MorseDrum.com

Copyright 2010 - Morse Mfg. Co., Inc. Form PL525-124 (242094-249854) (Updated December 21, 2010 3:26 PM) 5

The Specialist In Drum Handling Equipment

Models 525-N-124, 525-T-124 & 525M-T-124

Vertical-Lift Drum Pourer, Scale-Equipped,

106”, Air Power Lift, Manual Tilt

Operator’s Manual for Morse Models 525-N-124, 525-T-124 and 525M-T-124

with Serial Number 242094 to 249854

Operating Instructions

Push the Vertical-Lift Drum Pourer to the drum.1.

Using the “LIFT” control as described in “Machine Description2.

- Controls” (page 4), position the drum holder assembly with

the back band at the middle of the drum. With the ratchet plate

swung open and the cinch chain hanging from the chain hook,

pushtheunituntilthebackbandrestsrmlyagainstthedrum.

Some adjustment to the tilt angle of the saddle may be necessary

toensure bandtsushon thedrum.Engage theoorlock.

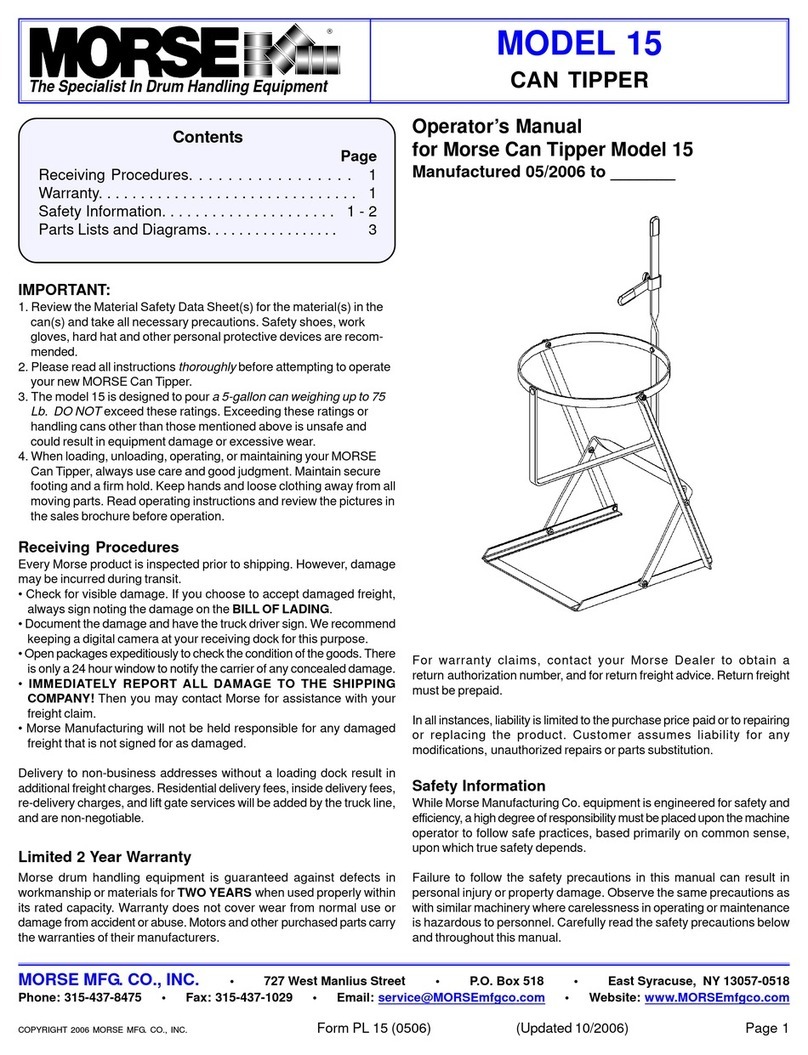

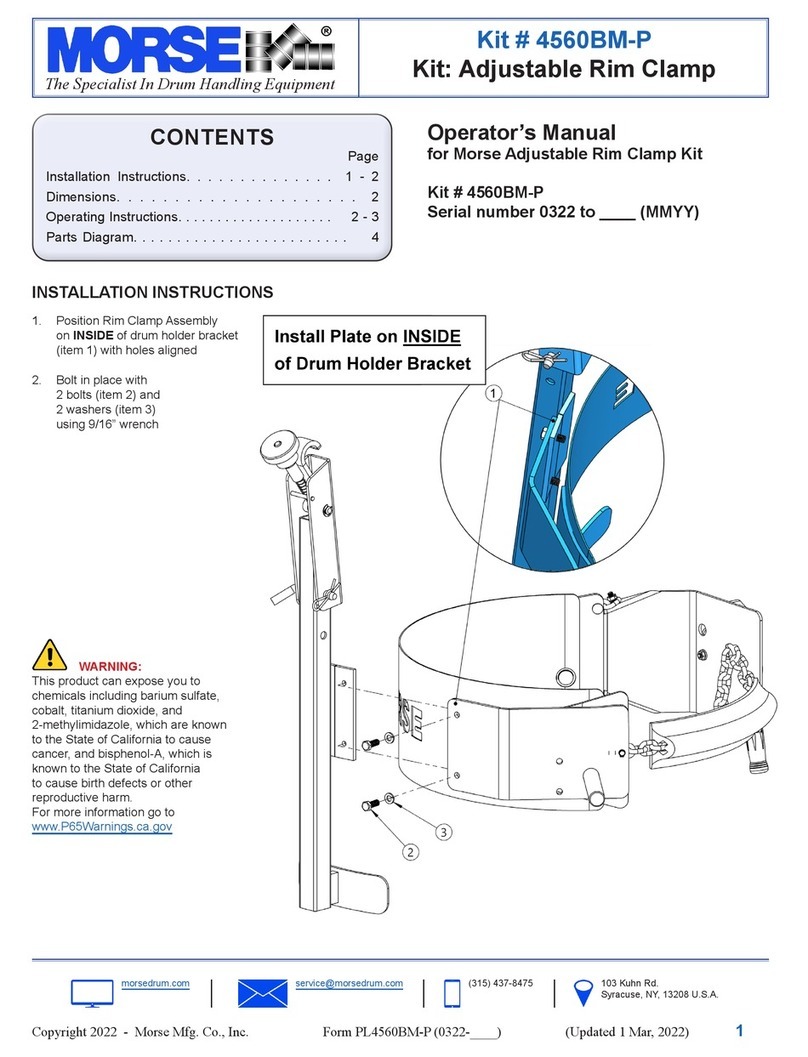

Attaching the drum:3. Drape the cinch chain across the front

of the drum and engage a chain link into the slot in the ratchet

(Figure 3.2). Turn the ratchet clockwise to tighten cinch chain. If

ratchet turns until the pawl is beyond the last ratchet tooth, turn

the ratchet back and slide the next link into the ratchet slot and

try tightening again. The cinch chain must be held tightly against

the drum with the pawl engaged securely in the ratchet teeth.

Operatetheliftfunctiontoliftdrumclearofoor.Disengageoorlock.Rolltodispensinglocation.NOTE:Donotallowthedrumto4.

impactonoor,pouringstation,etc.oraspillordamagecouldoccur.

CAUTION – Do NOT transport with drum raised.

ALWAYSLOWERTHEDRUMHOLDERTOLOWESTPOSITIONBEFORETRANSPORTING.

The unit can become unstable when transporting with a raised load.

Lift drum to desired pouring height. Operate the tilt control as described in “Machine Description - Controls” (page 4) to adjust the5.

drumattitude.Theoorlockshouldbeengagedwhiledispensing/draining.

Whendispensingiscomplete,tiltdrumbacktouprightposition.Disengagetheoorlockandlowerthedrumtotransportingheight;6.

about6”offtheoor.

WARNING - Stay clear of raised drum

NEVER allow anyone to be below any part of a raised drum handler or drum. Remain behind the push handle

while handling a drum.

WARNING – Do NOT disengage the cinch chain when drum is off the ground.

Whenthedrumisintheuprightposition,lowerthedrumtotheoorbeforereleasingthecinchchain.

Pushtheunittothedrumstorageareaandlowertotheoorinanuprightposition.Releasethecinchchainfromtheratchetby7.

applying pressure to the ratchet handle in a clockwise direction with one hand and opening the pawl to free the ratchet with the other

hand. Remove the cinch chain link from the ratchet.

Maintenance

Periodicinspectionforthegeneralconditionofstructuralandmechanicalcomponentsisimperativeforsafeandefcientoperation.1.

Periodically inspect all moving parts, framework, drum holder and contact areas for signs of wear, fatigue, or loosening. Tighten, adjust,2.

or replace parts as necessary to prevent failure and maintain proper function.

Inspectthehydraulicsystemforoildrips,hosedamage,orothersignsofwear.Inspectthelevelofthehydraulicuid.Replaceany3.

parts that show signs of wear.

Greasewheelbearingsperiodically.Oilorgreaseallmovingparts,including:thegearsandsprocketsinthetiltdrive,andtheratchet4.

and pawl.

Worn or damaged parts must be properly replaced with the correct, genuine Morse parts.5.

Hydraulic pump is shipped lled with Noco Premium plus automatic transmission uid d/m. Material safety data sheet (msds) is6.

available online. Change oil yearly, sooner depending on dirty conditions or outdoor use. Replace oil with Mobil dte 24 or equivalent for

indoor use (Mobil dte 13 for outdoor use).

Figure 3.2