Sit PROFLAME 880 Technical manual

880 PROFLAME

USE AND INSTALLATION INSTRUCTIONS

Read the instructions before use. This control must be installed in accordance with the rules in force.

9.957.018 02

USE AND INSTALLATION INSTRUCTIONS

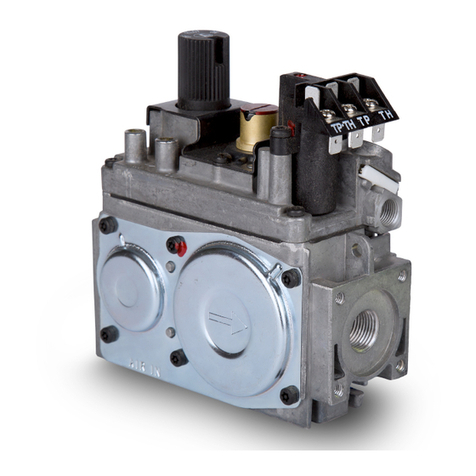

880 consists of two automatic shut-off valves and a servo pressure regulator in series in the main gas

path.

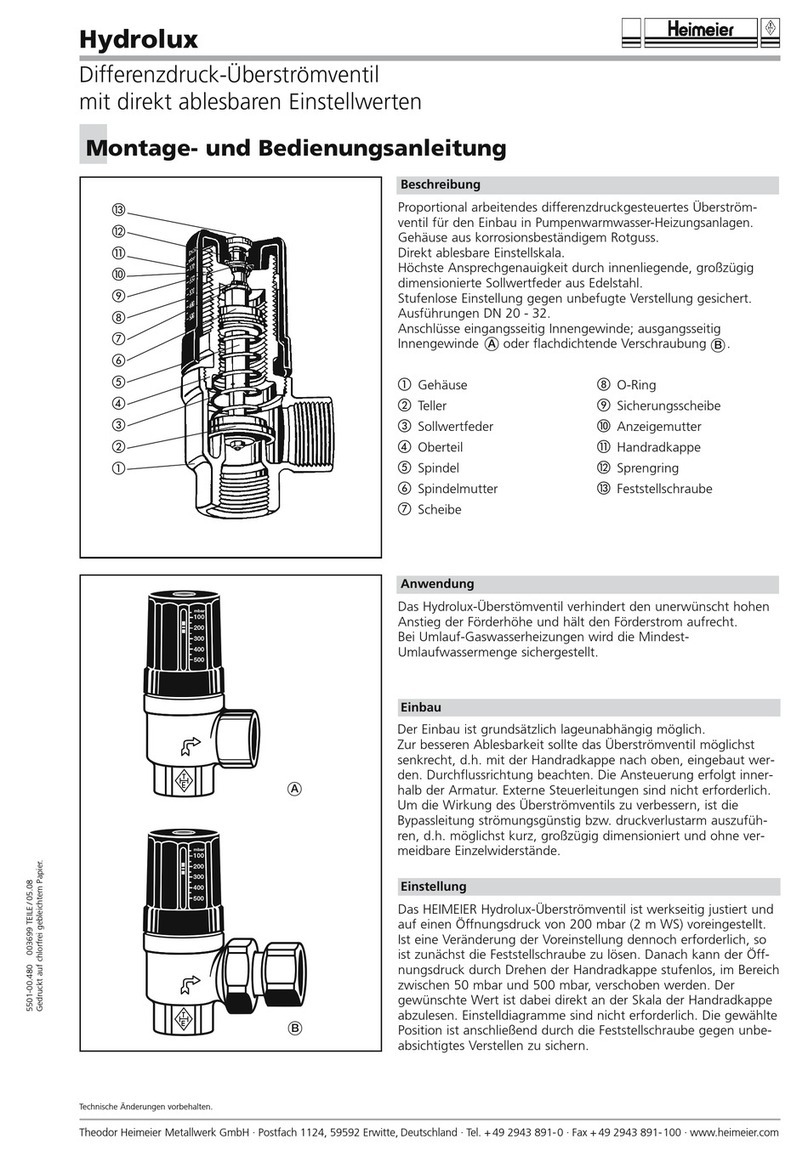

With reference to the schematic block in Fig. 1:

•

FLI is the inlet filter.

•

EV1 is the first automatic shut-off valve.

•

EV2 is the second automatic shut-off valve.

•

RP is a pressure regulator.

•

FLO is the outlet filter (on request).

•

PA is the pilot adjustment screw.

•

FLP is the pilot filter.

GAS

INLET

FLI

EV1

RP

EV2

MAIN

BURNER

PILOT

BURNER

FLP

FLO

MD

PA

GAS

INLET

FLI

EV1

RP

EV2

MAIN

BURNER

PILO

T

BURNER

FLP

FLO

PA

Fig. 1: 880 schematic blocks.

TECHNICAL DATA

Gas inlet and outlet connections 3/8”- 18 NPT ANSI B 1.20.1

Pilot outlet 7/16“- 24 UNS - 2B ANSI

Installation position Upright, LTD horizontal (Never Upside down)

Gas families Natural gas NG ,LPG

Maximum gas inlet pressure 1/2 PSI

2

NORMATIVE REFERENCE

ANSI Z21.78

CSA 6.20

USE AND INSTALLATION INSTRUCTIONS

3

1

ON-OFF solenoid EV1 terminal

2

ON-OFF solenoid EV2 terminal

3

Inlet pressure test point

4

Outlet pressure test point

5

Pressure regulator adjusting screw

6

Pilot adjusting screw

7

Pilot outlet

8

Gas inlet with protective seal

9

Gas outlet with protective seal

10

Ground connection

11

Mounting dead holes

12

Mounting through holes

VALVE DESCRIPTION

•

Aluminium alloy body

•

In-line inlet and outlet

•

Pilot outlet

•

Inlet filter

•

Inlet pressure test point

•

Outlet pressure test point

•

Two mounting through holes on the side

•

Two mounting dead holes on the gas inlet and outlet

MAIN FEATURES

12

10

6

8

11

11

4

3

5

7

9

12

12

11

11

USE AND INSTALLATION INSTRUCTIONS

4

INSTALLATION

When installation of this product begins…

1. Read all of these instructions carefully. Failure to follow these instructions could damage the

product or cause a dangerous condition.

2. Check the ratings given in the instructions and on the appliance to make certain that the control

is suitable for your application.

3. All operations of installation, calibration, conversion and regulation must be undertaken

exclusively by a qualified and certified Gas Appliance Service Technician following the

instruction specified in this catalog and those in the instruction manual of the appliance in which

the valve is installed.

4. After installation is complete, verify that the appliance is operating as indicated in these

instructions.

STOP

Do not install, replace, or in any way modify the gas valve or the appliance, unless

CERTIFIED and QUALIFIED as a Gas Appliance Service Technician on the appliance this

valve is used on. READ AND FOLLOW ALL INSTRUCTIONS.

CAPACITY

880- Power test gas A [Kbtu/h, d=0.64, Hi=37.3 Mj/m3]-Pinlet=3,5["w.c.]-d pil = 0.3mm

0

10

20

30

40

50

60

70

80

90

100

110

120

0 0.5 1 1.5 2 2.5 3

∆P ["w.c.]

P [kbtu/h]

FLOW RATE Q AS A FUNCTION OF PRESSURE DROP P

OPERATION

880 Proflame has two automatic shut-off valves. When both of them are de-energised, it is only

possible to measure the inlet pressure on the inlet pressure test point.

When the solenoid EV1 is energised the first gas valve opens. The pilot outlet is enabled.

Energising the second solenoid EV2, the second valve also opens and the gas flows through the

main outlet.

It is possible to measure the outlet pressure on the outlet pressure test point.

The servo pressure regulator diaphragm system allows improved performance of outlet pressure

regulation. The outlet pressure can be adjusted by a screw.

USE AND INSTALLATION INSTRUCTIONS

5

WARNING

Oxygen Depletion Hazard. Can cause injury or death by asphyxiation.

Do not use valves for vented appliances on unvented or vent free appliances. Do not use

valves for unvented or vent free appliances on vented appliances.

WARNING

Fire or Explosion Hazard. Can cause property damage, severe injury or death.

Follow these instructions completely.

1. Turn off gas supply at the appliance service valve before installation, and perform a Gas

Leak Test after the installation is completed.

2. Always install the sediment trap in the gas supply line to prevent contamination of the gas

control.

CAUTION

Electrical shock or equipment damage hazard.

Can shock individuals or short equipment circuitry.

Make sure to disconnect all electrical supplies before beginning the installation process.

IMPORTANT

•

These gas controls are shipped with anti-contamination seals over inlets and outlets.

•

Do not remove the seals until ready for connection to piping.

•

Appliance manufacturer’s instructions supercede any instructions listed in this instruction book.

WARNING

DO NOT SUBJECT THE VALVE TO BENDING IN EXCESS OF 310 LBF IN

AND TORQUE IN EXCESS OF 220 LBF IN

General recommendations

• Do not tamper with sealed parts

• Do not slacken assembly screws

• Do not remove labels

• Avoid blows (knocks, falls etc.)

• Only remove dust caps when installing

• Do not exceed recommended torque

• Ensure that the gas flows in the direction

shown by the arrow on the valve body

WARNING

IF A SINGLE VALVE FALLS, DO NOT USE FOR PERFORMANCE AND

SAFETY REASONS

WARNING

DO NOT TORQUE OR BEND

THE EV1 AND EV2 MALE

TERMINALS BEFORE, DURING

AND AFTER THE WIRING

CONNECTION OPERATION

TO AVOID THE RISK OF

BREAKING THE EV1 AND THE

EV2 MALE TERMINALS, SEE

PICTURE ON THE RIGHT.

EV1 EV2

EARTH

• Use only the specified spanner grips when making

the connections (see Fig. 3)

• Do not push on the side covers of the valve

• Do not immerse in water or subject the multifunctional

gas control to temperatures exceeding 70°C

• Turn off gas supply before starting installation.

USE AND INSTALLATION INSTRUCTIONS

INSTALL PIPING TO GAS VALVE

All piping must comply with local codes and ordinances or with the National Fuel Gas code (ANSI

Z223.1 NFPA No. 54) whichever applies. Tubing installation must comply with approved standards

and practices. Use appropriately sized fittings when

connecting aluminum tubing to the pilot outlet.

1. Use new, clean and correctly reamed pipe free from

burrs, chips, debris and any foreign matter. When

tubing is used, make sure the ends are square

and clean. All tubing bends must be smooth and

without deformation.

2. Run pipe or tubing to the valve. If tubing is used,

obtain a tube-to-pipe coupling to connect the tubing to the valve.

3. Install sediment trap (Drip Leg) in the supply line to the gas valve.

INSTALLING THE VALVE

1. Mount the valve in the desired position (NEVER UPSIDE DOWN).

2. Mount the valve so the flow of gas is consistent with the gas flow arrows on the valve.

3. Apply a moderate amount of quality pipe compound (DO NOT USE TEFLON TAPE)

to the pipe only, leaving two end threads bare. On LP installations, use compound that

resists exposure to LP gas.

4. Remove seals over inlet and outlets if necessary.

5. Connect pipe to valve inlet and outlet. Place a 1” 1/16 wrench on valve as shown in Fig. 3.

6. Thread pipe into the valve until a gas tight seal is achieved. Typically, for NPT thread,

penetration is usually no more than the diameter of the pipe or 2 and 1/4 turns thread. Valve

distortion or mechanical failure can result if the pipe is inserted too deeply.

7. Connect pilot tubing to valve with appropriately sized fittings as shown in Fig. 4.

8. Confirm gas tight seals with gas leak test.

3” MIN.

GAS SUPPLY

TO CONTROL

INLET

DRIP LEG (DOWN)

6

WARNING

THE MOUNTING DEAD HOLES DEPTH IS SHOWN IN FIG. 2. MAKE SURE

TO USE SCREWS OF APPROPRIATE LENGHT. THE SCREWS MUST NOT

PUSH THE BOTTOM OF THE MOUNTING HOLES.

Fig. 2

SECTION OF THE MOUNTING HOLES

7.5 [0.295] MIN

Ø 3.6 [Ø 0.142] (N° 4)

MOUNTING HOLES

SECTION OF THE MOUNTING HOLES

7.5 [0.295] MIN

Ø 3.6 [Ø 0.142] (N° 4)

MOUNTING HOLES

SECTION OF THE MOUNTING HOLES

7.5 [0.295] MIN

Ø 3.6 [Ø 0.142] (N° 4)

MOUNTING HOLES

Dimensions are in millimeters. Dimensions between [...] are in inches

USE AND INSTALLATION INSTRUCTIONS

7

PERFORM GAS LEAK TEST

GAS LEAK TEST

•

Using a solution of soapy water, paint the piping connections, which are upstream of the

control. The presence of bubbles indicates a gas leak.

If a leak is detected, tighten the pipe connections and repeat leak test.

•

Light the main burner.

•

With the main burner in operation, paint all piping connections from the valve with a soap and

water solution.

•

If another leak is detected, tighten the connection.

•

If after tightening the connections the leak is still present, replace the leaky part or valve. Shut

off the main gas supply before attempting replacement of parts or the valve.

•

Using the soap and water solution, test the pressure test ports to verify that no leak is present.

•

If a leak is detected, tighten the screw and retest.

•

If after tightening the pressure test port screw and the leak is still present, shut off main gas

supply, then replace the valve.

WARNING:

Fire or Explosion hazard.

Can cause damage to property and severe injury or death.

The appliance where this combination gas control is installed, does not have a permanent

pilot. It is equipped with an ignition device which automatically light the burner.

•

Do not try to light the burner by hand.

•

The appliance can turn on suddenly. Keep away from the main burner.

WARNING:

Stand away from the main burner while lighting.

Hidden gas leaks can cause flashbacks in the appliance area. Check for gas leaks with rich

soap and water solution any time work is done on a gas system.

FINAL CHECKS

MAINTENANCE

This valve is not field serviceable. There are no replaceable parts. Do not disassemble, or

attempt replacement of any parts on or in the valve. Improper adjustment or tampering with

settings can result in severe injury or death.

Fig. 4

Fig. 3

Table of contents

Other Sit Control Unit manuals

Popular Control Unit manuals by other brands

Savant

Savant SAV-LMP-0300 Quick reference guide

Robe

Robe ANOLiS SubDrive 1 user manual

Solar Frontier

Solar Frontier SF145 - 170 - S installation instructions

NEP

NEP PVG-4 Installation and operation manual

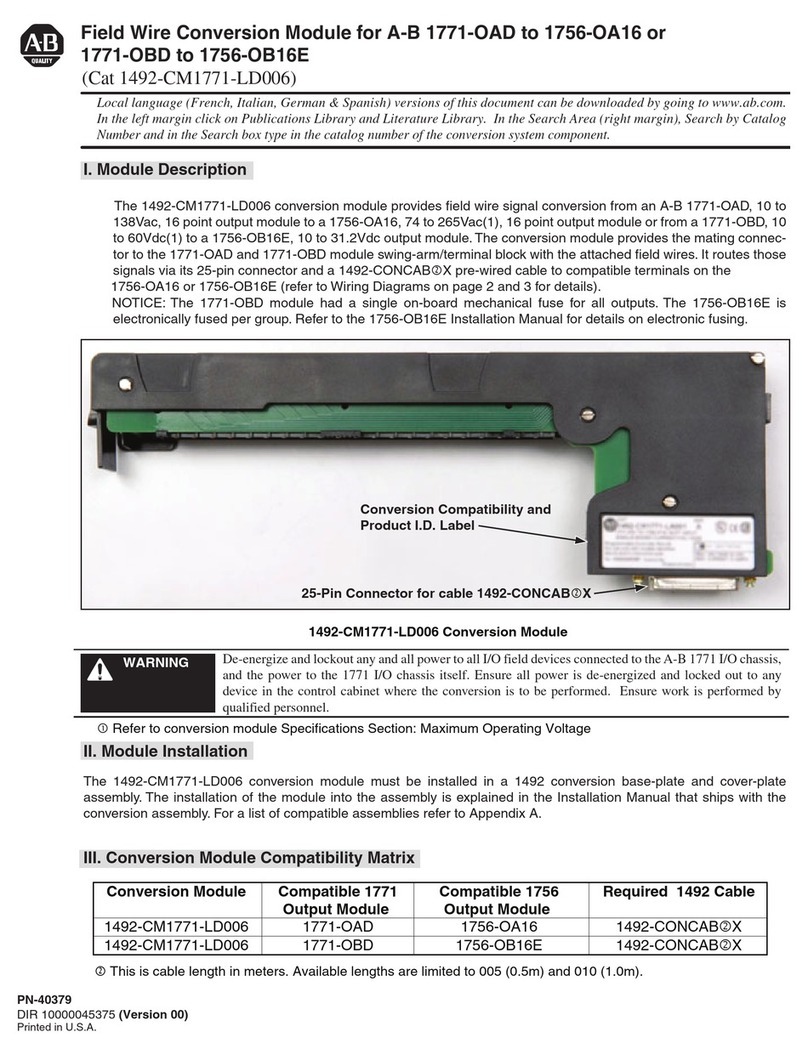

Allen-Bradley

Allen-Bradley 1492-CM1771-LD006 installation manual

Phaesun

Phaesun PN-XFlex 83W Safety and installation manual