SINTERIT POWDER HANDLING STATION User manual

POWDER HANDLING STATION

USER MANUAL

Read the instruction manual before using the device.

Version 12/2020

Table of Contents

1. Marking text conventions used in the document.................................................................................................................3

2. Important safeguards and warnings.....................................................................................................................................4

A. Environment and place of installation ..............................................................................................................................5

B. General safety rules............................................................................................................................................................6

C. Personal protection............................................................................................................................................................7

D. Power supply and grounding system................................................................................................................................7

E. Safety requirements during using the Sinterit PHS..........................................................................................................8

F. Safety during repair and maintenance...............................................................................................................................9

G. Working with powders .......................................................................................................................................................9

H. Safety plates (specication tag and symbols)...............................................................................................................10

I. Scrapping ...........................................................................................................................................................................11

3. Contents of Powder Handling Station packaging ..............................................................................................................11

4. Sinterit Powder Handling Station ........................................................................................................................................12

A. Description........................................................................................................................................................................12

B. Specication.....................................................................................................................................................................13

5. Initial startup of the Sinterit PHS after delivery ..................................................................................................................14

6. Powder transfer in the PHS device......................................................................................................................................20

7. Powder recovery process from Sinterit printers.................................................................................................................23

8. Powder emptying and cleaning process of the PHS device..............................................................................................28

9. Powder refreshment process ..............................................................................................................................................29

A. Adding Fresh Powder to the Used Powder from printer................................................................................................29

B. Mixing of powder (homogenisation)...............................................................................................................................30

10. Maintenance work................................................................................................................................................................31

A. Checking the condition of the sieve and removing dirt from it .....................................................................................31

B. Cleaning the Powder Feeding Screw...............................................................................................................................33

C. Cleaning the interior of the PHS device ..........................................................................................................................34

D. Replacement of the fuse..................................................................................................................................................35

11. General legal information ....................................................................................................................................................36

12. Disclaimer .............................................................................................................................................................................36

13. Trademarks...........................................................................................................................................................................36

14. Terms of warranty ................................................................................................................................................................36

15. Technical support.................................................................................................................................................................37

16. Residual risk .........................................................................................................................................................................37

17. Location of machines center of gravity ..............................................................................................................................38

A. PHS device itself ..............................................................................................................................................................38

B. PHS device with Sinterit Sandblaster..............................................................................................................................38

C. PHS device with Sinterit Sandblaster XL ........................................................................................................................38

POWDER HANDLING STATION Manual | 2

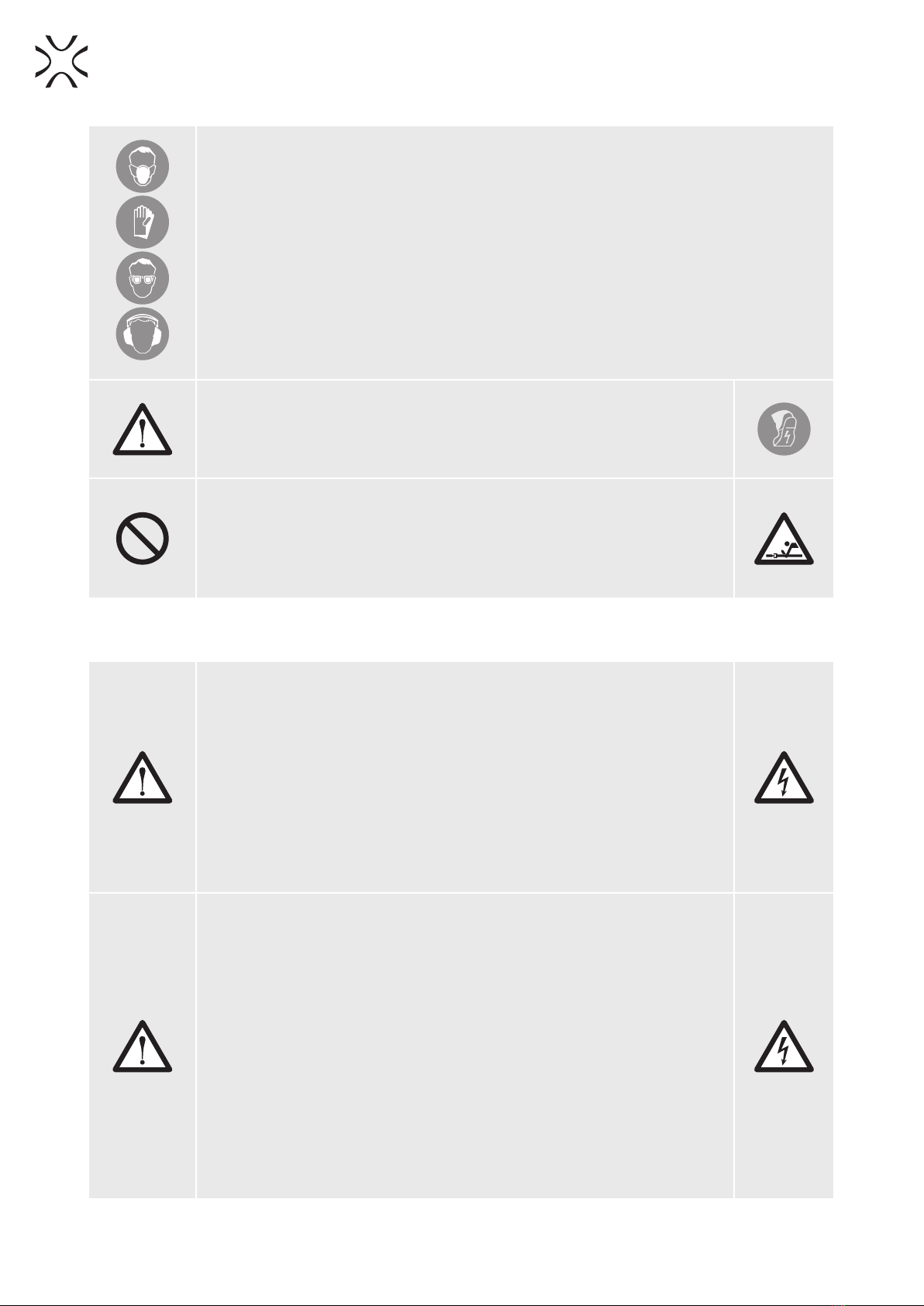

1. Marking text conventions used in the document

Listed below are descriptions of symbols used on the device. They constitute a warning or convey the information to

protect the user, other individuals, or surrounding objects and ensure the correct and safe use of the device.

WARNING!

An inevitably dangerous situation that can result in serious injury or even death. Initiation, the

omission of a specic procedure, or inattention can cause severe physical injury to the user.

ATTENTION!

Initiation or omission of a specic procedure can cause physical damage to the equipment or the

user.

WARNING!

Risk of electric shock which can be fatal or cause severe burns. An inevitably dangerous situation

that can result in serious injury or even death, if not mitigated. Before working with any equipment,

you should be aware of the dangers associated with the ow of electric current, and become

familiar with the standard procedures to prevent accidents.

CAUTION!

Beware of moving parts that can crush hands.

CAUTION!

Beware of sharp edges which can cause body cuts and injury.

WARNING!

Risk of re and explosion!

Avoid re! Powder dust is ammable

ATTENTION!

Risk of electric shock. A grounding is used in the device. Follow the instructions in the User manual

and the markings on the PHS device.

STOP!

Action prohibited.

3 | POWDER HANDLING STATION Manual

ATTENTION!

It is necessary to wear protective gloves, glasses, and a face mask. Mandatory action when working

with powder.

ATTENTION!

It is necessary to use hearing protection.

ATTENTION!

It is necessary to wear antistatic clothes and shoes. Mandatory action when working with powder.

IMPORTANT!

Information essential to correctly perform a specic task.

IMPORTANT!

You must read the instructions before taking action.

2. Important safeguards and warnings

WARNING!

• To ensure the safe use of the Sinterit Powder Handling Station (hereafter PHS), please read

and follow the instructions below.

• Keep this manual for future use. All warnings and instructions on the product should also be

followed.

• Unless these messages are heeded, operator injuries could occur.

• Unless these messages are heeded, PHS damage could occur.

WARNING!

The following indications are, by themselves, not enough to fully protect against all the hazards

that could arise during printer operation. These will have to be integrated with common sense and

the experience of the operator, both of which are crucial factors for preventing accidents. Each

section of this manual lists further specic safety warnings for the various operations.

POWDER HANDLING STATION Manual | 4

A. ENVIRONMENT AND PLACE OF INSTALLATION

WARNING!

• The PHS device may only be used with a vacuum cleaner having an explosion-proof certicate

(ATEX, INTERTEK).

• Sinterit recommends to use the PHS device solely with a vacuum cleaner delivered by Sinterit

or by one of the Company’s ocial distributors and from Sinterit offer.

• Sinterit is neither responsible for the operation of the PHS device nor for any defects or damages

if PHS device is used with a vacuum cleaner other than the one recommended by Sinterit. This

includes but is not limited to vacuum cleaners that may be provided by distributors or resellers

but from outside Sinterit`s offer.

• TO THE EXTENT PERMITTED BY APPLICABLE LAW, SINTERIT DISCLAIMS ALL WARRANTIES

AND CONDITIONS, WHETHER EXPRESS, IMPLIED OR STATUTORY, IN CASE OF THE PHS

DEVICE BEING USED WITH A VACUUM CLEANER OTHER THAN RECOMMENDED ABOVE.

WARNING!

• The PHS must be protected against atmospheric agents (rain, hail, snow, fog, dust in

suspension, etc.)

• An environmental temperature between 10°C and 40°C and relative humidity not above 70%.

Optimum operation of the device at a temperature of about 22°C.

• The work environment must be clean, well-enough lit, and devoid of any explosive materials

that may create an explosive atmosphere.

• The work environment must be well ventilated, adequately to its size.

• The PHS unit should not be located close to the air conditioner vents.

IMPORTANT!

• The product should be placed on a at, stable surface with sucient weight resistance as the

device weighs over 150 kg.

• The product will not work properly if it is set at an angle.

STOP!

Do not place or store the PHS:

• outdoors;

• near water, or heat sources;

• in areas with large amounts of dust;

• in places subject to shocks, vibrations, high temperature and/or humidity;

• extreme changes in temperature and humidity;

• near inammable and volatile substances, concentrated acids or corrosive vapors;

• in places easily accessible to children and animals.

STOP!

• The PHS must not be operated in a corrosive or explosive environment.

• Avoid using the device close to open ames or sources of heat.

5 | POWDER HANDLING STATION Manual

B. GENERAL SAFETY RULES

WARNING!

• The device should be installed in accordance with this manual and by trained personnel.

• Only trained and authorized personnel should replace or service the PHS.

WARNING!

• Only adults should use the PHS device.

• When using the machine, mind other people, especially children.

ATTENTION!

It is forbidden to use the device to collect any liquids, from containers, sinks, bathtubs, etc.

ATTENTION!

• Never put your hands between the grid and the Powder Chamber (main and

Fine Dust) especially during operation.

• Do not put your hands in the service area of the Powder Chambers where

the Powder Feeding Screw is located (if the safety guards are removed, e.g.

during service).

• Be careful when installing the Metal container into the Sifting module.

• Be careful when opening and closing Drawers and the door from the Sifting

module.

ATTENTION!

When restoring original working conditions, the appointed person should make sure that at the end

of the operating procedure, proper PHS operation safety conditions are restored, especially the

safety devices and the protective guards.

ATTENTION!

• Never leave various objects on the worktop or over the powder chambers of the PHS.

• Make sure all the guards and protection devices are in place and that all the safety devices are

in place and working properly.

• Do not insert any objects in holes not intended for this purpose.

• Do not use the device with blocked holes - remove any solid objects that may restrict airow.

STOP!

• Climbing on the PHS device is forbidden.

• Sitting/climbing on a Metal shelf (under a sandblaster) is prohibited.

POWDER HANDLING STATION Manual | 6

C. PERSONAL PROTECTION

ATTENTION!

• Wear individual protections (Protective gloves, Protective Glasses, Protective Dust Mask).

• Hearing protection is required when working with a PHS device. Staying with the device

unprotected for long periods may reduce attention and impair hearing.

• To prevent dust from being inhaled at all times, always wear a dust mask. When entering a PHS

room, pay attention to the solid particles that are released during sieving.

• Inhalation of the dust can cause serious lung problems.

ATTENTION!

• The operator must always wear antistatic clothes and shoes.

• The oor in the working area must be antistatic.

STOP!

• Do not wear untied hair, loose or hanging clothes such as ties, scarves, or torn

clothes that could become trapped by the PHS device.

• Do not place the Suction hose close to the body, especially to sensitive areas

such as eyes, ears, and lips!

D. POWER SUPPLY AND GROUNDING SYSTEM

WARNING!

• Before plugging in, make sure the power voltage and frequency are those shown

on the machine plate.

• When an extension cord is used for the power supply of the product, make sure

that the total power consumption of all devices connected to it does not exceed

the extension cord’s limit. Also, make sure that the total current drawn by

connected equipment does not exceed the ampere rating for the AC wall outlet.

• The PHS device should be connected to an electrical installation protected with

an overcurrent switch with this parameters:

• Characteristics: type B

• Rated current value: 10A

WARNING!

• Use only the Power cable supplied with the product.

• Do not use power cables from other devices! Using the power cables from

other devices or connecting the power cables supplied with the product to other

devices may cause re or electric shock.

• The device power plug should be suitable for the power outlet.

• The power cable should be placed in such a place that it is not rubbed, cut,

pulled, or twisted.

• Pay special attention to the fact that the Power cable is not bent at the points of

connection of the device.

• During use, mind the power supply cables and avoid crushing or pulling these.

• Periodically check the mains power cable to ensure it is not damaged.

• In the event of the cable being replaced, make sure it is protected against water

spray and check mechanical strength.

• Disconnect the Power cable whenever it is planned to shift/transfer the machine.

7 | POWDER HANDLING STATION Manual

WARNING!

In the following situations, unplug the product from the power supply and contact

with Sinterit Support:

• the power cord or plug is damaged;

• some liquid got into the product;

• the product has been dropped or the case has been damaged;

• the product does not operate properly or clear changes in eciency have been

observed.

STOP!

• Never touch electric wires, switches, buttons, etc. with wet hands.

• Do not pour the liquid onto the product.

• Do not place any containers on the device, in particular those containing water.

• Do not touch live parts.

• Never pull the machine using the power cable.

• When connecting/disconnecting the plug to/from the power socket always

hold the cover, not the cable.

• In the event of the cable being damaged, the machine must not be used.

• Never disassemble, modify or repair the power cable, plug, devices inside the

printer, except as described in the product manual.

• Do not place objects on the Power cable.

• Do not place Power cable in a path where people will have to walk or run.

ATTENTION!

The PHS must be connected to a grounded outlet to prevent electric shock in the

event of a fault.

E. SAFETY REQUIREMENTS DURING USING THE SINTERIT PHS

WARNING!

• Before using PHS always make sure the printer is free of all external materials such as debris,

oil, equipment, and other objects that could affect the operation and cause injury to persons.

• Before each use, check the device for damaged and/or defective parts.

• In the case of a defect or malfunction of the device, have it repaired by a qualied person/

company rst.

• No smoldering or smoking substances (e.g. cigarettes, matches, or hot ashes) may be sucked

in.

• Do not leave the device switched on unattended!

POWDER HANDLING STATION Manual | 8

F. SAFETY DURING REPAIR AND MAINTENANCE

WARNING!

• Only skilled persons should carry out repairs and maintenance.

• Read the operator’s and maintenance manual carefully before using the PHS or doing any

maintenance jobs.

• During cleaning operations, maintenance jobs, or when changing parts, the Power switch must

be off and the machine must be unplugged by removing the Power cable from the socket.

• During maintenance jobs, ax a notice to the appliance indicating „MACHINE BEING SERVICED,

DO NOT START”.

• Never disassemble, modify or repair the power supply, plug, or devices inside the PHS unit

except as described in the product manual.

• Do not adjust controls that are not described in the manual.

WARNING!

• Structural damage and improper alterations or repairs could change the protection capacity of

the PHS and therefore cancel the guarantee.

• Any alterations to the appliance can only be made by Sinterit Support.

• Use only with the equipment recommended by the producer. In the event of Customers tting

a tool to the machine not supplied by Sinterit, make sure the safety conditions required by

Machine Directive 2006/42/CE are complied with and in any event, Sinterit is unable to accept

liability for any problems arising from the use of such tool.

• Use only original spare parts.

STOP!

• Avoid using ammable or toxic solvents such as petrol, benzene, ether, and alcohol for cleaning.

• Do not immerse the device in water for cleaning purposes or use a pressurized water jet to

clean it.

G. WORKING WITH POWDERS

WARNING!

• When working with the polyamide powder or other designated printer powder

for the Sinterit Lisa PRO printer, always wear Personal Protection dedicated

to this device (Protective Glasses, Protective Gloves, Protective Dust Mask).

• When working with a polyamide/rubber powder, avoid inhalation or swallowing

and contact with skin and eyes.

WARNING!

First aid when working with PA/FLEXA powder:

• If the PA/FLEXA powder is inhaled, move to a place with fresh air and gargle thoroughly with

plenty of water. If coughing develops, contact a physician.

• If you eat a PA/FLEXA powder, rinse your mouth with water and drink 1-3 glasses of water to

dilute stomach contents. If necessary, contact your doctor.

• If the PA/FLEXA powder gets in your eyes, rinse them thoroughly with water. In case of

persisting eye irritation, contact a physician.

• When the PA/FLEXA powder gets in contact with your skin, wash it with soap and water.

9 | POWDER HANDLING STATION Manual

ATTENTION!

• Polyamide powder should be stored in tightly closed containers (e.g Sinterit Metal Container),

in a room at room temperature and low humidity.

• The powder should be stored out of reach of children and pets.

STOP!

• Do not attempt to burn/melt polyamide powder. The resulting sparks and hot

mass can cause severe burns.

• Keep the polyamide powder away from re.

ATTENTION!

Do not dispose of municipal waste! The used polyamide powder should be stored

in sealed containers and disposed of by local policy of waste plastic material.

H. SAFETY PLATES (SPECIFICATION TAG AND SYMBOLS)

DO NOT REMOVE THIS LEBEL!

Manufacurer:

SINTERIT Sp.z o.o.

ul. Nad Drwiną 10 bud. B3, 30-741 Kraków, Poland

www.sinterit.com

Name:

POWDER HANDLING STATION

Serial number:

1234597890

Manufactured: Made in: EU, POLAND

IEC Protection Class:

Machine type: SLS 3D PRINTS POST-PROCESSING STATION

Class 1 Dimensions: 1000 x 700 x 1800 [mm] 39.4 x 27.6 x 70.9 [in]

IP CODE: IP30 Total weight: 160 [kg]

Power consumption: 80-264 [V] AC, 47-63 [Hz], 6.67 [A], 80 [W]

Short-circuir current

rating 6 [A]

Warning! Read and undesrtand operator’s manual and all other safetry instuctions before using this machine.

Failure to follow operating instructions coul result in serious injury.

ATTENTION!

• Make sure all the safety messages are legible.

• Clean these with cloth, soap, and water. Do not use solvents, diesel fuel, or petrol.

• Replace the damaged plates with new ones supplied by Sinterit. If a plate is attached to a

replaced part, make sure a new plate is axed to the new part.

• When contacting the manufacturer or dealer, always quote the details shown on the printer

plate.

WARNING!

• Removing the safety plates on the printer is strictly forbidden!

• The manufacturer declines all liability about printer safety in the event of failure to comply with

the above indications.

POWDER HANDLING STATION Manual | 10

I. SCRAPPING

IMPORTANT!

In the case of scrapping, all the parts of the device will have to be disposed of

through adequate disposal channels by applicable legislation. Before scrapping,

all plastic and rubber parts will have to be separated from the electrical material.

Parts made of plastic, aluminum, and steel only may be recycled if collected by

special centers.

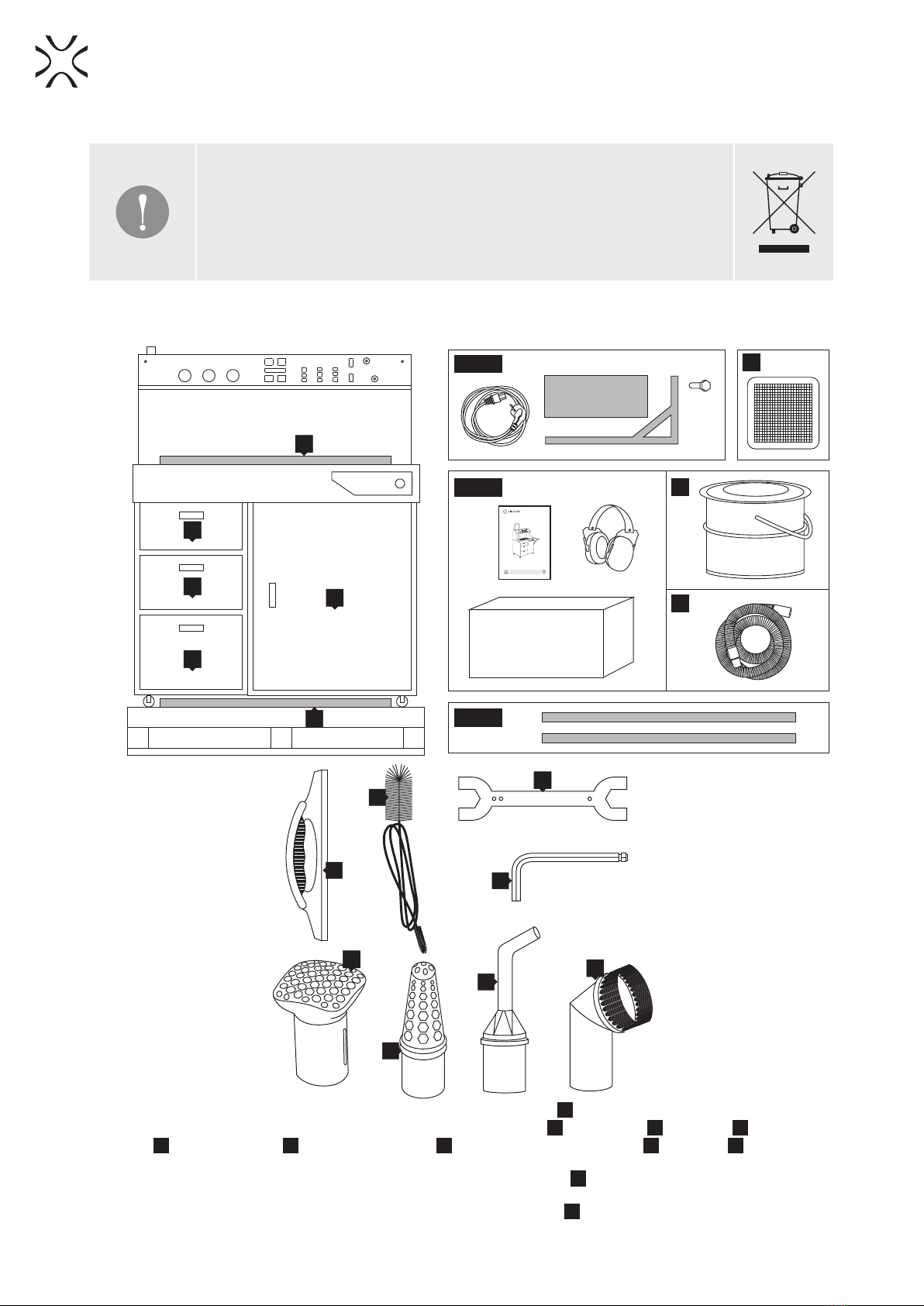

3. Contents of Powder Handling Station packaging

I

IV

III

II

V

V

III

IV

VI

ZONE I

x1

x2

x8

BOX OF

ACCESSORIES

FOR PHS

ZONE II

ZONE VI

POWDER HANDLING STATION

INSTRUKCJA OBSŁUGI

Przed użyciem urządzenia należy przeczytać instrukcję obsługi.

Wersja 1.0/2020

G

I

J

E

D

F

HK

Zone I: Components of the Metal shelf with screws 13 , Power cable.

Zone II: PHS User manual, Anti-noise headphones, Box with additional accessories: DPowder Wiper, ETube brush, FService wrench

17/10, GAllen key Hex 5mm, HGeneral-purpose nozzle, IPowder suction nozzle form cake, JGap nozzle, KPVC brush.

Zone III: Spare Metal container with lid.

Zone IV: Suction hose with Suction Handle 4.

Zone V: Additional Powder Chamber grid (for cleaning small parts).

Zone VI: Components of the Slope ramp A.

11 | POWDER HANDLING STATION Manual

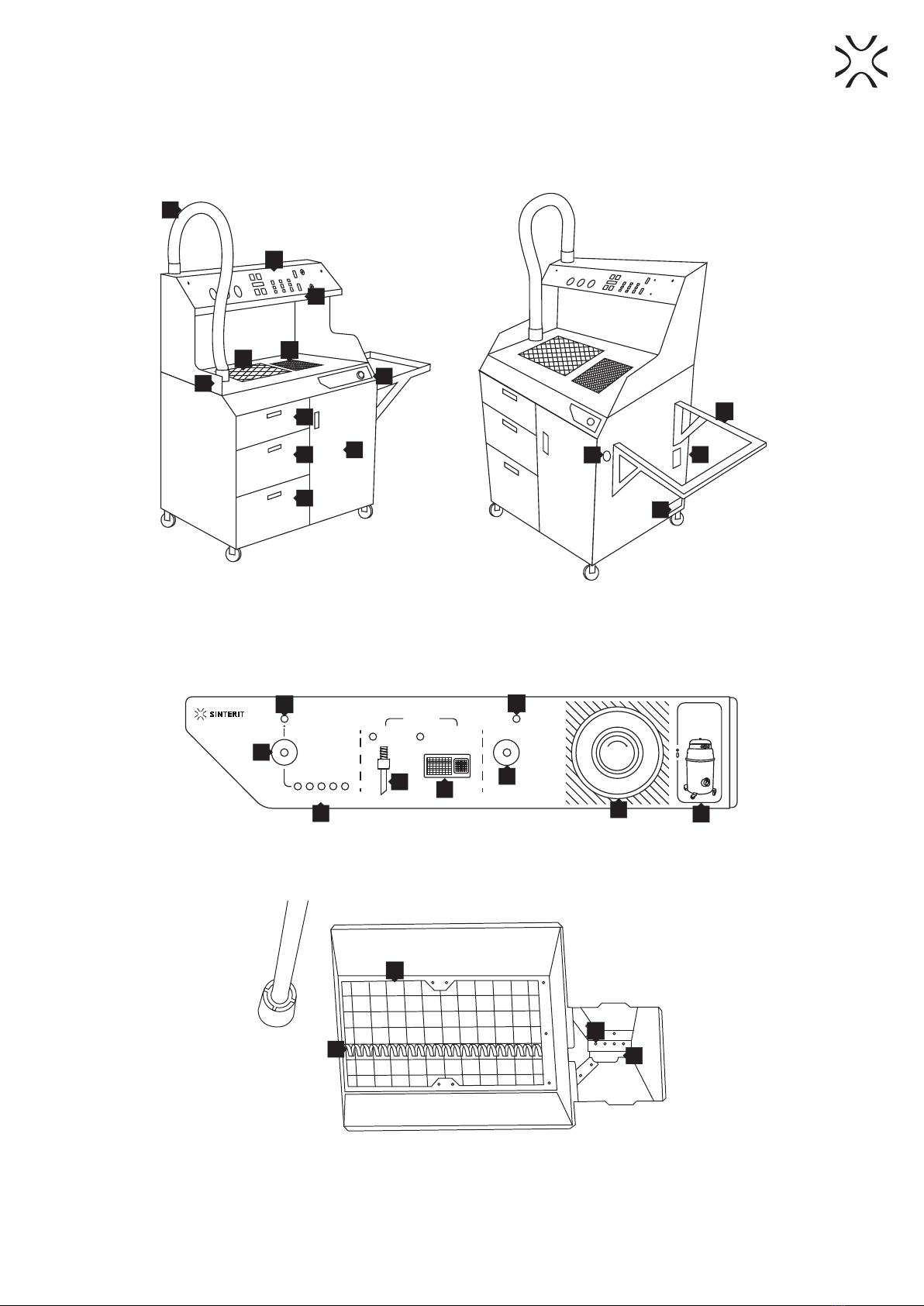

4. Sinterit Powder Handling Station

A. DESCRIPTION

3

4

40

12

5

41

7

8

9

11

10

12

6

13

Image 1. General view of the Sinterit PHS.

1.Powder Chamber with grid, 2.Fine Dust Chamber with grid, 3.Suction hose with Suction Handle, 4.Suction Handle socket,

5.LED light, 6.Toolboard, 7.Drawer 1 (for small printout cleaning equipment), 8.Drawer 2 (for IO Box),

9.Drawer 3 (for Spare Metal container and Funnel), 10.Control panel, 11.Sifting module (behind the door),

12.Connector for Antistatic hose, 13.Metal shelf for Sandblaster or Foldable Tray (option), 40.Power socket,

41. Service access to Powder Feeding Screw

TURN ON

VACUUM

FIRST

PHS

LIGHT

ON/OFF

POWER

SUCTION

VACUUM

SIFTING

ON/OFF

ON/OFF

TIMER

HANDLE DEPOWDERING

ZONE

SUCTION

S

T

O

P

E

M

E

R

G

E

N

C

Y

15

17

18

19 20

14

16

22 21

Image 2. View of the Control panel

14.Main switch, 15. Sifting module timer, 16.Suction Handle suction indicator, 17.Fine Dust Chamber suction indicator,

18.LED light switch (on/off), 19.Safety button (E-STOP), 20. Reminder to turn on the vacuum cleaner, 21.Power supply indicator,

22.Vacuum Suction sensor indicator

23 24

22

23

Image 3. View of the inside of Powder Chambers (main and Fine Dust).

22.Powder Feeding Screw guard (mesh) in Powder Chamber, 23.Powder Feeding Screw,

24.Powder Feeding Screw guard in Fine Dust Chamber

POWDER HANDLING STATION Manual | 12

30

29

33

34

36 37

27

25

27

32

28

38

35

33

26

31 Image 4. Detailed view of the Sifting module

25.Powder separator, 26.Powder separator shelf,

27.Magnetic holder for the Sieve ange,

28.A exible tube with ange (for Sieve),

29.(Sieve) Clamping ring with a pin, 30.Sieve,

31.Sieve drawer, 32.(Sieve) Drawer Lock,

33.Magnetic holder for the container ange,

34.A exible tube with ange (for the Metal container),

35.(Metal container) Clamping ring with a pin,

36.Metal container (12L), 37.Metal container drawer,

38.(Metal container) Drawer Lock

B. SPECIFICATION

GENERAL

Category SLS 3D Prints Post-processing Station

Type Industrial

PACKAGING

Size of package 1200 x 800 x 1800 [mm] (47.2 x 31.5 x 70.9 [in])

Package weight 185 [kg] (408 [lbs])

Space for unpacking 1700 x 4200 x 2000 [mm] (66.9 x 165.4 x 78.7 [in])

Space for installation 1700 x 2200 x 1800 [mm] (66.9 x 86.6 x 70.9 [in])

Package contains Powder Handling Station + set of accessories + manuals

POWER

Voltage 80 - 264 [V] AC, 47 - 63 [Hz], 6,67 [A]

Power 80 [W]

TECHNICAL DATA

Dimensions 1000 x 700 x 1800 [mm] (39.4 x 27.6 x 70.9 [in])

Total weight 160 [kg] (352.7 [lbs])

13 | POWDER HANDLING STATION Manual

Noise level without vacuum cleaner <60 [dB]

Equivalent continuous sound

pressure level (8 hours) 73,9 [dB]

Sound pressure level (A) 63,7 [dB]

Peak sound pressure level (C) 81,4 [dB]

Sound power level (A) 79,6 [dB]

Suction inlet 40 [mm]

Capacity of collection unit 12 [L] (3.17 [gal])

SAFETY

Certicates CE

IEC Protection Class Class 1

IP Code IP 30

5. Initial startup of the Sinterit PHS after delivery

WARNING!

The device weighs above 150 kg. Two adults will be needed to unpack the PHS device properly and

safely.

ATTENTION!

• Visually check if the package does not have any visible damage to the protective packaging

that may arise during transport. If any, contact Sinterit Technical Support immediately (https://

www.sinterit.com/support-page).

• The device must be properly installed according to these instructions before use.

IMPORTANT!

The tools: Powder Tools, IO Box, Powder Funnel, Trowel are not supplied with the PHS. They are

included in the accessories of the Sinterit Lisa and Lisa PRO printers.

IMPORTANT!

During installation, watch out for the metal edges of the device. Wear Protective

Gloves.

POWDER HANDLING STATION Manual | 14

For easy and safe unpacking you will need it:

Two persons Service wrench 17/10

F(1 point - size 17,

2 points - size 10)

Bookbinding knife,

Phillips screwdriver

The PHS device is delivered on a 1200 x 800 [mm] pallet, protected by a cardboard box lled with foams and foils.

1. Unwrap the security foil from the pallet.

2. Remove the security cardboard and remove the foam llers and edge protectors.

3. Visually check that the device has not been damaged during transport (visible dents, scratch damage to the casing).

If any, stop the installation and contact Sinterit Technical Support (https://www.sinterit.com/support-page).

4. Remove the foil protected elements of the Metal shelf 13 and the PHS User Manual from 2nd Drawer 8.

5. On the pallet, under the PHS device, are two elements

of the Slope ramp A. Cut off the clips holding the

ramp components

A

Image. 5. During transport, the Slope ramp

is located under the PHS device.

6. Place the Slope ramp A next to the pallet, always on the side of the Sifting module door (image 6).

7. Match both ends of the Slope ramp Awith the guide rail on a pallet B. Check the connection to ensure that it does

not disconnect during the PHS downhill (image 7).

A

A

3 m

Image. 6: Correct positioning the Slope ramp to the pallet.

15 | POWDER HANDLING STATION Manual

B

Image 7. Correct mounting of the Slope ramp Ato the guide rail on a pallet B (detailed view).

8. Unscrew screws the PHS device from the clamping

angles bars to the pallet C. The angles are on both

shorter sides of the device. The location of the screws

underneath the device is shown by the markers (image

8). To unscrew the screws (two for each angle, size

M10x40) use the service wrench F; select the side

with 1 point - size 17.

C

Image 8. Location of the angles that secure

the PHS to the pallet.

9. Unscrew screws xing the angle bar to the pallet

from the side of the Slope ramp, see picture opposite.

Remove it to allow the device to slide freely off the

pallet.

C

Image 9. Location of the screws securing

the angle bar to the pallet.

POWDER HANDLING STATION Manual | 16

10. Set all castors correctly and unlock the brakes on the

front castors.

11. Carefully, with the help of another person, slide the

PHS device off the pallet (image 10). Watch out for the

feet when the device sliding off from the Slope ramp!

12. We recommend that you position the device directly at

your target workplace.

13. Lock the brakes on the castors of the PHS.

EXIT DIRECTION

PUSH SECURE THE DESCENT

Image 10. The correct way to remove PHS

from the transport pallet.

14. Remove the transport safety catches from the Drawers 7, 8, 9. Remove the Suction hose 3with Clamp 39 from

the Drawer 9.

15. Connect Suction hose 3to the device using the supplied Clamp [39]. Tighten the Clamp using the Service wrench,

size 10 (two points) (image 11).

16. Place the Suction Handle in the Suction Handle socket on the PHS worktop 4.

INSTALL AND SCREW

CAREFULLY INSERT IT INTO THE SOCKET

39

3

3

4

Image 11. Locations of the Suction hose installation to the PHS device.

17 | POWDER HANDLING STATION Manual

17. Make sure that the red band on the Suction Handle

socket 4is completely covered by the Suction Handle

3. Only then is the suction system leakproof (image

12).

Image 12: Incorrect and correct seating

of the Suction Handle in the socket.

18. Peel off the transport safety catches from the grid of the Powder Chamber 1and the Fine Dust Chamber 2on

the PHS worktop.

19. Place the Powder Tools accessories on the PHS

Toolboard 6 (image 13).

20. Remove the Anti-noise headphones and the nozzles

for the Suction Handle from the rst Drawer 8and

place them on the Toolboard 6 (image 13).

Image 13. The positioning of additional accessories

on the Toolboard.

21. Place the Trowel, delivered with the printer, in drawer

1 7.

22. Place the IO Box, delivered with the printer, in drawer

2 8.

23. Place the Powder Funnel in an empty Spare Metal

container in drawer 3 9.

Image 14: Arrangement of accessories in PHS Drawers.

24. Install the Metal shelf for sandblaster or Foldable Tray

13 . Adjust the height of your device.

• The markers on the PHS device will help you choose

the height and orientation to match the appropriate

model of sandblaster from the Sinterit offer.

• There are sets of 3 mounting holes in the Metal

shelf, we recommend using the bottom lowest ones

(marked) but you can adjust the shelf height for your

comfort and use different mounting holes.

Image 15. Two assembly heights adapted to both Sinterit

Sandblaster and Sinterit Sandblaster XL.

POWDER HANDLING STATION Manual | 18

For easy installation of the Metal shelf to PHS you will need:

Two persons Service wrench 17/10 F

(1 point - size 17, 2 points - size 10)

25.a. Screw on the rst Metal shelf element. One person holds the element at the right height while the other screw two

screws into the dedicated positions. Check the stability of the connection (image 16a).

25.b. Screw on the second part of the Metal shelf, just like the rst. Check the stability of the connection (image 16b).

25.c. Screw on the platform connecting the two Metal shelf elements. One person is holding the platform while the

other is tightening 4 screws. Check the stability of the connection (image 16c).

a b c

Image 16. Steps in the installation of the Metal shelf for the Sandblaster.

25. Connect the grounding of the vacuum cleaner correctly (see Sinterit ATEX Vacuum Cleaner user manual).

26. Connect the Sinterit ATEX Vacuum Cleaner, using the supplied Antistatic hose, to the Connector for Antistatic hose

in the PHS 12 (image 17).

27. Connect the power supply to the vacuum cleaner

12

Image 17. Connection of the Sinterit ATEX Vacuum Cleaner to the PHS.

19 | POWDER HANDLING STATION Manual

Table of contents

Other SINTERIT Industrial Equipment manuals