Sit 695 NGA Technical manual

USE AND INSTALLATION

INSTRUCTIONS

0695000_IBK rev.00 1

695 NGA

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR

OPERATINGTHIS CONTROL COULD CAUSE PERSONAL INJURY AND/OR PROPERTY DAMAGE

DESCRIPTION

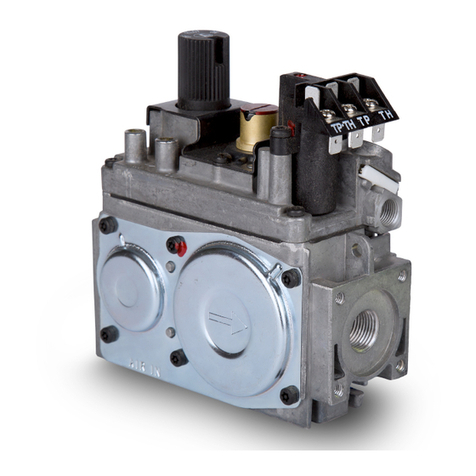

The 695 NGA water heater control is a combination gas valve

and thermostat for use on atmospheric water heaters.

The microcontroller equipped electronics monitor the water

heater and indicates the status via a green status LED on the

front of control.

Fixed Adjustment Regulator Controls: the gas regulator on this

control requires no field service. The regulator automatically

controls and maintains the burner gas pressure.

PRECAUTION

WARNING

WHAT TO DO IF YOU SMELL GAS

•Do not try to light any appliance

•Do not touch any electrical switch; do not use any phone in

your building

•Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's Instructions

•If you cannot reach your gas supplier, call the fi department

WARNING

Pay attention to use the gas controller with the correct gas:

•The 695 NGA with BLACK thermostat knob (see Figure 2) is

allowed to be used with Natural Gas only

•The 695 NGA with RED thermostat knob (see Figure 2) is

allowed to be used with LP Gas only

Improper operation could occur, resulting in personal injury

and/or death due to Carbon Monoxide (CO) poisoning, fire, or

explosion. Check for proper gas type as listed on the rating plate

affixed to the water heater.

WARNING

FIRE AND EXPLOSION HAZARDS

•Shut off main gas to appliance for service or until installation

is complete

•Replace existing control with recommended model

•Protect the control from direct contact with water (dripping,

spraying, rain, etc.)

•If the control has been in direct contact with water, replace

the control

•Label all wires before disconnection when servicing controls;

wiring errors can cause improper and dangerous operation

•Route and secure wiring away from flame

•Do not use tools to operate this control

•Do not take control apart, there are no serviceable parts

inside

•Do not use control if it has been flooded

•Never stand on the control or use as a step

EN

2

0695000_IBK rev. 00

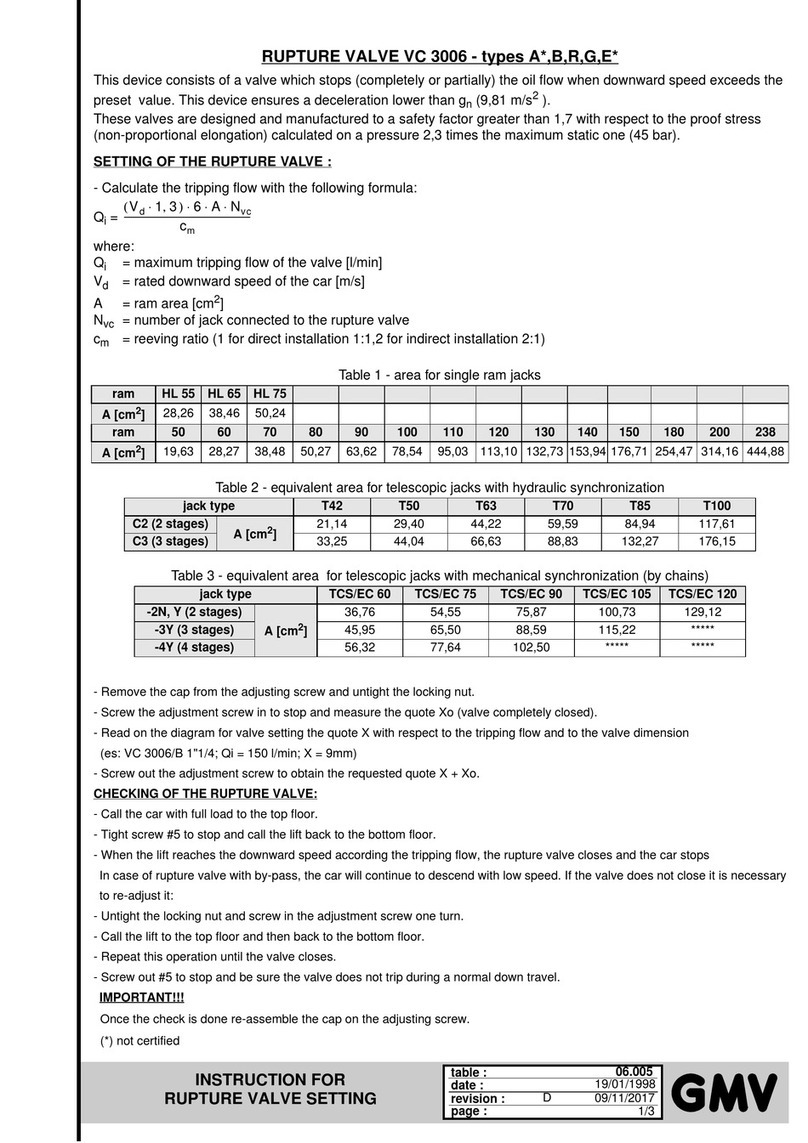

SPECIFICATIONS

NATURAL GAS LPG

Range of Regulation (Btu/Hr)4" outlet: Min 25,000 Max 75,000 10" outlet: Min 30,000 Max 100,000

1.0" Pressure Drop Capacity 55,000 Btu/Hr (4" outlet) a70,000 Btu/Hr (10" outlet) b

Maximum Inlet Pressure 1/2 PSI

Ambient Temperature Rating 20°F to 170°F (-7°C to 76°C)

Automatic High Temperature Cutoff Resettable Type, 195°F (90°C)

Body Configuration Right angle with a 1 /2" NPT inlet and a 1 /2" inverted flare outlet

Control Input Voltage Minimum: 435 mV dc, open circuit Voltage Maximum: 1200 mV dc, open circuit

Mounting Upright

aBased on 1000 Btu/ft3, 0.64 specify gravity natural gas

bBased on 2500 Btu/ft3, 1.53 specify gravity LP gas

INSTALLATION

NOTE

1. This control must be installed or serviced only by a qualified

service person.

2. For your safety, this control is supplied with tamper

resistant screws. Do not attempt to repair or adjust the

control. If you experience problems, replace the control

immediately. Continuing to use a damaged control could

result in fire and/or explosion.

3. An odorant has been added to the gas to help you detect it.

Before lighting, search for the odor of gas by sniffing at

floor level around the water heater.

4. In some situations, the gas may lose its odor.To detect

unodorized gas, you must have a gas detector, which can be

purchased from your gas company. If you do not have a

detector and have the slightest suspicion that gas may be

present, get out of the house and call the gas company.

DO NOT RELY TOTALLY ON YOUR NOSE.

REMOVING THE OLD CONTROL

1. Locate the gas control. Before performing any maintenance,

turn the gas control thermostat knob to the OFF setting.

(Figure 3)

2. Close gas shut off valve.

3. Remove the two electrical connections that are plugged

into the control (Figure 2).

4. Shut off the water at the cold water inlet.

5. Connect a hose to the water heater drain cock. Drain the

water to a nearby drain. Open a hot water faucet for faster

draining.

6. Disconnect the gas line at the union (Figure 1). Remove the

piping from the old control.

7. Disconnect main burner tube fitting and pilot tube fittings

(Figure 2).

8. Remove the control by turning counter clockwise ( )if

needed, a short piece of 1/2" black iron pipe can be

screwed into the control inlet to increase leverage.

INSTALLING THE NEW CONTROL

All piping must comply with local and state ordinances or with the

National Fuel Gas Code (ANSI Z223.1-NFPA 54), whichever applies.

1. Apply pipe compound to the male threads that screw into

the tank, leaving the first two or three threads clean.

2. Install control in the tank. Turn clockwise ( ). Use a short

piece of pipe to help in turning. Align the control so that the

burner tube may be connected.

3. Reconnect the main burner and pilot tube connection. Do

not use pipe joint compound or Teflon tape.

4. Connect the gas line. Use new black iron pipe that has been

properly reamed. If old pipe is used, be sure it is clean and

free from rust and scale. Use pipe joint compound on male

threads only. (Use pipe joint compound approved for natural

and LP gas service.) Do not use Teflon tape.Do not apply

compound to the first two threads.

5. Reconnect gas line at the union. DO NOT use joint

compound or tape on the union connection.

6. Reconnect the electrical connections to the control. There

are three connections for the control. Connect the positive

lead from control to the thermal switch on the tank.

Connect negative lead (white) from pilot generator to the

negative terminal on control. Connect piezo spark connector

to igniter wire connector (Figure 2).

NOTE

The cold water supply valve MUST be left open when the

water heater is in use

WARNING

Dirt or contamination in the gas line can block the control from

operating creating a risk of explosion, injury, or death. To protect

the control from dirt and contamination, a drip leg or sediment

trap (see Figure 1) must be installed in the piping leading to the

control.

3

0695000_IBK rev.00

INSTALLATION

Figure 1. Typical gas connection

7. To fill the water heater with water:

a. Close the water heater drain valve. The drain valve is

on the lower front of the water heater.

b. Open the cold water supply valve to the water heater.

c. Close the water heater drain valve. The drain valve is

on the lower front of the water heater.

d. Open the cold water supply valve to the water heater.

8. Open the gas shutoff valve

9. BEFORE TURNING ON THE APPLIANCE, CHECK THE GAS

LINES FOR LEAKS.

a. Use a soapy water solution. DO NOT test for gas

leaks using a match or open flame.

b. Brush the soapy water solution on all gas pipes,

joints and fittings. Use care that excess solution

does not enter the control's plastic housing.

c. Check for bubbling soap. This means you have a

leak. Close gas shutoff valve and make the

necessary repairs.

d. Open gas shutoff valve and recheck for leaks. Repeat

this process until you are sure the system is gas-

tight. If repeated work on a part does not stop the

leak, the part must be replaced.

e. Rinse off the soapy solution and wipe all the

plumbing parts dry.

Figure 2. Gas control features

TO LIGHT APPLIANCE

1. STOP! Before lighting, read the water heater's safety

information label.

2. Turn temperature setting knob to OFF position (Figure 3).

3. Wait at least five minutes to clear out any gas, and then

smell around the appliance area near the floor. If you smell

gas, STOP! Follow the instructions "

What to do if you smell

gas

"on the first page of the instruction sheet. If you do not

detect gas, continue with the next step.

4. To expose inner door sight glass, remove outer door and

insulation (if applicable). Do not attempt to remove inner

door assembly.

5. Rotate the combination gas control thermostat knob clock-

wise ( )to the "PILOT" position (Figure 3).

6. Depress and hold the gas control thermostat knob all the

way in while immediately depressing the "PILOT IGNITER"

button. Repeat pressing the "PILOT IGNITER" button until a

pilot flame can be seen through the inner door sight glass.

7. Once the "STATUS" indicator light begins to blink once,

release the combination gas control thermostat knob.

•If the gas control thermostat knob does not spring

back, stop immediately and call a qualified service

person or your gas supplier.

•If the "STATUS" indicator light does not start blinking

once after 90 seconds or the pilot is not lit, repeat

steps 2 through 6.

•If "STATUS" indicator light does not start blinking

once after 3 attempts, call a qualified service person.

8. Verify the pilot remains lit by viewing the pilot flame

through the sight glass window located on the inner door.

9. Replace the inner door insulation (if applicable) and the

outer door.

10. Set the gas control thermostat knob to the desired setting

(Figure 3).

If the gas control thermostat knob does not allow rotation

from the pilot position to a temperature setting, do not use

tools or excessive force, call a qualified service person or

your gas supplier.

PILOT TUBE

FITTING

PILOT

GENERETOR

CONNECTION

MAIN BURNER

TUBE FITTING

PIEZO

CONNECTION

PIEZO

IGNITER

BUTTON

THERMOSTAT KNOB

GAS CONTROL

GAS SUPPLY PIPE

SHUT OFF VALVE

GROUND JOINT

UNION

TEE

DRIP LEG (SEDIMENT TRAP)

3" MINIMUM (MANDATORY)

4

0695000_IBK rev. 00

WARNING

Scald burns occur in under one second with 155°F water, which

this thermostat will deliver if the temperature is set at "VERY

HOT". Lower settings of the temperature will reduce the risk of

scald and will reduce your fuel bill.

OPERATION

After the gas and electric connections are made and the water

heater tank is full of water, the control must be set to the desired

water temperature. The recommended thermostat knob setting is

the "HOT" setting. This is approximately the 125°F setting and the

safest and most economical setting for the water heater. If you

want hotter water rotate the thermostat knob clockwise ( )to a

higher setting. If you want cooler water, rotate the thermostat knob

counter clockwise ( )to a lower setting (Figure 3)

Figure 3. Thermostat knob settings

WARNING

The hotter the water the greater the risk of scald injury and the

shorter the time to cause injury.

WARNING

Never allow small children to use a hot water tap, or to draw

their own bath water. Never leave a child or impaired person

unattended in a bathtub or shower. Scald burns can result.

If you use hot water frequently and in short spurts, water

temperature can occasionally exceed the temperature setting by

up to 30°F because of the dynamics of the appliance.

Keep this in mind when you are selecting a temperature higher

than the factory default setting.

Be sure to protect babies, small children, and the infirm or other

with impaired mobility who cannot get out of the hot water

quickly. They are people most commonly hurt in scald injuries and

in need of lower temperature and other protection like

supervision, point of use temperature control equipment or a

system mixing valve. A point of use valve or system mixing valve

can be obtained from your local plumber.

To avoid scald injury, set the control to the lowest setting which

will deliver your needed hot water. Refer to Table 1 to determine

the approximate temperature setting, and the approximate time

for scald injury at that temperature

SHUTTING OFF GAS TO THE APPLIANCE

Rotate the temperature setting knob counter-clockwise to the "OFF" position. Note: The "STATUS" indicator light will briefly turn green then

go off after a short period of time (Figure 3).

TROUBLESHOOTING

The status indicator monitors the control system and indicates fault conditions via the status light. Fault conditions are indicated by a flash

sequence that identifies the probable cause of the fault. Note the status flash code and call your service technician or gas service supplier.

STATUS CODE DIAGNOSTIC

No LED Gas Control OFF - Pilot not Lit

1 Flash Every 4 Seconds Normal operation, Burner OFF

1 Flash Every 1 Second Normal operation, Burner ON

Solid LED Gas Control Recently Turned OFF - Thermopile Voltage Decreasing

2 Flashes Pilot Lit - Insufficient Voltage to Power & Run Gas Control

4 Flashes Water Temperature too High - Control Reset

5 Flashes Gas Control Problem - Replace Control

SETTING

APPROXIMATE

TEMPERATURE

APPROXIMATE

TIME

TO CAUSE INJURY

HOT 125°F 5 minutes

A133°F 30 seconds

B140°F 5 seconds

C148°F 1.5 seconds

VERY HOT 155°F Under 1 second

OFF setting PILOT setting

LOW setting

Table 1. Approximate temperature settings

VERY HOT setting HOT setting

Other Sit Control Unit manuals