Chopin Mixolab User manual

20, avenue Marcellin Berthelot - Z.I. du Val de Seine

92396 Villeneuve La Garenne cedex - France

Tél. : 33 (0)1 41 47 50 88 - Fax. : 33 (0)1 47 92 28 27 www.chopinservice.com

www.chopin.fr

Mixolab

Maintenance manual

Ref.: MM-MIXO-EN Ind. 0

Date: April 2012

Mixolab

3

Maintenance manual MM-MIXO-EN Ind. 0

04/2012

IMPORTANT

The technical elements that constitute this manual (text and illustrations) are not contractual,

their only target being to bring assistance for troubleshooting and repairing the Mixolab.

Use, duplication or disclosure of subject data, for any purpose other than relating to the

servicing or repair of the equipment, is strictly prohibited without the written authorisation of

Tripette & Renaud Chopin.

Mixolab

5

Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Table of contents

Chapter 1 Operation & Maintenance:

reminders & additional information . . . . . . . . . . . . .7

1. Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Precautions related to tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3. Control and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1. Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2. Fault handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3. Interconnection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 3 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2. Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

1. Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

2. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

3. Parts lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Mixolab

6 Maintenance manual MM-MIXO-EN Ind. 0

04/2012

7

Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

Chapter 1 OPERATION & MAINTENANCE:

REMINDERS & ADDITIONAL

INFORMATION

8Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

9

Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

Chapter 1 Operation & Maintenance:

reminders & additional information

Chapter 1. Operation & Maintenance: reminders &

additional information

This chapter summarizes most of the important instructions relating to operation and maintenance of the

Mixolab.

For detailed information, refer to the Instruction Manual.

In addition, this section contains further information solely intended for people entitled to carry out

maintenance and repair operations on these units.

1. Operating conditions ■ Installation

Installation of the equipment requires a plane, clear and clean sur-

face. The equipment must be levelled by means of its adjustable

feet.

Do not place the Mixolab behind a window, particularly if it is

exposed to sunlight for severals hours a day.

The Mixolab must not be placed right up against a wall. Leave

sufficient space to ensure proper ventilation.

The working area shall also take into account all subsidary opera-

tions.

The waste water cooling circuit shall be installed very carefully:

❏ use of reinforced hoses,

❏ fastening with cable clamps,

❏ discharge hose fixed.

■ Electrical connection

Electrical connection of each device shall be performed in compli-

ance with the standard IEC 1010 - installation class: II.

❏ Characteristics of the electric supply source :

• 230 V~ - 50/60 Hz - ≥2 kVA

• Connection with 2 Phase + Earth / 16 A plug

• The electrical network must incorporate, upline from the units, a

differential circuit breaker with a sensitivity ≤30 mA - class AC.

❏ A 2-Phase + Earth supply plug can only be connected to a socket

fitted with a protective conductor.

This is a safety measure: if plugging-in is not possible, do not try to

force it, call a specialist in order to install a suitable socket.

10 Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

Chapter 1 Operation & Maintenance:

reminders & additional information

■ Environment

❏ Operating temperature:

Lab ambient temperature: +10°C < T ≤+ 30°C

❏ Hygrometry:

Use: RH ≤85 %

❏ Pollution:

The Mixolab is designed to operate under conditions free of pollu-

tion, or with a dry and not conducting pollution.

❏ Water of the cooling water circuit

The water temperature of the cooling water circuit must be in a

range between 15 ˚C and 20 ˚C.

2. Precautions related

to tests

■ Tests on the Mixolab must always be conducted with great care.

All necessary instructions (test conditions, handling, cleaning) are

detailed inside the Instruction Manual, and must be respected scru-

pulously; failure to do so could lead to:

❏ erroneous results,

❏ severe damage to the equipment.

■ During handling, the operator must take care not to damage

kneading arm blades.

■ Always check if the placing of the temperature sensor for pastry

on the bowl plate is not being blocked.

11

Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

Chapter 1 Operation & Maintenance:

reminders & additional information

3. Control and

maintenance

■ Status of the LED on front panel

In case of error, the LED stops flashing when the error is

acknowledged on the PC. It returns to the colour reflecting

apparatus status.

■ General recommendations

To improve the efficiency of maintenance operations on the devices,

keep an updated record of interventions, dates and any relevant

information on device life.

■ Reminder of useful menus

❏ Maintenance screen

A screen showing the Mixolab mimic diagram monitors operation of

the main modules of the device.

In order to access this mimic diagram, click on "Configuration" and

then on "Maintenance".

Colour / LED status Meaning Note

Off Mixolab switched off

Green Mixolab ready

Flashing green Electronic init problem (memory...) or 230V on

the board

See Chapter 2

Amber Motor running (MIXOLAB in cycle)

Flashing amber ERR 4, 41, 42, 5, 51, 52, 53 (motor or torque

error)

See Chapter 2

Red Hot bowl (Temperature of the dough

thermocouple or heating block bowl > 50°C)

Blinking red ERR 11, 12, 13, 14, 15, 16, 21, 22 (temperature

error)

See Chapter 2

Flashing Green / amber / Red Mixolab self-tests

Continuous flashing Green / amber /

Red (more than 2 minutes)

Tank empty when switching on

=> switch off and fill the tank

12 Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

Chapter 1 Operation & Maintenance:

reminders & additional information

Note : For passwords, refer to the corresponding procedures in this

manual.

❏ Audit trail

The "Mixolab Chopin" software contains a settings and errors audit

trail that can be useful for Mixolab maintenance.

To access this menu, click on "Audit trail" and then on "Audit trail".

❏ Software update

An "Update" menu allows to download a new version of the

embedded software. This operation can only be performed by

entitled agents - see Operation 11-1 "Updating the Mixolab

software" page 90.

Dough

temperature

sensor

Mixer motor

speed setpoint

Mixer motor real

speed

Parameter access

(password

protected)

Close

Water injection

Cooling solenoid valveTorque sensorCover locking

Mixer bowl

temperature

setpoint

Mixer bowl real

temperature

Mixer bowl locking

Tank temperature

setpoint

Real temperature

of tank

Metering pump

Water injection

solenoid valve

Quantity of

water in ml

Test without temperature

adjustment (Maintenance mode)

13

Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

Chapter 1 Operation & Maintenance:

reminders & additional information

■ Preventive actions

USER It is reminded to users that a regular control of the device perform-

ance, like a "control chart", is highly recommended.

A regular control of the test results on known flour samples allows to

detect errors leading to possible failures (quality of testing opera-

tions, of testing environment or of the equipment).

ENTITLED AGENT It is furthermore recommended to ask CHOPIN or an authorized

agent for a complete overhaul of the equipment.

Recommended frequency: Once a year, possibly every 2 years in

case of less frequent testing.

14 Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

Chapter 1 Operation & Maintenance:

reminders & additional information

15

Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

Chapter 2 TROUBLESHOOTING

16 Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

Chapter 2 Troubleshooting 17

Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

Chapter 2. Troubleshooting

The aim of this chapter is, in case a fault appears, to find the probable origin and to isolate any failed compo-

nent or sub-assembly; the required actions are then detailed.

For any inquiry to TR Chopin, please mention the serial number of the equipment.

1. Method ■ Possible failures are listed in:

- A. Error messages

- B. Other faults.

❏ Other abnormal events may occur:it is then up to the serviceman

to find the solution using analyses and comparisons. Simplified

interconnecting schematics are provided in section 3. of this chap-

ter, they may help to locate failures.

Of course, in case of difficulty or doubt, the engineering services of

CHOPIN Technologies are available to try to solve the problem, via

phone, fax or e-mail.

If this fails, the unit will have to be sent back to CHOPIN for work-

shop troubleshooting and repair.

■ Before starting any troubleshooting, all useful indications should

be recorded.

❏ In the event of abnormal results, a consultation of the results fol-

low-up log (control chart), if one exists, may provide an immediate

answer (case of continual drift for example).

❏ It is recommended to consult the settings audit trail in the menu

"Audit trail".

❏ Regardless of the failure, it is recommended to carefully record

the conditions under which the failure occurred.

If a failure occurred during a test, it is recommended to keep a

record of the curves and test results.

18 Chapter 2 Troubleshooting Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

2. Fault handling Switch off the power supply and disconnect the power cable before

removing covers.

Follow safe practice if you need to perform operations on powered

equipment without covers.

A Error messages

ERR No Description Action See in

Chap.3

ERR 11 "Bowl block T˚ too high!"

Bowl block T˚ > 10% of setpoint in

stable phase

■ Confirm on maintenance screen.

Problem on cooling circuit

- Input water too hot: rectify

- No water a output:

Check hydraulic connection, solenoid valve

operation (using maintenance screen), flow

controller setting.

If the circuit is blocked, find where by dis-

mantling it piece after piece.

■ Wrong temperature information:

- Calibrate bowl temperature measurement.

- Replace temperature sensor if the problem

is not solved.

op. 11-7

op. 11-2

op. 2-2

ERR 12 "Bowl block T˚ too low!"

Bowl block T˚ < 90% of setpoint in

stable phase

■ Confirm on maintenance screen.

■ Wrong temperature information:

- Calibrate bowl temperature measurement.

- Replace temperature sensor if the problem

is not solved.

■ Cooling too important:

- Test the solenoid valve using the

maintenance screen and control its

efficiency on exhaust. If the solenoid valve is

jammed, replace it.

- Check water flow and adjust it if necessary

using the flow controller.

■ Insufficient heating:

- Control the heating circuit

- If necessary, replace the failed resistor(s).

op. 11-7

op. 11-13

op. 2-1

Chapter 2 Troubleshooting 19

Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

ERR 14 "Bowl block temperature rise in

problem!"

After 5 min in calibration, bowl block

T° < 90% of setpoint)

■ Confirm on maintenance screen.

■ Cooling too important :

- Test the solenoid valve using the

maintenance menu and verify its efficiency

on exhaust; if the solenoid valve is jammed,

replace it

- Check the water flow and set the flow

controller if necessary

■ Insufficient heating:

- Check the heating circuit

- If necessary, replace the failed resistor(s).

op. 11-7

op. 11-13

op. 2-1

ERR 13 "Bowl block still hot!"

10 min after end of test

bowl block T° > setpoint T° or 30°C

if setpoint T° > 50°C

■ Confirm on maintenance screen.

Problem on cooling circuit

- Input water too hot: rectify

- No output flow:

check hydraulic connection, solenoid valve

operation (using maintenance screen), flow

controller setting.

If the circuit is blocked, find where by dis-

mounting it piece after piece.

■ Wrong temperature indication :

- Calibrate the bowl block temperature

measurement.

- Replace the sensor if the problem is not

solved.

op. 11-2

op. 2-2

ERR 15 "Bowl still hot!"

10 min after end of test, bowl

thermocouple T˚ still > 50˚C (this

may be a thermocouple problem)

■ Confirm on maintenance screen.

Problem on cooling circuit

- Input water too hot: rectify

- No output flow:

check hydraulic connection, solenoid valve

operation (using maintenance screen), flow

controller setting.

If the circuit is blocked, find where by

dismounting it piece after piece.

■ Wrong temperature indication :

- Calibrate the bowl temperature

measurement.

- Replace the bowl thermocouple if the

problem is not solved

op. 11-7

op. 11-2

op. 2-3

ERR No Description Action See in

Chap.3

20 Chapter 2 Troubleshooting Maintenance manual MM-MIXO-EN Ind. 0

04/2012

Mixolab

ERR 16 "Electronic problem on bowl block

heating!"

Permanent bowl block heating

control detected by heating safety

■ Switch the Mixolab off and then on.

■ Problem on CPU board

- Check all connections on the Mixolab CPU

board

- Replace the CPU board if the problem is

not solved. op. 9-1

ERR 21 "Tank temperature too high!"

Cooling time out (after 15 min of

heating absence, tank T˚ > 110% of

setpoint)

■ Confirm on maintenance screen.

■ The lab temperature is too high (it shall be

lower than [setpoint_T – 5°C]) -> modify it

and wait for temperature decrease or

replace the water by colder water.

■ Wrong temperature indication:

- Calibrate the tank temperature

measurement

- Check and replace the sensor if the

problem is not solved.

op. 11-3

op. 4-5

ERR 22 "Tank temperature too low!"

Heating time out (after 15 min of

heating absence, tank T˚ < 90% of

setpoint)

■ Confirm on maintenance screen.

■ Wrong temperature indication :

- Calibrate the tank temperature

measurement.

- Check and replace the sensor if the

problem is not solved.

■ Insufficient heating :

- Check the heating circuit.

- If necessary, replace the failed resistor.

op. 11-3

op. 4-5

op. 11-13

op. 2-1

ERR 23 "Tank empty!"

Icon at the bottom of the screen = red

Fill the Mixolab tank. If there is enough

water:

■ Wrong indication of water level:

- sensor float jammed: remove it, check it

and replace it if necessary.

- Replace the CPU board if the problem is

not solved.

op. 4-2

op. 9-1

ERR 3 No communication with the Mixolab,

during access to a menu requiring a

dialogue

■ Verify that the Mixolab is correctly

connected and switched on.

■ Check the USB connection (or RS 232

connection) between the PC and the

Mixolab, including internal wiring.

■ Replace the CPU board if the problem is

not solved.

op. 9-1

ERR No Description Action See in

Chap.3

Table of contents

Other Chopin Laboratory Equipment manuals

Chopin

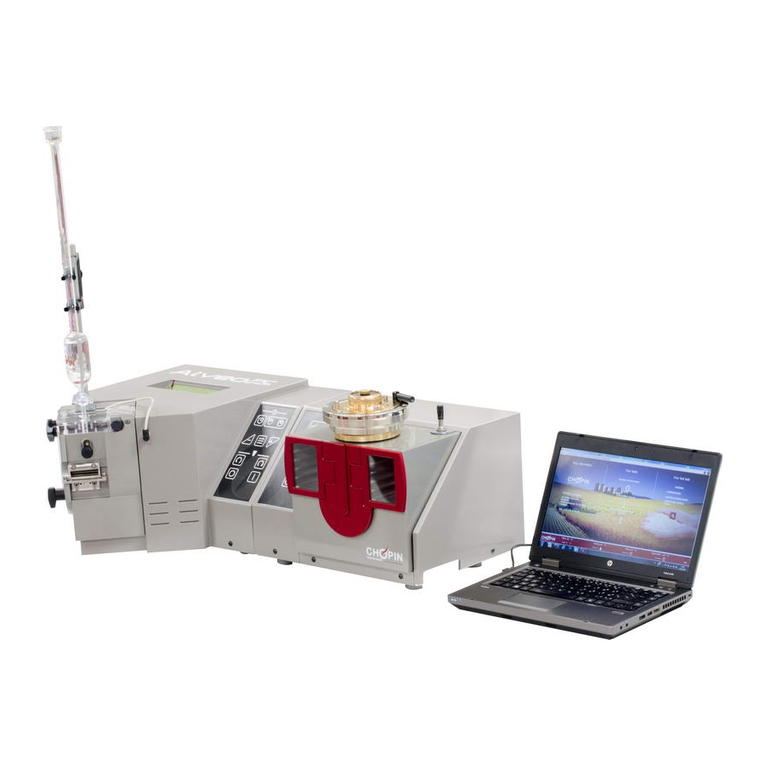

Chopin AlveoLabgraph Instruction sheet

Chopin

Chopin Mixolab 2 Instruction sheet

Chopin

Chopin RHEO F4 Instruction sheet

Chopin

Chopin Infraneo Instruction sheet

Chopin

Chopin SDmatic Instruction sheet

Chopin

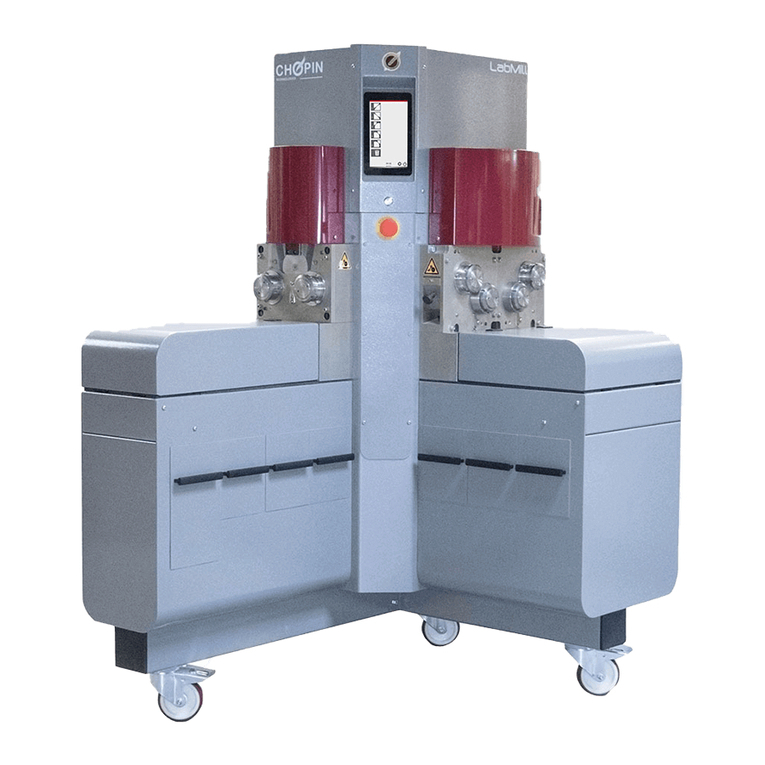

Chopin LabMill Instruction sheet

Chopin

Chopin Mixolab 2 User manual

Chopin

Chopin Alveo PC graph Instruction sheet