(4)

GENERAL INFORMATION

assembled on a level flat surface.

1) At the time of delivery, be sure to check all bundles

and parts for proper quantity and condition. If a

shortage or damage has occured, DO NOT ACCEPT

DELIVERY without making note on the freight or delivery

receipt. If shortage or damage is found, notify your

carrier immediately, so they can send an inspector

to make a formal report. Compliance with carrier's

procedure is essential for settlement of a claim as the

Company's responsibility ends when the carrier receives

shipment.

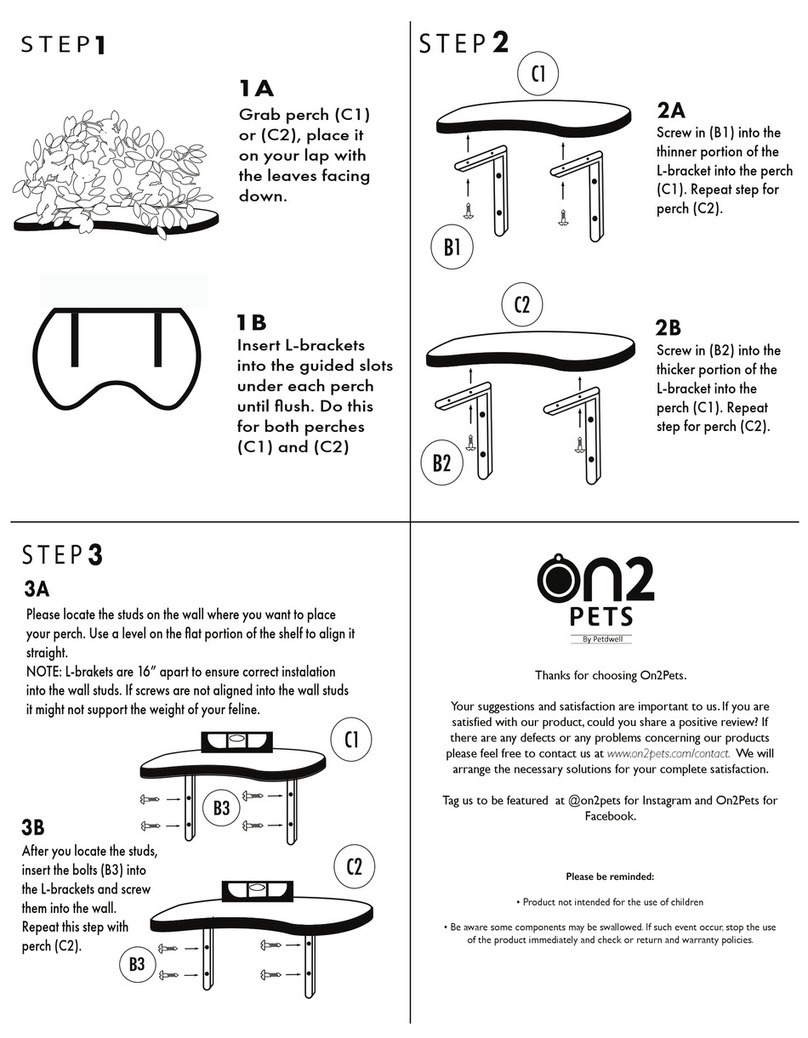

2) Carefully read and understand this manual before begining

construction of the Calving Pen Care Center.

Refer to parts identification diagrams on Pages 7 - 10

to familiarize yourself with each component and its

relative location in the final assembly. A detailed assembly

diagram is also included with each assembly step.

3) This manual shows the optional 191470PG Headgate Assembly

and the optional 168701 Step Plate.

4) It is recommended that the Calving Pen Care Center be

MANUAL NO. 15516