local

carrier at once. A report should also be forwarded to Simco-Ion, 2257

North Penn Road, Hatfield PA 19440. See Section 9 (Warranty) for Return

Shipment information.

5.2 Determining Power Supply Placement

Place the power supply in a convenient location on or near the machine to allow

the charging bar or applicator’s high voltage cable to reach the output terminals

located on the back of the unit. As a point of reference, the AC Power Cord and

the grounding wire are 7.5 feet in length.

CAUTION – Electrical Shock Hazard

The power supply unit must be placed in a limited access area to protect

operating personnel from accidental electrical shock. Do not install the

power supply in a dirty or damp environment where chemicals or other

corrosive agents are handled.

5.3 Mounting the Power Supply

CAUTION – Fire Hazard

Do not install or operate equipment in close proximity to any flammable

solvents or flammable materials.

The unit can be mounted above or below an appropriate mounting surface. To

ensure sufficient airflow, make sure the ventilation openings on the side and

underside are not blocked. Mounting brackets are provided to mount the unit

directly onto a machine, shelf, other surface or stacked on top of each other.

Hardware is provided to mount the mounting brackets to the power supply. There

are three mounting configurations for the Chargemaster VCM (see Figure 1).

To mount the VCM Power Supply:

a) Locate the accessory kit provided with the Chargemaster VCM.

b) Attach two mounting brackets, (see Figure 2), to the VCM with M4 x 8

screws (provided in kit). Use mounting bracket as a template to mark the two

mounting hole locations.

8

CHARGEMASTER VCM 5201067 Rev. B

c) Attach two mounting brackets, (see

Figure 2), to the VCM with M4

x 8 screws (provided in kit). Use

mounting bracket as a template

to mark the two mounting hole

locations.

e) Drill two 0.201” diameter clearance

holes at marked locations.

f) Position mounting bracket’s screw

holes directly above drilled holes.

Secure with #10 screws, nuts

and lock washers (fasteners not

supplied).

5.4 Grounding the Chargemaster VCM

CAUTION – Electrical Shock Hazard

It is essential that the machine frame, and all metal parts in the vicinity,

be grounded either through well-grounded electrical conduit or by heavy

copper wire to a water pipe.

All Chargemaster VCM power supplies must be properly grounded to ensure

proper operation and prevent shocks. A proper ground is also required to establish

the power supply electrical return and provide the return path for ion generation

of the attached bar or applicator.

a) The power supply should be connected to a grounded 3-terminal polarized

AC receptacle. Test the ground pin of the AC receptacle to assure proper

grounding.

b) Connect the green wire from ground terminal on the back of the power

supply to a well-driven ground rod. Do not ground to a hot water pipe.

c) Mount the unit using supplied mounting brackets to a well grounded

metal surface free of paint and / or any nonconductive surface treatment.

The unit is also grounded through the supplied mounting brackets.

Figure 2

9

CHARGEMASTER VCM 5201067 Rev. B

5.5 Supplying Power to the Unit

a) Connect the AC line cord to the (IEC 320 input) connector on back of

unit.

b) Plug the AC line cord into outlet. Verify that the voltage and

frequency marked on unit serial label match outlet power. If ON/OFF

cycling is required, remote switching MUST BE USED. Do not cycle

the VCM Power Supply ON/OFF through the AC input power line

cord (see Section 6).

5.6 Installation Options for Charging Bars and Applicators

VCM30 and VCM60 Power Supplies can be used to energize a variety of

charging bars and applicators manufactured by Simco-Ion, including the

following models:

• TETRA Charging Bar

• Pinner Arc Resistant Bar

• Pinner NR Arc Resistant Bar

• Pinner 5-Point Applicator

• Pinner Blade Applicator

• Pinner Claw Applicator

• Multi-Point Applicator

• FlexTac Applicator

Connecting a Chargemaster HV Power

Supply to a bar or applicator not

manufactured by Simco-Ion for use with that model of power supply, without the

written permission of Simco-Ion, will void the power supply’s warranty.

A TETRA Charging Bar (see Figure 3) will be used in this manual for purposes

of illustrating the three most common installation options for charging bars and

applicators. The three methods of installation generally apply to all types of bars

and applicators, except for option 2, which is normally used only with bars.

The TETRA bar is energized by connecting it to a Simco-Ion Chargemaster VCM

Power Supply, which provides the high voltage necessary to power the bar. The

energized TETRA Charging Bar is used to produce electrostatic adhesion for

temporarily bonding or pinning materials.

TETRA

10

CHARGEMASTER VCM 5201067 Rev. B

Option 1 – Charging Bar with Grounded Surface

This application illustrates the use of a

TETRA bar facing a grounded surface.

The material to be charged should rest

on the grounded surface. In the example

shown in Figure 4, the charging bar is

located facing an empty core in a roll-

to-roll changeover application. The

empty core is mounted on a grounded

metal shaft. The plastic film is between

the charging bar and empty core. The

negative ions created by the charging

bar are driven towards the grounded

metal shaft by the electric field between

the charging bar and grounded shaft.

The plastic film intercepts the ions and becomes electrostatically charged in the

process. The electrostatic charge in the plastic film causes adhesion of the film

to the empty core.

The charging bar may also be located facing a production fixture that moves

beneath the charging bar (or the charging bar could also move over the fixture).

The materials to be pinned together are

positioned on the fixture (Figure 5). As

the fixture moves beneath the charging

bar, the negative ions created by the

charging bar are driven towards the

grounded metal fixture by the electric

field between the charging bar and fixture.

The top material intercepts the ions and

becomes electrostatically charged in the

process. The electrostatic charge in the

top material causes adhesion of the top

material to the lower material and to the

fixture. This bar arrangement emulates an interleaving application where paper

or film is pinned to metal prior to cutting and stacking.

Film

Shaft

Cardboard

Core

Figure 4

11

CHARGEMASTER VCM 5201067 Rev. B

Option 2 – Charging Bar with Static Bar

The second application uses a TETRA

Charging Bar facing a static eliminating

bar (Figure 6). The materials to be

pinned together are guided between

these bars. The charging bar is facing

an insulative film while the static bar

faces a sheet of insulative material on

the opposite side (glass, plastic, light

particle board, etc.). As the materials

pass between the bars, the negative

ions charge the film and the static

eliminating bar attempts to neutralize

the apparent charge on the sheet. This

deposits a positive charge on the lower sheet. The use of the static bar improves

the process of pinning two insulating materials together and increases the

electrostatic pinning adhesion dramatically.

Option 3 – Two Charging Bars

The third application uses two TETRA Charging Bars of opposite polarity

facing each other (Figure 7). The

materials to be pinned together are

guided between the charging bars.

The ions created by each charging bar

are attracted towards each other due to

their opposite polarity. This method of

charging materials is generally used in

the most difficult pinning applications

and is most successful when arc-

resistant bars are used.

Chargemaster VCM Power Supplies

are designed to power the approved

Simco-Ion charging bars and

applicators identified in Section 4.

The Remote On/Off function should be used to cycle the power supply On

and Off whenever possible. The power supply requires about 60ms to achieve

maximum output voltage when energized.

Pinning using two

charging bars.

Figure 7

Static Bar

Pinning using a

charging bar and

static bar

Figure 6

12

CHARGEMASTER VCM 5201067 Rev. B

6. OPERATION

CAUTION – Electrical Shock Hazard

Do not touch Charging Bar during operation.

CAUTION – Fire Hazard

Do not operate equipment in close proximity to any flammable solvents

or flammable materials.

6.1 Turning On/Off

a) Turn power switch on front panel to OFF (“O”) position.

b) Ensure power supply GROUND TERMINAL is properly grounded. See

Section 5 for details.

CAUTION – Electrical Shock Hazard

Failure to properly ground the unit will result in damage to the unit and

create shock hazards for personnel.

c) Connect the charging bar or applicator to the high voltage output

connectors on rear of the Chargemaster VCM.

d) Insert the AC line cord into a properly grounded receptacle.

e) Turn front panel power switch to ON (“I”) position.

NOTE – It takes a few seconds for the display backlight to illuminate

fully.

13

CHARGEMASTER VCM 5201067 Rev. B

6.2 Main Screen

The “Main Screen” of the Chargemaster VCM displays:

a) Measured Voltage (kV)

b) Lightning bolt symbol “7” to indicate output is “on”

c) Measured Current (mA)

d) Control Mode: VLT (voltage control) or CUR (current control)

e) Operating Mode:

• KEYPAD CONTROL - No external control features enabled.

• KEYPAD+REM l/0 - Remote HV On/Off is the only control feature

enabled.

• REM:SETPOINT CTRL - Remote setpoints are the only external

features enabled.

• REM:SETPOINT+l/0 - All external control features enabled.

f) Key symbol to indicate the keypad is locked

g) Time remaining before the bar is scheduled to be cleaned

(a) (b) (c) (d)

(e) (f)

(g)

6.3 Operating Modes

Simco-Ion’s Chargemaster VCM Electrostatic Generating Power Supplies can be

run in either Constant Current or Constant Voltage mode. Select the mode that

is best for your application:

a) In the Constant Current mode, the power supply maintains stable and

strong pinning power even as ambient conditions change, or the ionizing

electrodes get contaminated with time, or the material’s properties

vary.

b) In the Constant Voltage mode, the power supply provides stable and

consistent pinning voltage, even with varying load impedance. This is

14

CHARGEMASTER VCM 5201067 Rev. B

the traditional control mode employed by earlier versions of Simco-Ion

Chargemaster power supplies.

6.4 Navigating the Menus

Enter one of the two available menus by pressing [MENU] to enter the “Control

Menu”, or pressing [MENU + ENTER] to enter the “Service Menu”. Navigating

through menu items is done by pressing [MENU]. To change the value of a

selected item, press [UP] or [DOWN]. Accept the newly selected menu item by

pressing [ENTER] (an asterisk will flash to confirm the change).

The Chargemaster VCM also has the possibility to reset the changed item back

to its original value. To do so, press [MENU + DOWN] and the original value

will be restored.

To escape from the menu system, press [MENU + UP]. If no buttons are pressed

for a period of 30 seconds, the “Main Screen” will be displayed automatically.

6.5 Control Menu Structure

Menu Item Possible Values Resolution Default

Control Mode Voltage Control

Current Control Voltage Control

Set point Voltage *1

0.0 kV

3.0 - 60.0 kV

3.0 - 30.0 kV

0.2 kV 0.0 kV

Set point Voltage *2

0.00 mA

0.10 - 2.50 mA

0.10 - 5.00 mA

0.05 mA 2.50 mA (VCM 60)

5.00 mA (VCM 30)

Voltage Limit *2

0.0 kV

3.0 - 60.0 kV

3.0 - 30.0 kV

0.2 kV 0.0 kV

Reset Bar Timer No

Yes No

Restore Factory Settings No

Yes No

*1 = VC mode only

*2 = CC mode only

15

CHARGEMASTER VCM 5201067 Rev. B

6.6 Service Menu Structure

Menu Item Possible Values Resolution Default

Remote Set Point Disable

Enable Disable

Remote On-Off Control Disable

Enable Disable

Readout Stretched 0.0 to 5.0 Sec

(Range) 0.1 Sec 0.7 Seconds

Limited Stretched 0.5 to 5.0 Sec

(Range) 0.1 Sec 0.7 Seconds

Limited Pos Delay 10 to 500 mSec

(Range) 10 mSec 300 mSec

Limited Neg Delay 10 to 1000 mSec

(Range) 10 mSec 500 mSec

Bar Timer Interval

48 Hrs

96 Hrs

168 Hrs

360 Hrs

1080 Hrs

1440 Hrs

48 Hrs 1080 Hrs

Remote I/O Mode OutU

0 - 5 V DC

0 - 10 V DC

0 - 20 mA DC

4 - 20 mA DC

0 - 5 V DC

All analog I/O same Yes

No No

Remote I/O Mode Out I

0 - 5 V DC

0 - 10 V DC

0 - 20 mA DC

4 - 20 mA DC

0 - 5 V DC

Remote I/O Mode SetU

0 - 5 V DC

0 - 10 V DC

0 - 20 mA DC

4 - 20 mA DC

0 - 5 V DC

Remote I/O Mode Set I

0 - 5 V DC

0 - 10 V DC

0 - 20 mA DC

4 - 20 mA DC

0 - 5 V DC

16

CHARGEMASTER VCM 5201067 Rev. B

6.7 Summary of Buttons and Their Functions

a) [Menu]: Go to the “Control Menu” or select the next menu item.

b) [Up]: Set the HV set-point or increase a menu item value.

c) [Down]: Set the HV set-point or decrease a menu item value

d) [Run]: Override the HV output in Remote mode.

e) [Enter]: Accept new set-point value after it has been changed.

f) [Menu + Enter]: Go to the “Service Menu”.

g) [Menu + Up]: Escape from a menu.

h) [Menu + Down]: Restore a menu item’s default value.

i) [Run + Enter]: Reset the Clean Bar Timer (only when the Clean Bar

Alarm message is on the screen).

j) [Up + Down]: Lock or unlock the keyboard.

6.8 Display or Change Set Points

a) Press [UP] or [DOWN] once.

b) If operating in Voltage Control Mode, the Voltage Set Point and the

Current Limit will be displayed. If operating in Current Control Mode,

the Current Set Point and the Voltage Limit will be displayed.

c) Press [UP] or [DOWN] again and the set point will be changed.

d) After 4 seconds the “Main Screen” will be displayed again.

When [UP] or [DOWN] is pressed for a longer time, the set point will be

incremented or decremented faster. As long as the set point information is

on the screen, it is possible to release the UP or DOWN button and change

the set point by pressing it again.

6.9 Lock/Unlock the Keypad

Lock the keypad buttons by pressing [UP + DOWN] for about 1 second. A key

character will display on the “Main Screen” indicating the keypad is locked. It is

no longer possible to change the set-point settings or to enter one of the available

menus. The use of the UP and DOWN buttons can still be used to display the

set-point values.

To unlock the keypad buttons, press [UP + DOWN] for about 1 second. The key

character in the display will disappear. It is again possible to change the set-point

values or enter one of the available menus.

17

CHARGEMASTER VCM 5201067 Rev. B

6.10 Clean Bar Timer

The Clean Bar Timer monitors the time that the high voltage output is present,

and counts down from a preset cleaning interval.

To set the cleaning interval:

• Press [MENU + ENTER] for the Service Menu.

• Press [MENU] until “Bar Timer Interval” is displayed.

• Press [UP] or [DOWN] until desired interval is displayed.

• Press [ENTER] to accept the setting (asterisk will flash).

• Press [MENU + UP] to return to the Main Screen.

When the Clean Bar Timer reaches zero, the cleaning interval has expired and

the “Clean Bar Alarm” message is displayed. After the bar has been properly

cleaned, the Clean Bar Timer can be reset by pressing [RUN + ENTER].

18

CHARGEMASTER VCM 5201067 Rev. B

7. REMOTE OPERATIONS

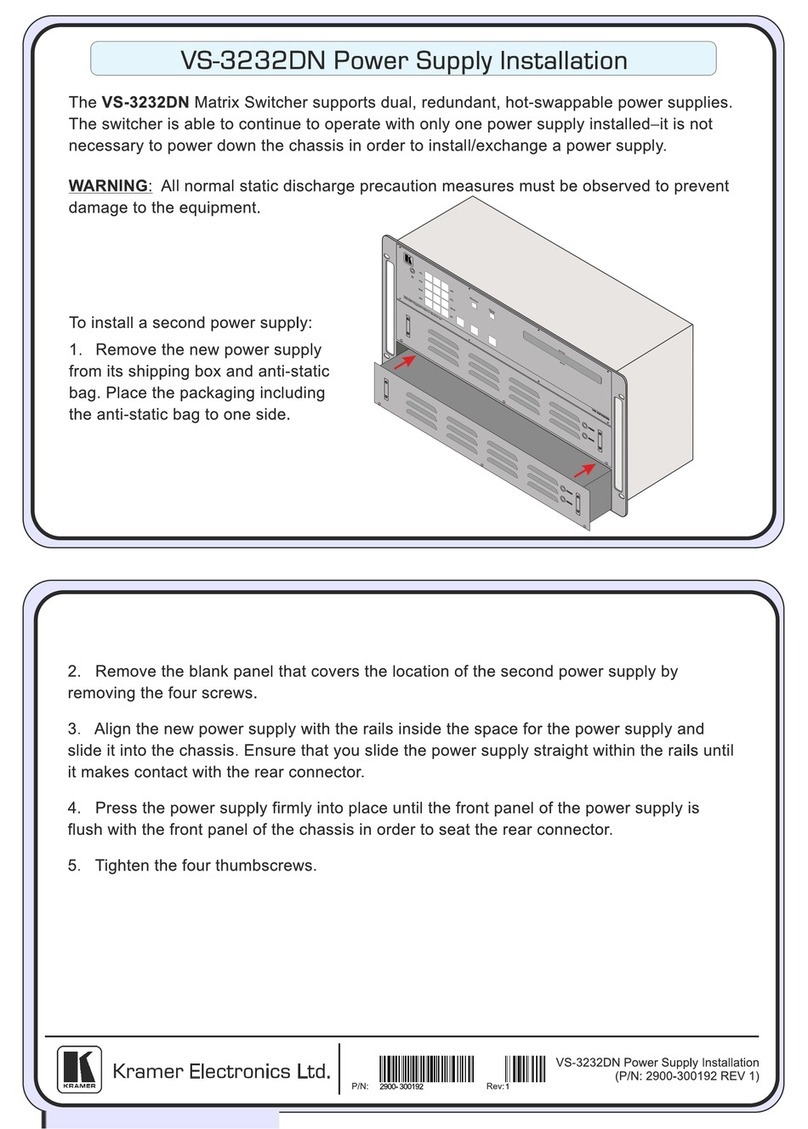

Pin Function Pin Function

1 Remote On/Off (+) 14 Remote On/Off (-)

2 Remote Current Set Point 15 GND

3 Remote Voltage Set Point 16 GND (blue)

4 Remote Voltage Output 17 GND (blue)

5 Remote Current Output 18 GND

6 +24V Internal Power Supply 19 GND

7 +12V Internal Power Supply 20 0V Internal Power Supply

8 Clean Bar (Open Collector) 21 Clean Bar (Open Emitter)

9 Limit Alarm (Open Collector) 22 Limit Alarm (Open Emitter)

10 HV On (open Collector) 23 HV On (open Emitter)

11 (Reserved) 24 GND

12 (Reserved) 25 GND

13 (Not Connected)

1

31

25

14

1

14

2

15

3

16

4

17

5

18

7

20

8

21

9

22

10

23

VA

1200

INTERNAL

CHARGEMASTER

VCM

61112

13

19

24

25

1200

1200

19

CHARGEMASTER VCM 5201067 Rev. B

7.1 Remote Functions

Several functions may be controlled remotely through the 25-pin D-Sub connector

located on the rear of the unit (the mating D-Sub connector and back shell are

supplied in the mounting kit with each unit):

• Turning On/Off the High Voltage Output

• Controlling the Voltage and Current Set Points

• Monitoring the Output Voltage, Current, and Alarms

7.2 Turning On/Off the High Voltage Output Remotely

a) The Remote On/Off function enables the power supply to be energized

from a remote location. This function switches the output voltage On/

Off, NOT THE AC MAIN VOLTAGE.

NOTE - The VCM Power Supply needs 60ms to reach maximum output

voltage from 0kV. The time needed to reach 0kV from the maximum

depends on the load connected.

b) To enable/disable the remote On/Off function:

• Press [MENU + ENTER] for the Service Menu.

• Press [MENU] until “REMOTE ON-OFF” is displayed.

• Press [DOWN] to toggle from “DISABLE” to “ENABLE”.

• Press [ENTER] to accept the setting (asterisk will flash).

• Press [MENU + UP] to return to the Main Screen.

c) Provide a dry contact between D-Sub connector pins 1 & 7.

d) Jumper D-Sub connector pins 14 & 20 to make available 12V with

which power to the contact.

e) Closing the contact will then energize the high voltage output; while an

open circuit will deenergize it.

NOTE - If the remote On/Off function is used, the Input Power switch

must remain in the “ON”, (I), position.

NOTE - If the remote On/Off function is used, the [RUN] button can be

used to temporary activate the output voltage manually for testing or

verification purposes.

20

CHARGEMASTER VCM 5201067 Rev. B

7.3 Controlling the Voltage Set Point Remotely

a) The output voltage can be controlled from a remote source that provides

any of the following control signals:

• 0 - 5 V DC • 0 - 10 V DC

•0 - 20 mA DC • 4 - 20 mA DC

b) To enable/disable the remote Voltage Control function:

• Press [MENU] for the Control Menu.

• Press [DOWN] to toggle to “VOLTAGE CONTROL”.

• Press [ENTER] to accept the setting (asterisk will flash).

• Press [MENU + UP] to exit the Control Menu.

• Press [MENU + ENTER] for the Service Menu.

• Press [DOWN] to toggle from “DISABLE” to “ENABLE”.

• Press [ENTER] to accept the change (asterisk will flash).

• Press [MENU] until “Remote I/O Mode SetU” is displayed.

• Press [DOWN] until desired control signal is displayed.

• Press [ENTER] to accept the change (asterisk will flash).

• Press [MENU + UP] to return to the Main Screen.

c) Connect the reference signal to D-Sub connector pins 3 & 16.

d) Inputting a high signal will drive the VCM Power Supply to its

maximum output; a low signal (or absence of a signal) will drive it to

zero output.

7.4 Controlling the Current Set Point Remotely

a) The output current can be controlled from a remote source that provides

any of the following control signals:

• 0 - 5 V DC • 0 - 10 V DC

• 0 - 20 mA DC • 4 - 20 mA DC

b) To enable/disable the remote Current Control function:

• Press [MENU] for the Control Menu.

• Press [DOWN] until “CURRENT CONTROL” is displayed.

• Press [ENTER] to accept the change (asterisk will flash).

• Press [MENU + UP] to exit the Control Menu.

• Press [MENU + ENTER] for the Service Menu.

• Press [DOWN] to toggle from “DISABLE” to “ENABLE”.

• Press [ENTER] to accept the change (asterisk will flash).

• Press [MENU] until “Remote I/O Mode SetI” is displayed.

• Press [DOWN] until the desired control signal is displayed.

This manual suits for next models

12

Table of contents

Other Simco-Ion Power Supply manuals