User manual - WEIGHT METER SWI-94

CONTENTS

1. BASIC REQUIREMENTS AND USER SAFETY.......................................................................................3

2. GENERAL CHARACTERISTICS...............................................................................................................4

3. TECHNICAL DATA....................................................................................................................................4

4. DEVICE INSTALLATION...........................................................................................................................6

4.1. UNPACKING.....................................................................................................................................7

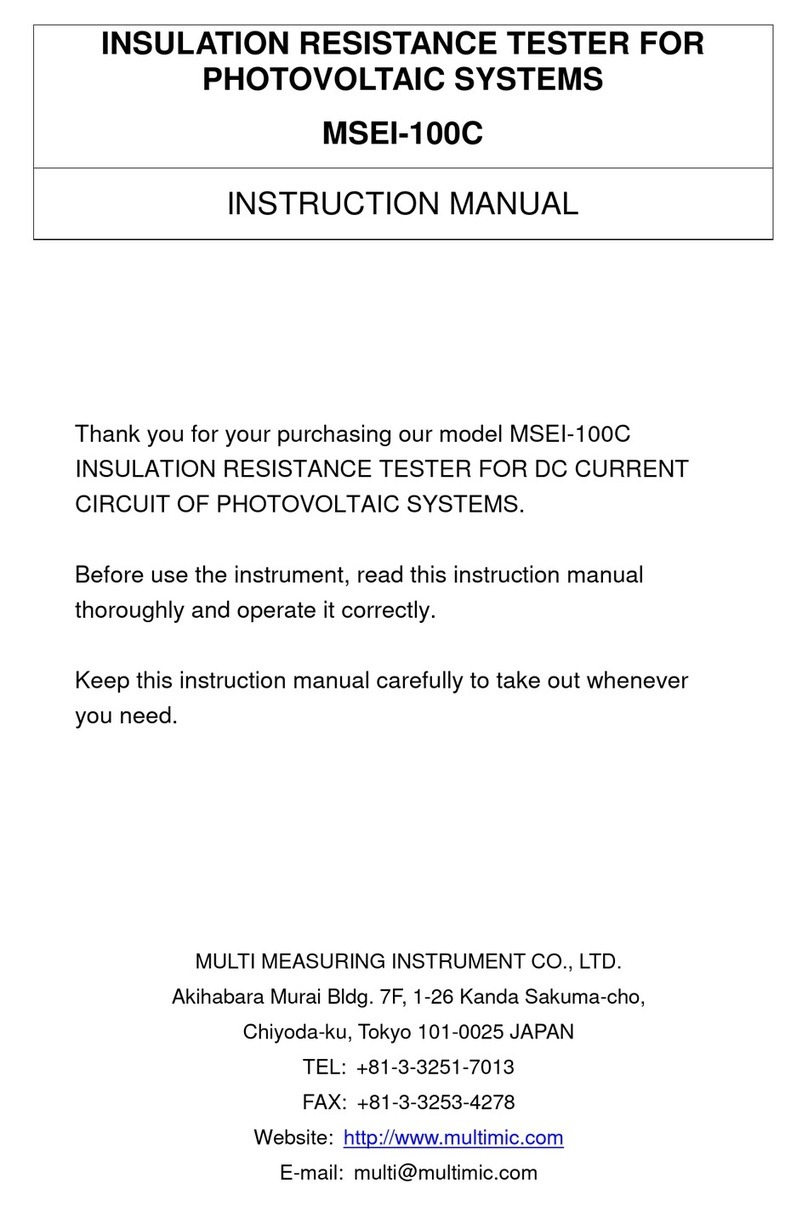

4.2. ASSEMBLY.......................................................................................................................................7

4.3. CONNECTION METHOD...............................................................................................................11

4.4. MAINTENANCE..............................................................................................................................20

5. FRONT PANEL DESCRIPTION .............................................................................................................21

6. PRINCIPLE OF OPERATION..................................................................................................................22

6.1. MEASUREMENT MODE................................................................................................................22

6.2. DETECTION OF THE PEAK VALUES...........................................................................................23

6.3. CONTROL OF THE RELAY OUTPUTS.........................................................................................24

6.3.1. On thr shold mod ..............................................................................................................25

6.3.2. Two thr sholds mod ............................................................................................................26

7. DEVICE PROGRAMMING.......................................................................................................................27

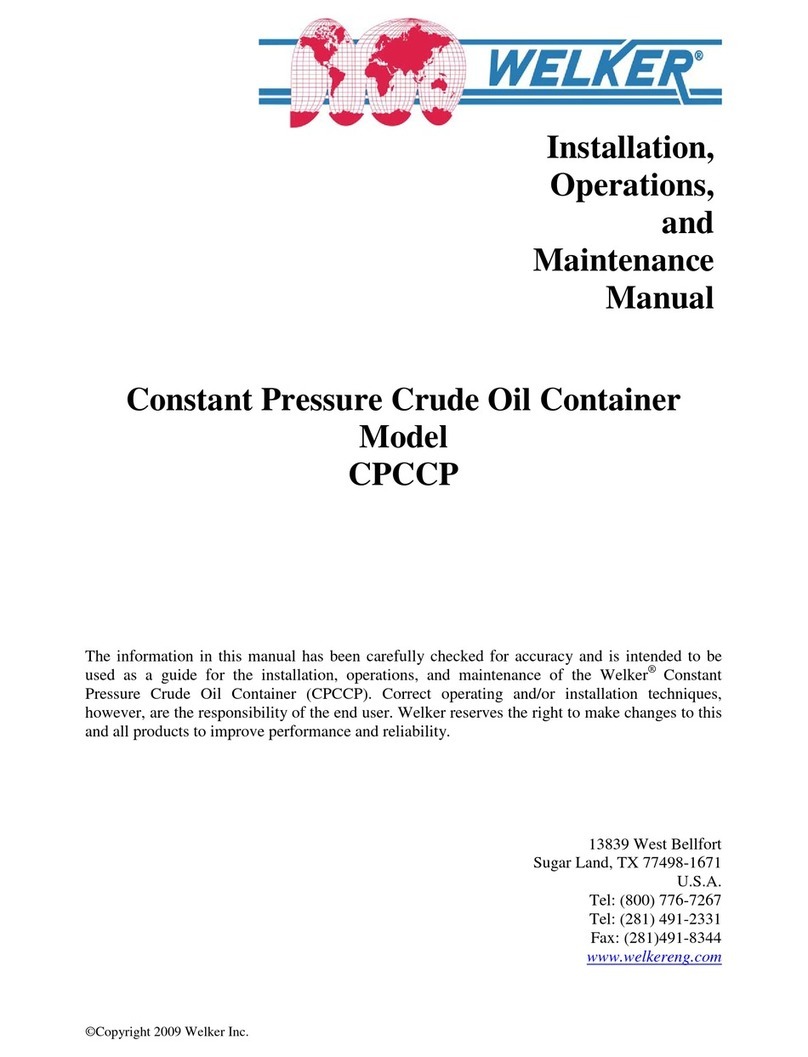

7.1. PROGRAMMING MENU.................................................................................................................27

7.2. PARAMETERS EDITION................................................................................................................28

7.2.1. Num ric param t rs (digit chang mod ).............................................................................28

7.2.2. Num ric param t rs (slid chang mod )............................................................................28

7.2.3. Switch param t rs (“LIST” typ )............................................................................................29

7.3. MENU DESCRIPTION....................................................................................................................29

7.3.1. “rELAy1” m nu.......................................................................................................................29

7.3.2. “bEEPEr” m nu......................................................................................................................32

7.3.3. “CALibr” m nu........................................................................................................................32

7.3.4. ”OutPUt” m nu.......................................................................................................................34

7.3.5. ”button” m nu.........................................................................................................................36

7.3.6. ”Pr inP” param t r.................................................................................................................37

7.3.7. ”HOLd” m nu.........................................................................................................................37

7.3.8. ”briGHt” param t r.................................................................................................................37

7.3.9. ”SECUr” m nu.......................................................................................................................38

7.3.10. ”rS-485” m nu......................................................................................................................38

7.3.11. ”Edit t” param t r.................................................................................................................39

7.3.12. ”dEFS” param t r................................................................................................................39

7.3.13. ”SErv” m nu.........................................................................................................................39

7.4. MENU STRUCTURE.......................................................................................................................40

8. OUTPUT VALUE CALCULATION...........................................................................................................42

. SIGNALISATION OF ERRORS...............................................................................................................42

10. THE MODBUS PROTOCOL HANDLING..............................................................................................43

10.1. LIST OF REGISTERS...................................................................................................................43

10.2. TRANSMISSION ERRORS DESCRIPTION................................................................................48

10.3. EXAMPLES OF QUERY/ANSWER FRAMES.............................................................................48

11. DEFAULT AND USER'S SETTINGS LIST............................................................................................51

2