Addressable Manual Stations

2099-9135, -9761, -9795, -9796, & -9797

Installation Instructions

2000 Simplex Time Recorder Co., Westminster, MA 01441-0001 USA

All specifications and other information shown were current as of publication, and are subject to change without notice.

574-155

Rev. A

These instructions describe installing and setting the address for a manual

station (single action, double action, or local). Installing a manual station

consists of the following tasks:

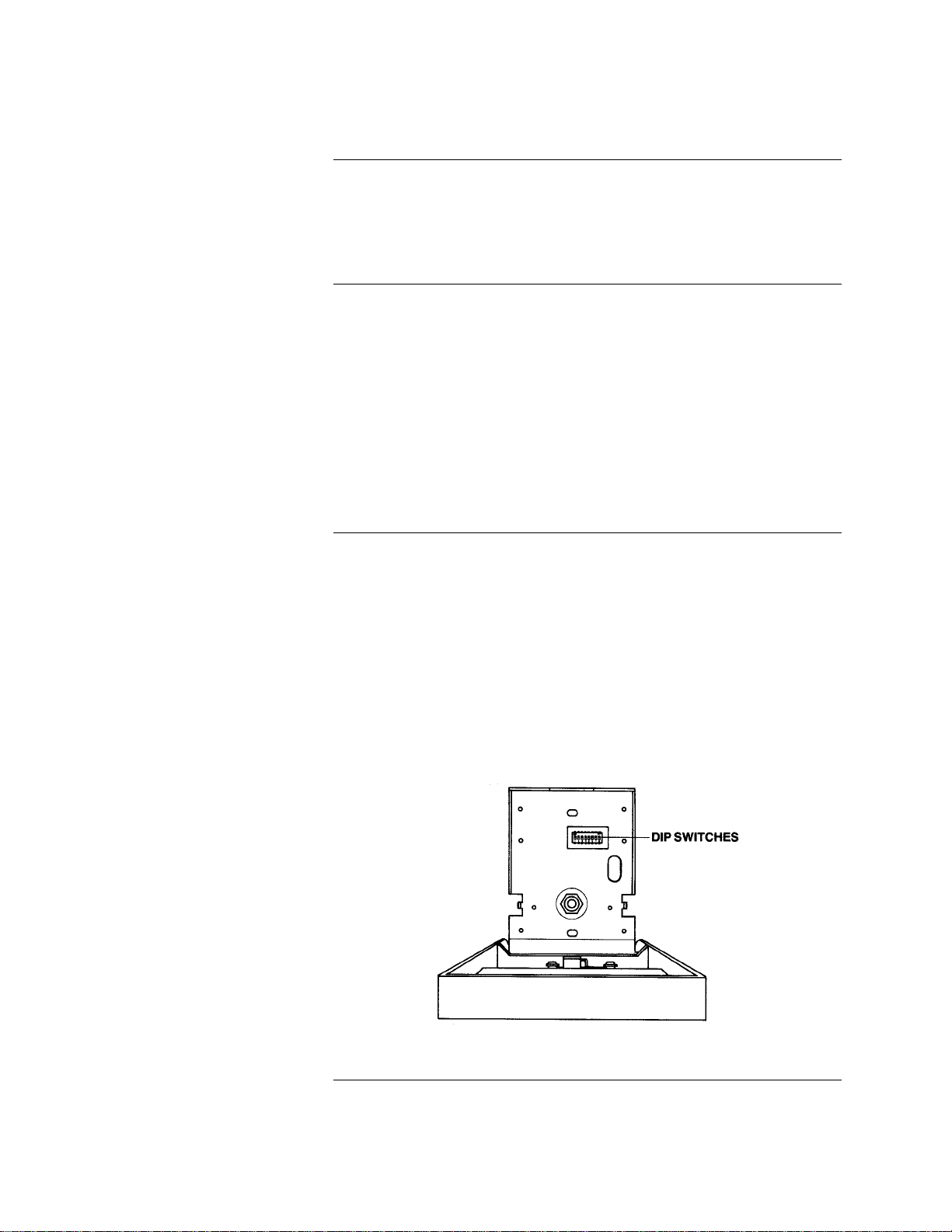

• Setting the Address. The address, which uniquely identifies the manual

station on the MAPNET IIchannel, must be set in two places the dip

switch on the rear of the manual station and through the programmer. The

address must match in both places.

• Wiring. Addressable manual stations connect to either a 2120 Multiplex

Communicating Device Transponder (CDT), 4020, 4100+, or 4120 system

by a twisted, shielded (recommended) wire pair (MAPNET), and receive

both power and data over this wire pair.

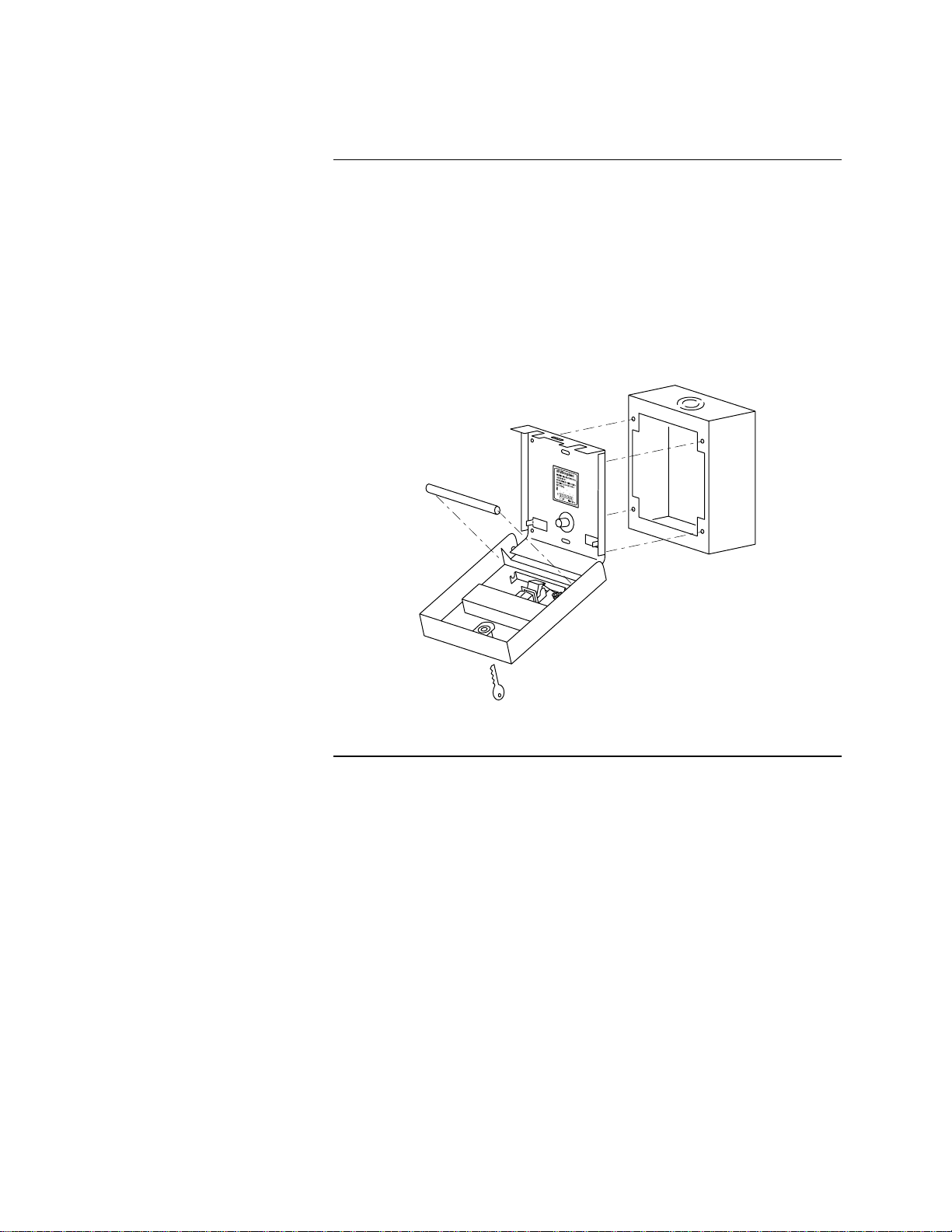

• Installing. Manual stations mount to a variety of standard switch and back

boxes.

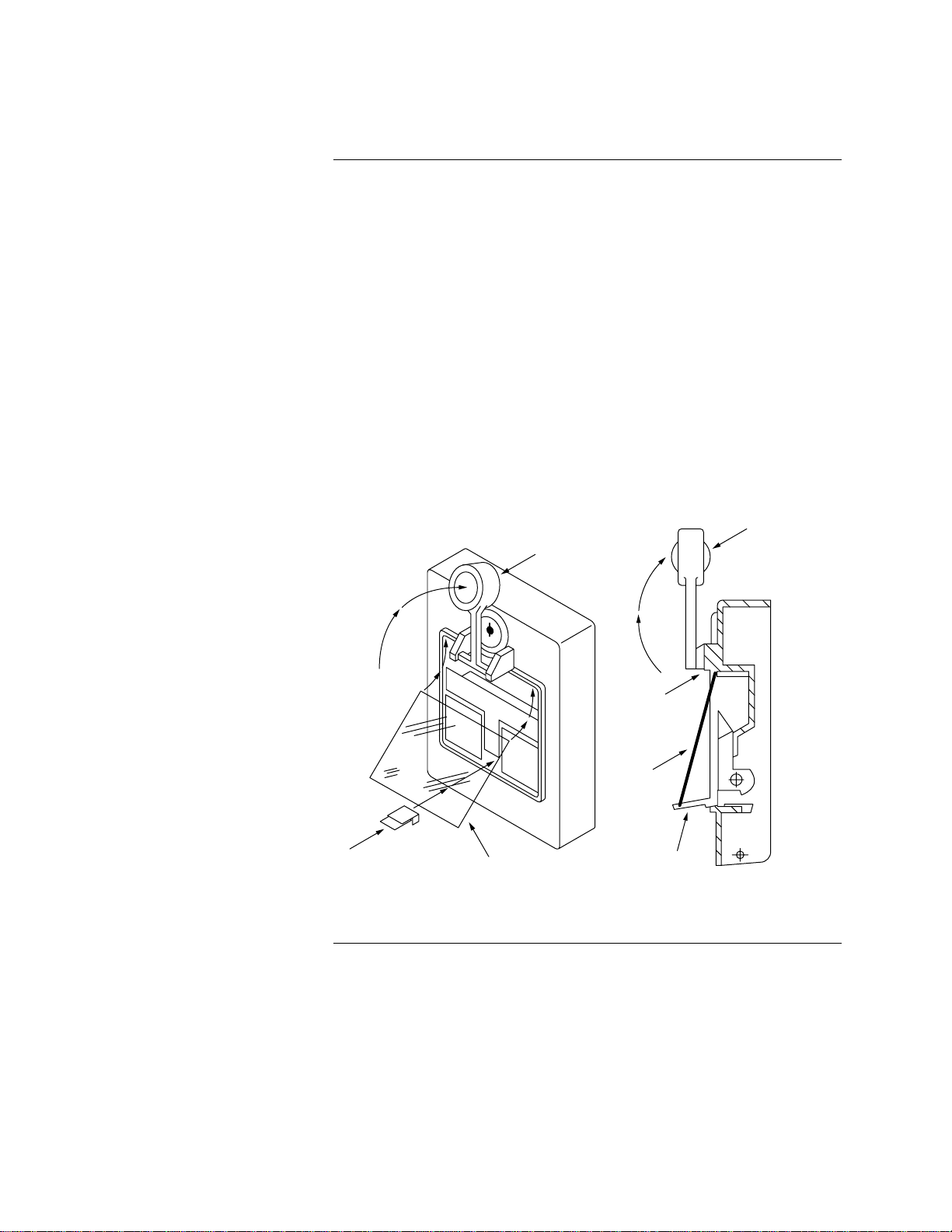

• Maintaining. Depending on the model of manual station, you may also

need to replace a small pane of glass or a glass rod following activation.

Table 1 summarizes the features of each manual station model.

PID Single

Action

Glass

Double

Action

Push

Double

Action

MAPNET

I MAPNET

IILocal

Cover

No

Simplex

Logo

2099-9135 X X X

2099-9761 X X

2099-9795 X X

2099-9796 X X

2099-9797 X X X

This publication discusses the following topics:

Topic See Page #

Setting the Manual Station’s Address 2

Wiring 4

Installing the Manual Station 5

Replacing Glass Pane/Glass Rod 6

Overview

Features

In this Publication

Technical Manuals Online! - http://www.tech-man.com