SciCan STATIM User manual

Other SciCan Laboratory Equipment manuals

SciCan

SciCan QUANTIM B User manual

SciCan

SciCan Hydrim L11w User manual

SciCan

SciCan HYDRIM C61w G4 User manual

SciCan

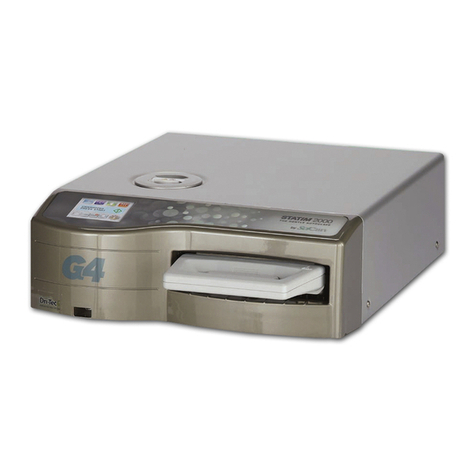

SciCan Statim 2000 Installation guide

SciCan

SciCan statim 2000 G4 User manual

SciCan

SciCan Statim 5000 User manual

SciCan

SciCan STATCLAVE G4 User manual

SciCan

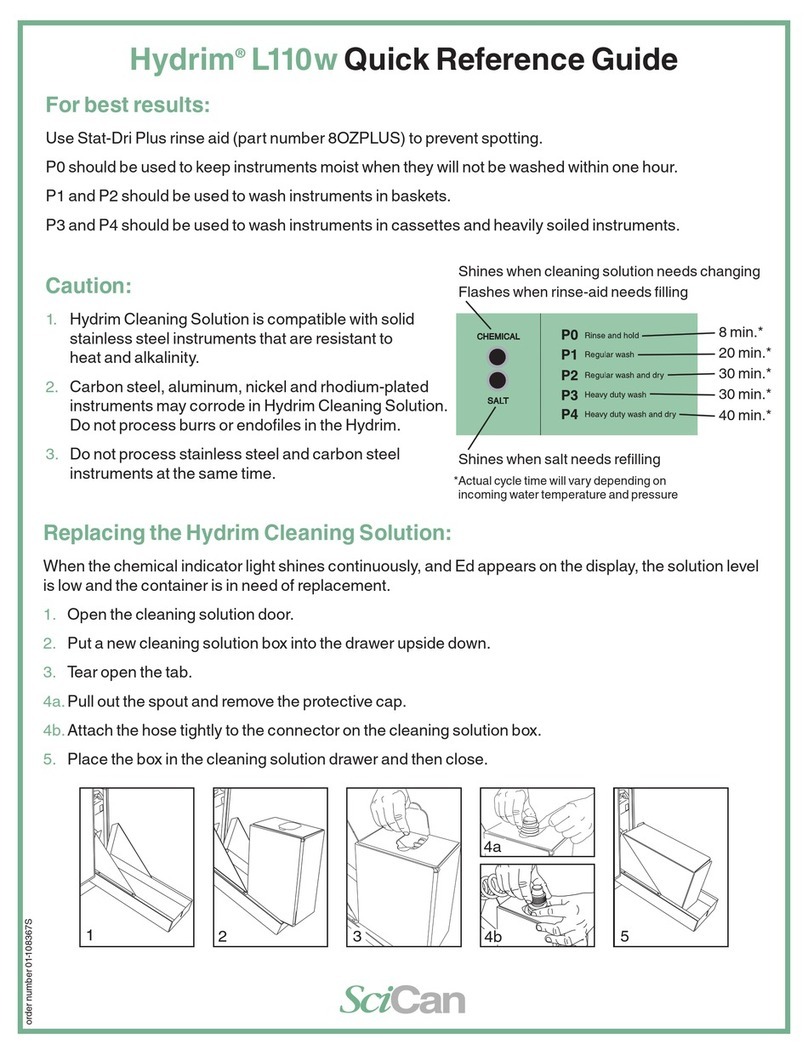

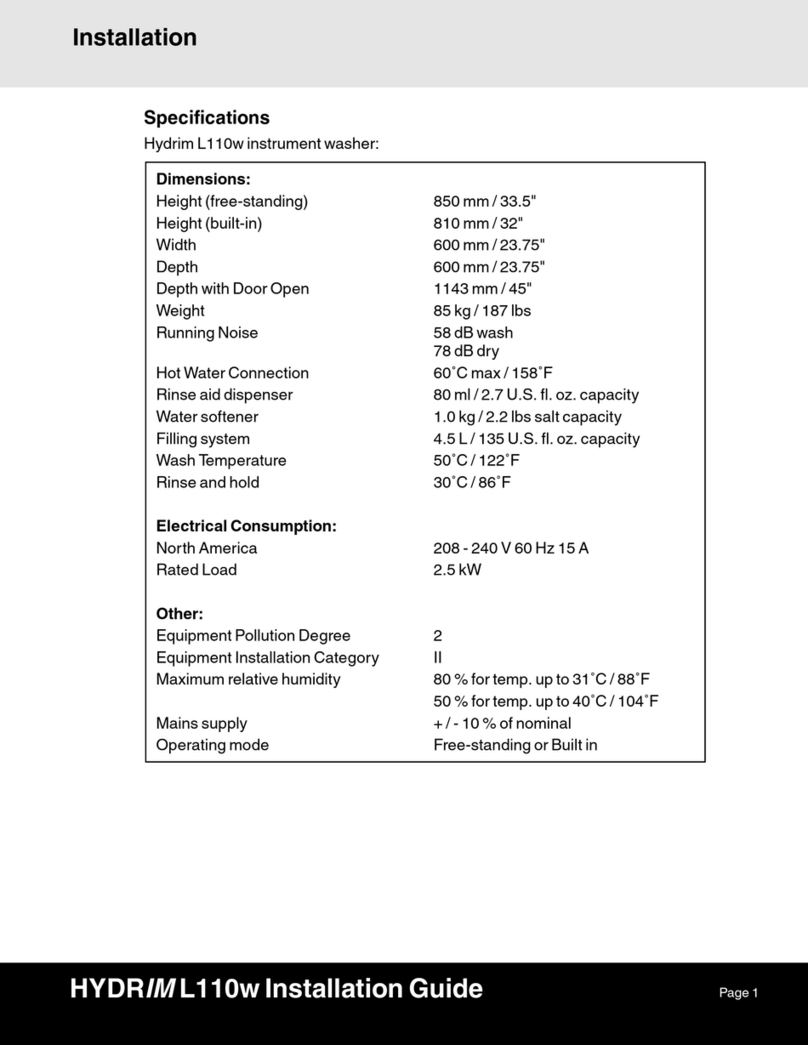

SciCan HYDRIM L110w User manual

SciCan

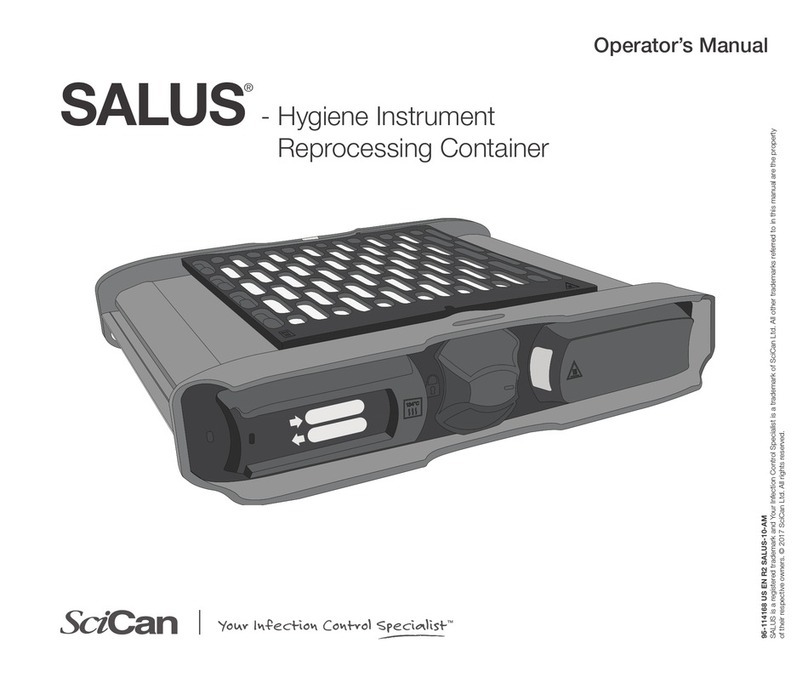

SciCan SALUS User manual

SciCan

SciCan Statim 2000 User manual

SciCan

SciCan BRAVO 17 User manual

SciCan

SciCan STATIM 900J User manual

SciCan

SciCan Bravo User manual

SciCan

SciCan HYDRIM L110w G4 User manual

SciCan

SciCan Statim 2000 Installation guide

SciCan

SciCan statim 5000 G4 User manual

SciCan

SciCan HYDRIM C61w G4 User manual

SciCan

SciCan statim 2000 G4 User manual

SciCan

SciCan Statim 2000 User manual

SciCan

SciCan Quantim 16 User manual

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual