Foreseen

Use

Of

The

Tool

-

5062

Thisdie grinder isprimarilydesignedfor usewith

bonded

abrasive mountedpointgrindingwheels. It may also beusedwith steelrotary

filesand carbide

buns

providedtheir speed ratingmatches the speedof the grinder.

This tool should not be fitted withcut offwheels, saw blades, drill bits, etc. Ifthere Isany doubt about the correct use of this product

contactyour supplierfor advice.

Also makesure that the shank sizeof the attachmentto bedrivenmatcheswith thecolletsize fined inthegrinderandthat the maximum

allowedrunningspeed of the attachment exceedsthat marked onthegrinder.

There are special rulesgoverningthe use of bonded abrasivemountedpoint grindingwheels

-

for detailssee section "Operating."

Work

Stations

Thetoolshouldonlybe usedasa handheld, handoperatedtool. Itisalwaysrecommendedthat thetoolisusedwhenstandingona solid

floor.Itcanbeusedinother positions,but beforeany such use, the operatormustbeina secure positionhavinga firm grip and footing

andbe awareof the extra safetyprecautionsthat mustbe observed when usinggrindingmachines.

Putting Into Service

Air

Supply

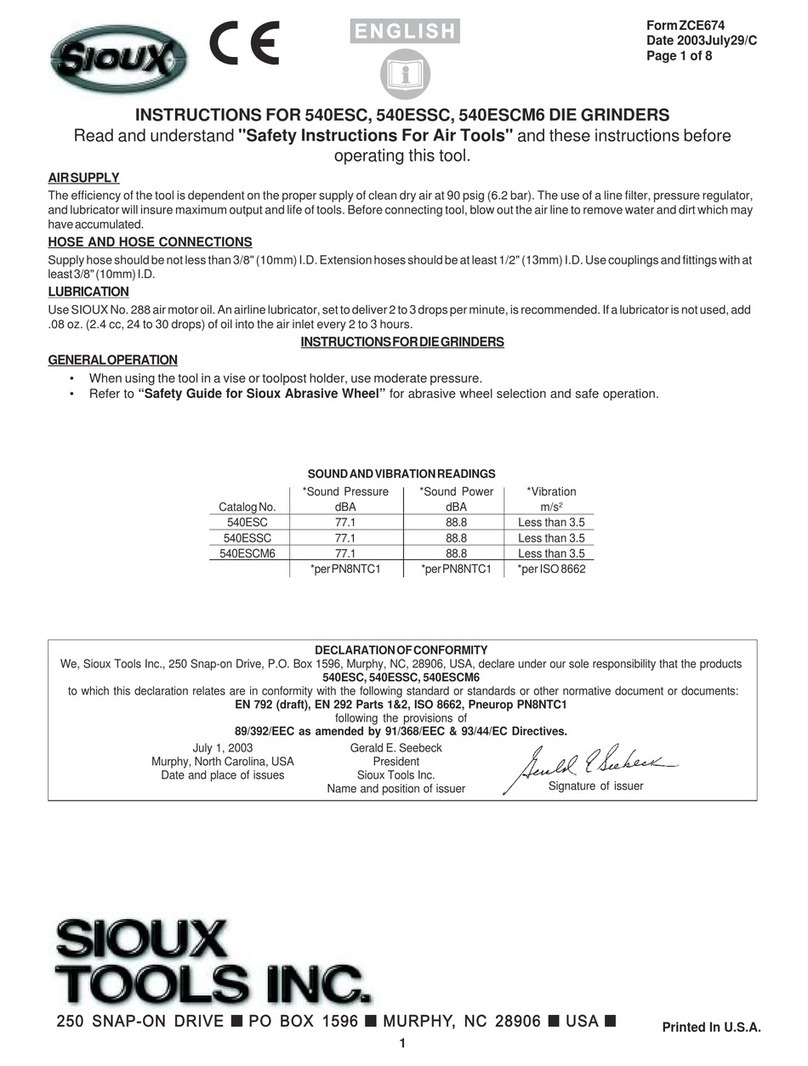

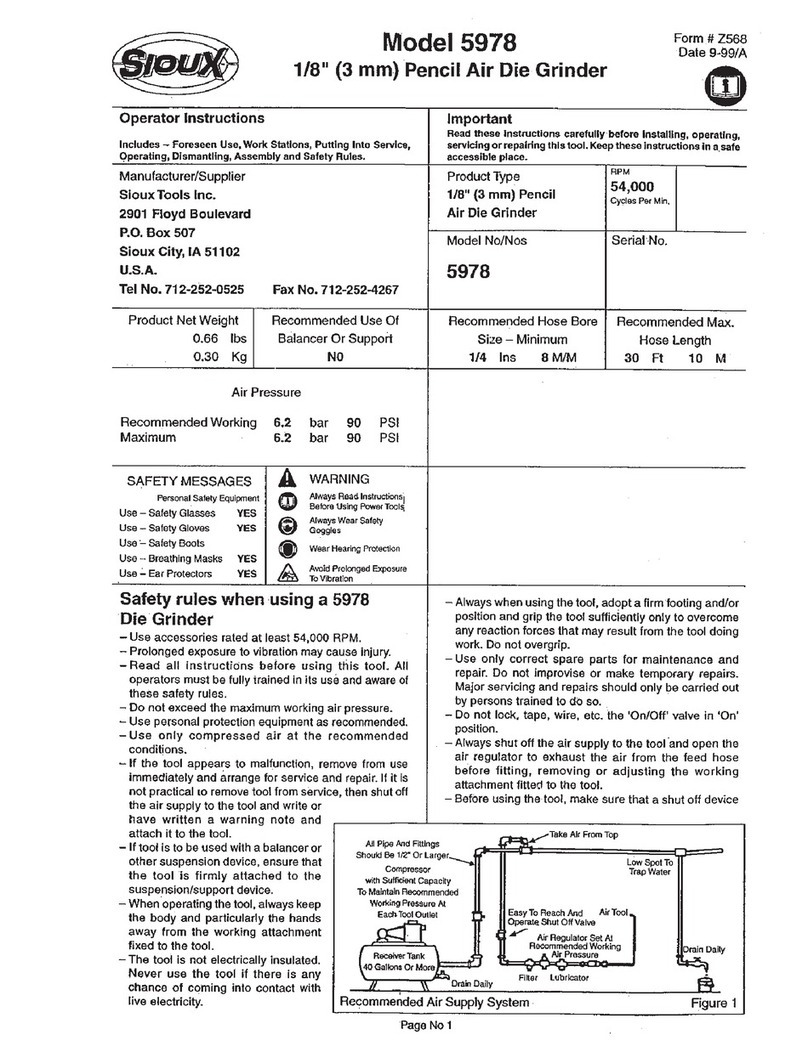

Usea cleanlubricatedairsupplythat willgivea measuredairpressureat the toolof 90 PSiG(6.2 bar)when the tool isrunningwith the

trigger~leverfully depressed.Use recommendedhose size and length. Itis recommendedthat the tool Is connectedto the air supply as

shownInfigure 1.Do notconnectthetooltotheairlinesystemwithout Incorporatinganeasy to reachandoperateairshut off valve.The

air supplyshould belubricated. It is stronglyrecommendedthat an airfilter, regulator, lubricator

(FRL)

Isusedas shownin Figure

1

as

this will supply clean, lubricatedair at the correctpressureto the tool. Detailsof such equipment can be obtainedfrom your supplier.

If

suchequipmentIsnotused, thenthetoolshouldbelubricatedbyshuttingoff theairsupplyto thetool, depressurizingthelineby pressing

thetriggeronthetool.Disconnecttheairlineandpourintothehoseadaptorateaspoonful(5ml)of asuitablepneumaticmotorlubricating

oilpreferablyincorporatinga rustinhibitor.Reconnecttoolto airsupplyandruntoolslowlyfor a few seconds to allow air to circulatethe

oil. If tool isusedfrequently, lubricateon dailybasisandif tool starts to slow orlose power.

Itis recommendedthat the air pressureat the toolwhile the tool is runningis 90 PSU6.2 bar.

Usinga screwdriver, turnthevalve (8) untiltheslotalignswiththe

center

line

of the tool tor maxlmum speedgnd power and roiate

1

Figure

2'

Gripping length

of

collet

and

chuck

Operating

Selecta suitable mountedpoint that

has

a freerunningspeed higherthan the maximum runningspeedmarked onthe tool.Makesure

thatthe diameterof the shank exactly matches the diameterof thecolletmountedInthe grinder.There are two standardsizes of collet

available for usewiththis grinder, i.e.,

1.

-

114" Dia.(0.250 ins)

(6.35

mm)

2.

-

6mm Dia. (0.236 ins)

Always matchcorrectlythe shank size to the colletsize. Ifuncertain, have partsmeasuredby a competent person.

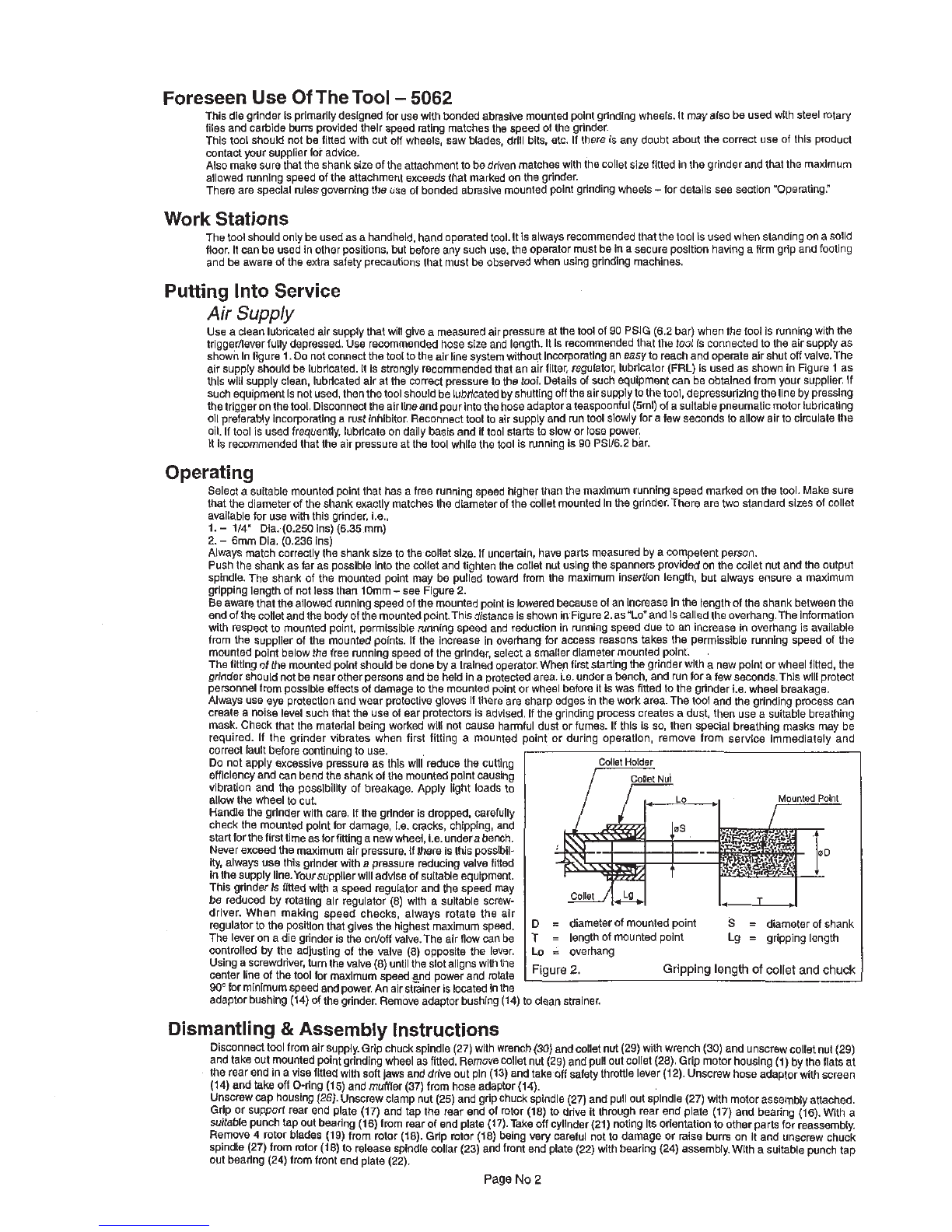

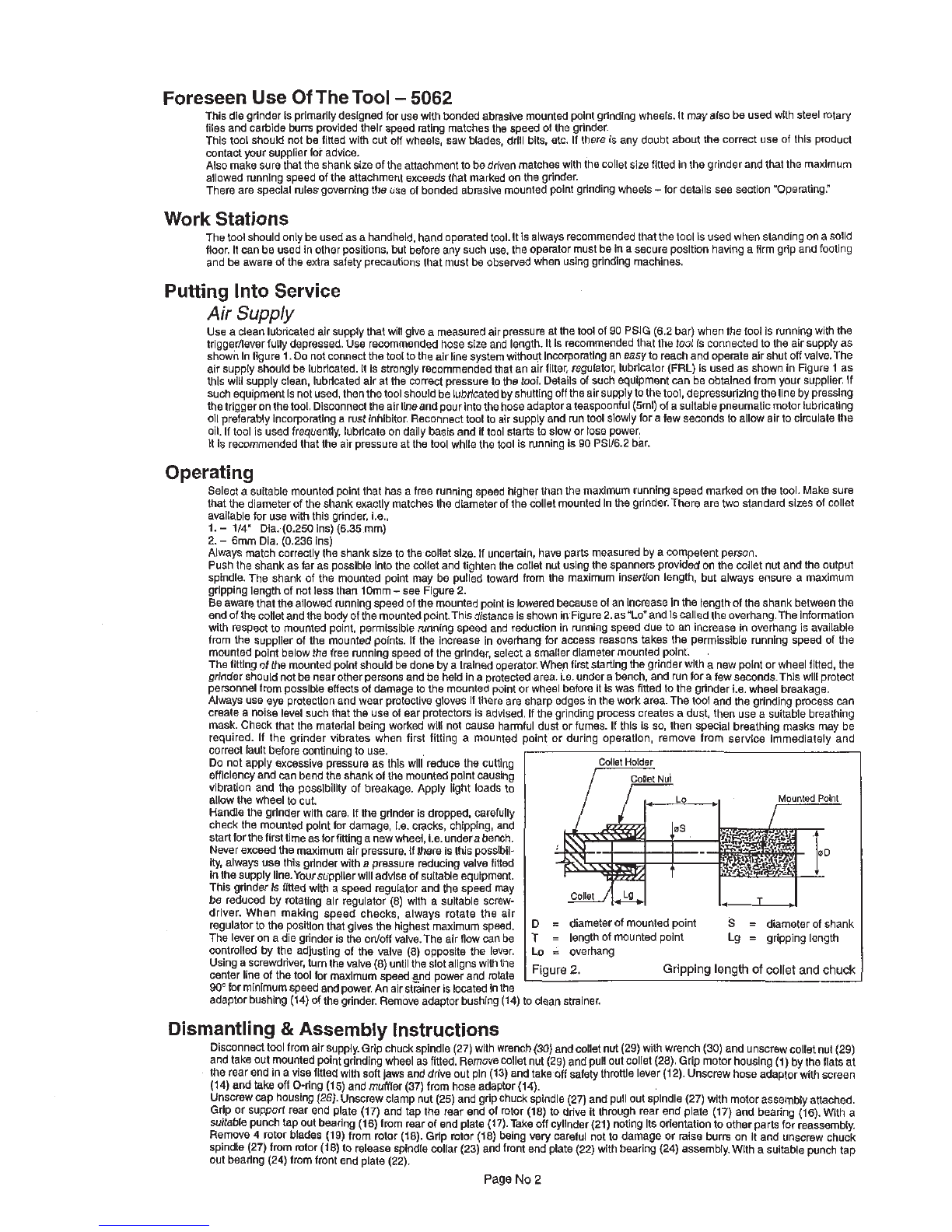

Pushthe shank

as

far

as possibleintothe colietand tightenthe collet nut usingthe spannersprovidedon the colletnutandthe output

spindle. The shank of the mounted point may be pulledtoward from the maximum insertionlength, but always ensure a maximum

grippinglengthof notlessthan 10mm

-

see Figure2.

Beawarethattheallowedrunningspeedofthe mountedpointisloweredbecauseof anIncreaseInthe iengthof the shank betweenthe

endof thecolletandthe bodyofthemountedpoint.Thisdistance isshowninFigure2.asULo'and iscalledthe overhang.Theinformation

with respectto mountedpolnt, permissiblerunningspeed and reductionin running speed due to an increase inoverhangis available

from the supplier of the mountedpoints. It the Increasein overhang for access reasons takes the permissible running speed of the

mountedpoint belowthe free runningspeedof thegrinder, select

a

smallerdiameter mountedpoint.

The fitting of the mountedpointshould be done by

a

trainedoperator.Whenfirst startingthe grinderwitha newpointorwheel fitted, the

grindershouldnotbenearotherpersonsandbe heldin

a

protectedarea. 1.e. under

a

bench,and runforafew seconds.This willprotect

personnelfrompossibleeffects of damageto the mountedpolntor wheel before itiswas fitted to the grinderi.e. wheel breakage.

Always use

eye

protectionandwear protective gloves

If

there are sharp edges inthework area. Thetool and the grinding process can

create

a

noiselevelsuchthat the useof ear protectorsis advised.If the grindingprocesscreates

a

dust, then usea suitablebreathing

mask. Check that the materialbeingworked will not cause harmfuldust or fumes. If this is so, then special breathingmasks may be

required. If the grinder vibrates when first fitting

a

mounted point or during operation, remove from service immediately and

90'

for minimumspeedandpower.Anairstrainerislocatedinthe

adaptorbushing(14)of thegrinder. Removeadaptorbushing

(14)

to cleanstrainer.

correctfault beforecontinuingto use.

Do notapply excessive pressureas this will reduce the cutting

efficiencyandcanbendthe shankof the mountedpointcausing

vibration and the possibilityof breakage. Apply light loads to

allowthe wheel to cut.

Handlethe grinderwith care. If the grinder is dropped, carefully

check the mountedpolnt for damage, 1.0. cracks, chipping,

and

startfor thefirsttimeasforfittinganewwheel, i.e. underabench.

Neverexceedthemaximumairpressure.Ifthereisthis possibii-

ity, alwaysuse this grinder with

a

pressurereducing

valve

fitted

inthesupplyline.Your supplierwilladviseof suitableequipment.

This grinderIs liltedwith

a

speed regulatorand the speedmay

be reduced by rotating alr regulator (8) with a suitable screw-

driver. When making speed checks, always rotate the air

regulatorto the positionthat gives the highest maximumspeed.

The lever on a die grinder is the ontoffvalve,Thg air flow

can

be

controlled by the adiustino of the valve

(81

ODDOS~~~

the lever.

Dismantling

&

Assembly

Instructions

Disconnecttoolfromairsupply.Gripchuckspindle (27)with wrench

(30)

andcolletnut(29)withwrench

(30)

andunscrewcolletnut(29)

andtake out mountedpointgrindingwheel as fitted.Removecolletnut

(29)

andpulloutcollet (28).Grip motor housing

(1)

bythe flats at

therearendIna vise fittedwithsoftjaws and driveout pin(13)andtake off safetythrottlelever(12).Unscrewhoseadaptorwithscreen

(14)

and

take

offO-ring (15)and muffler (37) from hoseadaptor

(14).

Unscrewcap housing(26).Unscrewclamp nut

(25)

andgripchuckspindle(27)andpullout spindle(27) with motorassemblyattached.

Gripor support rear end plate (17) andtap the rear end of rotor (18) to drive it through rear end plate (17) and bearing (16). With a

suitablepunchlap out bearing

(16)

fromrearof endplate (17).Takeoff cylinder(21) noting

US

orientationto other partsfor reassembly.

Remove

4

rotorblades

(19)

from rotor

(18).

Grip mtor (18) being

very

careful notto damage or raise burrs on it and unscrew chuck

spindle (27)from mtor (18)to releasespindlecollar (23) andfmnf endplate

(22)

with bearing(24) assembly.Witha suitablepunchtap

out bearing(24) fromfront end plate (22).

Collet

Holder

D

=

diarderof~'~~ountedpoint

S

=

diameterof shank

T

=

lengthofmountedpoint Lg

=

gripping length

Lo

=

overhand

Page

No

2