Sita ConSpector User manual

SITA Messtechnik GmbH

- Operating Instructions -

SITA Messtechnik GmbH – Operating Instructions SITA ConSpector

1

Contents

1Intended use .......................................................................................... 2

2Fluorescence measurement for monitoring bath contamination....................... 4

2.1 Measurement procedures.................................................................................... 4

2.2 Examples of Applications..................................................................................... 5

3Quick-start ............................................................................................ 8

3.1 Sampling ........................................................................................................... 8

3.2 Perform measurement......................................................................................... 8

3.3 Checking the device (short description) ................................................................ 9

3.4 Cleaning (short description)................................................................................. 9

4Getting to know the device..................................................................... 11

4.1 Design............................................................................................................. 11

4.2 Immersion probe .............................................................................................. 12

4.3 Power supply.................................................................................................... 13

4.4 Display ............................................................................................................ 13

4.5 Keyboard......................................................................................................... 15

4.6 Setting device options ....................................................................................... 15

5Putting the SITA ConSpector into Operation .............................................. 17

6Profiles and Profile settings ..................................................................... 20

6.1 Measurement of fluorescence intensity in RFU..................................................... 20

6.2 User-defined output – ContLevel ........................................................................ 22

6.3 User-defined output – e. g. Concentration .......................................................... 23

7Saving and readout of measuring data..................................................... 24

8Maintenance and Troubleshooting........................................................... 25

8.1 Device inspection ............................................................................................. 26

8.2 Cleaning the Immersion Probe........................................................................... 31

8.3 Adjustment of the Sensor................................................................................... 32

8.4 Replacing the battery ........................................................................................ 33

9Technical data ..................................................................................... 34

10 FAQ / Frequently asked questions ........................................................... 35

11 Transport, Disposal............................................................................... 37

12 Windows software SITA-ProcessLog.......................................................... 38

13 Appendix............................................................................................. 41

14 Admin Code ........................................................................................ 42

SITA Messtechnik GmbH - Operating Instructions SITA ConSpector

2

1Intended use

Please read these instructions completely before use and follow the safety instructions. No warranty

or liability will be accepted by SITA Messtechnik GmbH for any damage caused by improper han-

dling of the device or its components. Pay special attention to the following information:

Check the intactness of the device and the accessories and the compliance with the scope of

delivery and the packing list immediately after receipt.

Keep these operating instructions handy for all users.

Use the device for no other purposes than that specified in these operating instructions. Any other

use may cause hazards or damage. No liability for such damage will be accepted by the manu-

facturer. The user will bear the risk exclusively.

Attention: The radiation emission is in a non-hazardous range (EN 62471, free

group). Nevertheless, do not expose yourself directly to the invisible ultraviolet ra-

diation emerging from the immersion sensor of the sensor head. Avoid looking di-

rectly into the ray outlet opening.

Do not open the device (exception: battery replacement, see section 8.4), otherwise all warranty

claims will be voided. Any repair of open devices usually involves higher testing and repair costs.

Read the operating instructions and additional instructions, if any, prior to installation, start-up and

maintenance

Avoid any mechanical damage, especially to the display and the light conductor but also electrical

lines.

Avoid strong light irradiation or rapid light changes during a measurement.

Only the immersion sensor should come into contact with the liquids. Make sure the sensor housing

and the basic device do not come into contact with acids/alkaline solutions as well as organic

solvents. In case of doubt, test the chemical resistance of the SITA ConSpector according to the

material specifications (see section 4.2).

Do not use the device in a corrosive environment.

Avoid any extreme stress, such as high temperature or high air humidity. Allow the cold device to

adapt to room temperature before you switch it on.

To operate the device, always use USB-conforming interfaces or the original power pack supplied.

Should problems occur, contact the manufacturer of the device or your dealer.

SITA Messtechnik GmbH – Operating Instructions SITA ConSpector

3

Manufacturer:

SITA Messtechnik GmbH

Gostritzer Straße 63

01217 Dresden

Germany

Phone: +49 (0)351 871 8041

Fax: +49 (0)351 871 8464

http://www.sita-process.com

e-mail: info@sita-process.com

OI Version: Rev6 (07/2022)

Valid from device firmware version 2.02

Changes in the sense of the technical advancement reserved.

SITA Messtechnik GmbH - Operating Instructions SITA ConSpector

4

2Fluorescence measurement for monitoring bath contamina-

tion

This manual describes the SITA ConSpector measuring device. The handy and easy-to-use device

is used for fluorescence measurement in liquids, e.g. for monitoring bath contamination in cleaning

and rinsing baths. For this purpose, the device detects residues of fluorescent impurities in the

liquid on the basis of fluorescence measurement. The measurement result is output as relative

fluorescence intensity in RFU. The unit RFU stands for Relative Fluorescence Unit and refers to the

fluorescence standards of SITA Messtechnik GmbH. The higher the measured value in RFU, the

higher the concentration of fluorescent substances.

2.1 Measurement procedures

Short description

The fluorescence of the bath contamination (e.g. drops of oil)

is excited by a UV light source. A photodiode in the sensor head

of the SITA ConSpector measures the intensity of the radiation

emitted by the fluorescence at a defined wave length in the blue

light spectrum. The strength of the fluorescence depends on the

contamination level per volume.

The SITA ConSpector works on the confocal measuring

principle. The excitation light and the light emitted by the

fluorescence follow the same parallel ray path. The

measurement of the contamination level can be easily realised

by immersing the remote immersion probe into the bath sample.

Detailed Description

Measuring principle

The fluorescence of organic contaminants (oils, greases, cooling lubricants, release agents, etc.)

is excited by a UV light source. A photodiode in the sensor head of the SITA ConSpector measures

the intensity of the radiation emitted by the fluorescence at a specified wavelength in the range of

blue light. The intensity is measured in the unit RFU (Relative Fluorescence Unit) and is related to

the SITA fluorescence standards. The lower the measured value in RFU, the lower the exposure of

the bath sample to fluorescent substances.

The fluorescence measured in the process liquid is a cumulative parameter of all fluorescent matter.

If the process bath has different types of contamination, the measured fluorescence cannot be used

to determine the kind of contamination or the individual concentration of the same. Non-fluores-

cent contamination introduced into the process bath are not detected.

Besides the continuous inspection of the bath contamination the device can also be used to meas-

ure the oil concentrations in solvent baths.

SITA Messtechnik GmbH – Operating Instructions SITA ConSpector

5

Fluorescence of contamination

In production aids, fluorescence is largely due to the aromatic ring systems contained in additives

but primarily also in the mineral oil itself, as well as the unsaturated structures of the oils and fats.

Carboxylic acids and their esters as well as aliphatic ketones fluoresce, too. The fluorescence

measurement detects slightest traces of fluorescent substances.

Exceptions are substances that do not fluoresce when excited with UV light. Those include some

silicon oils, saturated organic compounds as well as short unsaturated hydrocarbons, metals and

their oxides. Processing aids such as oils, greases, cooling lubricants and release agents are tech-

nical liquids that also contain numerous additives, which can likewise contribute to fluorescence.

By adding fluorescent pigments or dyes as fluorescent markers, a non-fluorescent substance can

also be detected.

Photobleaching

Photobleaching is a dynamic process in which the contamination is photochemically destroyed by

UV excitation, thereby diminishing its ability to fluoresce. The strength of the photo-bleaching effect

depends on the substance. The SITA ConSpector was designed in such a way that the sampling

time of a measuring point keeps the photo-bleaching effect as low as possible. When measuring

in a sample mixed with the magnetic stirrer, the medium is also permanently exchanged and a

photo-bleaching effect will generally not be visible.

Defining limits for bath contamination

The displayed measurement value in RFU increases with increasing bath contamination (see appli-

cation examples). Based on reference samples or empirically by the effect on the part quality, a

limit value (alarm) of the contamination level can be defined. If this limit value is exceeded, the

device issues a warning and the plant operator can immediately initiate the necessary measures.

2.2 Examples of Applications

The quick and simple monitoring of the contamination level of the process baths is used as the

basis for process optimisation and achieving high process reliability. The SITA ConSpector captures

process-related changes and allows them to be compensated for through process management

measures. An example of this is the appropriately metered addition of cleaning components and

the removal of the contamination introduced with the immersed parts through bath maintenance.

Overdosing practiced for safety reasons and the premature new bath formulation can be avoided

by monitoring the contamination level.

The following examples illustrate the connection between the fluorescence intensity in RFU output

by the SITA ConSpector and the concentration of the contamination in the bath.

SITA Messtechnik GmbH - Operating Instructions SITA ConSpector

6

Example 1

In this example, the process

bath is contaminated through

the introduction of oil. The in-

creasing contamination of the

bath by the oil causes the

value of the measured fluo-

rescence to increase. The fig-

ure beside shows the develop-

ment of the fluorescence in-

tensity, measured by the SITA

ConSpector, in connection

with the oil concentration in

the process bath.

The value of the measured

fluorescence intensity depends not only on the amount but also on the type of contamination. Since

the requirements for the cleaned components can also vary greatly, the limit value for the degree

of contamination of the bath must be determined individually depending on the process.

A limit value (alarm) for the degree of contamination can be defined on the basis of reference

samples or empirically through the effect on the part quality. If this limit value is exceeded, the

device issues a warning and the plant operator can immediately initiate the necessary measures.

Example 2

The following figure shows the

change of the contamination

level in relationship to the time

for an aqueous cleaning bath

with high introduction of con-

tamination and a short bath

life time of two weeks. After the

new bath preparation, the flu-

orescence intensity increased

continuously due to the impu-

rities removed from the metal

parts. Partial discarding took

place at the weekend. After an-

other five days, the contamina-

tion level rose to the previously defined limit. Subsequently, the bath was discarded and a new

approach was made.

Oil concentration in %

Fluorescence intensity in RFU

Fluorescence intensity in RFU

SITA Messtechnik GmbH – Operating Instructions SITA ConSpector

7

Example 3

In order to preserve components after solvent cleaning, corrosion protection oils are used. The

corrosion protection of the components is influenced by the concentration of the corrosion protec-

tion oil in the solvent. Since the concentration decreases due to the process, it must be monitored

and re-dosed. The first figure shows the correlation between measured fluorescence intensity and

the concentration of the corrosion protection oil in the solvent. The second figure shows measured

bath samples before and after dosing.

46

4261

6824

8404 9397 10030

0

2000

4000

6000

8000

10000

12000

14000

012345

Fluorescece intensity in RFU

Concentration Anticorit MPC 5000 in %

in Dowclene 1601

18,3

1920,1

2449,7

1718,6

0

500

1000

1500

2000

2500

3000

3500

Dowclene 1601 Badprobe 19.03. vor

Nachdosieren

Badprobe 19.03.

nachdosiert

Badprobe 20.03 vor

Nachdosieren

Fluorescence intensity in RFU

Dowclene 1601 +

0,25 vol.-%

MPC 5000

Dowclene 1601 +

0,75 vol.-%

MPC 5000

Dowclene 1601

Bath sample

before redosing

Bath sample

after redosing

Bath sample

before redosing

on the next day

SITA Messtechnik GmbH - Operating Instructions SITA ConSpector

8

3Quick-start

The quick-start chapter contains the most important information for operation, conduct-

ing a measurement and inspection of the device in abbreviated form. The single sections

of the quick-start chapter provide cross references to later chapters with more detailed

information on the respective topic.

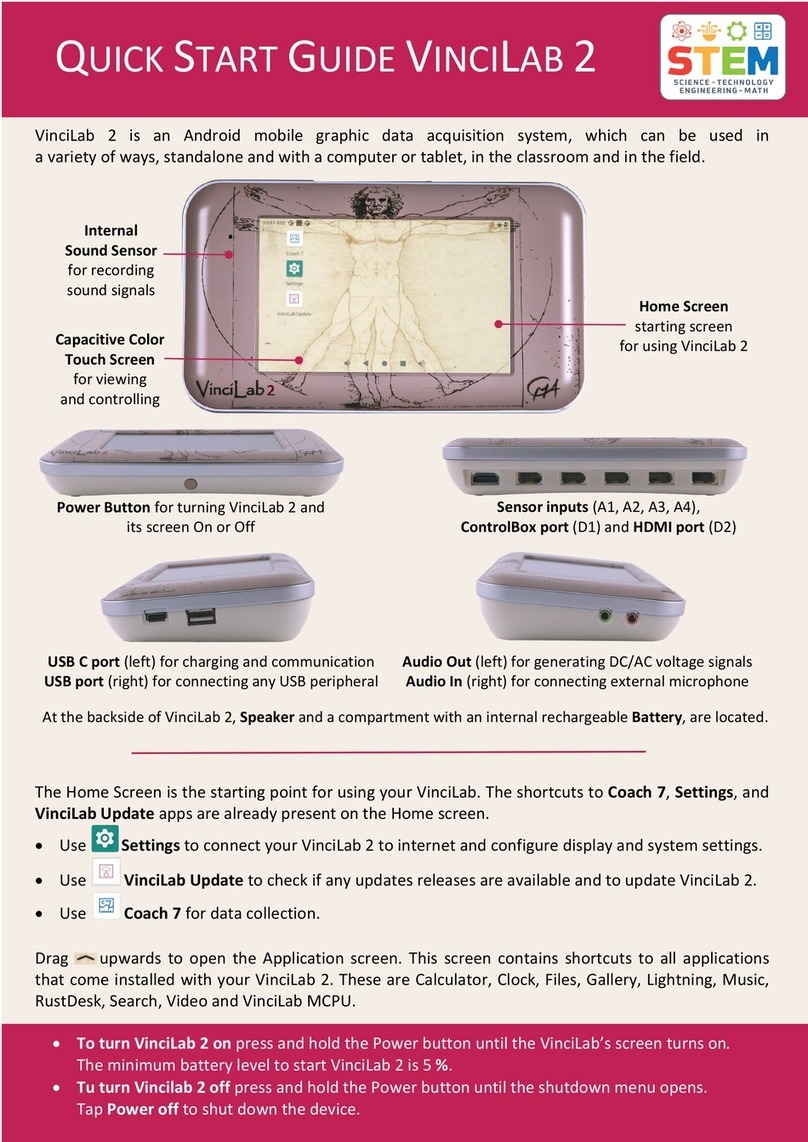

3.1 Sampling

Take samples at a well-mixed and representative sampling location. Always carry out

measurements at the same sample temperature. Allow samples to cool down to room

temperature before starting the measurement.

3.2 Perform measurement

1. Switch on the SITA ConSpector (press -key for 2 s).

2. Choose the desired measuring profile. The active

measuring profile appears at the lower right edge of

the display. Use the arrow selection keys Liquid to

change the profile.

3. Place the stainless steel beaker filled with approx. 80 ml of the sample liquid (ap-

prox. 1 cm below the rim of the beaker) on the support surface of the magnetic

stirrer. Place a magnetic stick in the beaker and turn the rotary knob to mid posi-

tion.

4. To immerse the immersion probe into the sample liquid, lower the device holder

by using the star knob screw (see set-up in picture above). Immerse the immersion

probe approximately half way into the bath sample. The limiter should rest against

one side of the beaker.

5. Use the lid to cover the bath sample.

immersion

probe

limiter

immersion

depth

active profile

lid closed

12 o'clock position

measurement in

stainless beaker

SITA Messtechnik GmbH – Operating Instructions SITA ConSpector

9

6. Observe the correct sample temperature (temperature indication on the display)

While measuring, mix the sample thoroughly using the magnetic stirrer.

7. To start the measurement press the START key.

8. Write down the measured value.

Please note:

The device comes with an internal data logger. In the default settings

all measuring values are automatically saved within the used profile. To export

measured values use the software SITA-ProcessLog. The measured values can be

displayed on the device by pressing the read key.

9. Rinse off the immersion probe with water (e.g. using a spray bottle). Continue

measuring with the next sample.

3.3 Checking the device (short description)

Check the device regularly to identify contamination on the

immersion probe (light conductor and limiter). Use the stand

and place the immersion probe in the clean and empty stain-

less steel cup; cover it with the respective lid (blank measure-

ment set-up). To start the device check select Menu>Check-

ing.

3.4 Cleaning (short description)

In most cases it is sufficient to rinse the outside of the

immersion probe after the measurements. When

measuring aqueous samples, water is suitable for

rinsing. When measuring solvent samples, rinse and

clean with the clean solvent.

If both aqueous samples and non-polar solvents are

measured, rinse or clean with an alcohol (e.g.

isopropanol) before switching from one to the other. The

intermediate step with a polar alcohol such as

isopropanol is needed because non-polar solvents and water are not mixable. The

alcohol removes the residues from the immersion probe and makes it wettable for the

following sample liquid.

blank measurement setup

SITA Messtechnik GmbH - Operating Instructions SITA ConSpector

10

You can pre-clean the immersion probe with a mild cleaning solution. To do so, please

prepare the measuring arrangement with screwed-on limiter and using the cleaning so-

lution instead of a sample.

Use demineralized water to rinse off cleaning agents and other residues after cleaning

using water. Check the result (see ‘Checking the device’) and repeat the cleaning process

if necessary.

Please clean the stainless steel beaker after use.

For a detailed cleaning, e.g. after a failed test/empty

measurement, you can also carefully unscrew the lim-

iter of the immersion probe. Then clean the end of the

glass rod. Cotton swabs soaked in alcohol or water are

suitable for this purpose. Avoid damaging the glass

rod.

For more information on cleaning, see the operating instructions in chapter 8.2.

SITA Messtechnik GmbH – Operating Instructions SITA ConSpector

11

4Getting to know the device

4.1 Design

BASIC UNIT

USB:

USB: Universal interface (USB-B) for power supply/battery

charging (see section 4.3) and for connection to the PC

Connecting line:

connects the basic unit with the sensor head

Display:

LCD graphic display with background lighting (see also

section 4.4)

Keyboard:

Robust membrane keyboard for direct access to device

functions (see also section )

Housing:

Sturdy aluminium housing

Service interface:

Log printer (optional)

Socket

To connect the connecting line with the basic

unit, make sure the socket and the plug are

properly aligned. An improper alignment or

force effects may damage the contacts.

(see section 5)

USB

Service

SITA Messtechnik GmbH - Operating Instructions SITA ConSpector

12

SENSOR HEAD

Connecting line:

connects the sensor head with the basic unit

Magnetic plate:

secures the sensor on the counterpart of the stand

Immersion probe:

The immersion probe is immersed approximately to the

middle of the probe into the liquid to measure the con-

tamination level. (see also section 4.2)

Limiter:

This is a part of the immersion probe. Limits the effective

space of the UV radiation thereby creating a defined liquid

space.

4.2 Immersion probe

The immersion probe on the sensor head of the SITA ConSpector is equipped with a light conductor

on the inside through which the excitation radiation is emitted into the liquid. The fluorescence

radiation excited in the defined liquid space at the end of the immersion probe is conducted via

the light conductor into the sensor head and from there to the photodiode.

The immersion probe and thus also the light conductor are chemically resistant against the effect

of organic, acid and alkaline solutions. The immersion probe consists of stainless steel (1.4301),

quartz glass and Viton. Avoid prolonged contact of the immersion probe hydrofluoric acid and hot

phosphoric acid, strong alkaline solutions (pH 12) and phosphates.

Avoid mechanical loads or mechanical damages of the light conductor.

Remove the limiter only to clean the immersion probe since it protects the

visible part of the light conductor against mechanical damages.

To connect the connecting line with the basic

unit, make sure the socket and the plug are

properly aligned (see section 5).

Make sure to regularly clean the immersion

probe, the limiter and especially the visible

part of the light conductor from contamina-

tion (see section 8.1

). Do not look directly into

the ray outlet opening while measuring is in

progress.

SITA Messtechnik GmbH – Operating Instructions SITA ConSpector

13

A temperature sensor is integrated in the immersion probe to measure the temperature of the

sample.

4.3 Power supply

In mobile operation power is supplied by an integrated lithium ion battery. The integrated charging

circuit of the device charges the battery gently within a maximum of 7 hours. So express battery

servicing is not needed and you can operate the device with the power pack supplied or an USB

interface if possible. When the battery is empty (as shown on the battery charge display or device

cannot be switched on) connect the device with the power pack supplied or a USB port.

For initial use charge the battery completely using the power pack. If the battery capacity decreases

noticeably after about 1,000 charging cycles, it can be replaced (see section 8.4).

It is possible to disable the battery charge function (see section

4.6) and thus conserve the battery if you permanently use the

power pack or the PC interface to operate the SITA ConSpector.

If the charging function is disabled, a warning symbol will ap-

pear on the display (see section 4.4).

Stored measured values and set device parameters will be maintained even if the battery is empty

or when there is no power supply.

4.4 Display

The SITA ConSpector has a display on which the necessary information is output according to the

various operating states (FluoLevel, Cont(amination)Level or User-defined profile). The most im-

portant output contents are shown below as an introduction:

Toolbar:

Battery charge level (3 bars = fully charged)

PC or power supply connection

Signal tones On/Off

Warning "Charge battery off"

Operating mode

(here: FluoLevel)

Measured value

Measured value

(graphically)

Toolbar

Date and time

Temperature

Profile name and warnings

Software key assignment

SITA Messtechnik GmbH - Operating Instructions SITA ConSpector

14

For better orientation, the current operating mode is displayed (FluoLevel: Determining the fluo-

rescence intensity, ContLevel: Determining the degree of contamination of a liquid, Concentration:

user-defined concentration characteristic curve). The recorded measured values always refer to the

respectively selected liquid profile ('Liquid x').

The software keys have different assignments. Depending on the operating state assignments may

be, for example, navigation arrows or OK, Exit or ESC. The relevant assignments are explained

in the following sections as needed.

The freely selectable alarm limit AlarmbarMin corresponds to the bar minimum and the freely

selectable alarm limit AlarmbarMax to the bar maximum (here 6000). If the alarm limits are ex-

ceeded or not reached, the current measured value and the bar graph flash.

You can also freely select the warning limits. These are indicated by a horizontal line in the bar

graph (here at 2000). The lower or upper warning limit must always be above or below the re-

spective alarm limit.

In case of warnings such as "ambient light fluctuation",

"overrange" or "check required", the measured value

flashes. In the software, the warning is additionally saved

as a comment on the measured value.

Alarm limit

Warning limit

SITA Messtechnik GmbH – Operating Instructions SITA ConSpector

15

4.5 Keyboard

ON/OFF key. Switch device on and off

(press for 2 s)

Start or continue determining contami-

nation level

Select liquid profile up

Select liquid profile down

Read out stored measured data

Store measured data

Software keys with changing assign-

ments (Symbols in display)

4.6 Setting device options

Pressing the software key Menu in the main screen takes

you to the unit menu, which allows the basic unit settings in

addition to the profile settings.

The selection of a menu item or the selection of numerical

values is done with the software keys and .

The selection is confirmed in each case with the OK key.

liquid

save

read

mem

SITA Messtechnik GmbH - Operating Instructions SITA ConSpector

16

Menu tree:

Menu Profiles Edit Changes the parameter for the selected surface profile

New

Creates a new surface profile (

FluoLevel

or

Cleanliness

)

Delete profile Deletes the selected surface profile

Clear mem Deletes all or the last data record

Exit Exits the menu level

Profiles

Device Display Changes the display contrast, brightness or language (Ger-

man/English/French)

Time Setting date and time of internal clock

Battery Enables or disables battery charging function

Beeper Enables or disables the signal tone

User level Selects the user level

Operator

or

Admin

Exit Exits the menu level

Device

Info Shows information of the basic device and the sensor head

Checking Checks the correct function of the sensor (see Paragraph 8.1)

Adjustment Carries out an adjustment of the SITA ConSpector (see Paragraph

8.3)

Exit Exits the

Menu

In each list view displayed by the unit, you can use the save key to jump alternately

to the beginning and end of the list.

Pressing the I/O key briefly takes you back one menu level. Pressing the

START key takes you to the main view.

Profiles can be created and edited in the Profiles menu. The parameters of the selected or newly

created profile can be called up and edited under the menu item Edit or from the main screen via

the software key Param. The structure and adjustable parameters can be found in chapter 6, ar-

ranged according to profile types.

User level

In the User Level menu you can choose between Operator and Admin. In the Operator user level

no settings/changes can be made in the parameter menu of the surface profiles to avoid manipu-

lations and operating errors. In the delivery state the Admin user level is enabled (device is un-

locked). An information sheet (Page 42) attached to the operating instructions describes how to

access the Admin user level. Take this information sheet if you prefer an exclusively administrated

operation of the device, and keep together with the sales receipts, for example.

The Service user level is a mode that can only be accessed by the manufacturer for maintenance

and servicing purposes.

The menu for changing the parameters of the currently selected liquid profile can also be accessed

directly from the main screen via the software key Param.

The parameters of the relevant surface profile can be edited/changed in

the Admin user level only. If the device is on the Operator user level, you

can only view the parameters of the relevant surface profile.

SITA Messtechnik GmbH – Operating Instructions SITA ConSpector

17

5Putting the SITA ConSpector into Operation

Contents equipment case:

1 Document compartment with operating instructions and calibra-

tion certificate

2

Quick-start guide

10

USB-cable under stand base

3

Stand rod

11

Magnetic stirrer bars

4

Calibration Standandards

12

Magnetic stirrer

5

Sensor

13

Lid

6 Magnetic holder 14 Stainless steel beaker 100ml

7 Device holder 15 USB stick with PC software

8

Basic unit

16

Cotton sticks

9

Stand base

17

Power supply unit

4

5

3

16

9

8

7

13

14

17

6

12

11

2

1

10

15

SITA Messtechnik GmbH - Operating Instructions SITA ConSpector

18

Connecting the sensor head to the basic unit:

Take the basic unit 6out of the case and connect it to the sensor head using the connecting line.

Pay attention to a proper alignment of the guide groove of the female connector and the guide

cam of the male connector. The connector must be easily pluggable.

Any improper alignment of the male connector and the female connector and excessive forces may

damage the contacts.

To loosen the connector, pull back the fluted outer sleeve only. It is not possible to loosen the

connector without unlocking by only pulling at the fluted outer sleeve. Please also refrain from

pulling at the cable, it may cause damage.

Set up the instrument stand:

It is recommended to use the supplied stand for the measurement.

The stand is set up as shown:

14

13

5

6

lid closed

12 o'clock position

measurement in

stainless beaker

Other manuals for ConSpector

1

Table of contents

Other Sita Laboratory Equipment manuals