30119-05 Rev. 4.0/07-09

4

C. CUT OUT the section of pipe within the scribed line

and remove all burrs, slag, and rough edges from the inside

and outside of the cutout section.

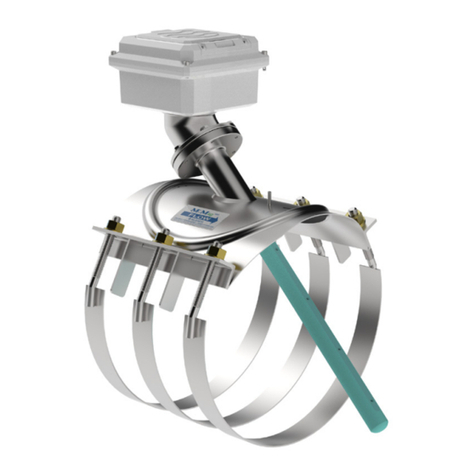

D. STRAIGHTENING VANES are recommended when there

are less than ten pipe diameters of straight pipe (no fittings

or obstructions) directly upstream from the meter location.

Straightening vanes are available from the factory and, when

required, should be installed in the following manner prior to

welding the saddle to the pipe:

a.) HOLD the vanes on the outside of the pipe ten

inches upstream from the center of the cutout opening.

The vanes must be parallel to the center line of the pipe

and should be equally spaced radially 120° apart.

b.) MARK the pipe around the straightening vane

bolts and drill holes for vane mounting (9/16” hole for

4-inch through 12-inch meters or 11/16” dia. hole for

14-inch through 20-inch meters).

c.) INSERT the vanes into the pipe through the

cut-out opening after installing the brass and stain-

less/rubber washers over the vane bolts. The brass

washer should be installed against vane bolt head with

the stainless/rubber washer installed against the brass

washer (rubber side away form vane). Position the

vanes inside the pipe with the bolts protruding through

the vane mounting bolt holes. Place stainless/rubber

washers over each bolt, rubber against the pipe. The

brass washer should be placed between the stainless

washer and the vane mounting nut. Secure nuts to hold

the vanes to the pipe (approx. 60 ft/lbs. torque). The

vanes can be welded to the pipe if desired; however,

the washers should not be used. NOTE: Meter head

assembly (#25) should be removed before welding (see

Section VI Step 1).

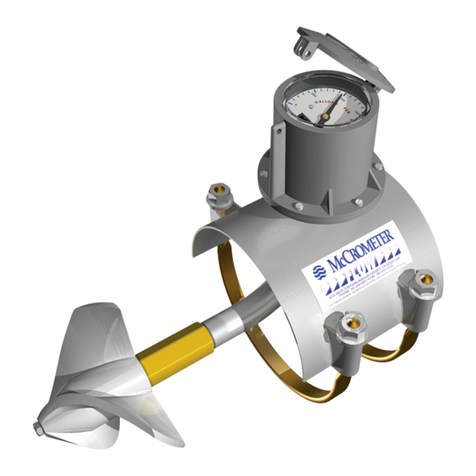

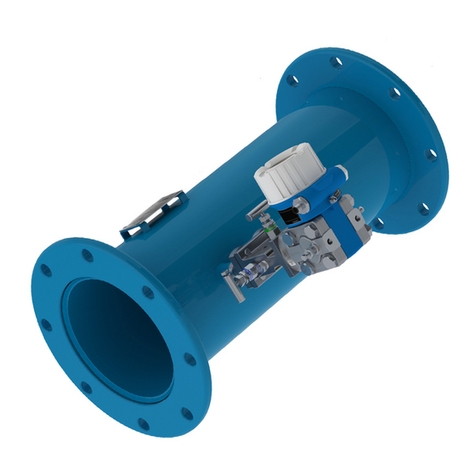

E. WELDING SADDLE should be centered over the cutout

section of the pipe. Make certain that no part of the pipe

protrudes past the inside edge of the welding saddle. Tack

weld the saddle to the pipe prior to welding a continuous

bead around the saddle. NOTE: Meter head assembly (#25)

should be removed before welding (see Section VI Step 1).

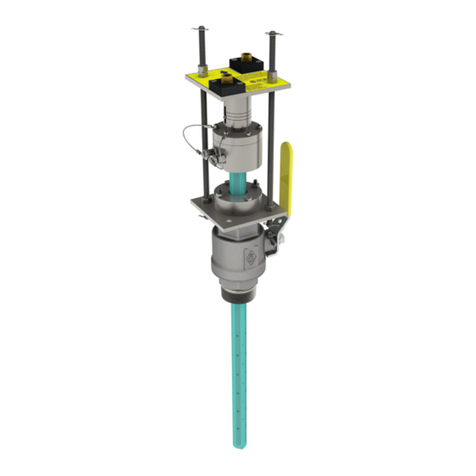

F. METER ASSEMBLY should be placed in the line with

the propeller nose facing the upstream flow in the pipe. Use

care when installing the meter not to damage the propeller

as it passes through the saddle opening. The meter head

O-ring should be covered with a thin coat of silicone grease

before installing the meter. Tighten the meter head bolts

securely.

III. MAINTENANCE. McCrometer products have been carefully

designed to be as maintenance free as possible. Periodic

preventive maintenance, however, is highly recommended

and should be practiced according to schedule to assure

continuous accuracy and trouble-free performance of your

propeller meters. The maintenance and inspection procedure

can also be used as a guide to locating a problem in the

unit that may be the cause of abnormal meter operation.

Routine preventative maintenance should be performed on

all meters, which includes cleaning and an inspection of the

propeller and its bearing. The intervals between inspections

depend on the water quality and the usage of the meter.

The initial inspection should be performed after one to two

years of service to determine the period between future

inspections. After five to ten years, the complete meter

should be inspected to ensure years of dependable service.

IV. WORKING AREA chosen for disassembly and reassembly of

the meter components should be clean to reduce the chance

of dust or dirt particles being introduced into the propeller

area.

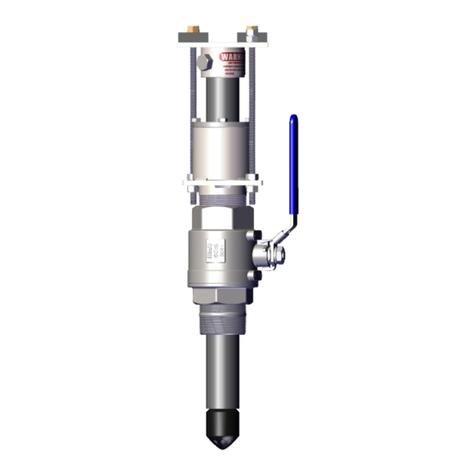

V. DISASSEMBLY AND INSPECTION OF METER includes

cleaning the propeller assembly (#1), ceramic bearing cartridge

(#8), separator/support spindle assembly (#12), and drive

magnet (#9).

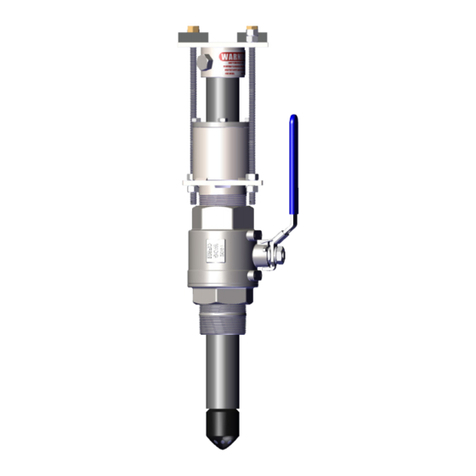

1. METER HEAD REMOVAL*. Meter head assembly (#25)

should be removed from the service line by removing the

meter head bolts (#24) and lifting up the rear (downstream)

portion of the meter head (#25), carefully pulling the assembly

back (downstream) and up at the same time to allow the

propeller (#1) to clear the inside of the meter saddle and

be lifted free. Inspect the meter head O-ring (#22) for any

sign of damage and replace if necessary. Replace the meter

assembly (#25) with a dummy cover plate if the service line

is to remain in operation.

* NOTE: 8-inch meter only:

a) Remove the meter head bolts (#24).

b) Lift the meter assembly and tilt it forward.

c) Slide the assembly back out of the saddle opening.

The propeller may have to be rotated to fit through the

saddle opening.

2. PROPELLER REMOVAL can be accomplished by first

removing the thrust bearing cartridge assembly (#5). Loosen

the set screw (#3) in the side of the nose of the propel-

ler. Remove the thrust bearing cartridge (#5) by turning it

counterclockwise while holding the propeller in place.

3. REVERSE THRUST BEARING CARTRIDGE (#6) must

now be removed. Turn the propeller (#1) so that the Allen

wrench clearance hole is lined up with the set screw (#7)

in the side of the reverse thrust bearing cartridge (#6). The

location of the set screw is marked by a small hole drilled

in the face of the reverse thrust bearing cartridge. With a

5/64” Allen wrench, loosen the set screw (#7) in the reverse

thrust bearing cartridge (#6) one turn, which will allow

the set screw to protrude about 1/32” and should allow

cartridge to be unscrewed without damaging the spindle

thread. NOTE: If the bearing area appears to be clogged

with dirt or sediment, making it difficult to locate the set

screw (#7) or to allow the Allen wrench to fit into the set

screw socket, then the bearing area should be flushed out

with water. Insert tool T-2402X-1 into the propeller through

the threaded nose. The tabs in the tool should engage in

the screwdriver slot in the end of the reverse thrust bear-

ing cartridge (#6). Remove the propeller assembly (#1)