SiTime SiT92216 User manual

SiT92216EB User Manual | Rev 0.5

Page 1 of 27

www.sitime.com

SiT92216 Evaluation Board (EVB) HW

User Manual

Table of Contents

1Introduction ......................................................................................................................................................................... 1

2Features.............................................................................................................................................................................. 1

3Functional Description......................................................................................................................................................... 2

3.1. VDD and VDDO Power Supplies...............................................................................................................................2

3.2. Clock Inputs...............................................................................................................................................................2

3.3. Clock States (Input vs Output States)........................................................................................................................1

3.4. Output Driver Type....................................................................................................................................................1

3.5. Reference Output......................................................................................................................................................1

4Power Supply Connections................................................................................................................................................. 2

5Setting Input Clock Select and REF Out Enable in the EVK ............................................................................................... 4

6Input Clock Configuration.................................................................................................................................................... 5

7Configuring for Single ended AC coupled Input Clock ........................................................................................................ 6

7.1. Driving Clock Inputs with LVCMOS Driver (AC coupled)...........................................................................................6

7.2. Driving Clock Inputs with LVCMOS Driver (DC coupled)...........................................................................................7

8Driving Differential LVDS or LVDS Boost (AC coupled)...................................................................................................... 9

8.1. Board Configuration for driving DC Coupled LVDS...................................................................................................9

9Board Configuration Required for Driving DC/AC coupled LVPECL................................................................................. 10

9.1. DC/AC Coupled LVPECL........................................................................................................................................10

10 Output Configuration......................................................................................................................................................... 11

11 EVB Snapshot................................................................................................................................................................... 12

12 Schematics of SiT92216 Evaluation Kit............................................................................................................................. 13

12.1. Schematic Sheet 1 ................................................................................................................................................13

12.2. Schematic Sheet 2 ................................................................................................................................................14

12.3. Schematic Sheet 3 ................................................................................................................................................15

12.4. Schematic Sheet 4 ................................................................................................................................................16

12.5. Schematic Sheet 5 ................................................................................................................................................17

12.6. Schematic Sheet 6 ................................................................................................................................................18

12.7. Schematic Sheet7 .................................................................................................................................................19

12.8. Schematic Sheet8 .................................................................................................................................................20

12.9. Schematic Sheet9 .................................................................................................................................................21

12.10. Schematic Sheet10 ............................................................................................................................................. 22

12.11. Schematic Sheet11 ............................................................................................................................................. 23

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 1 of 27

www.sitime.com

1 Introduction

The SiT92216 Evaluation Board is designed for evaluating the SiT92216, is a 4 differential output and 1 LVCMOS ultra low-jitter

clock fan-out buffer.

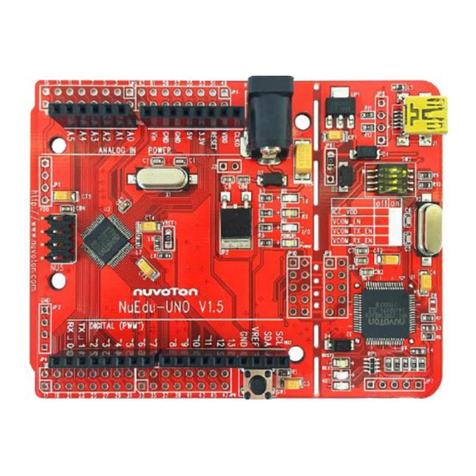

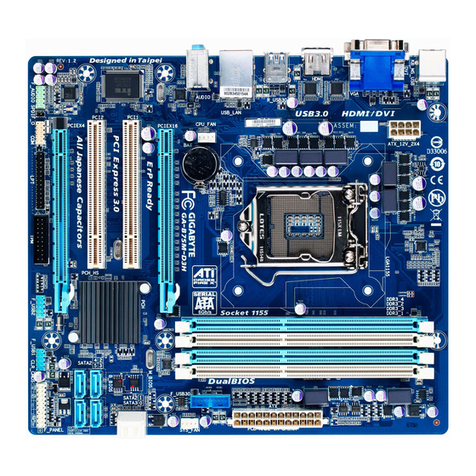

Figure 1. SiT92216 EVB Board

2 Features

1) Additive jitter performance of 50 fs RMS.

2) 3:1 input clock selection.

3) Two universal clock inputs can operate up to 2.1 GHz and accept LVPECL, LVDS, LVCMOS, CML, HCSL, SSTL or

single ended clocks.

4) One crystal input which can support crystals in the frequency range of 8 MHz to 50 MHz or it can accept single ended

input clock.

5) Two output driver banks A and B which can be programmed independently to LVPECL, LVDS, HCSL or HIZ mode.

6) Typical output skew between clock outputs is 30 ps.

7) Level translation with core supply voltage of 3.3 V/2.5 V/1.8 V and 3.3 V/2.5 V/1.8 V output supply for differential output

drivers.

8) SiT92216 buffer is pin controlled.

9) High PSRR -70/-73 dBc for LVPECL/LVDS modes.

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 2 of 27

www.sitime.com

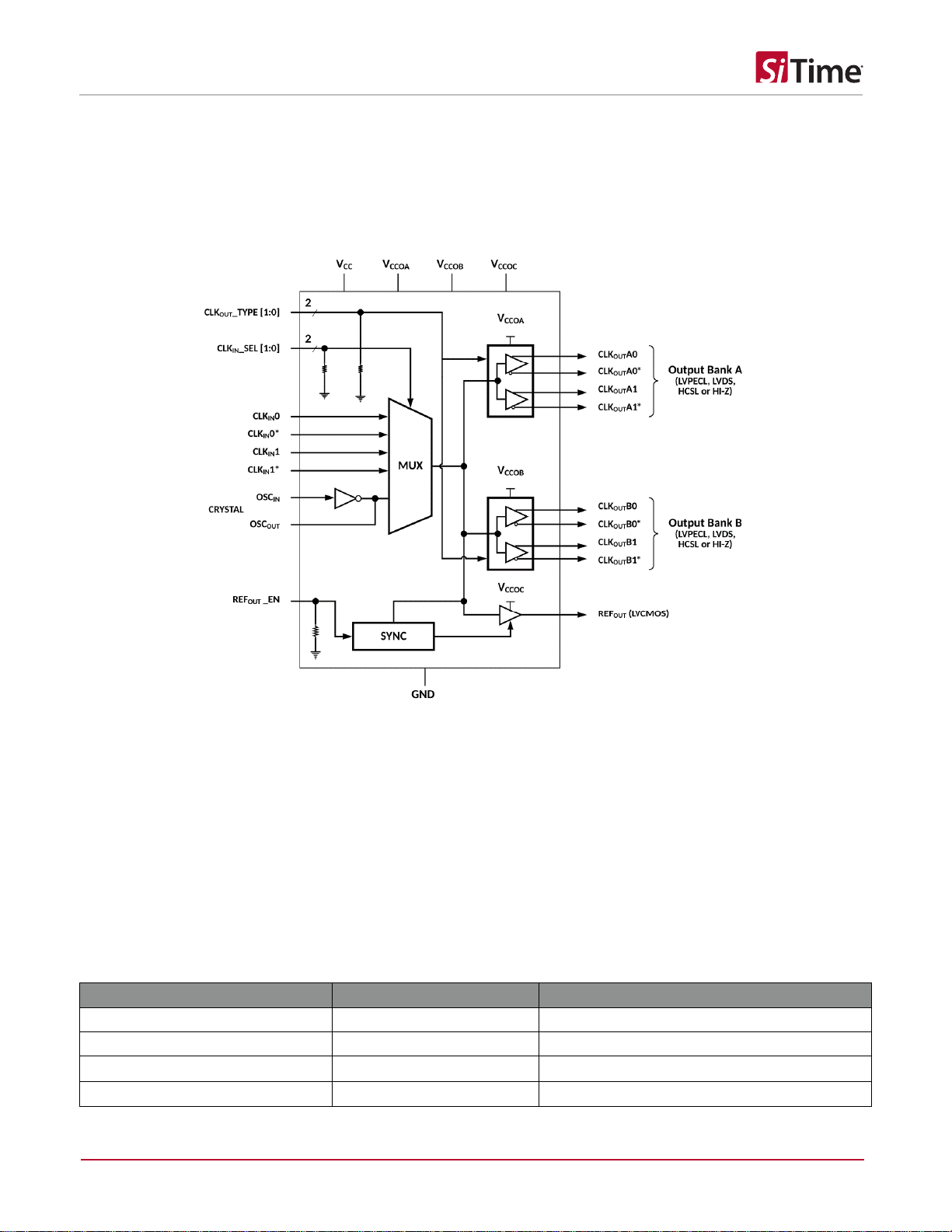

3 Functional Description

The SiT92216 is a 4 differential output and 1 LVCMOS output clock fan out buffer with low additive jitter that can operate up to

2.1 GHz. It features a 3:1 input multiplexer with an optional crystal oscillator input, two banks of 2 differential outputs with multi-

mode buffers (LVPECL, LVDS, HCSL, or Hi-Z), one LVCMOS output, and 3 independent output buffer supplies. The input

selection and output buffer modes are controlled via pin strapping. The device is offered in a 32-pin QFN package.

Figure 2. Functional Diagram

3.1. VDD and VDDO Power Supplies

The SiT92216 has separate 3.3/2.5/1.8 V core (VCC) and 3 independent 3.3 /2.5/1.8 V output power supplies (VCCOA,

VCCOB, and VCCOC) supplies. Output supply operation at 2.5/1.8 V enables lower power consumption and output-level

compatibility with 2.5/1.8 V receiver devices. The output levels for LVPECL (VOH, VOL) and LVCMOS (VOH) are referenced to

its respective VCCO supply, while the output levels for LVDS and HCSL are relatively constant over the specified VCCO range.

3.2. Clock Inputs

The input clock can be selected from CLKin0/CLKin0*, CLKin1/CLKin1*, or OSCin. Clock input selection is controlled using the

CLKin_SEL[1:0] inputs as shown in Table 1. When CLKin0 or CLKin1 are selected, the oscillator is power down. The user can

float OSCin and OSCout pins, since these pins are internally pulled down. OSCin is pulled down with a 56 KOhm resistance.

Table 1. Input Clock Selection

CLKin_SEL[1]

CLKin_SEL[0]

Selected Clock

0

0

CLK0

0

1

CLK1

1

0

Crystal Or Crystal bypass AC coupled mode

1

1

Crystal bypass DC coupled mode

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 1 of 27

www.sitime.com

3.3. Clock States (Input vs Output States)

Table 2. Input versus Output Stages

State of Selected Clock input

Output State

Inputs are floating

Logic low

Inputs are logic low

logic low

Inputs are logic high

logic high

3.4. Output Driver Type

The differential output buffer type for Bank A and Bank B outputs can be configured using the CLKout_TYPE[1:0] inputs, as

shown Table 3. For applications where all differential outputs are not needed, any unused output pin should be left floating with

a minimum copper length to minimize capacitance and potential coupling and reduce power consumption. If an entire output

bank will not be used, it is recommended to disable (Hi-Z) the bank to reduce power.

Table 3. Programming of Output Driver Type

CLKOUT_TYPE1

CLKOUT_TYPE0

CLK Buffer Type

0

0

LVPECL

0

1

LVDS

1

0

HCSL

1

1

HIZ

3.5. Reference Output

The reference output (REFout) provides a LVCMOS copy of the selected input clock. The LVCMOS output high level is

referenced to the VCCOC voltage. REFout can be enabled or disabled using the enable input pin, REFout_EN, as shown in Table

4.The reference output clock is internally synchronized to the selected clock. This avoids any glitches or runt pulses while

enabling or disabling the reference clock.

When REFout_EN goes from low to high, the output clock is enabled within a time delay td, where td is given by the following

equation.

. Tin is the time period of the input clock.

Table 4. Reference Output Enable

Refout_EN

Output State

0

Disabled (HiZ)

1

Enabled

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 2 of 27

www.sitime.com

4 Power Supply Connections

SiT92216 buffer has four suuplies VCC, VCCOA, VCCOB and VCCOC. The VCCOA supply is dedicated supply for the bank A

output drivers. The VCCOA supply can be 3.3 V+/-5%, 2.5 V+/-5%, 1.8 V+/-5%. The VCCOB supply is dedicated supply for the

bank B output drivers. The VCCOB supply can be 3.3V+/-5%, 2.5 V+/-5%, 1.8 V+/-5%. The VCCOC supply is dedicated supply

for the LVCMOS output driver. The VCCOC supply can be 3.3 V+/-5%, 2.5 V+/-5%, 1.8 V+/-5%. The VCC supply is dedicated

for the input clock receiver, clock distribution unit and the XO inside SiT92216. This supply is independent of VCCOA, VCCOB,

VCCOC. The VCC supply can vary from 3.3 V+/-5%, 2.5 V+/-5%, and 1.8 V +/- 5%.

The VCC, VCCOA, VCCOB, VCCOB supplies can be set as per the Table 5.

Table 5. Power supply connection for SiT92216 evaluation kit

Power Source

Jumper setting

Comments

PC/laptop USB port

J5 shorted between pins 1,2

Default EVK configuration

Single External Source of 5V

J5 shorted between pins 2,3

Note: Refer Figure 17. Schematic Sheet 5 VDD_AUX regulator for jumper J5 connection

after connecting the USB. SiT92216

can be programmed to different voltage levels using jumper settings as shown in Table 6.

Table 6. Setting VCC voltage

LDO

Jumper setting

VCC (V)

U1

J2 shorted between pins 2,3

3.3

J2 shorted between pins 1,2

2.5

J2 left open

1.8

Note:

1. Refer Figure 13. Schematic Sheet 1 VCC Regulator for Jumper J2 connection.

2.

Table 7. Setting VCCOA voltage

LDO

Jumper setting

VCCOA (V)

U2

J9 left open

3.3

J9 shorted between pins 1,2

2.5

J9 shorted between pins 2,3

1.8

Note:

1. Refer Figure 14. Schematic Sheet 2 VCCOA regulator for Jumper J9 connection.

2.

Table 8. Setting VCCOB voltage

LDO

Jumper setting

VCCOB (V)

U3

J11 left open

3.3

J11 shorted between pins 1,2

2.5

J11 shorted between pins 2,3

1.8

Note:

1. Refer Figure 15. Schematic Sheet 3 VCCOB regulator for Jumper J11 connection.

2. .

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 3 of 27

www.sitime.com

Table 9. Setting VCCOC voltage

LDO

Jumper setting

VCCOC (V)

U4

J14 shorted between pins 2,3

3.3

J14 shorted between pins 1,2

2.5

J14 left open

1.8

Note:

1. Refer Figure 16. Schematic Sheet 4 VCCOC regulator for Jumper J11 connection.

2.

Table 10. Setting VCC_AUX voltage

LDO

Jumper setting

VCC_AUX (V)

U8

J56 shorted between pins 2,3

3.3

J56 shorted between pins 1,2

2.5

J56 left open

1.8

Note:

1. Refer Figure 17. Schematic Sheet 5 VDD_AUX regulator for Jumper J56 connection.

2. VCC_AUX is the supply of level shifter outputs for automated control of clock select, REFOUT_EN pins, ODR type. Keep VCC = VCC_AUX

3. VCC_AUX is set to 3.3V using U8 L.

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 4 of 27

www.sitime.com

5 Setting Input Clock Select and REF Out Enable in the EVK

The jumper setting for controlling the input clock select and output enable are given below.

Table 11. Jumper settings to control clock select, ODR type change and REF out enable

Pin

Jumper state

Logic input

CLK_IN_SEL0

J67 shorted between 2,3

0

J67 shorted between 1,2

1

CLK_IN_SEL1

J68 shorted between 2,3

0

J68 shorted between 1,2

1

REF_OUT_EN

J71 shorted between 2,3

0

J71 shorted between 1,2

1

CLK_OUT_TYPE1

J22 shorted between 2,3

0

J22 shorted between 1,2

1

CLK_OUT_TYPE0

J60 shorted between 2,3

0

J60 shorted between 1,2

1

Note:

1. The programming for input clock select is given below.

2. Input clock select programming: 2'b00 - clock0, 2'b01 - clock1, 2'b10 XO

3. The programming for REF_OUT_EN is given below

a) REF_OUT_EN programming: 1'b0 - output disable, 1'b1 - output enable

4. Refer Figure 20. Schematic Sheet 8 FTDI signal to DUT mapping for Jumper J71 connection.

5. The programming for odr type for A and B bank is given below.

a) ODRA type programming : 2'b00 - LVPECL, 2'b01 - LVDS, 2'b10 - HCSL, 2'b11 HI

b) Refer Figure 20. Schematic Sheet 8 FTDI signal to DUT mapping for Jumper J22, J60 connection.

6. Jumpers labelled as JVDD1, JVDD2, JVDD3, Diag should be left in their default state: floating.

7. J8 should remain in the default state: between pin1 and pin2 t

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 5 of 27

www.sitime.com

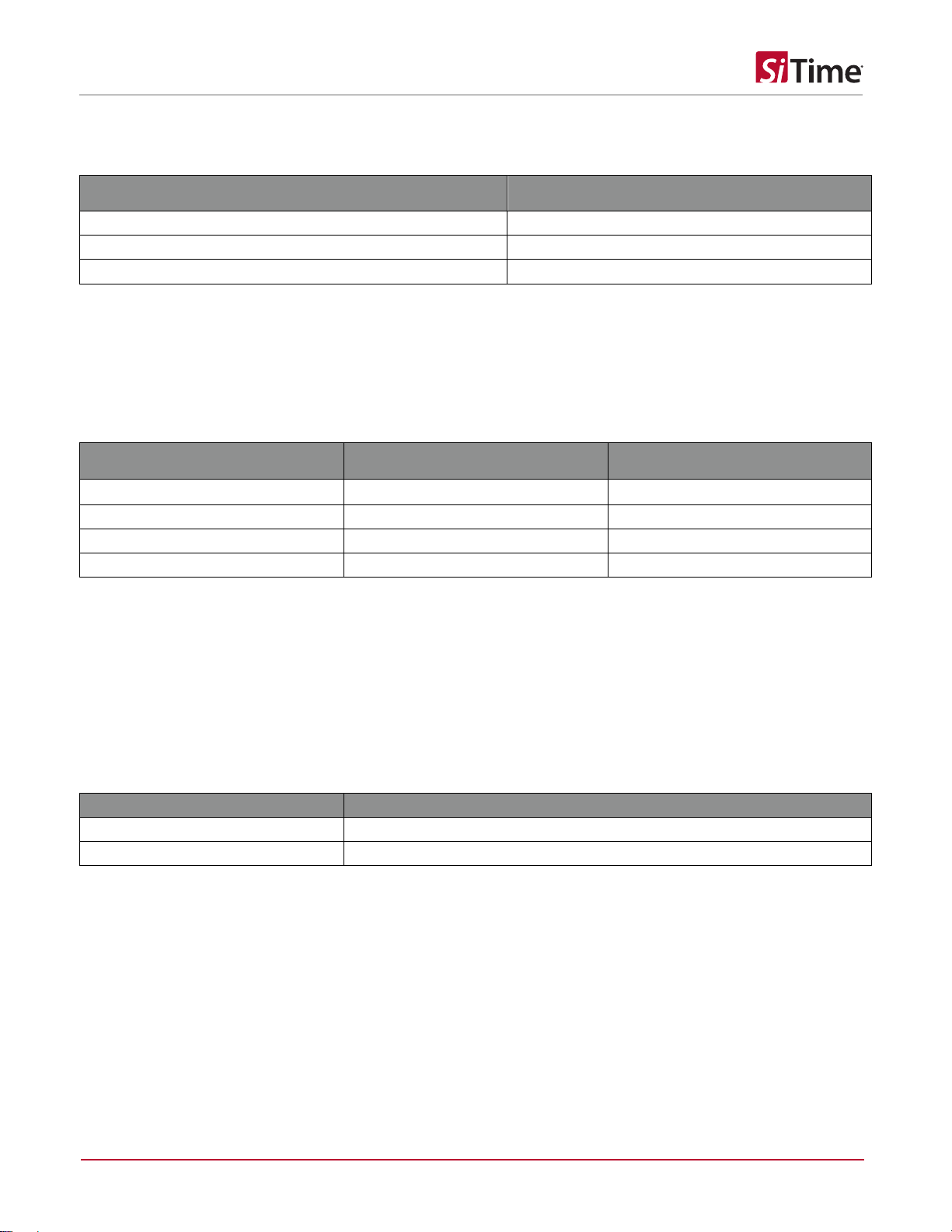

6 Input Clock Configuration

The input clock is ac coupled and terminated with differential 100 Ohms. Thus the EVK is configured for differential input clock

as shown in schematic sheet9. The clock is ac coupled to the chip clock input pins.

Figure 3. Input clock configuration

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 6 of 27

www.sitime.com

7 Configuring for Single ended AC coupled Input Clock

Many applications require the buffer to receive single ended input clock. Therefore, some minimal changes need to be done to

the EVK to accomplish single ended operation.

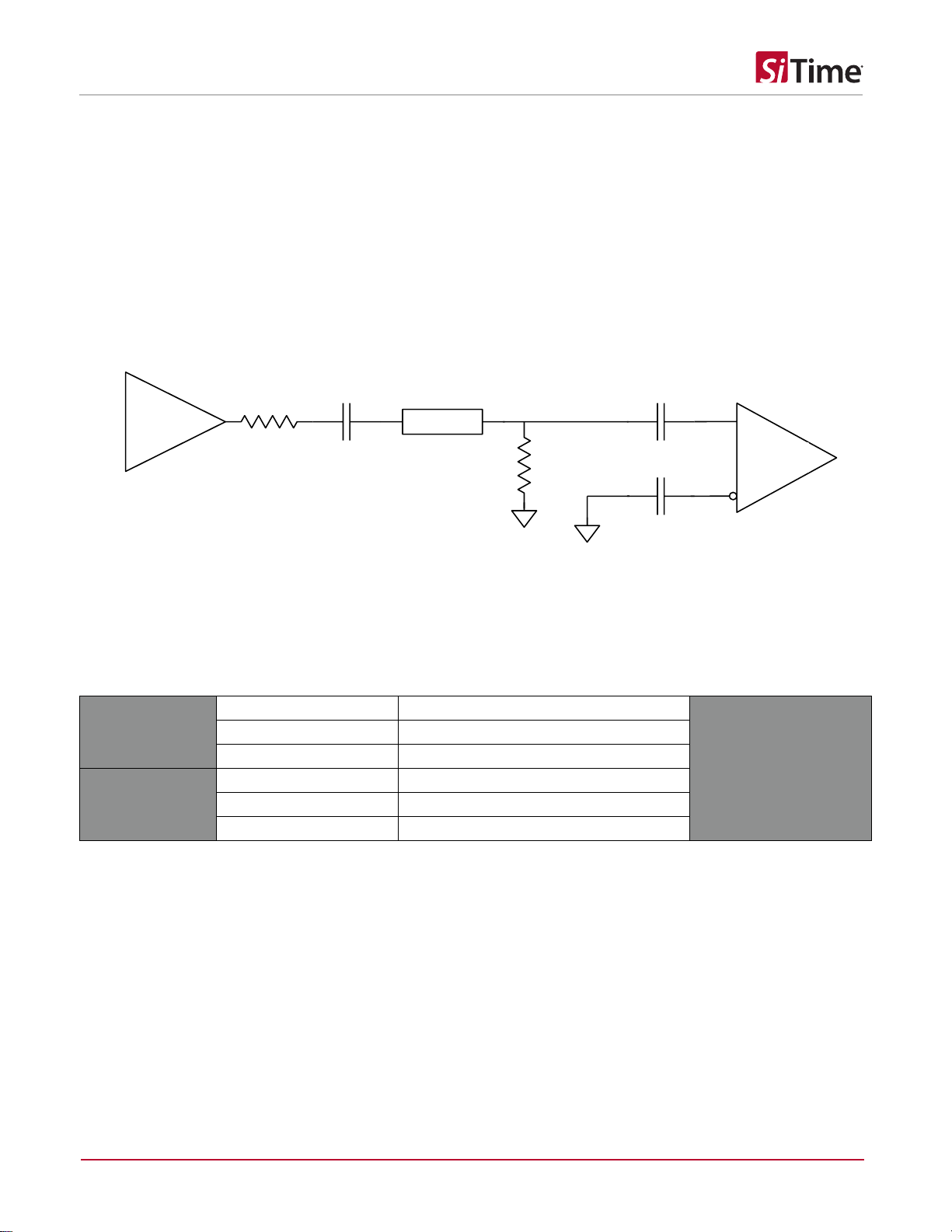

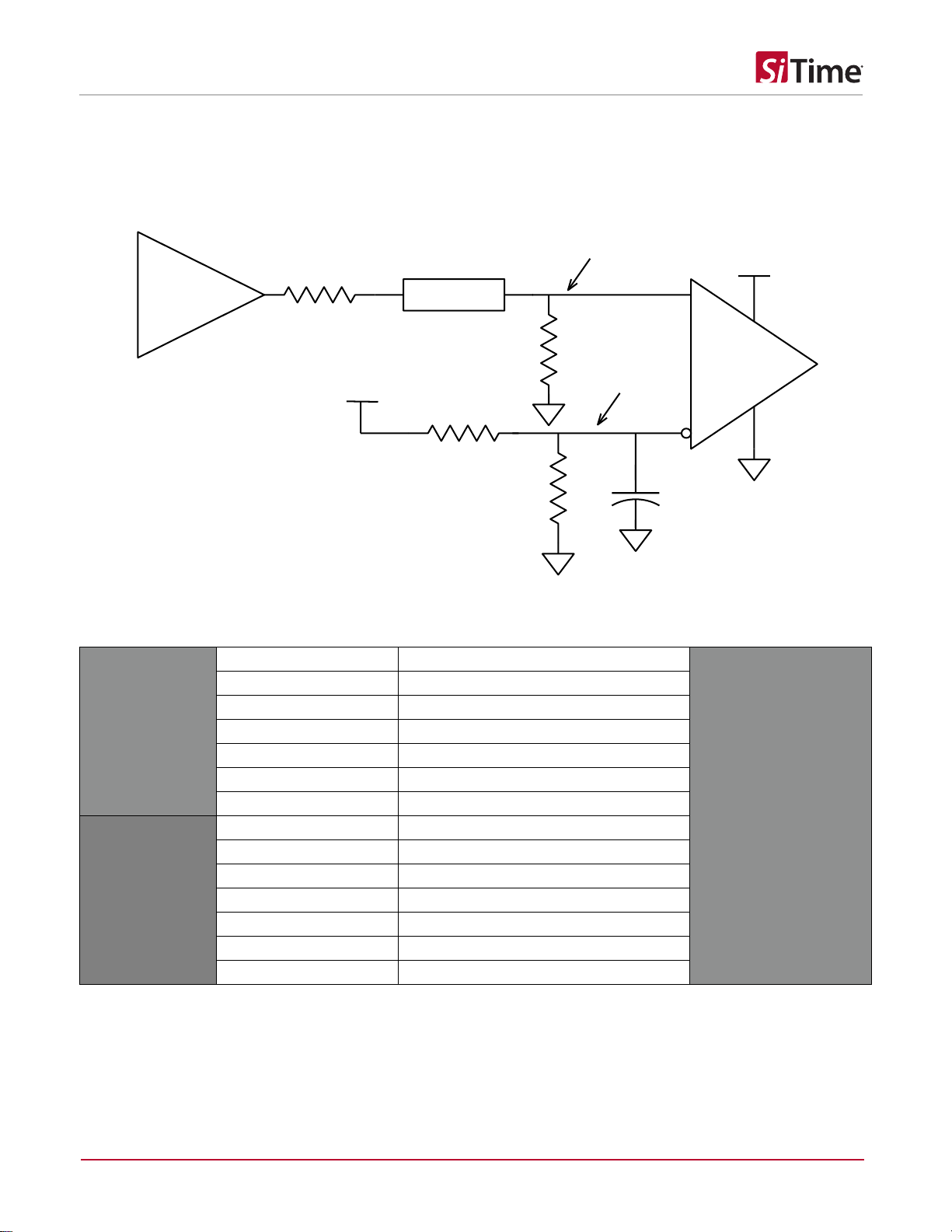

7.1. Driving Clock Inputs with LVCMOS Driver (AC coupled)

For large single-ended input signals, such as 3.3 V or 2.5 V LVCMOS, a 50 load resistor should be placed near the input for

signal attenuation to prevent input overdrive as well as for line termination to minimize reflections. The single-ended input slew

rate should be as high as possible to minimize performance degradation. The clock input has an internal bias voltage of about

(VDD-0.3)/2 V, so the input can be AC coupled as shown in Figure 4. The output impedance of the LVCMOS driver plus Rs

to match the characteristic impedance of the transmission line and load termination.

Figure 4 Single ended LVCMOS input, AC coupling

The board changes are listed in the table given below:

Table 12. Board component changes required to support single ended AC coupled LVCMOS

Clock 0 path

R37

change to 0.1uF

Schematic Sheet 9

C29

change to 0 Ohms

R29

change to 0 Ohms

Clock 1 path

R35

change to 0.1uF

C27

change to 0 Ohms

R30

change to 0 Ohms

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 7 of 27

www.sitime.com

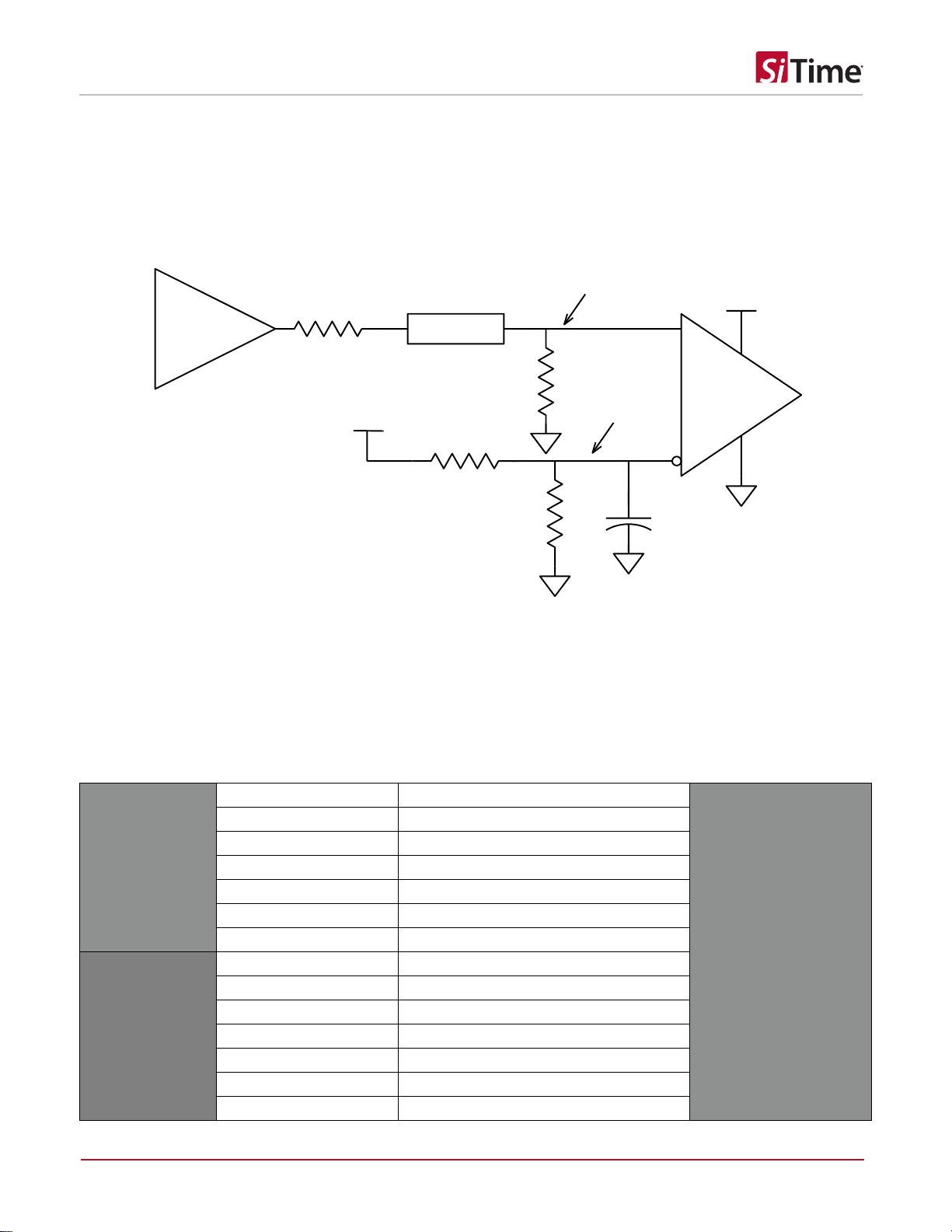

7.2. Driving Clock Inputs with LVCMOS Driver (DC coupled)

Single ended clocks can be DC coupled to the SiT92216 Buffer. If the CLKin is driven CLKin* voltage must be set using a resistor

divider to match the common mode of the DC coupled single ended clock. This is shown in Figure 5.

Figure 5. Single ended LVCMOS input, DC coupling

Case1: Let us look at the case where a LVCMOS driver (of 50 Ohm impedance) drive a 50 Ohm load which is located at the

input of SiT92216. Let the supply of LVCMOS driver be 1.8 V. Then the swing of the clock at the chip input is 0.9Vpp. We to set

the reference voltage at the reference node at 0.45 V. Choose VCC = 1.8 V, Rs2=3Rs1. Rs1, Rs2 should be in the kilo ohm

range. So if we set Rs1=3 K, Rs2=1 K.

Table 13. EVK board changes required to support single ended DC coupled LVCMOS

Clock 0 path

R29

remove

Schematic Sheet 9

C23

change to 0 Ohms

R23

change to 3KOhms

R27

change to 1K Ohms

C25

populate with 0.1uF

C32

change to 0 Ohms

C29

change to 0 Ohms

Clock 1 path

R30

remove

C24

change to 0 Ohms

R24

change to 3KOhms

R28

change to 1K Ohms

C26

populate with 0.1uF

C31

change to 0 Ohms

C27

change to 0 Ohms

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 8 of 27

www.sitime.com

Case2: If load is purely capacitive, let the supply of LVCMOS driver be 1.8 V. Then the swing of the clock at the chip input is 1.8

Vpp. We to set the reference voltage at the reference node at 0.9 V. Choose VCC = 1.8V, Rs2=Rs1. Rs1, Rs2 should be in the

kilo ohm range. So if we set Rs1=1K, Rs2=1 K.

Figure 6. Single ended LVCMOS input, DC coupling Capacitive load

Table 14. Single ended DC coupling for driving pure capacitive load

Clock 0 path

R29

remove

Schematic Sheet 9

R34

remove

C23

change to 0 Ohms

R23

change to 1K Ohms

R27

change to 1K Ohms

C25

populate with 0.1uF

C32

change to 0 Ohms

Clock 1 path

R30

remove

R31

remove

C24

change to 0 Ohms

R24

change to 1K Ohms

R28

change to 1K Ohms

C26

populate with 0.1uF

C31

change to 0 Ohms

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 9 of 27

www.sitime.com

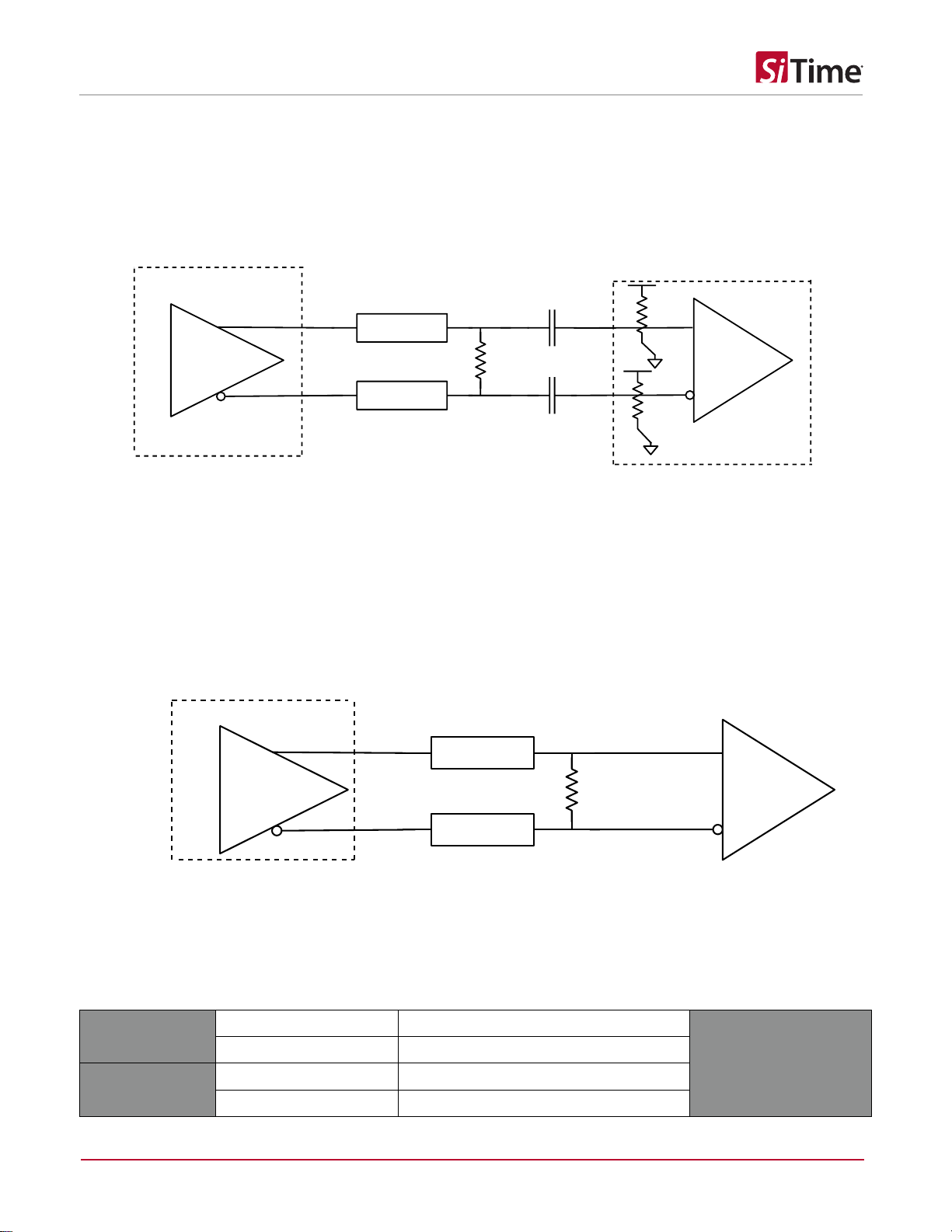

8 Driving Differential LVDS or LVDS Boost (AC coupled)

The input sees a 100 Ohm differential resistance which gives a current path for LVDS or LVDS boost. The 100 Ohm differential

signal is followed by AC coupling capacitor of 0.1 uF. So no change in board configuration is required.

Figure 7. LVDS or LVDS Boost AC coupled

8.1. Board Configuration for driving DC Coupled LVDS

LVDS (DC coupled)

Terminate with a differential 100 Ohm as close to the receiver as possible. This is shown in Figure 8.

Figure 8. Termination scheme for DC coupled LVDS

Board Changes Required for DC Coupled LVDS

Table 15. Board changes required for DC coupled LVDS or LVDS Boost

Clock 0 Path

C23

change to 0 Ohms

Schematic Sheet 9

C32

change to 0 Ohms

Clock 1 Path

C24

change to 0 Ohms

C31

change to 0 Ohms

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 10 of 27

www.sitime.com

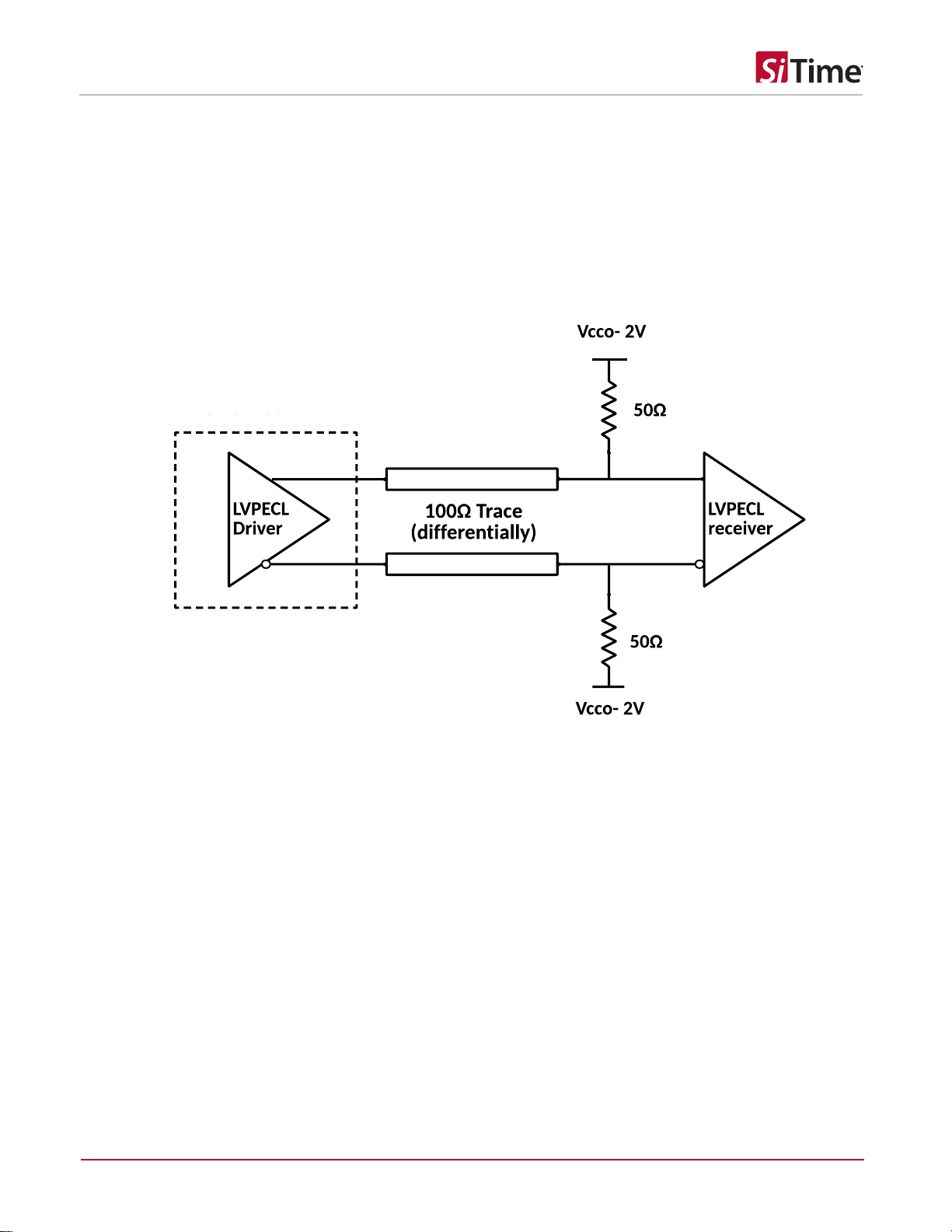

9 Board Configuration Required for Driving DC/AC coupled LVPECL

9.1. DC/AC Coupled LVPECL

The LVPECL standard requires a DC path for the input clock driver. The 50 Ohm termination at the receiver is biased with

VCCO-2 V. The VCM (VCC-2 V) need to be capable of sinking or sourcing current. There is a provision to provide VCM in the

input clock circuit through jumper J4, J7.

So no board changes are required but just give VCM through jumpers J4, J7.

Figure 9. DC coupled LVPECL

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 11 of 27

www.sitime.com

10 Output Configuration

The bank A and B outputs are by default configured for driving LVDS on the EVB. The bank A and B outputs are connected to

the SMA output connectors via a differential transmission line and 0.1uF ac coupling capacitor. Appropriate differential 100 Ohm

termination should be given for using LVDS configuration.

Figure 10. Bank A output configuration for LVDS

Figure 11. Bank B output configuration for LVDS

SiT92216 Evaluation Board (EVB) HW User Manual

SiT92216EB User Manual | Rev 0.5

Page 12 of 27

www.sitime.com

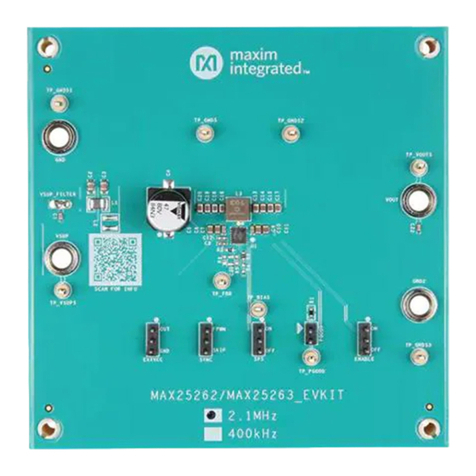

11 EVB Snapshot

Figure 12. EVB Snapshot

Block 1 has USB port to power up the board or to select jumper for power up using external supply as mentioned in Table 5.

Block 2 has jumper settings to configure chip VCC as mentioned in Table 6.

Block 3 has jumper settings to configure chip VAUX as mentioned in Table 10.

Block 4 has jumper settings to configure chip VCCOA as mentioned in Table 7.

Block 5 has jumper settings to configure chip VCCOB as mentioned in Table 8.

Block 6 has jumper settings to configure chip VCCOC as mentioned in Table 9

Block 7 has jumper settings to select CLK_IN_SEL0, CLK_IN_SEL1 and CLK_OUT_TYPE0 as mentioned in Table 11.

Block 8 has jumper settings to select REFOUT_EN as mentioned in Table 11.

Block 9 has jumper settings to select CLK_OUT_TYPE1 as mentioned in Table 11.

Table of contents

Other SiTime Motherboard manuals

SiTime

SiTime SiT6098EBB User manual

SiTime

SiTime SiT6731EB User manual

SiTime

SiTime SiT6502EB User manual

SiTime

SiTime Time Machine II User manual

SiTime

SiTime Time Machine II User manual

SiTime

SiTime SiT6731EB User manual

SiTime

SiTime SiT6722EB User manual

SiTime

SiTime SiT6098EBB User manual

SiTime

SiTime SiT6722EB User manual

SiTime

SiTime SiT6760EB User manual