FCI ST100 series Mounting instructions

ST100 Series

Thermal Mass Flow Meter

Conguration Software

Manual

Fluid Components International LLC (FCI). All rights reserved.

ST100 Series Conguration Software

Fluid Components International LLC

Notice of Proprietary Rights

This document contains confidential technical data, including trade secrets and proprietary information which is the property of Fluid Components International LLC (FCI).

Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your company only (and does not include manufacture or

processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

© Copyright 2017 by Fluid Components International LLC. All rights reserved. FCI is a registered trademark of Fluid Components International LLC. Information subject to change without notice.

ST100 Series Conguration Software 06EN003403 Rev. C

Fluid Components International LLC iii

Table of Contents

List of Figures

Introduction.......................................................................................................................................................................................................................1

Installation........................................................................................................................................................................................................................1

Running the PC Configuration Application ......................................................................................................................................................................1

Configuration Software Basics ........................................................................................................................................................................................3

Password Protection......................................................................................................................................................................................................3

Basic Setup Tab Screens ..................................................................................................................................................................................................4

Advanced Setup Tab Screens...........................................................................................................................................................................................7

Configuration Tab Screens................................................................................................................................................................................................9

Diagnostics Tab Screens ................................................................................................................................................................................................13

Factory Tab Screens........................................................................................................................................................................................................15

FE1-FE2 Process Data.....................................................................................................................................................................................................18

Parameter Reports..........................................................................................................................................................................................................19

Customer Service/Technical Support .............................................................................................................................................................................20

Figure 1 – USB & Ethernet Connectors on Customer Interface Board (Digital Interface Shown)...................................................................................1

Figure 2 – Welcome Screen.............................................................................................................................................................................................2

Figure 3 – Example Process Data Screen.........................................................................................................................................................................2

Figure 4 – Basic Application Screen Elements ................................................................................................................................................................3

Figure 5 – Example Groups Tab (Basic Setup)..................................................................................................................................................................4

Figure 6 – Example Units Tab (Basic Setup).....................................................................................................................................................................5

Figure 7 – Example Pipe Size Tab (Basic Setup) ..............................................................................................................................................................5

Figure 8 – Example Alarms Tab (Basic Setup)..................................................................................................................................................................5

Figure 9 – Example SD Card Logging Tab (Basic Setup) ..................................................................................................................................................6

Figure 10 – Example Totalizer Tab (Basic Setup) .............................................................................................................................................................6

Figure 11 – Example Pressure Offset Tab (Basic Setup) ..................................................................................................................................................6

Figure 12 – Example User Parameters Tab (Advanced Setup).........................................................................................................................................7

Figure 13 – Example Ethernet Tab (Advanced Setup) ......................................................................................................................................................8

Figure 14 – Example Data and Time Tab (Advanced Setup) ............................................................................................................................................8

Figure 15 – Example Download Calibration Tab (Advanced Setup).................................................................................................................................8

Figure 16 – Example Reboot Device Tab (Advanced Setup) ............................................................................................................................................9

Figure 17 – Example Output Tab (Configuration)..............................................................................................................................................................9

Figure 18 – Example 4-20mA User Tab (Configuration) .................................................................................................................................................10

Figure 19 – Example Modbus Tab (Configuration) .........................................................................................................................................................11

Figure 20 – Example Extended Op. Mode Tab (Configuration).......................................................................................................................................11

Figure 21 – Example Group Switch Setup Tab (Configuration) ......................................................................................................................................11

Figure 22 – Example AST Power Mode Tab (Configuration) ..........................................................................................................................................12

Figure 23 – Example Status Tab (Diagnostics)...............................................................................................................................................................13

Figure 24 – Example Fault Log Tab and Example Fault Log List (Diagnostics) ..............................................................................................................14

Figure 25 – Example idR Scheduled Tests Tab and Example idR On-Demand Test Results Display (Diagnostics).......................................................14

Figure 26 – Example idR Test Logs Tab and Example idR Test Log List (Diagnostics)...................................................................................................14

Figure 27 – Example Factory Parameters Tab (Factory) .................................................................................................................................................15

Figure 28 – Example Identification Tab (Factory) ...........................................................................................................................................................15

Figure 29 – Example 4-20mA Factory Tab (Factory) .......................................................................................................................................................16

Figure 30 – Example Options Tab (Factory) ....................................................................................................................................................................16

Figure 31 – Example HART Tab (Factory) .......................................................................................................................................................................16

Figure 32 – Example Memory Tab (Factory) ...................................................................................................................................................................17

Figure 33 – Example Reset idRs Tab (Factory) ...............................................................................................................................................................17

Figure 34 – Example Process Data Screen (FE1)............................................................................................................................................................18

Figure 35 – Example Parameter Report, Group 1...........................................................................................................................................................19

Figure 36 – Example Parameter Report, Group 5...........................................................................................................................................................19

06EN003403 Rev. C ST100 Series Conguration Software

iv Fluid Components International LLC

List of Tables

Table 1 – Basic Setup Tabs ..............................................................................................................................................................................................4

Table 2 – Advanced Setup Tabs .......................................................................................................................................................................................7

Table 3 – Configuration Tabs..........................................................................................................................................................................................10

Table 4 – Diagnostics Tabs.............................................................................................................................................................................................13

Table 5 – Factory Tabs....................................................................................................................................................................................................15

ST100 Series Conguration Software

Fluid Components International LLC 1

Introduction

The ST100 Configuration software is a Windows PC application that lets the user easily set up and configure the ST100 Multipoint Flow Meter prod-

ucts. Use this tool for all instrument commissioning activity. Note that the software application serves both ST100 Series and MT100 product lines.

This manual, however, covers operation with ST100 only (software version 3.1.0.x).

Installation

Find the Software Configurator MSI install file in the Software folder on the product documentation CD or downloaded over the web. The file can be

identified by name – ST MT100 Configurator v3100.msi. Copy this file to a location on your PC designated for ST100 documentation.

Run the MSI installer file (make sure you have administrative rights to install) and follow the on-screen instructions to complete the installation. The

installation process places an application shortcut icon of a stylized meter face on the Windows desktop: The installer also creates a folder

in the Start Menu named Fluid Components Intl, which contains another program shortcut.

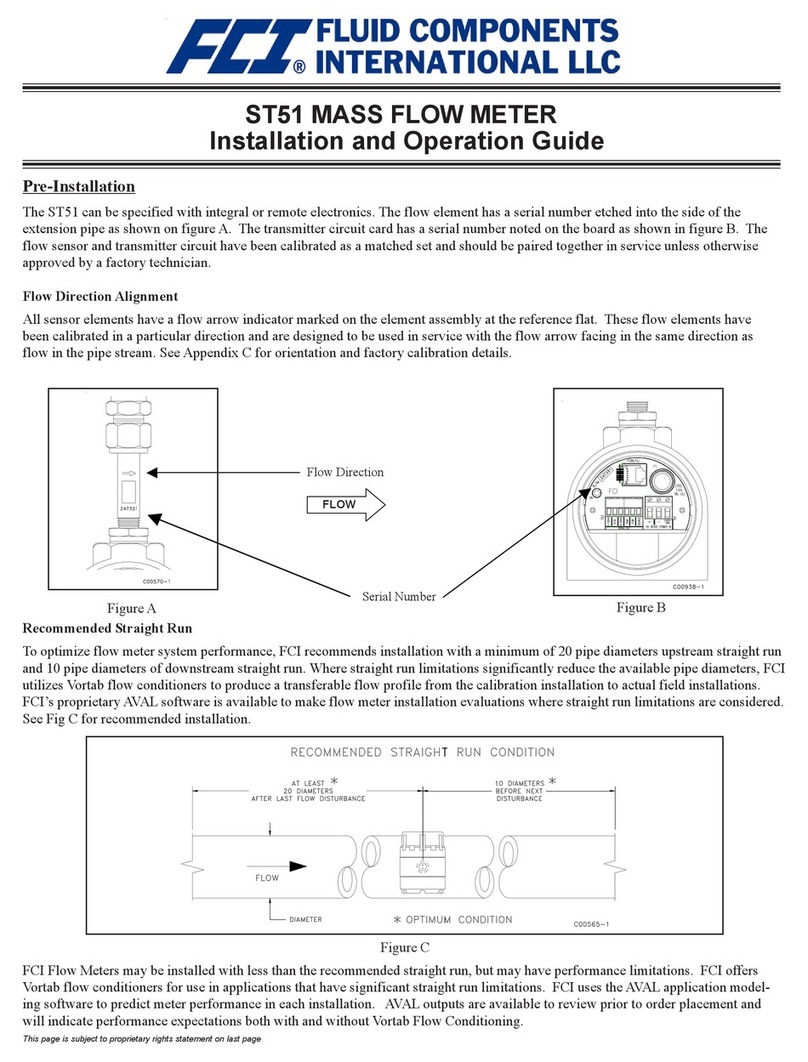

Running the PC Conguration Application

Connect the host PC via USB or Ethernet as required for the application:

• Use Ethernet for remote applications in which the host PC communicates with the instrument over an Ethernet network. Refer to “Advanced

Setup Tab Screens” on page 7 for info on setting Ethernet address values. Connect the instrument to a 100Base-T compatible network

switch or hub using a Cat-5 Ethernet patch cable.

• Use USB for local host PC connection to the instrument. Connect the instrument to the PC USB port using the USB cable provided (Type A to

Type A, male-male; passive, straight-through type).

The ST100 USB and Ethernet connectors are located on the customer interface board as shown in the figure below (remove blind lid for access).

Figure 1 – USB & Ethernet Connectors on Customer Interface Board (Digital Interface Shown)

Note

: To avoid any connection problems make sure the ST100 is fully booted before connecting to the PC USB port and/or launching

the ST100 Configuration software.

Caution

: A host PC connection is intended for temporary use only. Do not make the PC/network connection part of the permanent installation.

Double click the ST100 Configurator icon. The application opens to the Welcome screen as shown in the figure below. Click the appropriate connect but-

ton, USB Connect or Ethernet Connect, at the top of the screen to let the PC communicate with the instrument (with cable connection already made).

ST100 Body

(Blind Lid

Removed)

Customer

Interface

Board

USB Connector

C01264-1-2

Ethernet Connector

ST100 Series Conguration Software

2 Fluid Components International LLC

Figure 2 – Welcome Screen

Once connected, the application window shows the Process Data screen as shown in the figure below. The displayed information, which is the same

as that shown on the HMI front panel display, includes the following:

• Flow as percent of range (scale)

• Flow with engineering units

• Total Flow (if Mass or Volumetric units used)

• Temperature

• Pressure (for STP Series only)

• Calibration Group number and Group name

• Alarm/Fault indicators

Figure 3 – Example Process Data Screen

C01381-1-2

USB Connect

Button

Ethernet Connect

Button

Percent of Range

Configuration Menu

Flow

Temperature

Pressure

Group Number/Name

Alarm/Fault Indicators

C01261-2-1

ST100 Series Conguration Software

Fluid Components International LLC 3

Password Protection

To protect against unwanted/unauthorized change, two levels of password protection are provided: User and Factory. The User level pass-

word is associated with common user-accessed parameters that can only be changed after entering the User password. The Factory level

password is associated with more sensitive programming that can only be modified by the factory or its representatives. The dialog box for

password entry is shown below. When prompted, type the password and then click OK. The User password is: 2772. The password is also

shown in this manual with the tab summary tables.

Conguration Software Basics

The ST100 is set up using a configuration menu arranged in a hierarchical tree structure on the left side of the window. Select a menu item to see the

related tabs on the right side of the window. Within the tab area parameter data is typically organized into one or more data fields, which are set off

with a thin divider line or a thin box outline.

Many screens show Get from Device and/or Send to Device buttons at the bottom portion of the window. These buttons are shown if the window

tab includes parameter data that can be retrieved from the instrument for display (Get from Device) and/or transmitted to the instrument for

programming (Send to Device). The Send to Device button is normally grayed out (inactive) initially until a change is made in a data field. Once a

parameter change is detected, the Send to Device button becomes active as shown by its solid appearance.

Figure 4 – Basic Application Screen Elements

Note

: Once the PC’s configuration software is communicating with the instrument, some HMI display items/menus are inactive due

to control being handed over to the configuration application. For example, front panel selection of groups in the Service menu

(HMI Setup mode) is inactive. Inactive HMI display menu items are shown with an asterisk (for example, Select Group*).

Click Disconnect to break the connection between the PC and ST100. Click the application window Close button or type ALT+F4 (with the applica-

tion window having the focus) to quit the application altogether.

C01401-1-1

Tabs

Menu

(Basic Setup

Branch)

Data Field

(Units)

Disconnect

Button

Application

Close Button

Get from Device

Button

Send to Device

Button (Grayed)

ST100 Series Conguration Software

4 Fluid Components International LLC

Basic Setup Tab Screens

Select the Basic Setup branch on the menu tree to access basic setup items. The Groups tab is the first of several tabs across the top of the

screen. Each tab provides a particular menu within the Basic Setup branch.

Figure 5 – Example Groups Tab (Basic Setup)

The table below summarizes the tabs within the Basic Setup branch.

Table 1 – Basic Setup Tabs

Tab Name Tab Description Password Level

Groups

Select and name groups. Switching between established groups

takes place immediately once the radio button is clicked (no pass-

word required).

User

Units Select flow and temperature units. User

Pipe Size Select pipe type and dimensions. User

Alarms Select and set alarm requirements. User

SD Card Logging Select logging requirements. User

Totalizer Select and reset Totalizer requirements. User

Pressure Offset

Lets users enter a compensating pressure offset value so that the

instrument’s pressure reading matches the reading from an external

trusted reference.

User

[User password 2772]

To verify the current configuration of any setup parameter, click Get from Device on any of the Setup menus. After changing any of the setup

parameters, click Send to Device. Click Get from Device again to verify the parameter(s) change. Observe that the changed parameters are now

displayed. The remaining Basic Setup tab screens are shown below.

ST100 Series Conguration Software

Fluid Components International LLC 5

Figure 6 – Example Units Tab (Basic Setup)

Figure 7 – Example Pipe Size Tab (Basic Setup)

Figure 8 – Example Alarms Tab (Basic Setup)

ST100 Series Conguration Software

6 Fluid Components International LLC

Figure 9 – Example SD Card Logging Tab (Basic Setup)

Figure 10 – Example Totalizer Tab (Basic Setup)

Figure 11 – Example Pressure Offset Tab (Basic Setup)

ST100 Series Conguration Software

Fluid Components International LLC 7

Advanced Setup Tab Screens

Select the Advanced Setup branch on the menu tree to access advanced setup items. The User Parameters tab is the first of several tabs across

the top of the screen. Each tab provides a particular menu within the Advanced Setup branch.

The table below summarizes the tabs within the Advanced Setup branch.

Table 2 – Advanced Setup Tabs

Tab Name Tab Description Password Level

User Parameters Shows min/max process variable limits, K Factor, and Flow Damping1

(ncrease in value = increase in flow damping). User

Ethernet Sets Ethernet address values (unit IP address, gateway address, and

subnet mask). User

Date and Time Set Clock date and time. Lets users copy the system (host PC) time

and transmit it to the instrument’s battery-backed real time clock. User

Download Calibration

Lets users download a full calibration to their ST100 via a text file.

Contact FCI to obtain the .txt file that was generated by the factory

linearization software (Cal2).

User

Reboot Device Lets users perform a warm boot of the ST100. User

Note 1. Flow damping smooths out flow signal output. Flow response is reduced with high flow damping values.

[User password 2772]

To verify the current configuration of any setup parameter, click Get from Device on any of the Setup menus. After changing any of the setup

parameters, click Send to Device. Click Get from Device again to verify the parameter(s) change. Observe that the changed parameters are now

displayed. The remaining Advanced Setup tab screens are shown below.

Figure 12 – Example User Parameters Tab (Advanced Setup)

ST100 Series Conguration Software

8 Fluid Components International LLC

Figure 13 – Example Ethernet Tab (Advanced Setup)

Figure 14 – Example Data and Time Tab (Advanced Setup)

Figure 15 – Example Download Calibration Tab (Advanced Setup)

ST100 Series Conguration Software

Fluid Components International LLC 9

Figure 16 – Example Reboot Device Tab (Advanced Setup)

Conguration Tab Screens

Select the Configuration branch on the menu tree to access configuration setup items. The Output tab is the first of several tabs across the top of

the screen. Each tab provides a particular menu within the Configuration branch. For ST100 units with AST only (shown with AST label in menu

tree): The AST Power Mode tab is added to the configuration setup screens.

Figure 17 – Example Output Tab (Configuration)

ST100 Series Conguration Software

10 Fluid Components International LLC

Figure 18 – Example 4-20mA User Tab (Configuration)

The table below summarizes the tabs within the Configuration branch.

Table 3 – Configuration Tabs

Tab Name Tab Description Password Level

Output

Analog Output board: Sets 4-20 mA channel configuration1and Frequency

and Pulse output configuration.

Digital Output board: Selects Modbus or FF/Profibus)2.

User

4-20mA User Manual mA Output loop check; configure/enable NAMUR fault. User

Modbus Sets Modbus communication parameters. User

Extended Op. Mode

Expands flow measurement capabilities by providing 3 additional modes

of operation. Refer to Extended Operation Modes in main manual

06EN003400 for detailed information.

User

Group Switch Setup

Sets up automatic calibration group switching depending on an external

4-20 mA output driving the ST100 auxiliary input port. Refer to External

Control Group Switching (EGS) in main manual 06EN003400 for detailed

information.

User

AST Power Mode

For ST100 units with AST only: Sets heater mode (Constant Delta T

[AST] or Constant Power) and max. heater current for AST (90 mA or 105

mA). The max. current value forms the threshold at which the instrument

switches over to Constant Power mode.

User

Note 1. To set HART operation, select HART Flow from 4-20 mA #1 drop-down list (in Analog Output Selection field).

Note 2. Digital busses (includes HART, Modbus, and FF/Profibus) are mutually exclusive, meaning only one can be active at

a time. Attempting to enable HART when Modbus or FF/Profibus is in effect causes the Digital Bus Deactivation Warning

dialog to display: Click OK to make the change and force the Digital Output Selection to None or click Cancel to leave the

setting unchanged. Attempting to enable Modbus or FF/Profibus when HART is in effect causes the HART Deactivation

Warning dialog to display: Click OK to make the change and force the 4-20 mA #1 Selection to Flow or click Cancel to leave

the setting unchanged.

[User password 2772]

To verify the current configuration of any setup parameter, click Get from Device on any of the Setup menus. After changing any of the setup

parameters, click Send to Device. Click Get from Device again to verify the parameter(s) change. Observe that the changed parameters are now

displayed. The remaining Configuration tab screens are shown below.

ST100 Series Conguration Software

Fluid Components International LLC 11

Figure 19 – Example Modbus Tab (Configuration)

Figure 20 – Example Extended Op. Mode Tab (Configuration)

Figure 21 – Example Group Switch Setup Tab (Configuration)

ST100 Series Conguration Software

12 Fluid Components International LLC

Figure 22 – Example AST Power Mode Tab (Configuration)

ST100 Series Conguration Software

Fluid Components International LLC 13

Diagnostics Tab Screens

Select the Diagnostics branch on the menu tree to access diagnostic items. The Status tab is the first of several tabs across the top of the screen.

Each tab provides a particular menu within the Diagnostics branch. The table below summarizes the tabs within the Diagnostics branch.

Table 4 – Diagnostics Tabs

Tab Name Tab Description Password Level

Status Indicates system status and fault flags. Read only

Fault Log Shows fault history. Click Get Fault Logs from Device to list the faults in the

scrollable text box. Click Clear Fault Log to clear the log. User

idR Scheduled Tests1

For internal Delta R (idR) resistance check – Select FE (FE1 or, for dual-point

models, FE2), set pass/fail criteria, set FE output mode during test, schedule

periodic idR test, display previous idR test results, and start idR test on-

demand. Test results display in FEx idR Test Results field (table format) when

finished.

User

idR Test Logs Click Get Test Log from Device to show idR test results in the scrollable text

box. Click Clear Test Logs to clear the log. User

[User password 2772]

The remaining Diagnostics tab screens are shown below.

Figure 23 – Example Status Tab (Diagnostics)

ST100 Series Conguration Software

14 Fluid Components International LLC

Figure 24 – Example Fault Log Tab and Example Fault Log List (Diagnostics)

Figure 25 – Example idR Scheduled Tests Tab and Example idR On-Demand Test Results Display (Diagnostics)

Figure 26 – Example idR Test Logs Tab and Example idR Test Log List (Diagnostics)

ST100 Series Conguration Software

Fluid Components International LLC 15

Factory Tab Screens

The Factory branch on the menu tree provides factory-only setup items. Only the factory or its respresentatives can change data in this group.

Table 5 – Factory Tabs

Tab Name Tab Description Password Level

Factory Parameters Factory use only. (Calibrated Min/Max data.) Factory

Identification Factory use only. (Instrument ID data and unit MAC address.) Factory

4-20mA Factory Factory use only. (4-20 mA output DAC count scaling and manual output con-

trol, plus 4-20 mA input raw A/D counts and gain & offset adjustment.) Factory

Options Factory use only. (Option inventory: HMI display, FEs [2 max. for ST100]), and

pressure sensor type. Factory

HART Factory use only. (HART ID info: electronics revision, HART ID, int. HART rev.) Factory

Memory Factory use only. (Erase various memory spaces.) Factory

Reset idRs Factory use only. (Run idR check for selected FE, and then set Measured Ohms val-

ues as new baseline for Expected Ohms values [click Reset Expected idR Values]). Factory

Figure 27 – Example Factory Parameters Tab (Factory)

Figure 28 – Example Identification Tab (Factory)

ST100 Series Conguration Software

16 Fluid Components International LLC

Figure 29 – Example 4-20mA Factory Tab (Factory)

Figure 30 – Example Options Tab (Factory)

Figure 31 – Example HART Tab (Factory)

Other manuals for ST100 series

4

Table of contents

Other FCI Measuring Instrument manuals

FCI

FCI ST100 series User manual

FCI

FCI ST100 series User manual

FCI

FCI ST50 Operating instructions

FCI

FCI DM10-FM User manual

FCI

FCI ST51 Operating instructions

FCI

FCI ST51-1 Operating instructions

FCI

FCI ST100A Series User manual

FCI

FCI MT100 User manual

FCI

FCI ST50 User manual

FCI

FCI ST100 series Mounting instructions

Popular Measuring Instrument manuals by other brands

Hanna Instruments

Hanna Instruments HI84531 instruction manual

Keysight

Keysight N9068A Demo guide

PCB Piezotronics

PCB Piezotronics IMI SENSORS 626B02 Installation and operating manual

Isspro

Isspro EV Installation instructions manual

Polymer Technology Systems

Polymer Technology Systems CardioChek user guide

Geo

Geo Multi-Digit Pro + operating instructions