Sinexcel Energy Freedom S90 User manual

S90 Outdoor Cabinet

Manual

Sinexcel Co.

S90 Energy Storage Outdoor All-in-One Cabinet User's Manual

Version: 1.0

Shenzhen Sinexcel Electric Co.

All rights reserved. Contents are subject to change without notice.

Shenzhen Sinexcel Electric Co.

Company website: www.sinexcel.com

Address:Block 6, Block 2, Baiwangxin Hi-Tech Industrial Park, No.1002 Songbai Road,

Nanshan District, Shenzhen, China

Contact:0755-8651-1588

1

CONTENT

1 OVERVIEW............................................................................................................................................... 4

1.1APPLICABLE MODELS ..................................................................................................................................4

1.2 TARGET GROUP...........................................................................................................................................4

1.3 TERMINOLOGY.............................................................................................................................................4

2 SAFETY INSTRUCTIONS....................................................................................................................... 5

2.1 SYMBOLS.....................................................................................................................................................5

2.2 IMPORTANT SAFETY INSTRUCTIONS ...........................................................................................................5

2.3ADDITIONAL INFORMATION..........................................................................................................................6

3 PRODUCTS.............................................................................................................................................. 7

3.1 SYSTEM INTRODUCTION..............................................................................................................................7

3.2APPEARANCE OF THE INTEGRATED ENERGY STORAGE CABINET..............................................................7

3.3 DIMENSION AND WEIGHT............................................................................................................................7

3.4 SYSTEM SCHEMATIC DIAGRAM...................................................................................................................8

3.5 HEAT DISSIPATION DESIGN.........................................................................................................................8

4 TECHNICAL SPECIFICATIONS............................................................................................................. 9

5 STORAGE, HANDLING AND TRANSPORT....................................................................................... 11

5.1 TRANSPORTAND STORAGE .......................................................................................................................11

5.2 TRANSPORT...............................................................................................................................................13

5.3 UNPACKING INSPECTION...........................................................................................................................14

5.3.1 Unpacking........................................................................................................................................14

5.3.2 Inspection.........................................................................................................................................15

6 EQUIPMENT INSTALLATION............................................................................................................... 16

6.1 INSTALLATION REQUIREMENTS..................................................................................................................16

6.1.1 Basic requirements.........................................................................................................................16

6.1.2 Outdoor requirements ....................................................................................................................16

6.1.3 Foundation support requirements ................................................................................................16

6.1.4 Space requirements .......................................................................................................................17

6.1.5 Ventilation requirements................................................................................................................18

6.2 SITE INSTALLATION....................................................................................................................................19

6.2.1 Wire channel design.......................................................................................................................19

6.2.2 Fixation of Energy Storage Integrated Cabinet ..........................................................................19

6.3 ELECTRICAL CONNECTION ........................................................................................................................20

6.3.1 General safety rules .......................................................................................................................20

6.3.2 Installation tools ..............................................................................................................................21

6.3.3 Wiring parts......................................................................................................................................21

6.3.4 Preparation before wiring...............................................................................................................22

2

6.3.5 Cable requirements ........................................................................................................................22

6.3.6 Wiring precautions..........................................................................................................................23

6.3.7 Wiring area overview......................................................................................................................24

6.3.8 DC Side Wiring................................................................................................................................28

6.3.9 AC Measurement Wiring................................................................................................................28

6.3.10 Ground Connection......................................................................................................................29

6.3.11 Communication Interface.............................................................................................................30

6.3.12 Installation Checklist.....................................................................................................................31

7 PRODUCT OPERATION ....................................................................................................................... 32

7.1 CHECK BEFORE OPERATION......................................................................................................................32

7.1.1 Check cable connections...............................................................................................................32

7.1.2 Check the Energy Storage Converter..........................................................................................32

7.1.3 Check the Battery/Grid Side Voltage ...........................................................................................33

7.2 OPERATION OF THE EQUIPMENT ...............................................................................................................34

7.2.1 Power-up operation ........................................................................................................................34

8 S90-GATEWAY CONFIGURATION INSTRUCTIONS......................................................................... 35

8.1 PRE-CONFIGURATION PREPARATION........................................................................................................35

8.2 EMS SYSTEM INTRODUCTION..................................................................................................................37

8.2.1 Dashboard .......................................................................................................................................39

8.2.2 PCS...................................................................................................................................................40

8.2.3 EMS..................................................................................................................................................40

8.2.4 History...............................................................................................................................................41

8.2.5 Tools..................................................................................................................................................41

9 S90 OUTDOOR CABINET FFS............................................................................................................ 43

10 TROUBLESHOOTING......................................................................................................................... 44

10.1 PRE-EXAMINATION ..................................................................................................................................45

10.2 LED INDICATORS AND TROUBLESHOOTING METHODS............................................................................45

10.3 COMMON FAULTS AND HANDLING METHODS...........................................................................................46

10.3.1 Energy storage converter-related faults....................................................................................46

10.3.2 Air conditioning system related faults....................................................................................... 61

10.4 OTHER FAULTS........................................................................................................................................65

11 MAINTENANCE ................................................................................................................................... 65

11.1 SECURITIES &CAUTIONS........................................................................................................................66

11.2 MAINTENANCE WORK AND CYCLE ...........................................................................................................67

11.3 COMPONENT INSPECTION.......................................................................................................................68

11.3.1 Replacing the dust jacket.............................................................................................................68

11.3.2 Check and maintain the fire extinguishing system...................................................................68

11.3.3 Check vents...................................................................................................................................69

3

11.3.4 Maintaining the Fire Hose............................................................................................................70

11.4AIR CONDITIONER MAINTENANCE...........................................................................................................70

11.4.1 Maintenance of the air conditioner module structure...............................................................70

11.4.2 Check Normal operation............................................................................................................. 71

11.5 COMMON FAULTS AND TROUBLESHOOTING MEASURES.........................................................................72

12 APPENDIX ............................................................................................................................................ 74

12.1 QUALITYASSURANCE...............................................................................................................................74

13 CONTACT............................................................................................................................................. 74

4

1 Overview

1.1 Applicable models

This document applies to the following equipment models:

S90 Outdoor Cabinet BESS

This section describes the product model definitions in this instruction manual,

As shown in Figure 1-1.

1.1 Product Model Definition

1.2 Target group

The content described in this document should only be operated by professionals.

Professionals must have the following skills.

Understand how the product works and how to operate it

Understand how batteries work and how to operate them

Trained and understand how to deal with hazards and risks that arise during the installation

and use of electrical equipment

Understand the installation and commissioning of electrical equipment and devices

Understand all applicable standard operating instructions

Understand and comply with this manual and all safety information

1.3 Terminology

Name

Definition

STS

Static Transfer Switch

AC

AC

DC

DC

BESS

Battery Energy Storage System

ESS

Energy Storage System

EMS

Energy Management System

BMS

Battery Management System

PCS

Bidirectional Energy Storage Converter

SLD

Single Line Diagram

SOH

Battery health status, expressed as a percentage

SCR

Thyristor rectifier

DOD

Depth of discharge, expressed as a percentage

EOD

Discharge cutoff

SOC

Remaining power, expressed as a percentage

UI

User Interface

EPO

Emergency Power Off

SPD

Surge Protector

5

2 Safety instructions

2.1 Symbols

Logo

Explanatory notes

Indicates a dangerous situation that, if not avoided, will result in

death or serious injury.

Indicates a dangerous situation that, if not avoided, will result in

death or serious injury.

Indicates a hazardous situation that, if not avoided, could result in

minor or moderate injury.

Indicates that property damage will occur if not avoided.

Attention to important information, best practices and

recommendations.

Attention is drawn to information used to resolve issues unrelated

to personal injury, equipment damage and environmental

degradation.

2.2 Important Safety Instructions

This user manual is about the installation and operation of the SES-90K outdoor cabinet

from Sinexcel.

Please read this user's manual carefully before installation.

The S90 outdoor cabinet must be commissioned and maintained by an engineer designated

by the manufacturer or an authorized service partner. Failure to do so may endanger

personal safety and result in equipment failure. Damage to the equipment caused as a result

is not covered by the warranty.

The S90 Outdoor Cabinet should not be used in any environment or application related to life

support equipment.

This manual contains important instructions for the SES-90K series models and should be

followed when installing and maintaining the Energy Storage Outdoor Cabinet.

Any touching of the copper strip, contacts, or terminals connected to the grid circuit inside the unit may

result in a fatal burn or electric shock!

Do not touch any terminals and wires connected to the grid circuit.

Pay attention to any instructions and safety documents regarding grid connection.

6

There may be a risk of electric shock inside the equipment!

Any operation related to this equipment must be carried out by qualified personnel.

Please note the safety precautions listed in the safety instructions and installation documentation.

Please note the safety precautions listed in the operating and installation manuals and other

documentation.

Large amount of leakage current

Before connecting input power, make sure grounding is reliable.

The equipment must be grounded in accordance with local electrical codes.

When the battery is connected to the energy storage outdoor cabinet, DC voltage may be present at

the input port. Be aware or check the battery system user manual during operation.

Do not touch energized parts within 15 minutes of power failure!

Dangerous energy is stored in the internal capacitors, so do not touch the terminals, contacts, copper

strips, etc. of the equipment for 15 minutes after disconnecting all power sources.

All internal maintenance and servicing of the equipment should be performed by trained personnel.

Internal components that require tools to open cannot be maintained by the user.

Please read this user manual before operation.

2.3 Additional Information

For additional details, please click: www.sinexcel.com.

7

3 Products

3.1 System Introduction

S90 energy storage cabinet is an all-in-one outdoor cabinet system containing bi-directional

energy storage inverter module, DCDC PV optimizer module, STS intelligent switching

module, battery system, transformer, fire protection system, air conditioning system,

auxiliary source power supply and other energy storage batteries.

The two-way energy storage converter can charge and discharge the built-in battery system,

the DCDC PV optimizer module can access the PV system to store PV power to the battery

or power the load through the energy storage converter, and the STS intelligent switching

module can realize fast and intelligent automatic switching to and from the grid.

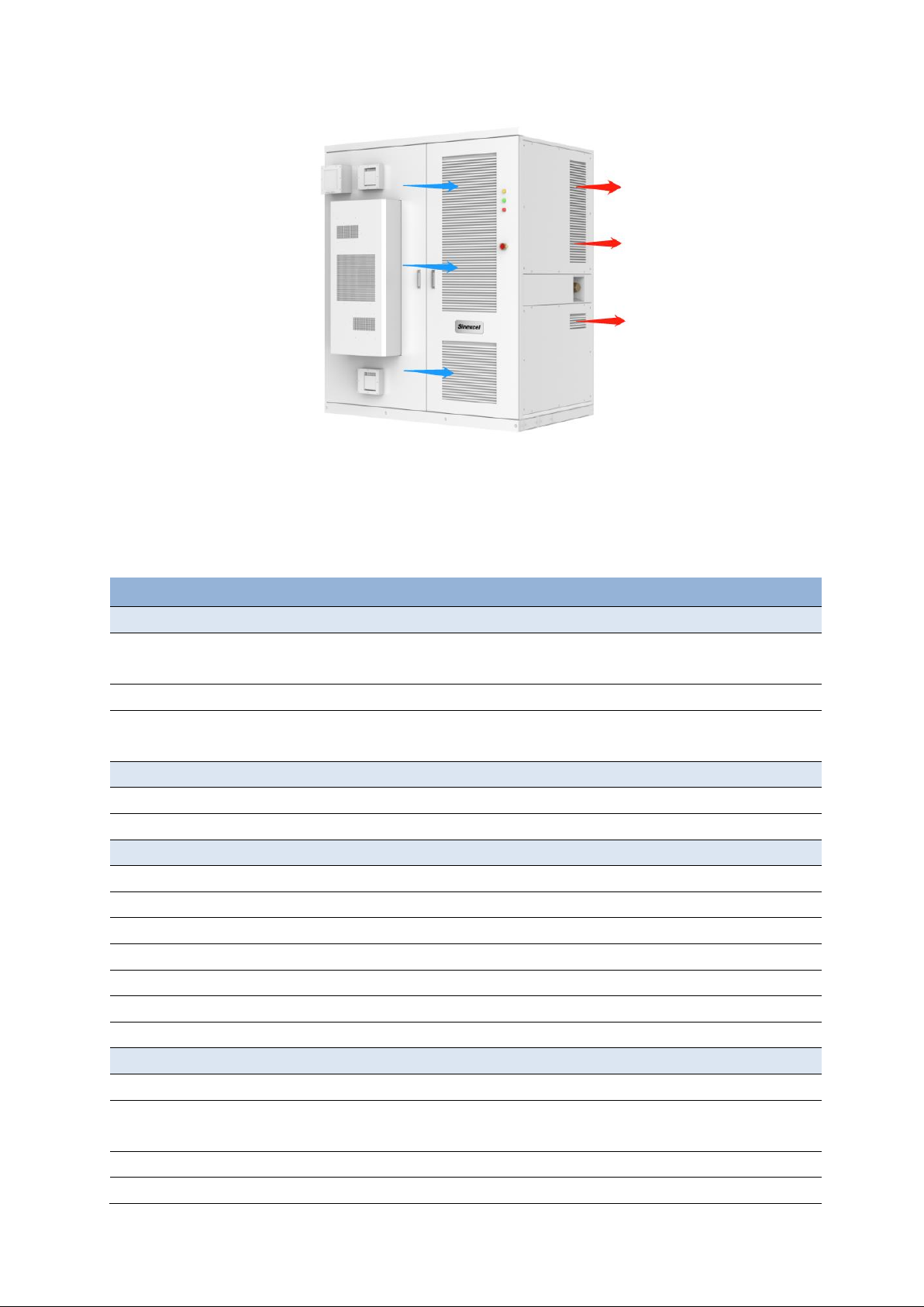

3.2 Appearance of the Integrated Energy Storage Cabinet

Figure 3.1 Appearance of the energy storage all-in-one cabinet

Location

Name

Description

A

Power indicator

Control circuit power supply indicator.

B

Run indicator

Always on when the outdoor cabinet is in

normal operation.

C

Fault Indicator

Always on when there is a fault, flashing

when there is an alarm.

D

Emergency stop knob

Press in case of emergency to disconnect

AC and DC power immediately.

3.3 Dimension and Weight

The dimensions of SES-90K energy storage outdoor cabinet are marked as shown in Figure 3.2.

The net weight of the product is about 1800kg, and the specific weight is subject to the actual

nominal weight.

8

Figure 3.2 External dimensions of the energy storage integrated cabinet

3.4 System Schematic Diagram

S90 energy storage outdoor cabinet contains PCS, DC/DC module,ATS, battery

pack, SPD protector, GATEWAY and auxiliary power distribution unit, etc. Up to 3 groups

of DC/AC module, 3 groups of DC/DC module and 1 ATS are optional. The PCS AC

measurement can be connected to the grid or AC load through the isolation transformer,

and the PV interface can be directly connected to the PV system.

Figure 3.3 Topology diagram of the integrated energy storage cabinet

3.5 Heat Dissipation Design

The S90 Outdoor Cabinet BESS is IP54 outdoor machine, the whole adopts the structure design

of forward air and side air outlet, the outdoor air enters through the front air inlet window of the

energy storage all-in-one machine, the hot air is discharged through the exhaust air outlet at the

bottom, the fan exhaust is 1880m³/h, the ventilation design is shown in Figure 3.4.

9

Figure 3.4 Ventilation design of energy storage outdoor cabinet

4 Technical Specifications

Technical parameters table

Model

S90 Outdoor Cabinet BESS

DC Side

Charging and Discharging

voltage range

200V-750V (350V-750V @full load)

(Due to the electrical design different with the 30P module)

Rated Power

30kW*n (1~3)

Maximum Charging and

Discharging Current

90A*n(1~3)

DC Bus Side

PV Voltage Range

250V-830V

Maximum Input Current

65A*n (1~3)

AC Side

Rated Output Power

30kVA*n (1~3)

Maximum Apparent Power

33kVA*n (1~3)

Maximum Active Power

30kW*n (1~3)

AC Voltage Grid-tied

400V(-15%~15%)3P4W+PE/480V(-15%~15%)3P3W+PE

AC Voltage Off-grid

400V(-20%~20%)3P3W+PE/480V(-5%~5%)3P3W+PE

AC Frequency

50Hz/60Hz(-2.5Hz~2.5Hz)

THDi

<3%

General Specification

Dimension(W*H*D)

2100*1300*2450mm

Cooling

Forced air cooling for power electronics

5kW Air-conditioned for battery system (pre-installed)

Enclosure

NEMA 3R/IP54

Weight

1800kg (without battery)

10

Operation Altitude

3000m (>2000m derating)

Operation Temperature

-20℃~55℃(De-rating over 45°C)

Operation Humidity

0-95% (No condensing)

Noise

70dB

Power Converter Compatibility

Model

Sinexcel PWS2-30M-EX

PWS2-30P-EX/NA

Max PCS units

3

AC power range

30kW (400 Or 800Vac & 350-750Vdc) *n units (n=1,2,3)

15kW (400 Or 480Vac & 150-350Vdc) *n units (n=1,2,3)

DCDC Charger Compatibility

Model

Sinexcel PDS1-45K

Max DCDC units

3

PV Input Power

45kW*n units (n=1,2,3)

PV Input Voltage Range

200V-810V

Battery Compatibility

Battery string voltage range

150-750Vdc

Max. battery pack width

<1080mm /42.5 in

<520mm /20.5 in

One column

Two columns

Max. battery pack depth

915mm / 36 in

Max. battery rack height

1880mm / 74 in

Battery capacity

Up to 240kWh

Auto-switching Compatibility

Model

PWD-100K

Switching Time

Active Switching: Seamless

Passive Switching: 30ms

Communication

Communication Port

CAN/RS485/Ethernet

Communication Protocol

Modbus TCP/RTU,IEC104

BMS Access

Support

Optional Components

Fire Fighting System

Sensor tube, with the agent of NOVEC 1230 or FM200

or water

Built-in transformer

400V/400Vac or 480V/480Vac, 100kVA

Built-in gateway

For Peak-shaving, demand charge management or back-up

power supply.

Aux power

220V single phase built-in, up to 5kw transformer

120V built-in, up to 3kW

Salt spray prevention

Optional Salt spray prevention version

with special coating and filter

Compliance

UL9540

11

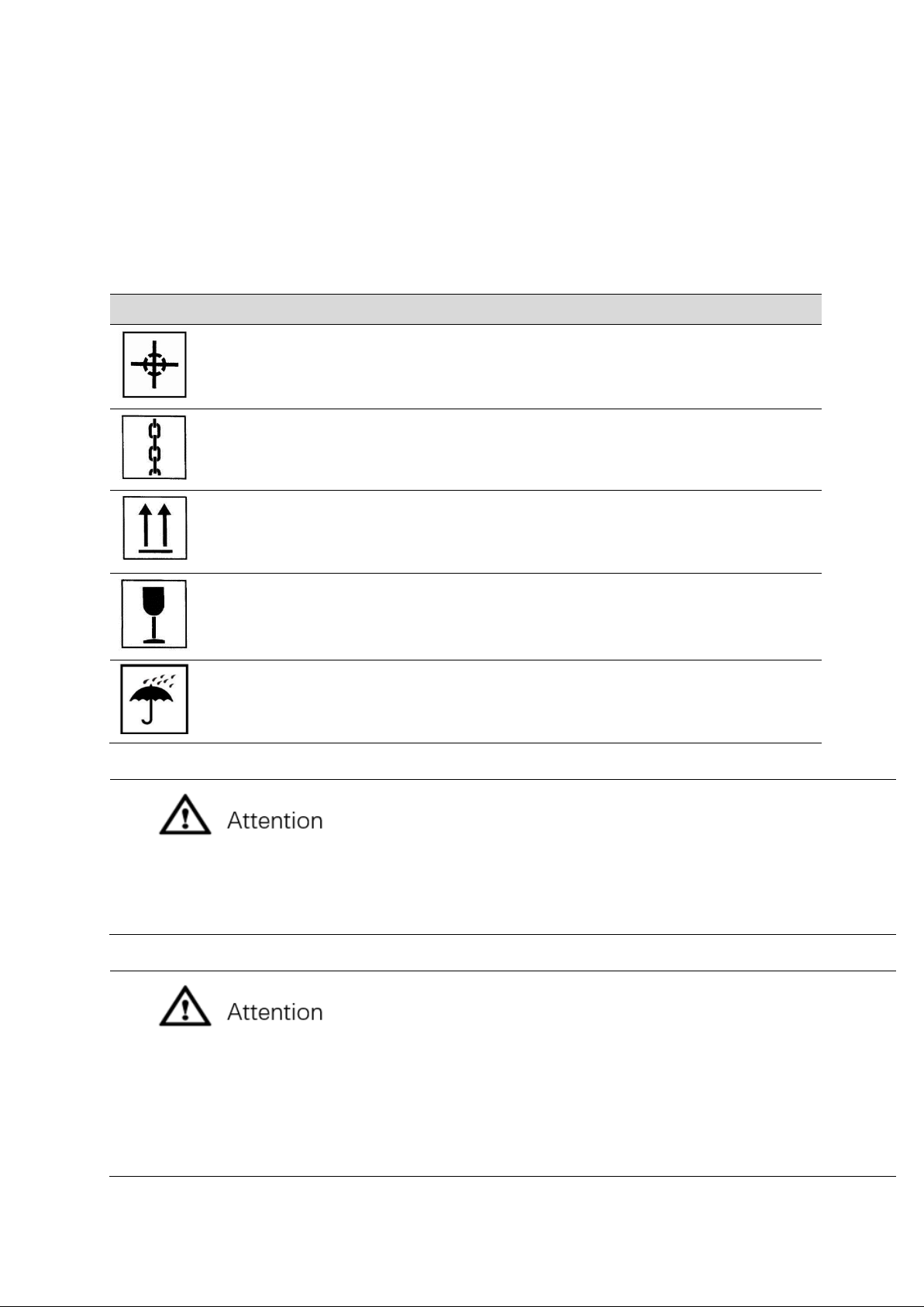

5 Storage, Handling and Transport

5.1 Transportand Storage

During transportation, in order to ensure that the energy storage outdoor cabinet is in a

better protected state, please choose to transport with packaging as far as possible, and

transport according to the indication of various markings on the packaging, the illustration of

packaging markings is shown in Table 5-1.

Table 5-1 package logo description

Icon

Description

Center of gravity marking, indicating where the center of gravity of the

energy storage outdoor cabinet is located

Lifting sign, indicating the position of chain or rope when lifting the

energy storage outdoor cabinet

Upward marking, indicating the way to place the energy storage

outdoor cabinet when handling and placing, forbidden to invert, place

horizontally or tilt.

Lightly placed signs, transport and placement process should avoid

violent friction or collision.

Fear of moisture signs, transportation and storage process should

avoid energy storage outdoor cabinets suffer from rain or moisture.

As the location of the center of gravity is not the mechanical center of the energy storage outdoor

cabinet, in the transportation process, must always pay attention to the center of gravity mark on the

packaging box.

Whether or not the outdoor cabinet with external packaging, moving process is strictly prohibited to tilt

angle > 5 °. Due to its volume and weight, tilt angle is too large may make the equipment backwards,

resulting in casualties or equipment damage.

In the process of moving should avoid physical impact on the equipment, such as suddenly put down,

lift, etc.

12

Avoid rain or bad weather conditions for the transport of energy storage outdoor cabinets, if

unavoidable, please take the necessary protective measures.

If on-site installation is not carried out immediately after the completion of delivery and

acceptance work, the energy storage outdoor cabinet with external packaging should be stored in

a ventilated, dry and tidy indoor environment. At the same time, the following aspects should be

noted.

⚫Restore the package to the state at the time of receipt, and the desiccant inside the

package must be retained.

⚫Storage floor is flat and sufficient to carry the weight of the energy storage outdoor

cabinet with outer packaging.

⚫Equipment storage needs to pay attention to ventilation and moisture, storage

environment is strictly prohibited to have standing water.

⚫Storage environment temperature requirements -40 ℃~ +60 ℃, storage environment

relative humidity requirements 0 ~ 100%, non-condensing.

⚫Pay attention to deal with the harsh environment around, such as sudden cold, sudden

heat, collision, etc., so as not to cause damage to the equipment.

⚫Regular inspection, at least once a week. Check whether the packaging is intact to avoid

insect and rodent bites, and the outer packaging should be replaced immediately if it is

broken.

⚫If the storage time exceeds six months, the package should be opened for inspection

and repackaged after replacing the desiccant.

Energy storage outdoor cabinet for a whole device, transportation or storage are not allowed to break it

down. Equipment failure caused by modifications not authorized by Sinexcel Electric is not covered by

the warranty.

When transporting and storing the equipment, stacking is strictly prohibited and no other items are

allowed to be stacked on top of it.

13

The equipment should be transported and stored in an environment free of corrosive gases, high

temperature and heat sources, non-dusty, and in accordance with fire protection requirements. Storage

without packaging is strictly prohibited.

5.2 Transport

Short distance handling not removed from the transport packaging box of energy storage

outdoor cabinet is recommended to preferably use forklift to move the entire box, moving the box

should pay attention to the center of gravity mark and lifting mark position, and ensure that the

transport tools have sufficient bearing capacity, the use of lifting is strictly prohibited.

Moving energy storage outdoor cabinets without boxes are usually used in the vicinity of the

equipment installation, and it is recommended that they be operated preferably with a forklift,

which requires the removal of the bottom baffle.

1) Forklift movement (preferred)

Using forklift to carry the energy storage outdoor cabinet is the standard way to move. The

center of gravity of the converter should fall between the two forks of the forklift when carrying,

and be pre-inserted to ensure that it will not tilt after lifting. As shown in Figure 5-1, the length of

forklift forks should not be less than 2.1m.

When using forklift to fork up, put down and move the energy storage outdoor cabinet, make

sure that it is slow and smooth, and the energy storage outdoor cabinet must be placed on a solid

and flat ground.

In the whole process of using forklift for operation, the forklift safety operation specification

must be strictly observed. Due to the large size of the energy storage outdoor cabinet, it may

block the driver's view, and there should be supporting personnel to cooperate.

5.2 Forklift diagram

2) Pallet truck movement

The use of pallet trucks to move the energy storage outdoor cabinet is only applicable to the

case where the transportation route is relatively smooth. The center of gravity of the outdoor

cabinet should fall between the two forks of the forklift when it is moved, and be pre-inserted to

ensure that it will not be tilted after being lifted. As shown in Figure 5-2, the length of forklift forks

shall not be less than 2.1m, the inner distance between the two fork arms of pallet truck shall not

14

be less than 0.8m and the outer distance shall not be more than 1.2m, and the load-bearing

capacity of pallet truck needs to be >1800kg.

In the process of using forklift to fork up, put down and move the energy storage outdoor

cabinet, make sure that it is slow and smooth, and the energy storage outdoor cabinet must be

placed on a solid, flat ground.

In the whole process of using forklift for operation, the relevant safety operation specification

must be strictly observed. Due to the large size of the energy storage outdoor cabinet, the

operator's view may be blocked, there should be support personnel to cooperate.

Diagram of pallet truck

The bottom baffle of the energy storage outdoor cabinet must be removed before

using forklift or pallet truck for mobile operation, otherwise the bottom baffle will be

damaged.

Regardless of the method chosen to move the energy storage outdoor cabinet, it must be

ensured that:

⚫The position of its center of gravity must always be noted.

⚫Its size and weight must always be taken into account.

⚫Operator safety must be ensured at all times.

Take the necessary auxiliary measures to ensure that the equipment is delivered to

the installation site in good condition.

5.3 Unpacking Inspection

5.3.1 Unpacking

After transporting the energy storage outdoor cabinet to the vicinity of the installation site, the

15

transport packing box needs to be dismantled, and the dismantling steps are as follows.

①Removing the top panel of the packing box.

②Disassemble the wooden side panels of the packing box.

③Remove the shielding material from the box.

④Remove the anchoring components that secure the energy storage outdoor cabinet to

the shipping wood tray.

After removing the anchoring parts between the energy storage outdoor cabinet and

the transport wood tray, it is strictly forbidden to carry the energy storage outdoor

cabinet through the wood tray again.

5.3.2 Inspection

Before leaving the factory, the energy storage outdoor cabinet has been checked by

Sinexcel Electric staff themselves and packed firmly. Nevertheless, after the removal of energy

storage transport packaging still need to inspect the following.

Check whether the quantity of each item in the packing list is consistent with the physical

object.

Check whether the nameplate data of the product matches with the ordering contract, such

as product type, rated capacity, voltage level, etc..

Check whether the factory documents and accessories are complete.

Check whether the appearance of the energy storage outdoor cabinet is consistent with the

description in this manual.

Check whether the energy storage outdoor cabinet has deformation, paint loss and loose

parts.

The packing list of energy storage outdoor cabinet is shown in Table 5-2.

Table 5-2 Packing list

Serial

number

Name

Quantity

1

SES-90K energy storage outdoor cabinet (including cabinet door

key and related accessories)

1 set

2

SES-90K series user manual

1 copy

3

Equipment wiring diagram

1 copy

4

Product Certificate of Conformity

1 copy

5

Inspection report

1 copy

6

Warranty card

1 copy

16

Only the inspection is correct and complete without damage to the energy storage outdoor cabinet can

be installed and commissioned, check the process, once the problem is found, please contact with the

transporter or Sinexcel Electric in a timely manner.

6 Equipment installation

6.1 Installation requirements

6.1.1 Basic requirements

SES-90 energy storage all-in-one cabinet has IP55 protection level and can be installed

outdoors, but it should not be placed in high humidity environment for a long time. Due to the

noise generated during operation, the energy storage inverter should be installed in a location

away from residential areas and the installation location should be free from corrosive and

combustible gases.

To ensure the safe and efficient operation of the energy storage cabinet, it is important to

observe the following when selecting the installation environment.

⚫The energy storage integrated cabinet must be mounted on a suitable concrete support

with a refractory surface, and the converter inlet and outlet must not be obscured.

⚫The installation ground is dry and flat, no water accumulation, the ground level does not

shake, and it can completely carry the weight of the energy storage all-in-one cabinet.

⚫Installation site ambient temperature range: -40℃~+60℃; relative humidity range:

0~100%, non-condensing.

⚫Energy storage integrated cabinet grounding resistance <4Ω.

⚫Cabinet should be installed in a location that ensures easy viewing of the LED indicators

and operation of the LCD touch screen.

⚫If the machine is placed directly outdoors, it is recommended to take the necessary

shading measures for the machine to avoid the machine temperature rising due to direct

sunlight, causing the machine to run at reduced capacity.

6.1.2 Outdoor requirements

SES-90 is capable of operating within an ambient temperature of -40°C to 60°C.

When the temperature is higher than 45℃the machine will run at a reduced rate. When the

temperature is lower than -20℃, it needs to warm up first before high power operation.

The sunlight irradiation intensity should be ≤1200W/m^2, and it is recommended that the

converter installed outdoors should take the necessary shading measures.

6.1.3 Foundation support requirements

Since the electrical compartment of the energy storage all-in-one cabinet is side air outlet

and the front air outlet of the battery compartment, it is recommended to ensure at least 1m air

ducts on the side and front when installing the all-in-one cabinet.

17

Due to the installation of wall-mounted air conditioning in the battery compartment door of

the integrated cabinet, 350mm space is reserved on the side of the battery compartment to

ensure the normal opening of the door.

The energy storage cabinet needs to be installed on a concrete foundation or a structure

supported by steel channel with a surface of flame retardant material. Must ensure the foundation

is flat and solid, safe and reliable, and has sufficient bearing capacity, strictly forbidden to install

on the surface of the foundation with depression or tilt.

When building the foundation, according to the overall design of the power station and the

location of the cables in and out of the bottom of the energy storage cabinet, the cable trench

should be preset.

Pre-opening holes are required on the base, and the size of the opening holes must be

exactly the same as the positioning holes of the base of the energy storage cabinet, in order to

firmly connect the energy storage cabinet with the foundation.

As shown in Figure 6-1, the base of the energy storage cabinet is equipped with eight

35mm*20mm positioning waist holes, and it is recommended to use M16*45 bolts to fasten the

converter base to the foundation.

Figure 6-1 Bottom view of SES-90 cabinet

6.1.4 Space requirements

As shown in Figure 6-2, when installing the energy storage all-in-one cabinet, sufficient

distance must be retained between it and the wall and other equipment in order to meet the

requirements for the narrowest maintenance access, evacuation routes and ventilation. This

subsection requires the minimum space requirement for the normal operation of the energy

storage all-in-one cabinet. If the site conditions allow, it is recommended to choose a larger

spacing to ensure the reliable and efficient operation of the energy storage all-in-one cabinet.

18

A

B

C

D

E

F

A 1000mm

B 0mm

C 1000mm

D 350mm

Figure 6-2 SES-90 cabinet space requirements

Note: The distance E between the air outlet at the bottom of the converter and the ground is

required as a minimum space requirement, and this space must be ensured for normal air duct

cooling.

6.1.5 Ventilation requirements

The converter will generate a lot of heat when running, and the high temperature will directly

affect the electrical performance of the equipment and even damage the equipment, so the

ventilation and heat dissipation needs of the equipment should be fully considered when planning

the installation environment of the converter to ensure the normal and efficient operation of the

equipment.

To ensure the reliable and efficient operation of the energy storage cabinet, please regularly

clean the grille, filter and filter cotton of the air inlet and outlet of the equipment, and regularly

check whether the equipment exhaust fan is functional.

In order to meet the ventilation requirements of the integrated energy storage cabinet, its

installation environment needs to meet the following requirements.

1) The energy storage cabinet should be avoided to be installed in poor ventilation

conditions and low air flow.

2) The air inlet should have sufficient fresh air supply.

3) Air quality must be ensured. If the air contains too much sand, dust and other

suspended matter, the air purity can be improved by installing filters at the air supply

grille and other measures.

4) The ventilation system of the energy storage cabinet must be independent of the

ventilation system of other equipment and do not affect each other.

Cooling ducts should be designed by professionals in advance to avoid placing the cabinet

at backflow wind phenomenon. At the same time, each combination must be sealed to prevent air

leakage, the choice of sealing materials to withstand the temperature of at least 80 ℃. After

Table of contents

Other Sinexcel Storage manuals