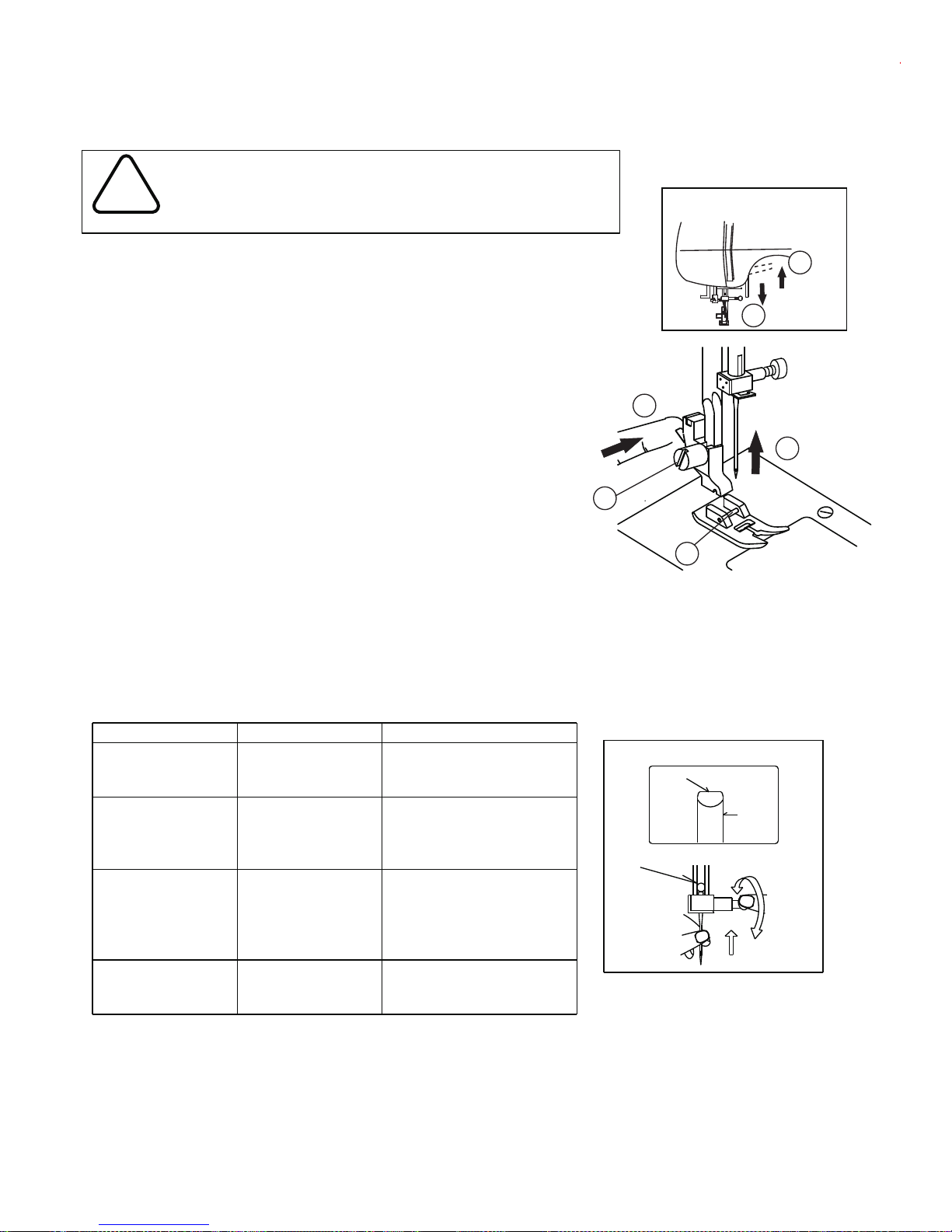

CHANGING THE PRESSER FOOT

The presser foot must be changed according to the stitch you sew, or work you do.

CAUTION:To prevent accidents.

Turn off the power switch before you change the presser foot.

1.Turn the hand wheel toward you until the

needle is at its highest point.

2.Raise the presser foot lifter.

3.Remove the presser foot by pushing the

presser foot release lever toward you.

4.Place desired foot with its pin directly under

the slot in presser foot holder.

5.Lower the presser foot lifter and the presser

foot will snap into place.

REMOVING THE PRESSER FOOT HOLDER

5

A

3

4

1

!

You may need to remove the presser foot holder to use

some presser feet.

To remove, raise the presser foot lifter and loosen the

presser foot thumb screw (A).

To attach, tighten the screw after raising the presser foot

holder.

2

-6-

weight woolens,linen.

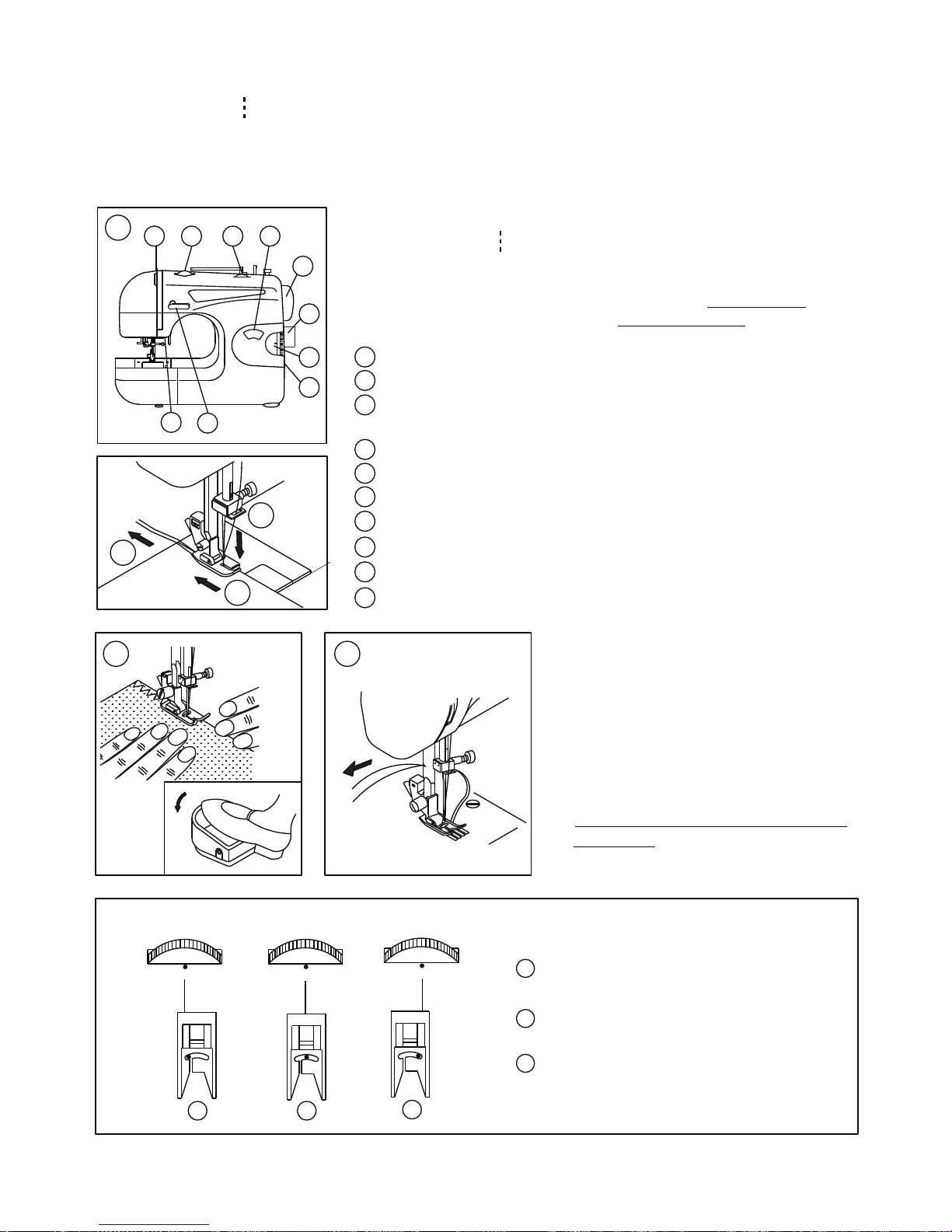

1.Raise the needle bar to its highest position by turning the hand wheel towards you.

weight woolens,denim

Heavy weight cotton,

2: Needle

illustration 1: Flat side 3.Stop

6.Tighten the needle clamp screw firmly with the screw driver.

5.Push the needle up as far as itcan go.

4.Insert the new needle into the needle clamp with the flat side away from you.

3.Remove the needle by pulling it downward.

2.Loosen the needle clamp screw by turning it towards you.

Changing the needle

Mercerized heavy

duty

Cotton 30-60

100 medium to heavy

gingham,velvet,light

poplin,seersucker,

medium weight synthetics,

Medium weight cottons,

synthetics,fine laces,

For normal sewing,the same size and type of thread should be used in the bobbin as

Use the standard needle.The size of your needle should match the size of the thread

Mercerized 50-60

Machine embroidery

Machine embroidery

For successful sewing of stretch fabrics use stretch needles.

Never use a bent or blunt needle.

on the upper part of the machine.

and both should match the fabric.

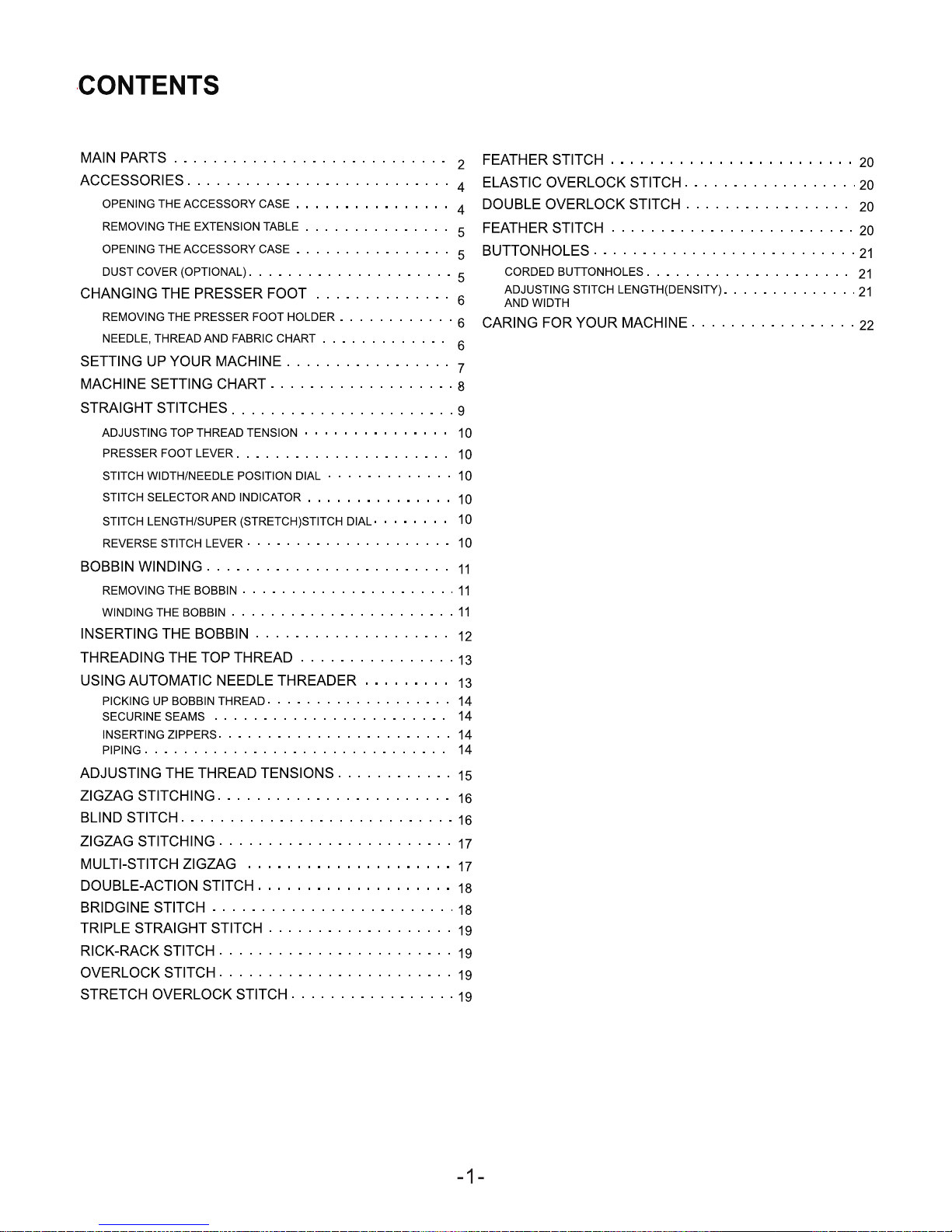

NEEDLE,THREAD AND FABRIC CHART

Cotton 60-100

Sillk A

Synthetic

Cotton 60-80

Synthetic

Cotton

Synthetic

Thread Size

All stretch fabrics.

Stretch

80

or

90

80

or

70

Needle

batiste,dimity.

Sheer cottons silk

Needle Size Needle Size

3

2

1