Sisis DART User manual

DART

INSTRUCTION MANUAL

SP20015_REV3

OCTOBER 2017

2

CERTIFICATE OF CONFORMITY

Variseeder 1300 CN Code: 84323011

Manufacturer:- Howardson Ltd, Howardson Works, Kirk Langley, Derby, DE6 4NJ. UK

Owner of Technical Document:- Mr I.D. Howard, Howardson Ltd, Howardson Works Kirk Langley, Derby, DE6 4NJ, UK

I the under signed Declare that these machines:-

Model: DART Measured Sound Power Level: 79dB Lwa Guaranteed Sound Power Level: 98dB Lwa

The reliability and quality of performance of the SISIS DART depends upon some simple care maintenance

carried out regularly. This manual has been prepared to allow the user to carry out all such work.

It is advisable to read the instructions carefully. Proper care and attention will enable the machine to give a continuous,

satisfactory, and reliable service. Failure to carry out regular lubrication and maintenance as outlined in this manual may

render any guarantee or warranty invalid.

In the case of any difficulty, or if further information or advice is required, our Service Department is always at your call. In

the interests of speed and accuracy of information please quote the serial numbers of the machine and engine when

making enquiries.

For the machine, this is to be found on a plate attached to the side frame. The engine number is stamped

on either the crank case or the gear casing facing towards the front of the machine. We suggest you write

the numbers on the front page of this book.

INTRODUCTION

SERIAL NUMBERS

Tested at:- Howardson Works test site September 2012

Complies with the applicable requirements of:-

- Machine Directive 2006/42/EC

- Noise Directive 2000/14/EC (annex VI Procerure 1)

Ian Howard

Managing Director

MACHINE SERIAL NUMBER

NOTE:- MAKE A NOTE OF THE SERIAL NUMBER OF YOUR MACHINE AND ALWAYS

QUOTE IT IN ANY COMMUNICATION WITH PERSONNEL AT DENNIS.

ENGINE SERIAL NUMBER

SP20015_REV3

OCTOBER 2017

3

CONTENTS

IMPORTANT SAFETY INTRODUCTIONS

TECHNICAL DATA

CAUTION:- READ THE INSTRUCTIONS. We want you to obtain the best performance from this

machine. If you have any difficulty in carrying out the following instructions please contact

your local SISIS dealer.

NEVER

•Carry out adjustments whilst the machine is running.

•Allow any unauthorised person to handle machines in any way at any time.

ALWAYS

•Read the operating instructions carefully and understand the controls before commencing work.

•Be extra careful to avoid spillage, when using petrol or diesel fuel. DANGER no smoking or naked flames.

•Use safety guards and make sure they are correctly in position. They are supplied for your protection.

•Before starting work always visually check machine for damage or wear to parts.

•Look behind before starting to reverse and watch out for children or pedestrians.

•Respect powered machines. Always keep hands and feet clear of moving parts and remember that tine cylinders or

drums can continue to rotate even after the power unit is switched off.

•Switch off the power before making adjustments or repairs and never lift or carry a machine whilst any parts are moving.

EYE PROTECTION

In dry, dust or windy conditions it may be necessary to wear eye protection to protect your eyes from flying debris.

FIRE HAZARD

Always clean the machine. Remove all debris from around the engine. Blocked engine cooling fins can cause the engine to

over heat.

Page

Declaration of Conformity...................................................................................................................................................... 2

Serial Numbers...................................................................................................................................................................... 2

Introduction............................................................................................................................................................................ 2

Technical Data....................................................................................................................................................................... 3

Important Safety Instructions...............................................................................................................................................3-4

Operating Instructions............................................................................................................................................................ 5

Maintenance …………………................................................................................................................................................. 6

Tines …………………………………………………………………………………………………………………………………..….7

Parts Listings.................................................................................................................................................................. P0-P9

MODEL DART

WIDTH (mm) 680

LENGTH (mm) 1550

HEIGHT (mm) 1180

ENGINE GX160

WEIGHT (Kg) 217

WORKING WIDTH (mm) 16” (430mm)

Wheels –Rear

Wheels –Front (2) 13 x 6.50-6 slick

(2) 260 x 85-3.00-4 ribbed

Hand Arm Vibration (𝑚/𝑠𝑒𝑐2) 9.5

Measured Sound Power Level (dB(A)) 80

Guaranteed Sound Power Level (dB(A)) 98

SP20015_REV3

OCTOBER 2017

4

IMPORTANT SAFETY INSTRUCTIONS

in order to operate the machine safely please follow these health and safety guidelines.

TRAINING

CAUTION -Read the instructions contained in this manual with care. If you are in any doubts ask

your employer or contact us direct at SISIS.

•Be familiar with the controls and the proper use of the equipment.

•Never allow children or people unfamiliar with these instructions to use the machine. Local regulations or insurance may

restrict the age of the operator.

•Never operate while people, especially children, or pets are nearby.

•Keep in mind that the operator or the user is responsible for accidents or hazards occurring to other people on their

property.

PREPERATION

•While operating always wear substantial footwear and long trousers. Do not operate the machine in bare foot or in open

sandals.

•Thoroughly inspect where the equipment is to be used and remove all stones, sticks, wire, bones and other foreign

objects

WARNING - petrol is highly flammable and will damage grass if spilt.

A. Store fuel in containers specifically designed for this purpose

B. Refuel outdoors and do not refuel whilst smoking.

C. Add fuel before starting the engine. Never remove the cap of the fuel tank or add petrol while the engine is running or

when the engine is hot.

D. If petrol is spilled do not attempt to start the engine but move the machine away from the area of spill and avoid creating

any sources of ignition until the vapours have dissipated.

•Replace damaged or faulty silencers

•Before using the machine always inspect the safety devices including the cut off switch and the blades for excessive wear

or damage. Replace if necessary.

OPERATION

•Do not operate in daylight or good artificial light.

•Operate only in daylight or good artificial light.

•Always be sure of your footing on slopes.

•Walk. Never run.

•Exercise extreme care on slopes when changing direction.

•Do not operate on excessively steep slopes.

•Use extreme caution when reversing or pulling the machine towards you.

•Stop the tines when transporting the machine.

•Never operate the machine with defective guards or shields or without the safety devices, for example without the

deflector plate or grass box in place.

•Do not change the engine governor settings or over speed the engine.

•Disengage all blades and drive clutches before starting.

•Start the engine carefully following the instructions with feet well away from the blades.

•Do not tilt the machine when starting the engine.

•Do not put hands or feet near or under moving parts.

•Never pick up or carry the machine while the engine is running.

SP20015_REV3

OCTOBER 2017

5

OPERATING INSTRUCTIONS

CAUTION –Please read these operating instructions carefully before commencing work.

We want you to obtain the best performance from this machine. If you have any difficulties in carrying out the following

instructions please contact SISIS direct or your local SISIS territory manager or SISIS dealer.

OPERATING PRINCIPLE

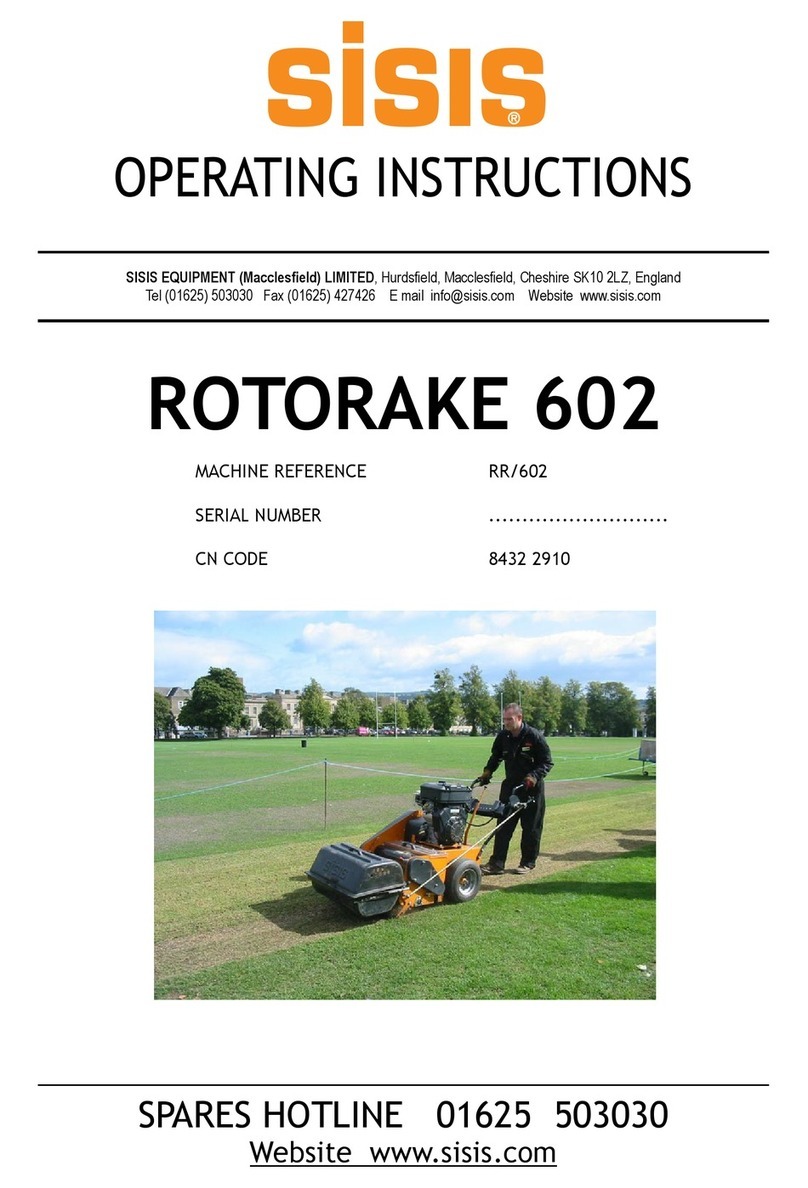

The SISIS DART is an engine driven vertical aerator for the use on fine turf areas such as bowling greens, tennis courts and all

areas of fine turf.

Offering clean vertical action of larger tractor mounted machines, the DART is easy to use and highly manoeuvrable. It has an

effective working width of 42cm and is powered by a Honda GX160 5.5hp engine. A wide range of tines are available (see

listings). Maximum working depth is 10cm (4ins).

All controls, including the balanced depth control are on the handles. The SISIS DART has been designed to require minimal

maintenance with sealed bearings throughout the mechanism and an easily removable cover.

OPERATING

WARNING –The deadmans lever must be kept depressed whilst the engine is running or when starting

the engine. If the lever is released the engine will stop and will not restart until the lever is

depressed again.

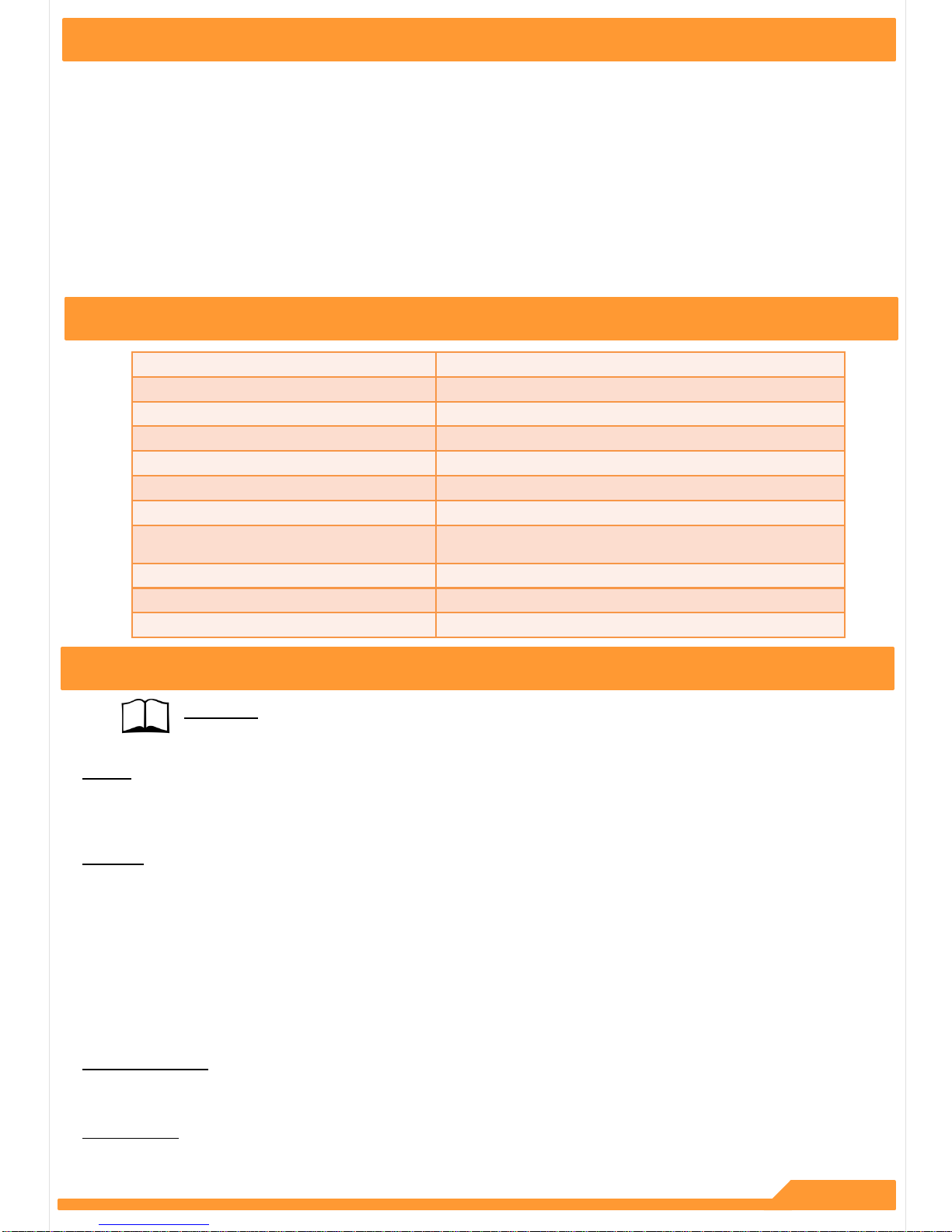

1. Firstly ensure that the over centre lever to the tine drive is disengaged and that the tines are clear of the ground (see image

1)

2. Move the choke lever on the engine to start ( see image 2).

3. Ensure the isolator switch in the engine is on.

4. Depress the deadmans handle lever (see image 3)

5. Set the revs to the engine to approximately half way and pull the recoil starter.

6. When the engine is running smoothly, keeping the deadmans lever depressed, line up the machine for the first run,

7. Engage the over centre lever so that the tines are in drive.

8. Pull the drive clutch lever into operation and with the machine moving forwards pull the depth selection lever until the

desired depth is achieved. This is visible on the depth setting indicator.

9. When nearing the end of the run, lift the tines clear of the ground and take the tines out of drive with the tine drive over

centre lever.

10. Manoeuvre the machine into position for the next run and continue to proceed as previously described.

CAUTION - If the machine begins to bounce or the engine tries to stall, the ground is too hard for the

chosen depth. Select a shallower depth and the treat the ground at this depth until

conditions allow deeper penetration.

Image 1

Image 2

Image 3

SP20015_REV3

OCTOBER 2017

6

ROUTINE MAINTENACE

TO CHANGE A DRIVE BELT

Loosen the nuts on the bearing block and slide back until the belt may be slipped over the edge of the toothed pulley.

When fitting a new belt do not over tension. 10mm of deflection should be left at the centre of the new belt.

TIMING OF TOOTHED BELTS

When fitting a new belt it is important to rest timing.

Looking from the front of the machine, the right hand cam should be at 12 o’clock.

The left hand cam should be at 15 minutes past the hour. (See image below)

FOR THE ENGINE MAINTENANCE SEE MANUFACTURERS HAND BOOK WHICH IS SUPPLIED WITH THE MACHINE

Image 4

10mm

15 minutes past

12 o’clock

SP20015_REV3

OCTOBER 2017

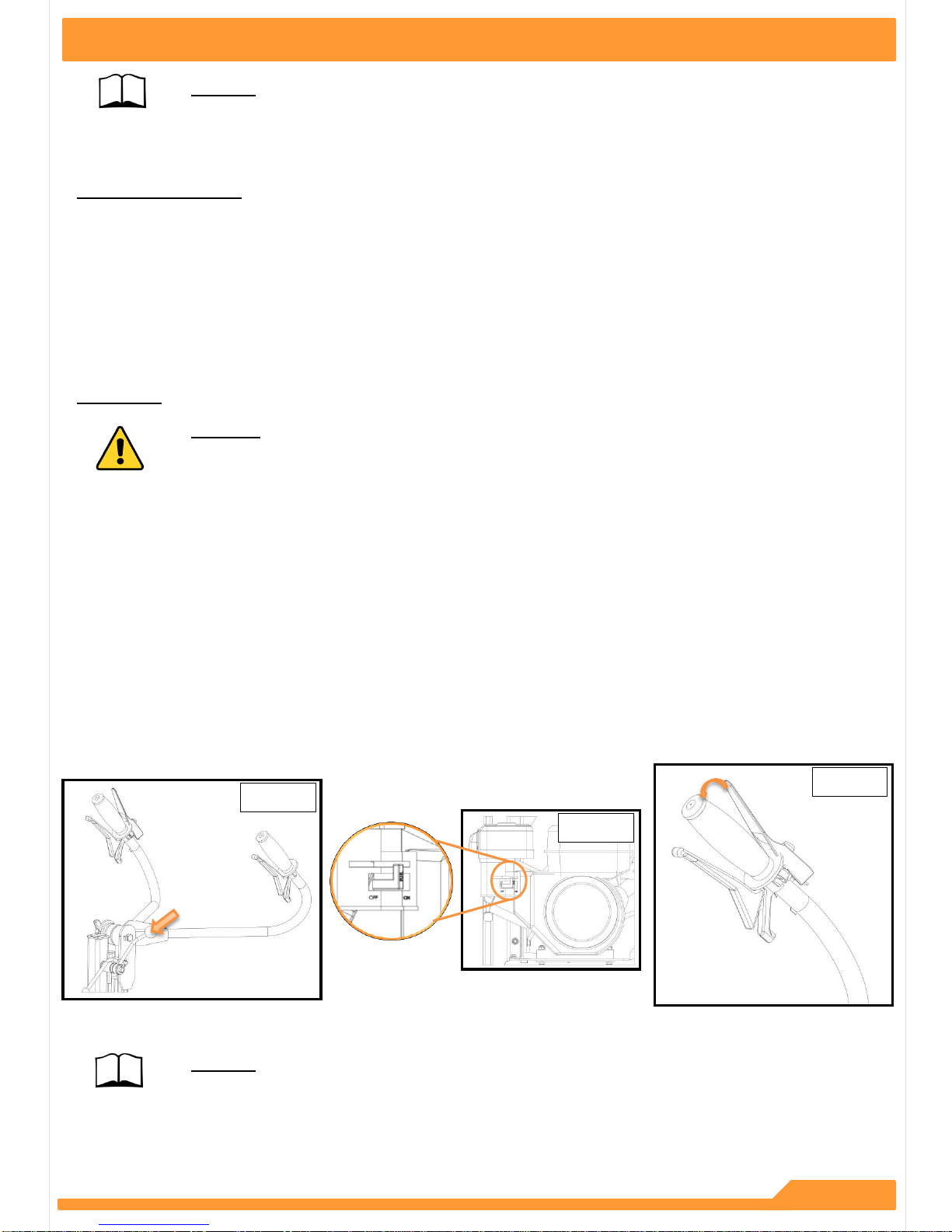

TINES

1 2 3 4 5

NOTE Tine spacing = 50mm

The tines above are available for use with the dart. Maximum depth for all tines is 100mm.

1.) & 2.) Hollow Coring Tines –1 - D2107 (12.5mm Dia), 2 –F36447 (16mm Dia)

These remove cores of soil to relieve compaction caused by play and rolling and to exchange soil. In areas where compaction

is severe use round solid tine treatment say 4-6 weeks before hollow tining to allow moisture to penetrate the compacted layer.

3.) Chisel Tine –D2109

These encourage new root growth and permit the entry of fertilisers and dressings.

4.) Round Pointed Solid Tines –D6728

Used to assist moisture and air getting to the grass roots during the growing season.

5.) Pencil Tine –F34257

Has all the benefits of the solid tine, but is more acceptable on greens because of the smaller surface hole. These tines are not

as strong as the tapered tine so care must be taken on outfield turf or where stony ground is prevalent.

7

SP20015_REV3

OCTOBER 2017

NOTES

SP20015_REV3

OCTOBER 2017

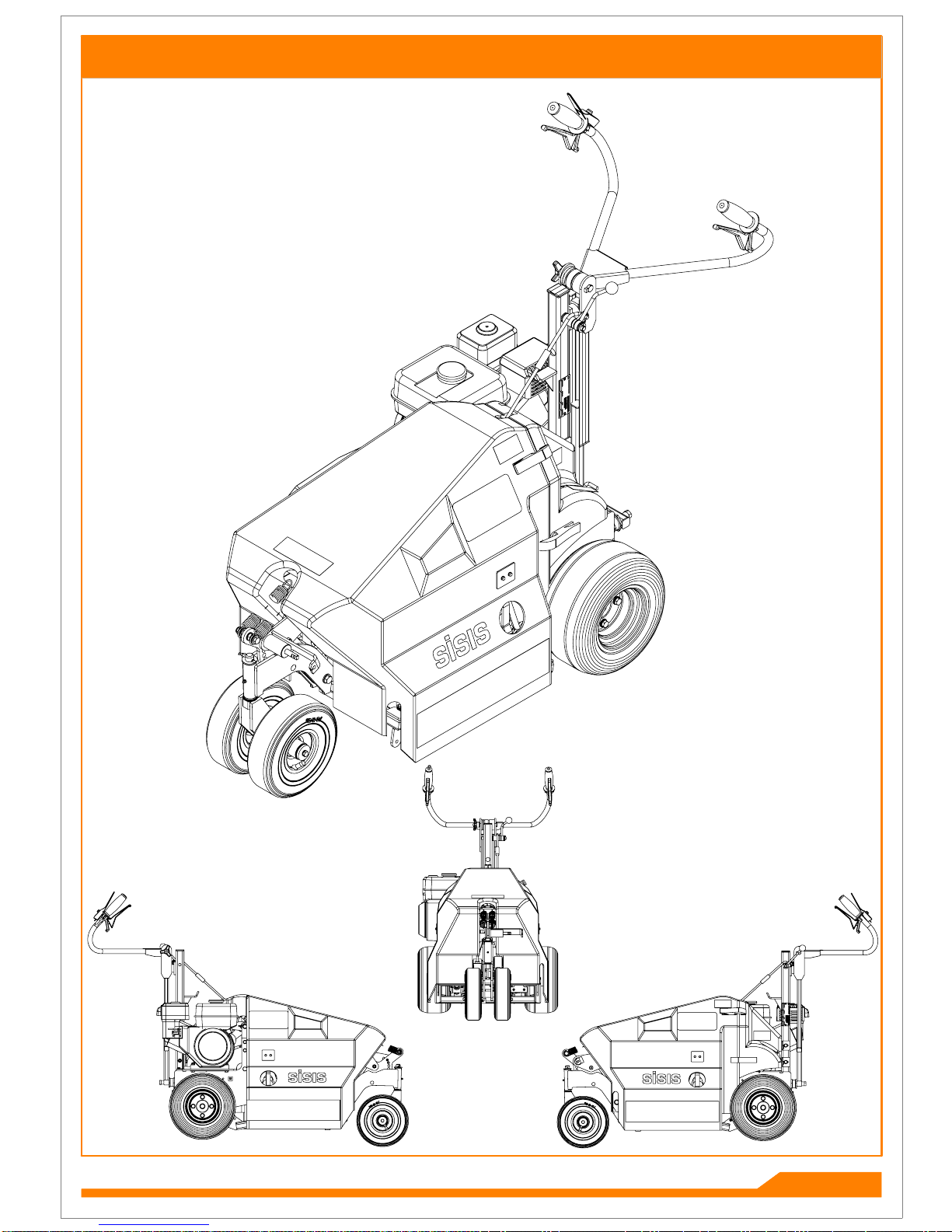

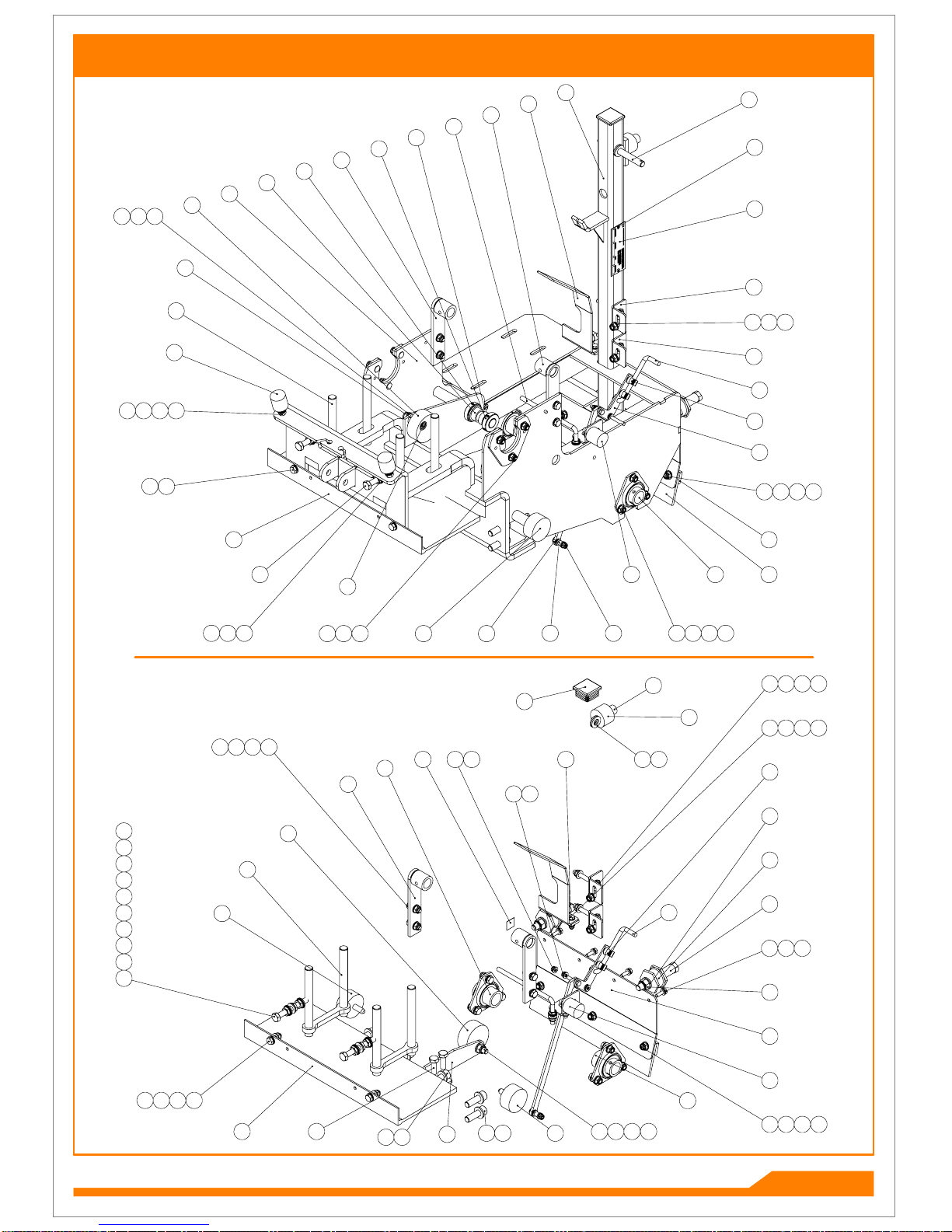

DART - PARTS BOOK

P0

SP20015_REV3

OCTOBER 2017

6

23

10

6

29

33

2819

36 51 51 46

18

26

6

4151

1

1

36 51 46

31

22

30

27

41 51 51 46

40

505653

5

365146 16

8

7

6515549

34

18

32 32

3

20

11

12

13

475353

17

29

Main chassis removed for clarity

14

44

2

54 54

5

26 4

41515146

29

41515146

35

40

50

56

53

53

56

50

50

56

53

16 31

22

25

21

54

48

41 51 51 46

8

13 53 53 47

18

25

24

4354

38 51 51 46

43 54

9

9

39 15 52

45 52

45 52

37 52 52 45

42 16

FRAME

P1.01

SP20015_REV3

OCTOBER 2017

FRAME

ITEM NO.

PART NUMBER

DESCRIPTION

CHASSIS/QTY.

1

401646_REV0

GUARD BRACKET

3

2

401820_REV0

HANDLE SPACER

1

3

402054_REV0

COLLAR

2

4

402077_REV0

TENSIONER ARM

1

5

402081_REV0

BLOCK CLAMP

2

6

402102_REV2

MAIN FRAME (DART)

1

7

402119_REV0

SPACER

1

8

402120_REV0

TENSIONER BLOCK

2

9

402125_REV0

AXLE SPACER

2

10

D1871_REV1

RIVET 3.2 X 6

2

11

D1947_REV1

GREASE NIPPLE M6

1

12

D8068_REV0

GRUB SCREW M6 X 6

4

13

D8522_REV0

CAP HEAD M10 X 35

2

14

D8955_REV1

INSERT 40MM SQUARED

1

15

E1-1061_REV0

WASHER M6 SPRING

4

16

F20080_REV0

RUBBER STOP

2

17

F21711_REV0

BUSH NYLON 008 0600 000 02

3

18

F21739_REV1

RUBBER BUFFER

3

19

F21872_REV1

BEARING BPFT5-16

2

20

F21885_REV1

BUSH AL2026 - 15

2

21

F21922_REV1

VIBRATION MOUNT (METALASTIK NO 17/1386/01 )

2

22

F22321_REV0

CLIP

2

23

F36000_REV2

SERIAL NO PLATE (SISIS)

1

24

F36369_REV4

REAR GUARD

1

25

F36474_REV2

BARREL NUT

2

26

F36502_REV1

BOTTOM BRUSH

1

27

F36669_REV1

REAR GUARD STRIP

1

28

F36670_REV1

RUBBER STRIP

1

29

F37184_REV3

TOP MOUNT

2

30

F37274_REV3

CONNECTING ROD

1

31

F37275_REV3

POINTER

1

32

F37276_REV2

LINK

1

33

F37279_REV3

GUARD STRIP

1

34

F37286_REV1

BELT FINGER

1

35

HUEO-004-81_REV1

STICKY CABLECLIP SMALL

2

36

SP01009_REV0

HEX SET SCREW M8 X 20

14

37

SP01015_REV0

HEX SET SCREW M6 X 25

2

38

SP01023_REV0

HEX SET SCREW M8 X 60

2

39

SP01028_REV0

HEX SET SCREW M6 X 20

4

40

SP01032_REV0

HEX SET SCREW M10 X 80

2

41

SP01045_REV0

HEX SET SCREW M8 X 25

10

42

SP01105_REV0

HEX SET SCREW M10 X 30

2

43

SP01120_REV0

CAP HEAD M12 X 35

8

44

SP01130_REV0

CAP HEAD M12 X 45

1

45

SP02004_REV0

NUT M6 NYLOC

5

46

SP02006_REV0

NUT M8 NYLOC (T)

28

47

SP02008_REV0

NUT M10 NYLOC (T)

4

48

SP02010_REV0

NUT M12 NYLOC (T)

2

49

SP02012_REV0

NUT M8 LOCK (THIN)

3

50

SP02013_REV0

NUT M10 LOCK (THIN)

6

51

SP03008_REV0

WASHER M8 FORM A

52

52

SP03010_REV0

WASHER M6 FORM A

15

53

SP03011_REV0

WASHER M10 FORM A

10

54

SP03012_REV0

WASHER M12 FORM A

12

55

SP03029_REV0

WASHER M8 SPRING LOCK

3

56

SP03034_REV0

WASHER M10 SPRING LOCK

6

P1.02

SP20015_REV3

OCTOBER 2017

183315

9

7

32

13

14

4

3411

20303026

1

1

6

19 31 31 24 29

8

11

20303026

2531312429

2

25

5

21

12

1217272723

35

16 28

3

3

10

34

28 22

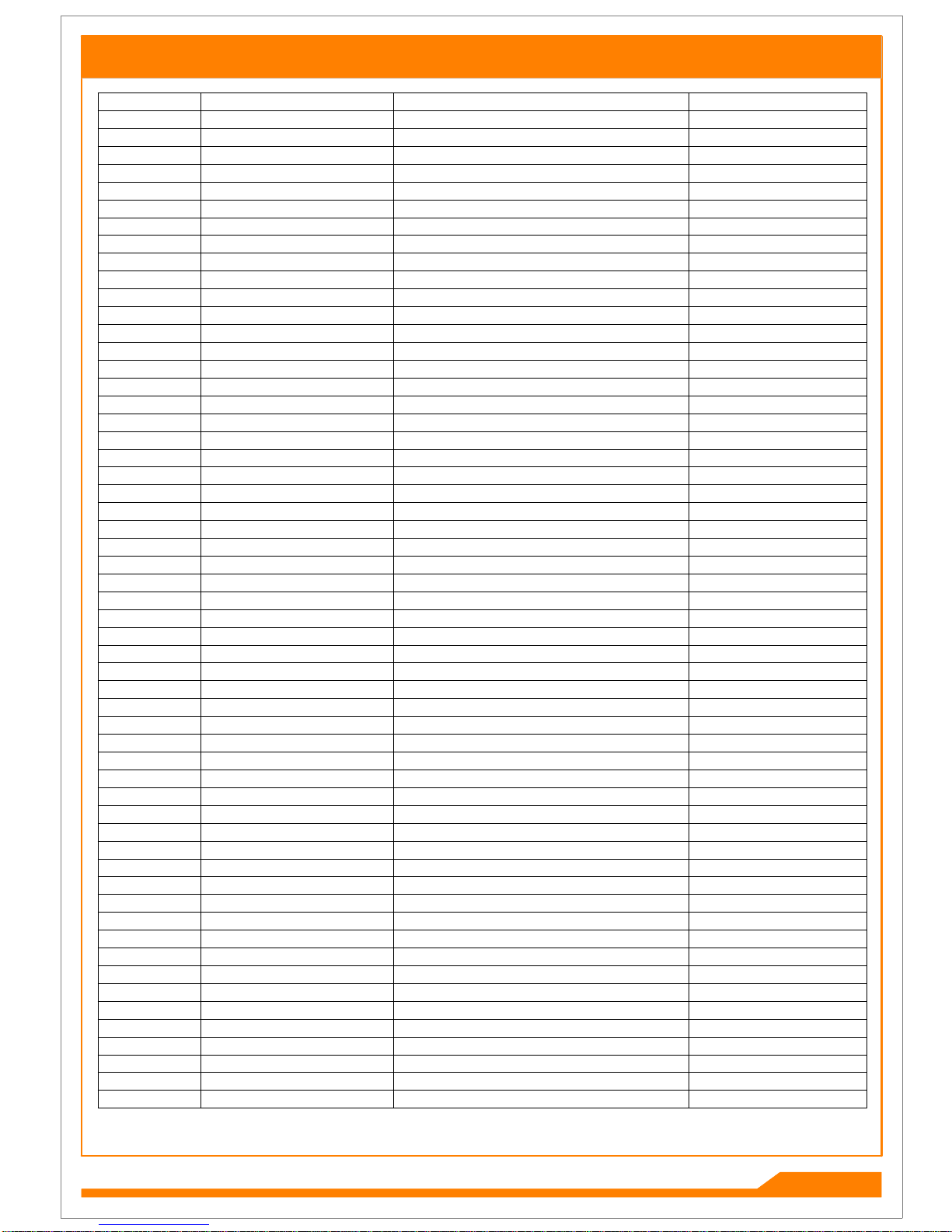

CHASSIS

P2.01

SP20015_REV3

OCTOBER 2017

CHASSIS

ITEM NO.

PART NUMBER

DESCRIPTION

CHASSIS 2/QTY.

1

402086_REV0

UPPER LINK ARM

1

2

402089_REV0

LINK ARM

1

3

402096_REV1

LOWER FRAME

1

4

402098_REV0

FRONT WHEEL SHAFT ASSY

1

5

402101_REV0

BUSH

2

6

402126_REV0

PLUNGER

1

7

D1947_REV1

GREASE NIPPLE M6

1

8

D5622_REV0

SPLIT PIN DIA5 x 50

1

9

D8733_REV0

WHEEL

2

10

F21338_REV0

SPRING

1

11

F21466_REV0

BUSH NYLON 008 1207 000 02

4

12

F21872_REV1

BEARING BPFT5-16

2

13

F21885_REV1

BUSH AL2026 - 15

2

14

F21928_REV0

THRUST BEARING

1

15

F36351_REV1

WASHER

2

16

SP01004_REV0

HEX SET SCREW M5 X 20

1

17

SP01009_REV0

HEX SET SCREW M8 X 20

6

18

SP01045_REV0

HEX SET SCREW M8 X 25

2

19

SP01047_REV0

HEX SET SCREW M10 X 60

1

20

SP01102_REV0

HEX SET SCREW M12 X 70

2

21

SP01141_REV0

SHOULDER BOLT 12 X 20 M10

1

22

SP02002_REV0

NUT M5 NYLOC (T)

1

23

SP02006_REV0

NUT M8 NYLOC (T)

6

24

SP02007_REV0

NUT M10 STD

2

25

SP02008_REV0

NUT M10 NYLOC (T)

2

26

SP02010_REV0

NUT M12 NYLOC (T)

2

27

SP03008_REV0

WASHER M8 FORM A

12

28

SP03009_REV0

WASHER M5 FORM A

1

29

SP03011_REV0

WASHER M10 FORM A

2

30

SP03012_REV0

WASHER M12 FORM A

4

31

SP03016_REV0

WASHER M10 FORM C

4

32

SP03022_REV0

WASHER M20 FORM A

1

33

SP03029_REV0

WASHER M8 SPRING LOCK

2

34

SP13006_REV0

SPRING EXTENSION

2

35

SP14019_REV0

P CLIP 10MM NYLON

1

P2.02

SP20015_REV3

OCTOBER 2017

38

34

35

36

9

27

27

27

33

18

24

66

65

63

25

57 57

58

34

34

53535339

20 29 20

48

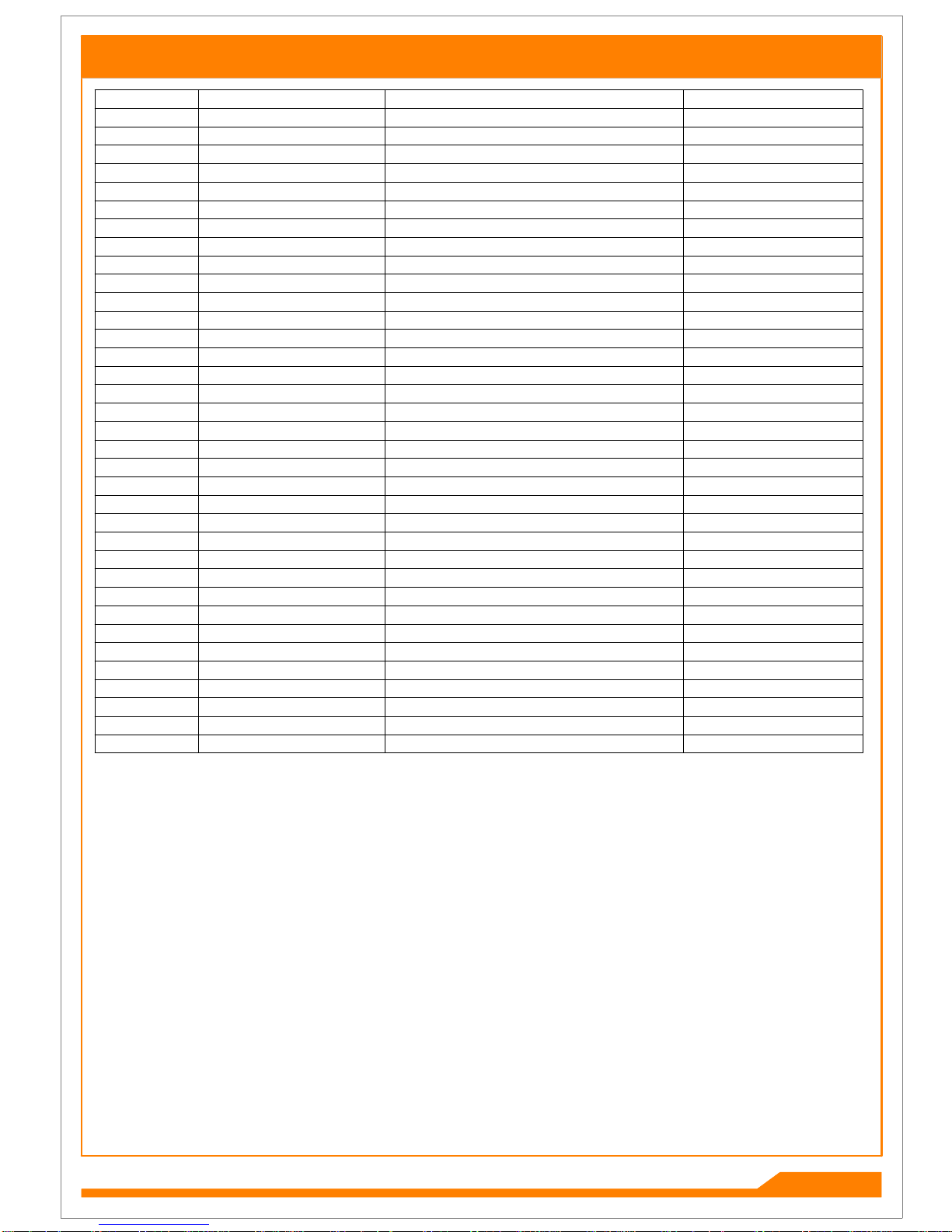

DRIVE SYSTEM

ITEM NO.

PART NUMBER

DESCRIPTION

DRIVE/QTY.

1

062276_REV0

BEARING 6207-2RS 3

4

2

229636_REV0

BUSH AM2530 - 25

2

3

401870_REV0

PULLEY BODY 38MM

1

4

402022_REV0

TIMING CRANK

2

5

402023_REV1

DRIVE CRANK

2

6

402031_REV1

CRANK

4

7

402051_REV1

SPACER

1

8

402052_REV0

SPACER

1

9

402069_REV1

PULLEY

1

10

402075_REV0

WASHER

4

P3.01

SP20015_REV3

OCTOBER 2017

DRIVE SYSTEM

ITEM NO.

PART NUMBER

DESCRIPTION

DRIVE/QTY.

11

402076_REV0

SPACER

2

12

402080_REV0

BEARING BLOCK

2

13

402118_REV0

TOP SHAFT

1

14

402121_REV0

TENSION PIVOT

1

15

402122_REV0

TENSION PIVOT

1

16

402123_REV1

SPRING RETAINER

1

17

403080_REV0

LAYSHAFT

1

18

D1558_REV1

CHAIN

1

19

D1792_REV1

EXTENSION SPRING

2

20

D1873_REV1

CHAIN

1

21

D1947_REV1

GREASE NIPPLE M6

3

22

D1986_REV0

HEX SET SCREW M5 X 20

1

23

F20184_REV1

TAPERLOCK 2517 25

1

24

F21150_REV1

BEARING BPFT5-25

2

25

F21862_REV1

HTD TOOTHED BELT

2

26

F21885_REV1

BUSH AL2026 - 15

2

27

F21890_REV1

V BELT

3

28

F21923_REV0

BUSH AM2026 - 25

2

29

F36340_REV2

SPROCKET 08B SPECIAL 13T 55T

1

30

F36344_REV1

PULLEY SPA-2 TYPE 8

1

31

F36345_REV1

SPROCKET & PULLEY SPECIAL 08B 15T

1

32

F36346_REV6

SPACER

2

33

F36375_REV1

SPROCKET 08B1 50T

1

34

F36510_REV1

DRIVE LEVER

1

35

F37284_REV1

OVER CENTRE ROD

1

36

F37285_REV3

ROD

1

37

HUGT108_REV0

CLEVIS ASSY M8 SHORT

1

38

J20017_REV1

KNOB - RED

1

39

J20406_REV0

SPLIT PIN 3/32" X 1"

2

40

J20467_REV0

GRUB SCREW M8 X 8

4

41

J209006_REV1

CIRCLIP 47 M1308-0470

4

42

J209012_REV0

WASHER M16 FORM B

4

43

J209040_REV1

BEARING 6005-2RS

4

44

J209047_REV0

TENSIONER PULLEY

1

45

SP01013_REV0

HEX SET SCREW 3/8" UNF X 2"

1

46

SP01054_REV0

HEX SET SCREW M6 X 35

2

47

SP01068_REV0

HEX SET SCREW 3/8" UNF X 2 1/2"

1

48

SP01114_REV0

GRUB SCREW M6 X 20

2

49

SP02002_REV0

NUT M5 NYLOC (T)

1

50

SP02004_REV0

NUT M6 NYLOC

2

51

SP02018_REV0

NUT 3/8" UNF NYLOC (T)

2

52

SP02028_REV0

NUT M16 NYLOC (T)

8

53

SP03008_REV0

WASHER M8 FORM A

2

54

SP03009_REV0

WASHER M5 FORM A

2

55

SP03010_REV0

WASHER M6 FORM A

4

56

SP03011_REV0

WASHER M10 FORM A

2

57

SP03012_REV0

WASHER M12 FORM A

2

58

SP05010_REV0

SPLIT PIN 1/8" X 1"

1

59

SP06012_REV0

BEARING 6200-2RS

3

60

SP07009_REV0

CIRCLIP D1400 - 035

2

61

SP07010_REV0

CIRCLIP D1400 - 032

2

62

SP07012_REV0

CIRCLIP D1300 - 030

2

63

SP10002_REV0

KEY 8 X 7 X 40 RD END

3

64

SP10006_REV0

KEY 8 X 7 X 30

4

65

SP11025_REV0

PULLEY 56-8M-20 HTD (TAPERED)

2

66

SP11026_REV0

TAPERED BUSH 2012 - 25MM

2

P3.02

SP20015_REV3

OCTOBER 2017

6

43

41

10

52

64

61

4

1

11

12

6

4

12

5

5

52 42

60

65 66 63 51

3

62

59

45

44

47 56

51 56

31

30

22

32

40

32

46

55

55

50

19

21 15

37

37

16

15 15

14 14

13

1723

22545449

26

26

7

8

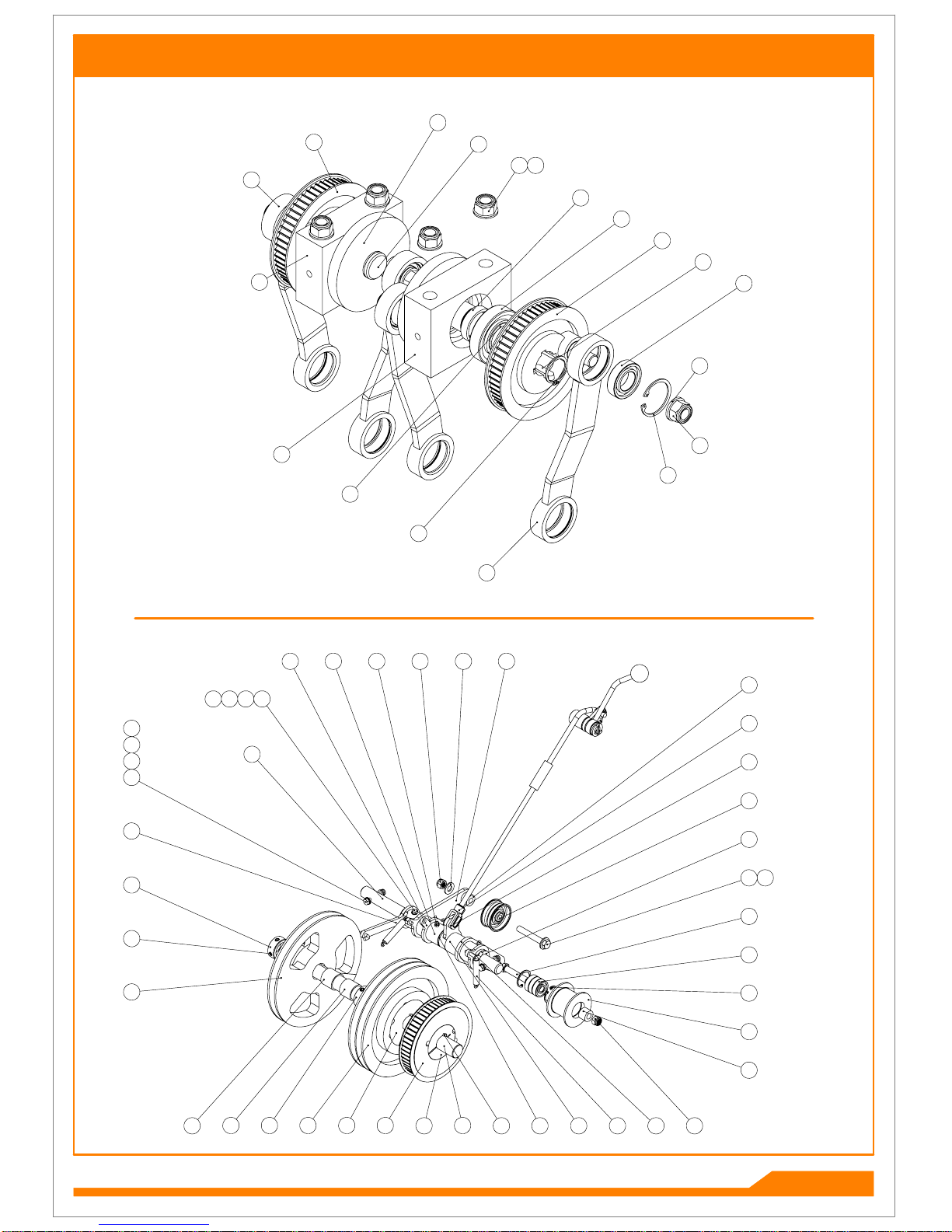

DRIVE SYSTEM

P3.03

SP20015_REV3

OCTOBER 2017

25

10

5

9

23

12

18

7

243432

16

1

11

1115

16

10

7

21 4

19

9

29 26

18

7

7

23

23

21

2

2533

2533

9

5

10

26

29

9

12

301720

21

19

16

6

7

1 152016 11

243432

21

3

13 8

13 8

27 1428

32

3 2

TINE DRIVE

P4.01

SP20015_REV3

OCTOBER 2017

TINE DRIVE

ITEM NO.

PART NUMBER

DESCRIPTION

TINE DRIVE/QTY.

1

400496_REV0

PLATE

8

2

402034_REV0

SPACER

8

3

402035_REV0

SPACER

16

4

402036_REV0

SPACER

8

5

402037_REV0

LINK ARM PLATE

4

6

402038_REV0

LINK ARM PLATE

4

7

402039_REV0

PIVOT PIN

12

8

402040_REV0

WASHER

12

9

402111_REV1

TINE HOLDER

4

10

402112_REV0

BEARING HOUSING

4

11

402113_REV1

SPRING FORK

4

12

D1947_REV1

GREASE NIPPLE M6

4

13

E1-1066_REV0

WASHER SPRING M16

12

14

F21739_REV1

RUBBER BUFFER

4

15

F21987_REV1

COMPRESSION SPRING

4

16

F35946_REV7

SHAFT SWIVEL

4

17

F36407_REV3

SPACER

4

18

J20430_REV0

CAP HEAD M6 X 30

8

19

J209006_REV1

CIRCLIP 47 M1308-0470

4

20

J209012_REV0

WASHER M16 FORM B

12

21

J209040_REV1

BEARING 6005-2RS

20

22

J209085_REV1

BUSH AM1216 - 20

8

23

SP01037_REV0

HEX SET SCREW M16 X 30

12

24

SP01045_REV0

HEX SET SCREW M8 X 25

16

25

SP01120_REV0

CAP HEAD M12 X 35

8

26

SP01139_REV0

SHOULDER BOLT 12 X 55 M10

4

27

SP02004_REV0

NUT M6 NYLOC

8

28

SP02006_REV0

NUT M8 NYLOC (T)

4

29

SP02008_REV0

NUT M10 NYLOC (T)

4

30

SP02028_REV0

NUT M16 NYLOC (T)

4

31

SP02029_REV0

NUT M16 LOCK (THIN)

4

32

SP03008_REV0

WASHER M8 FORM A

20

33

SP03012_REV0

WASHER M12 FORM A

8

34

SP03029_REV0

WASHER M8 SPRING LOCK

16

P4.02

SP20015_REV3

OCTOBER 2017

5

8

1

6

7

4

1

5

3

2

9

10

ITEM NO.

PART NUMBER

DESCRIPTION

Handle Bars/QTY.

1

229754_REV0

CLUTCH LEVER

2

2

E1-1728_REV0

HEX BOLT M10 X 110

1

3

F21063_REV1

LOCK KNOB

1

4

F21905_REV0

DEADMAN LEVER

1

5

F22019_REV1

HANDLE GRIP

2

6

F36320_REV5

BACK FRAME

1

7

F36405_REV1

LABEL FORWARD DRIVE

1

8

F37288_REV1

HANDLE BARS

1

9

SP03011_REV0

WASHER M10 FORM A

1

10

SP03034_REV0

WASHER M10 SPRING LOCK

1

HANDLE BARS

P5.01

SP20015_REV3

OCTOBER 2017

5

3

71110

6

2

1

4 9 9 8

ITEM NO.

PART NUMBER

DESCRIPTION

WHEELS/QTY.

1

401650_REV0

AXLE DIFF M/C

1

2

402055_REV0

AXLE SPACER

2

3

D8733_REV0

WHEEL

2

4

E1-1116_REV0

HEX BOLT M8 X 70

2

5

F21061_REV0

WHEEL

2

6

F33607_REV1

WHEEL HUB

2

7

SP01034_REV0

HEX SET SCREW M10 X 20

8

8

SP02006_REV0

NUT M8 NYLOC (T)

2

9

SP03008_REV0

WASHER M8 FORM A

4

10

SP03011_REV0

WASHER M10 FORM A

8

11

SP03034_REV0

WASHER M10 SPRING LOCK

8

WHEELS

P6.01

SP20015_REV3

OCTOBER 2017

Table of contents

Other Sisis Lawn And Garden Equipment manuals

Popular Lawn And Garden Equipment manuals by other brands

Jonsered

Jonsered J208F24 Operator's manual

Jata hogar

Jata hogar mosquitoTRAP MELI0620 Instructions of use

ILESTO

ILESTO GUARDI GARTENBOX L BENJAMIN Construction manual

VegeBox

VegeBox Growlight HGLITE instruction manual

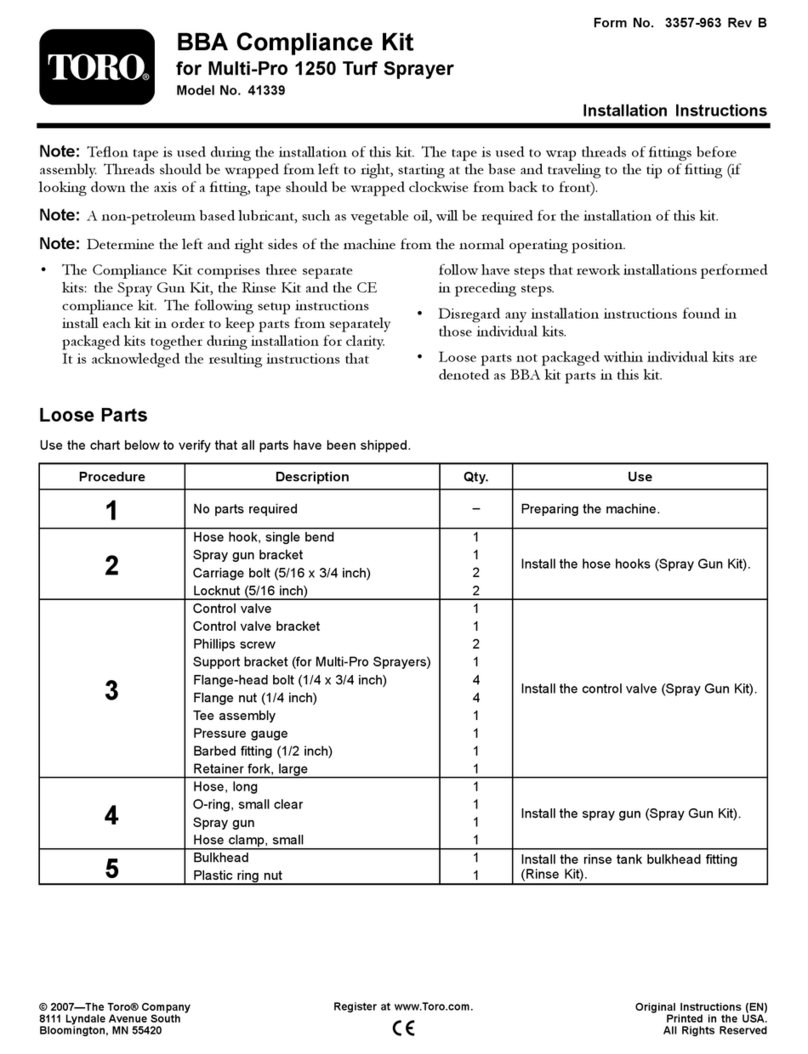

Toro

Toro 41339 installation instructions

Gardena

Gardena EVC 1000 operating instructions

AquaScape

AquaScape 78241 Instructions & maintenance

Superior

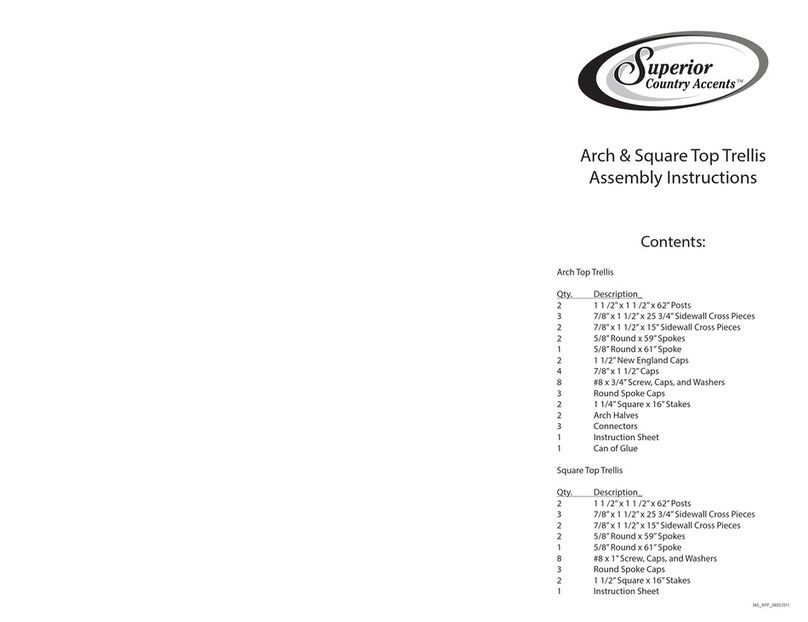

Superior Country Accents Arch Top Assembly instructions

SNOWJOE

SNOWJOE AJHN102-RM manual

Grouw!

Grouw! 98046 instruction manual

aidapt

aidapt VL125 Usage and maintenance instructions

New England Arbors

New England Arbors Urbanscape Raised Planter Box Assembly instructions