User Manual

Bio-Optica Milano S.p.A. Via San Faustino 58 - 20134 Milan

Phone +39 02.21.27.13.1 - Fax Italy +39 02.21.53.000 - Fax Export +39 02.21.54.155

Publication date: 02/03/2020

Rev. 00

1IMPORTANT INFORMATION

1.1 PRECAUTIONS FOR USE

Before using the instrument, carefully read the instructions and warnings contained in this manual and keep

them for further reference. They provide important information regarding the functions and safety in installing,

using and maintaining the instrument.

Bio-Optica Milano S.p.A. cannot be held liable for any damage resulting from improper or incorrect use and for

failure to comply with the provisions of this manual and the current safety standards.

1. After removing the packaging, make sure that the instrument is intact without visible damage that may have been

caused by transportation.

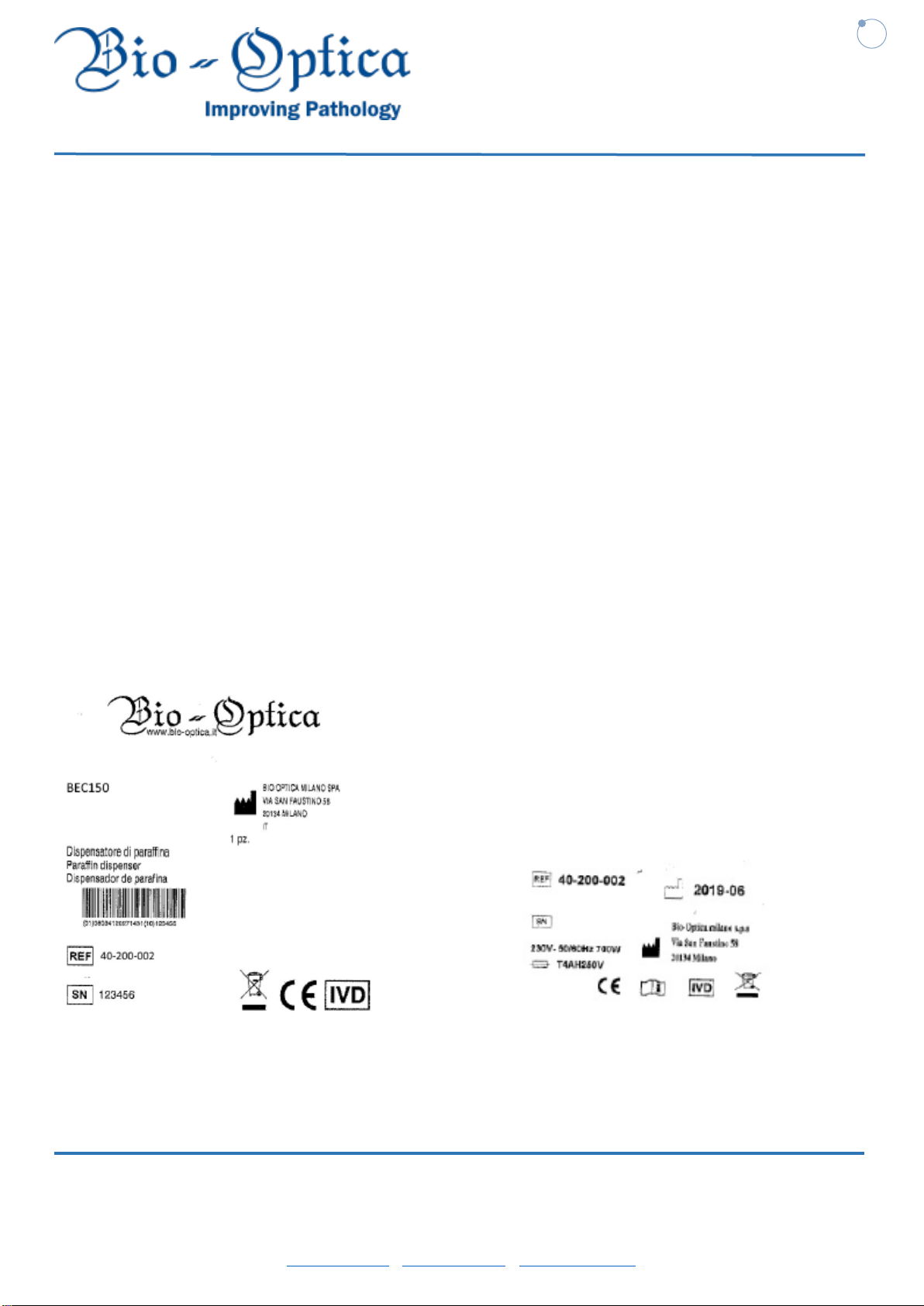

2. Before connecting the instrument, make sure that the data on the nameplate corresponds to that of the power supply.

3. This instrument must only be used for the purpose for which it was expressly designed, that is, as a paraffin dispenser

for laboratory use. Any other use is to be considered improper and therefore hazardous.

4. The instrument must only be used by authorized and professionally qualified personnel.

5. Periodic annual maintenance must be carried out only by qualified personnel authorized by Bio-Optica. For

information, please contact the Technical Assistance Service at Tel. 02-21271310.

6. The electrical safety of this instrument is ensured only when it is correctly connected to an efficient grounding system

as required by current electrical safety standards. It is necessary to check this fundamental safety prerequisite, and if in

doubt, please request a thorough check of the system. The instrument is equipped with a power supply cable having 2

wires + earth to be connected to the power outlet.

7. Do not remove the frame or its parts during operation. Turn off the instrument and disconnect it from the power outlet

before opening it. This operation must only be carried out by authorized and professionally qualified personnel.

8. To eliminate the risk of instrument malfunction, the instrument must operate in an environment free of strong

electromagnetic fields; this means that transmitters such as cell phones should not be used near the instrument.

In case of serious malfunction, turn off the instrument and contact the Technical Assistance Service.

9. All scraps and wastes, both infectious and radioactive, deriving from the work cycle of the instrument must be disposed

of in compliance with the relevant laws in force.

This equipment is marked with the symbol shown on the side, in accordance with the European Parliament

Directive 2002/96/EC and subsequent amendments regarding WEEE (Waste Electrical and Electronic Equipment). This

means that it is forbidden to dispose of this appliance as normal waste; it must instead be taken to a special WEEE

collection center authorized and set up by the Public Administration.

10. The contents of this manual are subject to change without notice.

11. Please find enclosed the declaration of conformity.