Sit 650 DELTA Technical manual

9.957.059 04

650 DELTA

USE AND INSTALLATION INSTRUCTIONS

Read the instructions before use. This control must be installed in accordance with the rules in force.

650 DELTA USE AND INSTALLATION INSTRUCTIONS

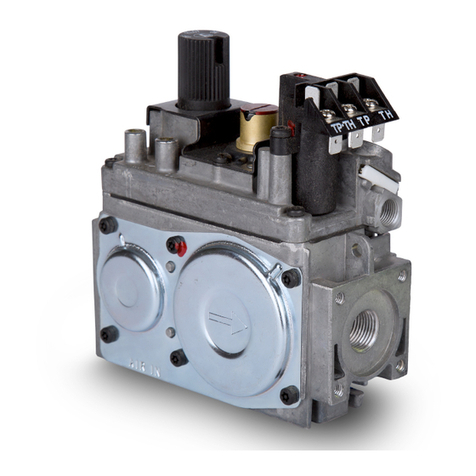

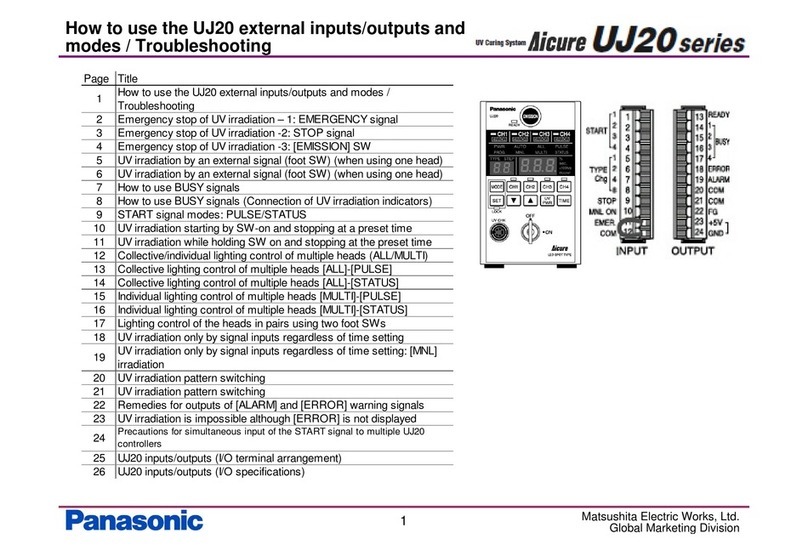

MAIN FEATURES

•

Inlet filter (FL)

•

Control knob for off, pilot and temperature selection (MS)

•

Thermoelectric flame supervision device (GM)

•

Non-resettable safety thermostat (TL)

•

ON/OFF adjustable thermostat (TH)

•

Pressure regulator on main burner (PR)

•

Pilot filter (PFL)

•

Pressure regulator on pilot burner (PPR)

•

Outlet pressure test point

650 DELTA is a combination gas control with thermoelectric flame supervision device and ON/OFF

thermostatic control.

650 DELTA is designed and intended for gas fired storage water heaters.

2

TECHNICAL DATA

Inlet gas connection 1/2” NPT

Main burner outlet 0.7500 - 18 - UNS 2B inverted flare

Pilot outlet 7/16”- 24 - UNS 2B

Mounting shank 3/4” NPT

Thermocouple connection 11/32” ASA

Outlet pressure test point 1/8” NPT

Installation position any position with shank in horizontal position

Gas families Natural Gas or Liquefied Petroleum Gas

Maximum inlet pressure 1/2 PSI

Main outlet pressure setting range 3"... 5" w.c. for NG and 8"...12" w.c. for LPG

Pilot outlet pressure setting range 3"... 6" w.c. for NG and 8"...12" w.c. for LPG

Ambient temperature range 32...175 °F

GM

INLET

MAIN

PILOT

BURNER

BURNER

TH

PR

PPR

PFL

TL

MS

FL

GAS

650 DELTA USE AND INSTALLATION INSTRUCTIONS

3

VALVE DESCRIPTION

1 Ignition button for thermoelectric flame

supervision device

2 Control knob

3 Reference arrow mark

4 Gas inlet with protective dust cap

5 Main gas outlet with protective dust

cap

6 Pilot outlet

8 Outlet pressure test point

9 Thermocouple connection

10 Mounting flange

11 Thermostat Rod

12 ECO Well

13 Piezoelectric igniter (Optional)

14 Plastic cover (Optional)

10

2

11

8

5

9

THERMOSTAT REGULATION SPECIFICATIONS

Thermostat Features

•

Regulating thermostat

Differential (a) 16 +/-5.5 °F

•

ECO

Type one-shot

Calibration 196 +0/-9 °F

TEMPERATURE

a

GAS FLOW

a

A B

MIN position MAX position

control knob at control knob at

STOP

Do not install, replace, or in any way modify the gas valve or the appliance. Always

use a QUALIFIED Gas Appliance Service Technician to service appliances this valve is

installed on. ALWAYS READ AND FOLLOW ALL THE ENCLOSED INTRUCTIONS.

12

4

14

2

4

13

96

13

3

1

4

11

12

650 DELTA USE AND INSTALLATION INSTRUCTIONS

4

INSTALLATION

When installation of this product begins…

1. Read all of these instructions carefully. Failure to follow these instructions could damage the

product or cause dangerous conditions.

2. Check the ratings given in the instructions and on the appliance to make certain that the control

is suitable for your application.

3. All operations of installation, setting and adjustments must be undertaken exclusively

by a qualified Gas Appliance Service Technician following the instruction specified in this

catalog and those in the instruction manual of the appliance in which the valve is installed.

4. After installation is complete, verify that the appliance is operating as indicated in these

instructions.

WARNING!

Oxygen Depletion Hazard.

Can cause injury or death by asphyxiation.

Do not use valves for vented appliances on unvented or vent free appliances. Do not use

valves for unvented or vent free appliances on vented appliances.

WARNING!

Fire or Explosion Hazard.

Can cause property damage, severe injury or death.

Follow these instructions completely.

1. Turn off gas supply to the appliance before installation, and perform Gas

Leak Test after the installation is completed.

2. Always install the sediment trap in the gas supply line to prevent contamination of the

gas control.

3. Do not force the control knob. Use only your hand to turn the knob. If the knob does

not move by hand, the valve should be replaced by a qualified service technician.

CAUTION!

Electrical shock or equipment damage hazard.

Can shock individuals or short equipment circuitry.

Make sure to disconnect all electrical supplies before beginning the installation process.

IMPORTANT

•

These gas controls are shipped with anti-contamination seals over inlets and outlets.

•

Do not remove the seals until ready for connection to piping; remove dust caps only

when installing.

WARNING!

Avoid any foreign matter getting into the device, check inlet and outlet pipes for cleanness.

WARNING!

In case of overpressure of the input gas on the valve greater than 14.5 PSI, replace the valve.

650 DELTA USE AND INSTALLATION INSTRUCTIONS

INSTALLING THE VALVE

1. Install the valve using the provided mounting flange.

Screw using using the specific tool SIT code 0.999.996,

suitable as accessory. Tighten to 45 ÷ 60 ft·bs torque.

2. Mount the valve so the flow of gas is consistent with

the gas flow arrows on the valve.

3.Apply a moderate amount of quality

pipecompound to the pipe only, leaving two end

threads bare. On LP installations, use compound

that resists exposure to LP gas.

4. Remove seals over inlet and outlet if necessary.

5. Connect pipe to valve inlet and outlet. Place wrench on

valve in position

(see Fig. 2). Tighten inlet connection

to 30 ft

·

lbs torque, outlet connection to 20 +/-10 ft

·

lbs

torque.

6. Thread pipe into the valve until a gas tight seal is

achieved. Typically, for NPT thread, penetration is

usually no more than the diameter of the pipe or 2

and 1/4 turns thread. Valve distortion or mechanical

failure can result if the pipe is inserted too deeply.

7. Connect pilot tubing to valve with appropriately

sized fittings. Recommended torque 40 ÷ 70 lbf·in.

8. Confirm gas tight seals with gas leak test.

9. Connect thermocouple to safety magnet. Hand tighten, and then rotate 1/4 turn with wrench

appling a torque not higher than 10 ÷ 20 lbf·in.

5

INSTALL PIPING TO GAS VALVE

All piping must comply with local codes and ordinances or with the National Fuel Gas code (ANSI

Z223.1 NFPA No. 54) whichever applies. Tubing installation must comply with approved standards

and practices. Use appropriately sized fittings when

connecting aluminum tubing to the pilot outlet.

1. Use new, clean and correctly reamed pipe free from

burrs, chips, debris and any foreign matter. When

tubing is used, make sure the ends are square

and clean. All tubing bends must be smooth and

without deformation.

2. Run pipe or tubing to the valve. If tubing is used,

obtain a tube-to-pipe coupling to connect the tubing to the valve.

3. Install sediment trap (Drip Leg) in the supply line to the gas valve.

3” MIN.

GAS SUPPLY

TO CONTROL

INLET

DRIP LEG (DOWN)

WARNING!

Do not immerse in water or subject the control to temperatures exeeding 175 °F

operating ambient temperature..

28 mm

29 mm

Fig. 2

Fig. 1

650 DELTA USE AND INSTALLATION INSTRUCTIONS

6

WARNING!

DO NOT OPERATE THE DEVICE WHEN THE STORAGE WATER HEATER IS NOT FILLED WITH WATER.

WARNING!

•

Do not tamper with sealed parts.

•

Do not loosen assembly screws.

•

Do not remove labels and marking.

WARNING!

Observe recomended torques.

Use only specified spanner grips when making the connections (see Fig. 1 and Fig. 2).

WARNING!

AVOID ANY DAMAGE TO THE DEVICE (KNOCKS,FALLS,ETC.). IN CASE OF FALL OF THE

VALVE, IT IS RECOMMENDED NOT TO USE IT.

OPERATION

STOP!

It is imperative that you read and follow all safety warnings before lighting the pilot burner.

Refer to ANSI Z21.10 and ANSI Z21.78.

WARNING!

If you do not follow these instructions exactly, a fire or explosion may result causing property

damage, personal injury, or loss of life.

WARNING!

Make certain that the water heater is completely filled with water before attempting to ignite the

pilot burner or otherwise operate the gas control.

Note:

All knob settings referenced to the reference arrow marks (a) in

Fig. 3.

IMPORTANT:

Always start operation from the OFF position of the control knob.

Pilot flame ignition

Start from the OFF position (Fig.3). Rotate the control

knob

counter-clockwise

to the PILOT position (Fig.4).

Press and hold the ignition button PILOT (b) for thirty (30)

seconds or more and simultaneously press several times

the Piezo Igniter button (c) to light the pilot flame (Fig.5).

Release the ignition button PILOT and make sure that the

CAUTION!

Wait a minimum of (5) five minutes before attempting to re-light the

pilot burner after the gas control has been switched to the OFF position

and/or the pilot flame has been extinguished. Repeat the pilot ignitionRepeat the pilot ignition

sequence starting from the OFF position. (Fig. 3)

(a)

Fig. 3: OFF position

WARNING!

THE 650 DELTA VALVE IS DISPOSABLE. THE VALVE ALREADY MOUNTED ON A STORAGE WATER HEATER

MUST NOT BE REMOVED FROM THE STORAGE WATER FOR REUSE ON ANOTHER WATER HEATER.

650 DELTA USE AND INSTALLATION INSTRUCTIONS

7

Main burner ignition

Turn the control knob counter-clockwise to the ON

position (Fig.6).

Gas will flow to the main burner when the

water temperature stored within the appliance is lower than

the set-point temperature.

Temperature setting

To increase the water temperature set-point rotate the control

knob counter-clockwise to the desired temperature

setting

(Fig.7)

. The gas path to the main burner opens when

the water temperature within the appliance is lower than the

temperature set-point.

To decrease the water temperature set-point, rotate the

control knob clockwise to the desired temperature

setting

(Fig.8)

. The gas path to the main burner opens when

the water temperature within the appliance is lower than the

temperature set-point.

Stand-by position

To maintain a flame at the pilot burner with the main burner

off, turn the control knob

clockwise

to the PILOT

position (Fig.9).

Turning off

Turn the control knob

clockwise

to the OFF position

(Fig.10).

Fig. 6: ON position

Fig. 4: PILOT position

Fig. 7: LOW position

Fig. 8: VERY HOT position

Fig. 9: PILOT position

Fig. 10: OFF position

pilot flame remains lit. If it goes out, repeat the ignition process, starting from the OFF position.

Fig. 5: Ignition button PILOT

and Piezo Igniter button

(b)

(c)

650 DELTA USE AND INSTALLATION INSTRUCTIONS

PERFORM GAS LEAK TEST

GAS LEAK TEST

•

Using a solution of soapy water, paint the piping connections, which are upstream of the

control.

The presence of bubbles indicates a gas leak.

If a leak is detected, tighten the pipe connections and repeat leak test.

•

Light the main burner following the lighting instructions..

•

With the main burner in operation, paint all piping connections from the valve with a soap and

water solution.

•

If another leak is detected, tighten the connection.

•

If after tightening the connections the leak is still present, replace the leaky part or valve. Shut

off the main gas supply before attempting replacement of parts or the valve.

WARNING!

Stand away from the main burner while lighting.

Hidden gas leaks can cause flashbacks in the appliance area. Check for gas leaks with rich

soap and water solution any time work is done on a gas system.

WARNING!

Fire or Explosion hazard.

Can cause damage to property and severe injury or death.

Do not force the control knob. Use only your hand to turn the knob. If the knob does not move

by hand, the valve should be replaced by a trained service technician.

FINAL CHECKS

SETTINGS AND ADJUSTMENTS

The valve is preset at the factory, and is not field

adjustable.

Verify the outlet pressure via the 1/8”NPT outlet pressure

test plug (8 in Fig. 11). Upon completion of testing, the

sealing plug must be reinstalled using a 3/16” hex key,

with 22 lbf·in of torque and a gas leak test must be

performed.

8

8

Fig. 11

650 DELTA USE AND INSTALLATION INSTRUCTIONS

WARNING!

Fire or Explosion Hazard.

Can cause severe injury or death.

Perform the safety shutdown check any time work is done on a gas system.

1. Place the appliance in operation. The pilot and main burners should be lit.

2. Place gas control knob in PILOT position. Main burner should extinguish and pilot should

remain lit.

3. Extinguish pilot flame. Pilot gas safety shutoff proves complete shutdown due to the fact the

safety shutoff valve prohibits main burner and pilot gas flow.

4. Wait at least five minutes for the safety magnet to reset and residual gas to clear from the

combustion chamber.

5. Relight pilot burner and operate the system through one complete cycle to ensure all functions

operate correctly.

SHUTDOWN PERFORMANCE TEST

9

650 DELTA USE AND INSTALLATION INSTRUCTIONS

10

WARNING!

The piezoelectric igniter should be replaced by a qualified service technician.

The appliance and the gas valve may be hot: wait until the temperature has dropped before

touching the appliance or the gas valve.

1.Turn the control knob of the gas valve

clockwise

to the OFF position.

2. Turn off gas supply at the appliance service valve.

3. Remove the female cable connector from the male igniter connector.

4. Remove the old igniter from the gas valve making lever with a flat screwdriver of appropriate

size, as shown in Fig.12 & 13. Discard the old igniter.

5. Position the new igniter, available as spare part SIT code 0073002, into his seat of the gas

valve, as shown in Fig.14. Apply by hand a maximum force of 44 lbf (20 Kgf ) on the button of

the igniter. The applied force makes operating the igniter which will generate one click and one

spark in air. Continuing to apply the force, a second click is made. The second click confirms

full insertion and the mechanical locking of the body of the new igniter into its seat, as shown in

Fig. 15. Once inserted, do not remove the igniter.

6. Reconnect the female connector of the electric cable to the male igniter connector.

7. Relight pilot burner and operate the system through one complete cycle to ensure all functions

are correct.

PIEZOELECTRIC IGNITER REPLACEMENT

Fig. 13

Fig. 15

Fig. 12

Fig. 14

650 DELTA USE AND INSTALLATION INSTRUCTIONS

11

DIMENSIONAL DRAWING

Dimensions are in millimeters.

Other Sit Control Unit manuals

Popular Control Unit manuals by other brands

Pentair

Pentair ERICO CADWELD PLUS Operation instructions

AUZA

AUZA WAVE PACKETS quick start guide

jcm-tech

jcm-tech RB3 TGLA868 user manual

resideo

resideo Braukmann BA295D-3/4WH installation instructions

ICPDAS

ICPDAS HRT-710 user manual

Power Computing

Power Computing PowerCenter Pro Low Profile 180/210 manual

Eaton

Eaton XN300 manual

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SC-SL2N-E installation manual

Realtek

Realtek UWB BG13 HMC user guide

Johnson Controls

Johnson Controls GS-20 Series Installation Sheets Manual

Becker

Becker Centronic SunWindControl SWC445-II Assembly and operating instructions

National Instruments

National Instruments NI 9423 operating instructions