Sita IT Series Reference manual

ULTRAVIOLET DISINFECTION

IT SERIES

UV 80 IT

MANUAL OF INSTALLATION, USE AND SERVICING

English 01-2015 Rev. 06-2019 Rev.C

1

INDEX

1. Introduction.........................................................................................................................................................2

2. General Principles ...............................................................................................................................................3

3. Permissible operating range (data) according to ÖNORM M5873-1:2001.........................................................6

4. Instruction for installation and servicing............................................................................................................8

4.1. Installation scheme recommended...............................................................................................................................9

5. The UV Chamber Installation ...........................................................................................................................12

5.1. Assembling of the UV chamber.................................................................................................................................12

6. Safety measures and regulations .......................................................................................................................16

6.1. Elettricity...................................................................................................................................................................17

6.2. Mechanical dangers...................................................................................................................................................17

6.3. Esposure to high intensity UV light...........................................................................................................................17

7. Run the System.................................................................................................................................................17

8. Touch Screen Panel...........................................................................................................................................18

8.1. Main Screen...............................................................................................................................................................18

8.2. Setting menu..............................................................................................................................................................19

8.3. Lamps menu ..............................................................................................................................................................20

8.4. Panel menu ................................................................................................................................................................23

8.5. Sensor menu ..............................................................................................................................................................27

8.6. Automatic cleaning system........................................................................................................................................30

8.7. Parameters .................................................................................................................................................................31

8.8. Datalog - Events ........................................................................................................................................................33

8.9. List of alarms and troubleshooting ............................................................................................................................35

9. Spare parts.........................................................................................................................................................39

10.Warranty Condition...........................................................................................................................................40

11.Declaration Of Conformity ...............................................................................................................................41

2

1.Introduction

This manual is for the following models of UV IT Series.

UV 80 IT

This Pressure UV Systems is manufactured by S.I.T.A. s.r.l.

These operating instructions contain important information for the operation and maintenance of the

equipment.

Please ensure that these operating instructions are carefully read by all relevant persons before putting

into operation, to ensure the safe use of the UV system. The operating instructions are an integral part

of the equipment supply.

Before putting into operation, all the conditions necessary for safe operation of the equipment must be

fulfilled.

The installation, commissioning and maintenance of the equipment should only be carried out by

qualified personnel.

The equipment should only be operated by authorized personnel who have been trained accordingly.

No modifications should be made to the equipment without consulting S.I.T.A., as this could effect the

safe operation of the unit. S.I.T.A. shall not be held responsible for damage resulting from unapproved

modifications.

INSTRUCTION:

The operating instructions are to be kept where they will be accessible for operating and

maintenance personnel.

3

2.General Principles

The UV 80 IT SERIES sterilizers have been planned specially for destroying harmful bacteria and

viruses present in your water.

Their working is based on a physical principle which is a warrant of security: the output of ultra-violet

irradiation.

The UV light given out by special mercury fumes lamps (UV-C rays = 254nm) is highly germicidal

because it interacts with DNA and RNA, at a molecular level.

The deep bio-structural disorder caused by such irradiation interferes with the development and the

ability of reproduction of every kind of micro-organism, making it harmless.

Generally it is better to mount a pre-filter before the UV sterilizer, in this way the impurities of every

nature and consistence are kept.

This system comes to be necessary if we want to have a high degree of sterilization, infact the non-

filtration and removal of suspended particles in the water has, as a consequence, a decrease of the

sterilizer's efficiency.

If the water to be treated contains sulphydric acid or more than 0.3 p.p.m. of iron or filtrable solids,

once passed through the sterilizer, it leaves a residual sediment on the quartz sleeve, which, therefore,

must be periodically cleaned (the frequency depends on the quantity and quality of water treated).

The sterilization equipment is constituted by different electronical and electromechanical components

assembled in such a way to realize effectively the sterilization process, giving a bacteriologically pure

water.

GENERAL DIRECTIONS

According to the European rules EN 60204-1 (safety of the set-up off the electrical equipment-general

rules) the low tension electrical instruments (rule 2014/35/CE) must be connected to a current-tap

provided with grounding.

SAFETY DIRECTIONS

The light of ultra-violet lamps can cause serious burns to unprotected skin and eyes,

therefore it is recommended not to connect it to the current tap without having before

ensured the UV lamp in its housing and inserted the PVC cover.

INDICATIONS FOR THE DISPOSAL

We remind that, according to what is fixed by D.L. 4 May 2014, N°27 "Accomplishment of directive

2011/65/CE, concerning the reduction of dangerous subrtances in electric and electronic equipments"

both mercury vapours lamps and electrical panels, when no more used, must be considered as special

waste, and in the same way disposed of.

To do that, it is possible to address to specialized centres for the recovery of dangerous materials, or to

contact directly our technical department.

ELECTRICITY

The lightning flash and arrowhead symbol is to alert the user to the presence of un-

insulated "DANGEROUS VOLTAGE” within the enclosure.

The equipment may only be opened if the mains supply is isolated. The mains supply must not be

restored as long as the equipment is open. This applies to both the electrical control panel and the

reactor vessel.

4

Attention:

Working on live equipment is forbidden.

INFORMATION TO USERS pursuant to art. 14 of the 2012/19 / EU DIRECTIVE OF

THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 4 July 2012 on waste

electrical and electronic equipment (WEEE)

The crossed bin symbol on the appliance or on its packaging indicates that the product

at the end of its useful life must be collected separately and not disposed of together

with other mixed urban waste.

Please contact your municipality, or local authority, for all information regarding the separate

collection systems available in the area. The retailer is obliged to collect the old equipment free of

charge when buying new equipment of an equivalent type, for the purpose of starting the correct

recycling / disposal.

Appropriate separate collection for the subsequent start-up of the disused equipment for recycling,

treatment and environmentally compatible disposal helps to avoid possible negative effects on the

environment and on health and favors the re-use and / or recycling of the materials it is composed of

the equipment

5

INSTALLATION GUIDANCE

The reactor control panel utilises air cooling. The following guidelines must be adhered to when

locating the unit.

The reactor and control panel must not be located in a position where the ambient air temperature

exceeds 40ºC.

The reactor and control panel must not be located adjacent to other equipment that directly emit heat

The reactor and control panel must not be located adjacent any chemical equipment that is likely to

emit fumes.

The reactor should be located within the piping system in such a manner as to ensure that sufficient

clearance is available in a horizontal direction to allow for lamp replacement and wiper maintenance.

See the relevant data information included in this manual.

The reactor must be positioned with the side flanged pipe connections pointing in an upwards direction.

Never install the reactor in a position directly adjacent to chemical dosing points.

6

3.Permissible operating range (data) according to ÖNORM M5873-1:2001

Permissible range of operation is the result of typetest according to ÖNORM M5873-1:2001.

For each UV-transmittance (%) is reported the minimum reference irradiance (W/m2) and the

maximum flow (m3/h) considering that the minimum Reduction Equivalent Fluence demanded is 400

J/m2.

UV 80 IT

UV-trasmittance

%T100 (100mm)

UV-trasmittance

%T10 (10mm)

Minimum reference

irradiance Emin

Maximum flow

Qmax

%

%

W/m2

m3/h

< 9

< 78,6

not permitted

0,00

9

78,6

97,14

14,59

10

79,4

100,48

15,90

11

80,2

103,54

17,14

12

80,9

106,36

18,32

13

81,5

108,98

19,45

14

82,2

111,44

20,53

15

82,7

113,76

21,57

16

83,3

115,95

22,57

17

83,8

118,04

23,55

18

84,2

120,03

24,50

19

84,7

121,95

25,43

20

85,1

123,80

26,35

21

85,6

125,60

27,24

22

85,9

127,34

28,13

23

86,3

129,04

29,00

24

86,7

130,70

29,87

25

87,1

132,33

30,73

26

87,4

133,93

31,59

27

87,7

135,51

32,45

28

88,0

137,07

33,31

29

88,4

138,62

34,16

30

88,7

140,15

35,02

31

88,9

141,67

35,89

32

89,2

143,18

36,75

33

89,5

144,68

37,63

34

89,8

146,18

38,51

35

90,0

147,68

39,39

36

90,3

149,17

40,29

37

90,5

150,67

41,19

38

90,8

152,16

42,10

39

91,0

153,65

43,03

40

91,2

155,15

43,96

41

91,5

156,64

44,90

42

91,7

158,14

45,86

43

91,9

159,65

46,82

44

92,1

161,16

47,80

45

92,3

162,67

48,79

46

92,5

164,18

49,79

7

47

92,7

165,70

50,80

48

92,9

167,22

51,83

49

93,1

168,75

52,86

50

93,3

170,28

53,91

51

93,5

171,81

54,98

52

93,7

173,35

56,05

53

93,8

174,89

57,14

54

94,0

176,43

58,23

55

94,2

177,98

59,34

56

94,4

179,53

60,47

57

94,5

181,08

61,60

58

94,7

182,63

62,74

59

94,9

184,19

63,90

60

95,0

185,74

65,06

61

95,2

187,30

66,24

62

95,3

188,85

67,42

63

95,5

190,40

68,61

64

95,6

191,95

69,82

65

95,8

193,50

71,03

66

95,9

195,05

72,24

67

96,1

196,59

72,24

68

96,2

198,13

72,24

69

96,4

199,67

72,24

70

96,5

201,19

72,24

71

96,6

202,72

72,24

72

96,8

204,23

72,24

73

96,9

205,74

72,24

74

97,0

207,24

72,24

75

97,2

208,73

72,24

76

97,3

210,21

72,24

77

97,4

211,68

72,24

78

97,5

213,13

72,24

79

97,7

214,58

72,24

80

97,8

216,01

72,24

81

97,9

217,43

72,24

82

98,0

218,83

72,24

83

98,2

220,22

72,24

84

98,3

221,59

72,24

85

98,4

222,94

72,24

86

98,5

224,27

72,24

Table max flow at each UVT obtained with interpolation of the test points results

In the table is shown the maximum flow rate that the UV system can treat at each transmittance of the

water.

eg. at water UVT(10) = 91% the UV system can treat max 43.03 m3/h . and the minimum irradiance

is 153.65 W/m2.

NOTE: In this condition the alarm threshold level of the UV system MUST be set at 153.65 W/m2.

Once that the end user knows approximately the UVT% of the water then he can check the min

Irradiance in W/m2that the system can show to give at least 400 J/m2.

8

An UV irradiance higher than the threshold level means that the dose is higher than 400 J/m2and this

guarantee a good disinfection. If it’s lower than the user must clean the quartz sleeves, clean the sensor

measuring window or check the UVT% of the water. The irradiance threshold level can be set in the

electrical panel.

4.Instruction for installation and servicing

General premise

The installation of the UV 80 IT SERIES sterilizer units must be carried out by specialized staff,

scrupolously following the instructions given hereby. It has been moreover considered necessary to

give some general information about the electrical and water connections.

Cautions: check that the UV panel is not connected to the power supply and that the tap of the water to

be treated is turned off.

•Connect the delivery of the water to be treated to the special water connection

•Turn on water and check for possible leaks in any part of the unit

•Connect the plug to the current tap

•Check that the disinfected water comes out and that the LEDS on the panel of the control board, signal

the correct working

Let the disinfected water flow down to outlet for at least 10 minutes before using it, in order to make

the possible impurities present in the unit drain out.

NOTE: it is recommended to install a water filter directly before the UV sterilizer in order to remove

the suspended particles, eventually present in the water to be treated, which could limit the efficiency

of sterilization.

CHECKS

The UV 80 IT SERIES is ready for producing disinfected water, once the connection to the water

system and to the electrical grid is carried out. The unit works automatically, the electronical boards

which control the signals reaching the control panel, allow the visualization (or the sonorization) of the

correct working or of anomalies which may occur during the operating of the unit.

MAINTENANCE

The UV System of UV 80 IT SERIES have been projected and realized by S.I.T.A. Srl with simple

and functional principles which make the checking procedures and the periodical servicing particularly

easy.

The main points which characterize the ordinary servicing are the following: check quarterly the

quartz sleeves, which contain the UV lamps, in order to ensure the maximum disinfection, for the

cleaning.

Maintenance work may only be carried out by personnel who have been trained and authorized for this

work by the owner and/or user. The owner and/or user must ensure that the maintenance personnel are

familiar with the safety measures and regulations, and that they also comply with them, in addition to

having read and understood the operating instructions.

Only original replacement parts from the supplier must be used.

The following are the recommended service intervals for replacement parts:

UV lamp change - once per 14000 hours

UV lamp o-ring change - once per year

UV lamp thimble clean - frequency depends on the quality of the water

Control Panel filter mat - clean or change at same time as UV lamp change.

In addition the wiper drive mechanism should be inspected on a yearly basis.

9

4.1. Installation scheme recommended

10

11

12

5.The UV Chamber Installation

5.1. Assembling of the UV chamber

● Unscrew the s/s sleeve bolts (A) from both sides by using the key supplied.

● Insert the quartz sleeves (B) by using the special bar supplied and the o-rings 38x4 (C) on both sides

of the quartz sleeves.

13

● Screw again the s/s sleeve bolts on both sides of the UV chamber, and carry out the hydraulic test,

verifying that the o-rings are watertight and that no water leaks outside the sleeve bolts or inside the

quartz sleeves.

● On the openable side of the UV chamber, insert the UV-C lamps (D) into the quartz sleeve

previously mounted.

14

● Each lamps has 2 wires connected from the top to the bottom .Lamps must be inserted into the

chamber with these wires in the opposite side to the sensor.

To do this the two pins (signed with the red circle in the photo below) must be in the opposite side to

the sensor.

● Connect to the UV-C lamps the 4-pins connectors (E) mounted as on the figure together with the Ø 1

¼” ring nuts (F), the PG9 nipples (G), and the 4-pins holders in black polyethylene (H) with the

pertinent o-rings 2112 type.

15

● Screw the Ø 1 ¼” ring nuts (F) on the s/s sleeve bolts.

● Mount the o-ring (I) (4112 type) on the measuring window (L) and screw this one on the Ø 1” bush

welded in the middle part of the UV chamber.

16

Insert the sensor (M) inside the measuring window and screw the ring nuts.

Finally, connect the pertinent electrical cable.

6.Safety measures and regulations

17

The equipment must be installed, put into operation and maintained by trained specialists. The owner

and/or user must ensure that the operating personnel have been suitable instructed.

The equipment has been subjected to a hazard analysis, corresponding precautionary measures

regarding the safety of persons and domestic animals have been made. Nevertheless, it is still possible

that danger could arise as a result of incorrect use, bad maintenance, material changes, etc. These

dangers are associated with:

✓Electricity

✓Mechanical dangers

✓Exposure to high intensity UV light

6.1. Elettricity

The lightning flash and arrowhead symbol is to alert the user to the presence of un-insulated

"DANGEROUS VOLTAGE” within the enclosure.

The equipment may only be opened if the mains supply is isolated. The mains supply must not be

restored as long as the equipment is open.

ATTENTION:

Working on live equipment is forbidden.

6.2. Mechanical dangers

The equipment contains glass which must be handled with care.

Broken lamps emits dangerous mercury vapours.

6.3. Esposure to high intensity UV light

The reactor contains UV emitting lamps and if exposed while energised can cause serious eye and skin

damage. Ensure that the mains supply is isolated before opening any of the covers of the reactor.

7.Run the System

The commissioning personnel authorised by the owner and/or user, must read and understand the

operating instructions.

18

The commissioning personnel must be familiar with the safety measures and regulations applicable to

the country/area in which the system is installed.

Turn On/Off the system

The preconditions for starting are:

✓Water is flowing through the vessel.

✓The electrical panel is feeded

✓The lamps have been turn off for 10 minutes

If all these conditions are respected turn on the general switch.

To shut OFF the system turn off the general switch. To shut OFF the lamps but still give power to the

el panel push the OK button for more than 3 sec.

8.Touch Screen Panel

8.1. Main Screen

19

Main screen of the system.

It displays the parameters of flow rate, transmittance, temperature, irradiation, lamps hour meter and

quartz cleaning system (if available). It also displays the lamps power. In case of alarm flashing

"ALARM button” is displayed.

Buttons

ON/OFF

-) Turn on and off the UV lamps.

SETTING MENU

-) It allows to access the settings menu. The user can set all the parameters

useful measures and operation of the system, operate the UV system and

read all the parameters that the system records or stores (see “Main menu”).

Manual Start/Stop cleaning system

-) If the system is equipped with a cleaning system, it allows to start and stop

the cleaning system (when automatic cleaning system is activated the button

is disabled).

Alarms button

-) Visible in case of alarm. Touch to access to the alarm and lamps status

visualization (see "Alarm screen").

8.2. Setting menu

In this menu the user can set, read and manage all the necessary parameters for the measures and the

operation of the system.

Trasmittance

Flow rate

Power lamp

Residual lamps life

Cleaning system

with end switch

animation

Alarms

Temperature

UV irradiance

Date and clock

Unit Shape

Lamps menu

This manual suits for next models

1

Table of contents

Other Sita Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Organomation Associates

Organomation Associates ROT-X-TRACT-LC 13318 instruction manual

Thinky

Thinky ARV-310 instruction manual

Bio-Optica

Bio-Optica BEC150 Instructions for use

SciCan

SciCan STATIM troubleshooting guide

Bertin Technologies

Bertin Technologies Coriolis m user manual

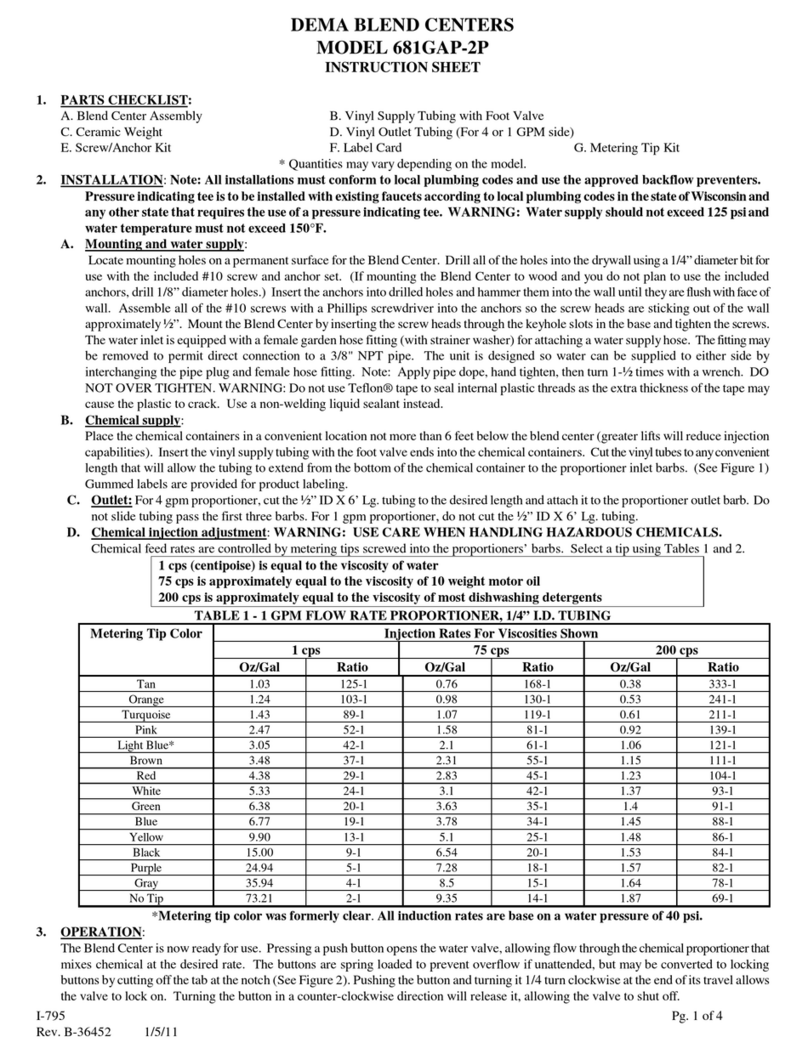

DEMA

DEMA 681GAP-2P instruction sheet

Barnstead Thermolyne Corporation

Barnstead Thermolyne Corporation EASYpure RF 1051 Series Operation manual and parts list

NUVE

NUVE NC 23B user manual

newster

newster NW30 user manual

BIO RAD

BIO RAD Helios Gene Gun System instruction manual

Waters

Waters ACQUITY UPLC Operator's, overview and maintenance guide

Waters

Waters 2707 Operator's guide