Form

#

Z440

Model

5268

Date2-02lA

Angle

Disc

Grinder

4

112

Dia. Disc

C?

@

Ã

IMPORTANT

I

I

Readtheseinstructionscarefullybefore installing,operating,servicingor repairingthis

tool. Keepthese instructionsin

a

safe accessible place.

w

1

SAFETY MESSAGES

1

A

WARNING

1

Operator Instructions

-

Wear safety goglesof the impacttype.

-

Neverusethe tool if

the

disc guardisnotfitted.

-

Useaccessoriesratedat least 12,000 RPM.

-

Prolongedexposureto vibration maycause injury.

-

Readallinstructionsbeforeusingthistool. All operators

must

befullytrainedinits

use

andawareof thesesafetyrules.

-

Donotexceedthe maximumworkingair pressure.

-

Usepersonalprotectionequipment as recommended.

-

Some dustcreatedby powersanding, sawing, grinding,

drilling, and other construction activities contains

chemicalsknowntocausecancer, birthdefectsandother

reproductiveharm.

-

Usecompressedaironlyatthe recommendedconditions.

-

If the tool appears to malfunction, remove from use

immediatelyandarrangefor serviceandrepair.If itisnot

practicaltoremovetoolfromservice, thenshutofftheair

supply to the tool and write or have written a warning

noteandattachittothetool.

-

Iftool is to be usedwith a balanceror other suspension

device, ensure that the tool is firmly attached to the

suspension/supportdevice.

-

When operating the tool, always keep the body and

particularlythehandsaway fromtheworking attachment

fixedto the tool.

-

The toolis not electrically insulated.Neverusethe toolif

there is any chance of coming into contact with live

electricity.

-

Always when usingthe tool, adopta firmfooting and/or

position and grip the tool sufficiently only to overcome

any reactionforces that may resultfrom the tool doing

work. Donotovergrip.

-

Useonly correctsparepartsfor maintenanceandrepair.

Do not improvise or make temporary repairs. Major

servicing and repairs should only be carried out by

personstrainedto do so.

-

Donot lock, tape, wire, etc.the

'On/Off'valve

inWposition.

The throttletrigger~lever,etc.mustalwaysbe

free

to returnto

the

"Off"

positionwhenreleased.

-

Alwavsshutofftheairsu~~lvtothetool

,

Personal

Safety

Equipment

Use

-

Safety Glasses

YES

Use

-

Safety Gloves

YES

Use

-

Safety Boots

YES

Use

-

BreathingMasks

Use

-

Ear Protectors

YES

andDressthe'On/~ff'valvetoexhaust

1

the air from the feed hose before

fitting, removing or adjusting the

working attachment fitted to the tool.

-

Before using the tool, make sure that a

shut off device has been fitted to the

supplylineandthe

position

is

known

and

easilyaccessibleso thatthe air supply to

thetoolcanbeshutoff in

an

emergency.

-

Checkhoseandfittings regularlyforwear.

-

Take care against entanglement of the

movingpartsof thetoolwithclothing,hair,

ties,cleaningrags,rings,jewelry, watches,

bracelets,etc.This couldcausethe

body

or partsof the bodyto be drawntowards

andincontactwiththemovingpartsof the

Safety ruleswhen usinga

5268

DiscGrinder

Always ReadInstructions Before

a

Using PowerTools

@

AlwaysWear SafetyGoggles

@

Wear HearingProtection

Avoid ProlongedExposure

A

ToVibration

toolandcould

be

verydangerous.

-

Itisexpectedthatuserswilladoptsafeworkingpractices

and observe all local, regional or country legal require-

mentswhen installing,usingor maintainingthe tool.

-

Takecarethatthe exhaustairdoes notpointtowardsany

other person or material or substance that could be

contaminatedbyoildroplets.When first lubricatinga tool

or if the tool exhausthas a highoil content, do notallow

theexhaustairto comenearvery hotsurfacesor flames.

-

Never lay thetooldownuntilthe working attachmenthas

stoppedmoving.

-

When the tool is not in use, shut off the air supply and

pressthrottle triggerllever to drain the supply line. If the

tool is notto be usedfor a period of time, first lubricate,

disconnectfromairsupplyandstoreinadryaverageroom

temperatureenvironment.

-

If the tool is passedfrom one user to a new or inexperi-

enceduser, makesurethese instructionsareavailableto

bepassedwiththe tool.

-

Do not remove any manufacturerfitted safety devices

where fitted, i.e., wheel guards, safety trigger, speed

governors, etc.

-

Whereverpossible,secureworkpiecewithclamps,avise,

etc. to make it rigidso it does not move during the work

operation. Keepgood balanceat alltimes. Do not stretch

or overreach.

-

Try to matchthetooltothe work operation.Do notusea

tool that istoo light or heavy for the work operation. If in

doubt, seek advice.

-

Ingeneralterms, this tool is not suitable for underwater

useor useinexplosiveenvironments

-

seekadvicefrom

manufacturer.

-

Trytomakesurethatthework area

is

clearto enablethework

task to

be

performedsafely. If practicaland possible,

try

to

dearunnecessaryobstructionsbefore

starting

work.

-

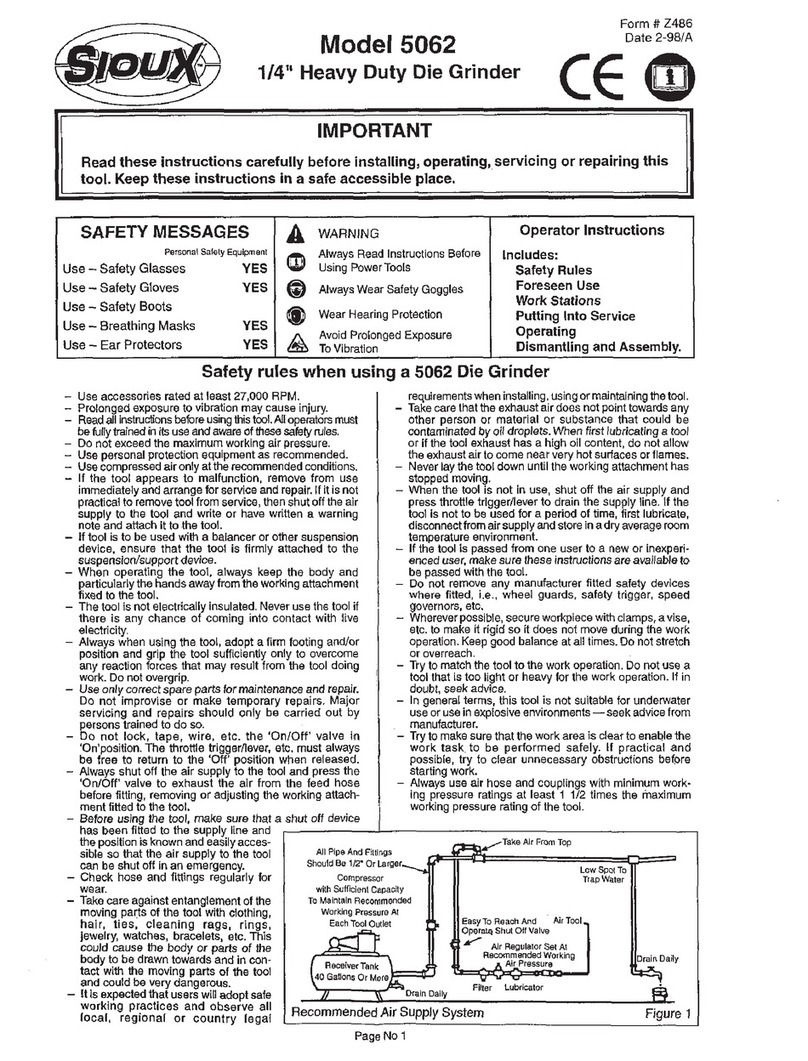

Always use air hose and couplings with minimum

working pressure ratings at least 1 112 times the

maximumworking pressureratingof the tool.

Includes:

Safety Rules

ForeseenUse

Work Stations

PuttingIntoService

Operating

Dismantlingand Assembly.

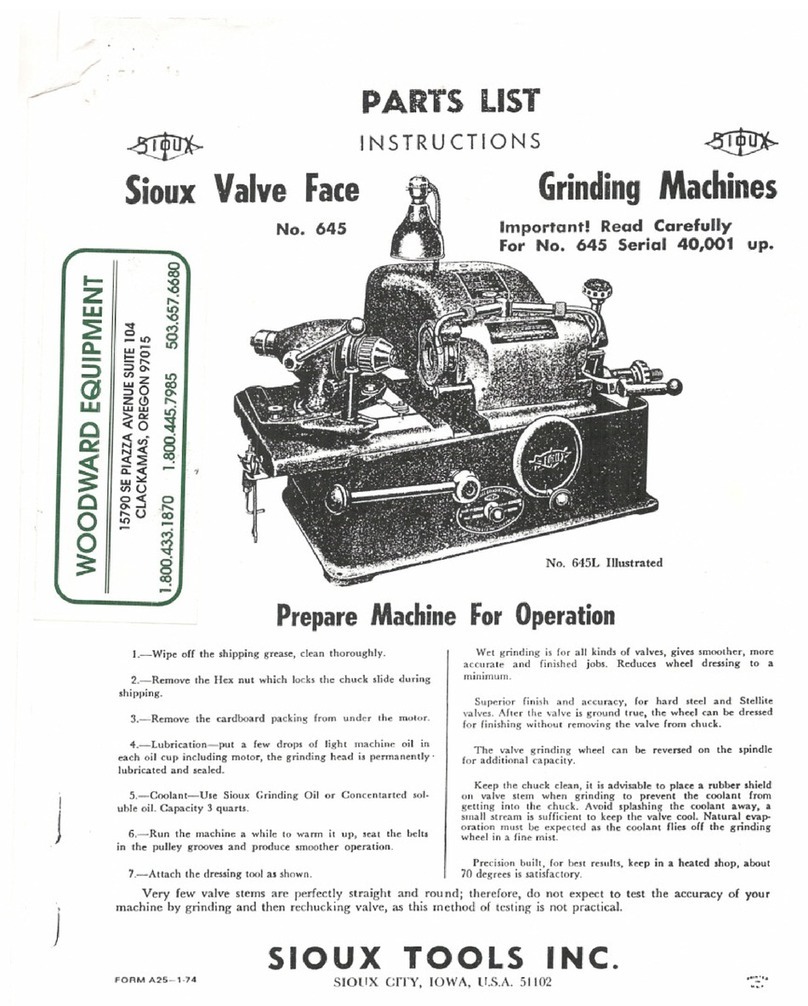

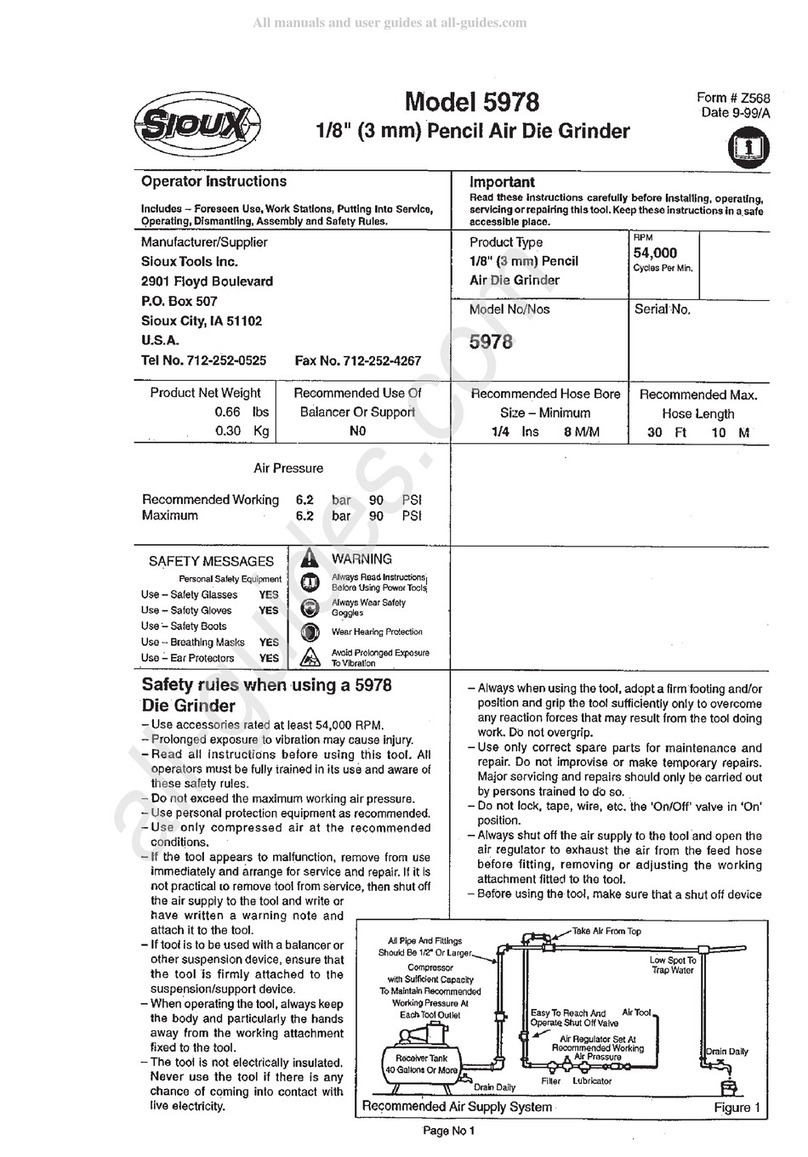

RecommendedAir Supply System Figure

1

PageNo 1