GROUNDING

INSTRUCTIONS

In

the

event

Qf

a malfunctiQn

Qr

breakdQwn,grQunding

provides a

path

Qf

least

resistance

fo.r

electric

current

to.

reduce

the

risk

o.f

electric shock.

This

to.o.l

is equipped

with

an

electric

co.rd

having

an

equipment-gro.unding

cQnducto.r

and

a gro.unding plug.

The

plug

must

be plug-

ged into. a

matching

o.utlet

that

is properly

installed

and

gro.unded in accQrdance with all local codes

and

o.rdi-

nances.

Do.

no.t

mo.dify

the

plug

pro.vided -

ifit

will

no.t

fit

the

o.utlet,

have

the

pro.per o.utlet installed by a qualified

electrician.

Impro.perco.nnectio.n

o.f

the

equipment-gro.unding

co.n·

ducto.r can

result

in a risk

o.f

electric sho.ck.

The

co.nduc-

to.r

with insulatio.n

having

an

Quter

surface

that

is green

with

o.r

withQut

yello.w

stripes

is

the

equipment-

gro.unding co.nducto.r.

If

repair

Qr

replacement

Qf

the

electric

cQrd

Qr

plug is necessary.

do.

nQt

connect

the

equipment-gro.unding co.nducto.r

to.

a live

terminal.

Check with a qualified electrician

o.r

serviceman

ifthe

grQunding

instructions

are

not co.mpletely understood,

o.r

ifindo.ubt

as

to.

whether

the

to.ol

is pro.perly gro.unded.

Use

o.nly

3-wire extensio.n

co.rds

that

have

3-pro.ng

gro.unding plugs

and

3-po.le receptacles

that

accept

the

to.o.rs

plug.

Repair

o.r

replace

damaged

o.r

wo.rn

co.rd

immediately.

"GlOUNQIO"

0."

..

e

••

~

~GrOundlng

terminal

Aa.FlU

eyelet

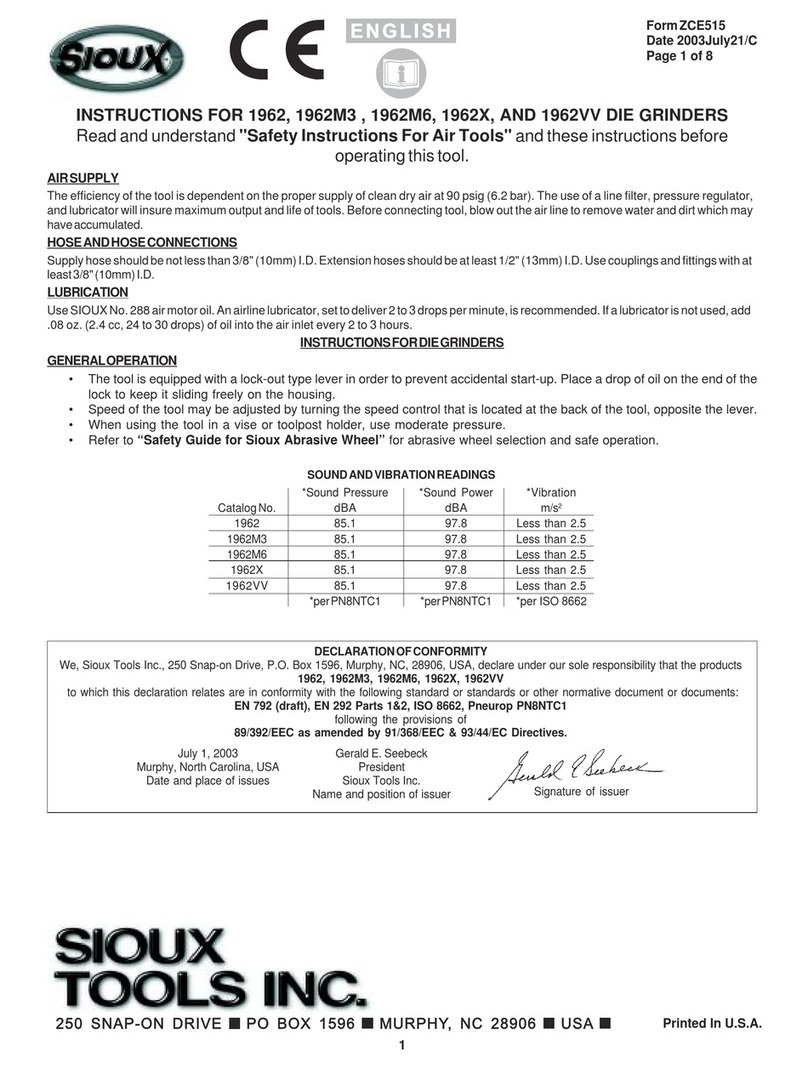

This

to.o.l

isfactory wired

fo.r

115Vo.peratiQn

fo.r

use

o.n

a

circuit

that

has

an

o.utlet

that

Io.o.ks

like

the

o.ne

illustrated

in

Sketch A

in

Figure

72.1.

The

to.Ql

has

a

grounding

plug

that

lo.o.kslike

the

plug

illustrated

in

Sketch A

in

Figure

72.1. Atempo.rary

adapter,

which

lo.o.ks

like

th

~

adapter

ill

ustrated

in

Sketches

Band

C, may be used

to.

co.nnect

this

plug

to.

a

2-po.le

receptacle

as

sho.wn in Sketch B

if

a pro.perly gro.unded

o.utlet isno.t available.Thetempo.rary

adapter

shQuld be used

o.nly

until

a pro.perly gro.undedo.utletcan be

installed

by a qualifiedelectrician.

The

green-co.lo.red

rigid

ear,

lug. etc.

extending

fro.m

the

adapter

must

be co.nnected

to.

a

permanent

gro.und

such

as

a pro.perly gro.unded

o.utlet

bo.x.

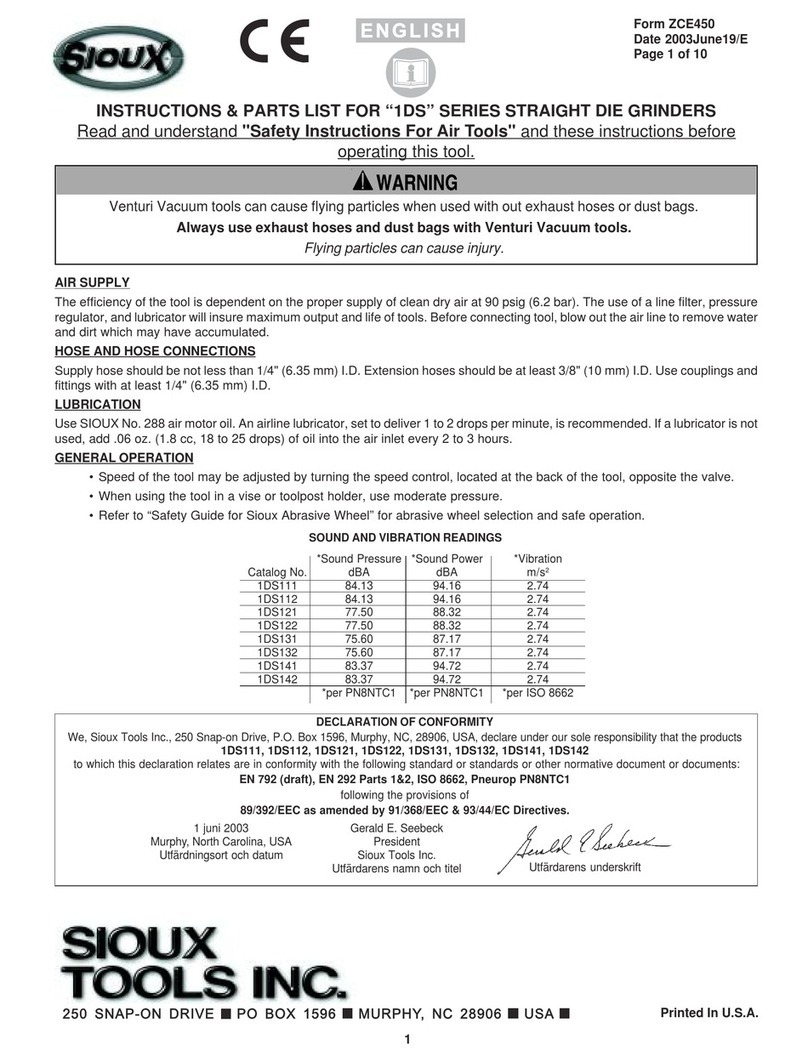

DUAL VOLTAGE CONVERSION

On

grinders

having

dual

voltage capability, convert to 230V by

fo.llo.wing

wiring

instructio.ns

and

warnings

located inside base.

Fo.r

230V

o.peratiQn, o.utlet

bo.x

must

look

like

Figure

C. Co.rd

plug

must

be replaced with

plug

as

per

Figure

C.

PERMANENTLY CONNECTED TOOLS

This

to.o.l

sho.uld be connected

to.

a gro.unded,

metal,

permanent

wiring

system;

o.r

to.

a

system

having

an

equipment-gro.undingco.nducto.r.

MAINTENANCE

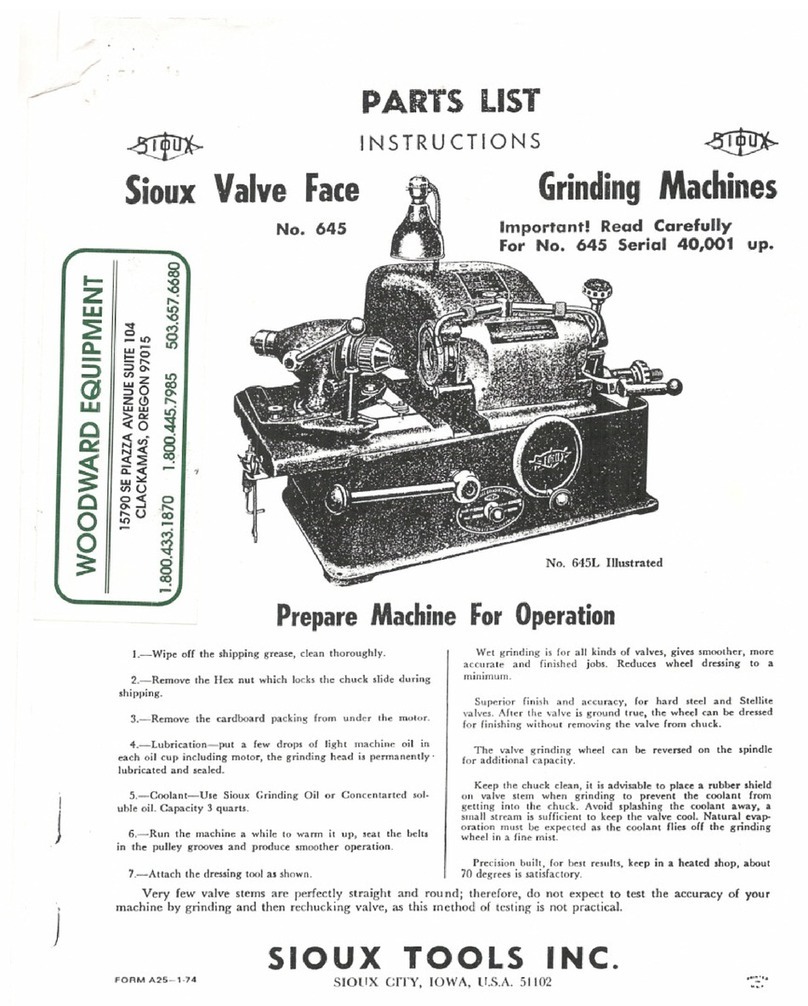

The basic grinderrequires no periodic maintenance as it is equipped with sealed ball bearings.

VIBRATION/NOISE.

Vibrationsaregeneratedentirelybythecondition

of

balance

of

thewheel. Grinding wheelsrequire periodic

truing up with a wheel dresser.When replacing wheels use only industrial grade balance wheels suitable

for

the RPM rating

of

the machine. NOTE: The rotary switch will

"click"

in and make a slight rubbinglsqueaking sound when the grinder

is

slowing

down which

is

normal.

PLEASE

DO

NOT

RETURN

GOODS TO

US

WITHOUT

OUR

SHIPPING

INSTRUCTIONS