Operations

For information regarding the operations of

options not listed here or servicing questions,

please call a SJE Rhombus®

customer service technician at

1-800-RHOMBUS

(1-800-746-6287)

Warranty void if panel is modied.

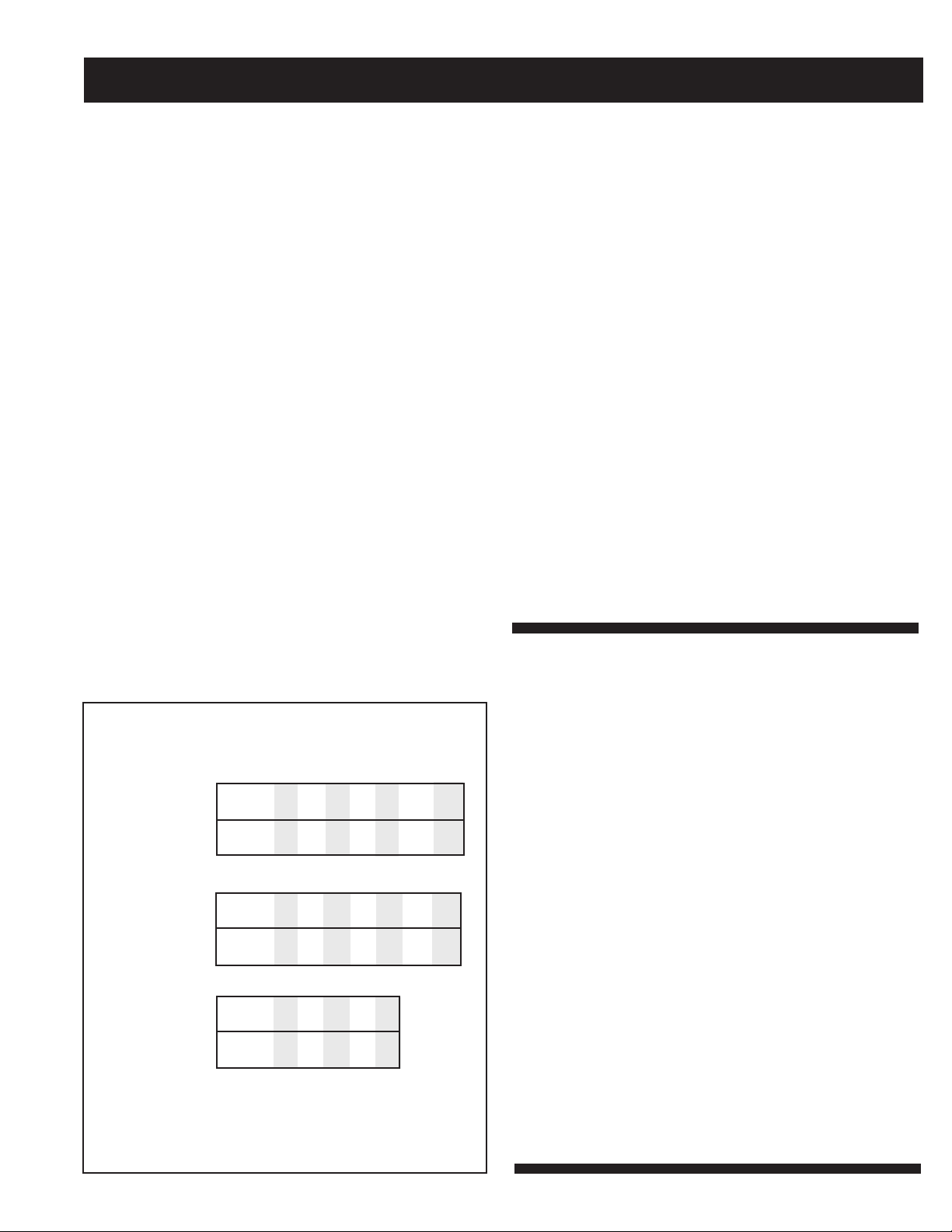

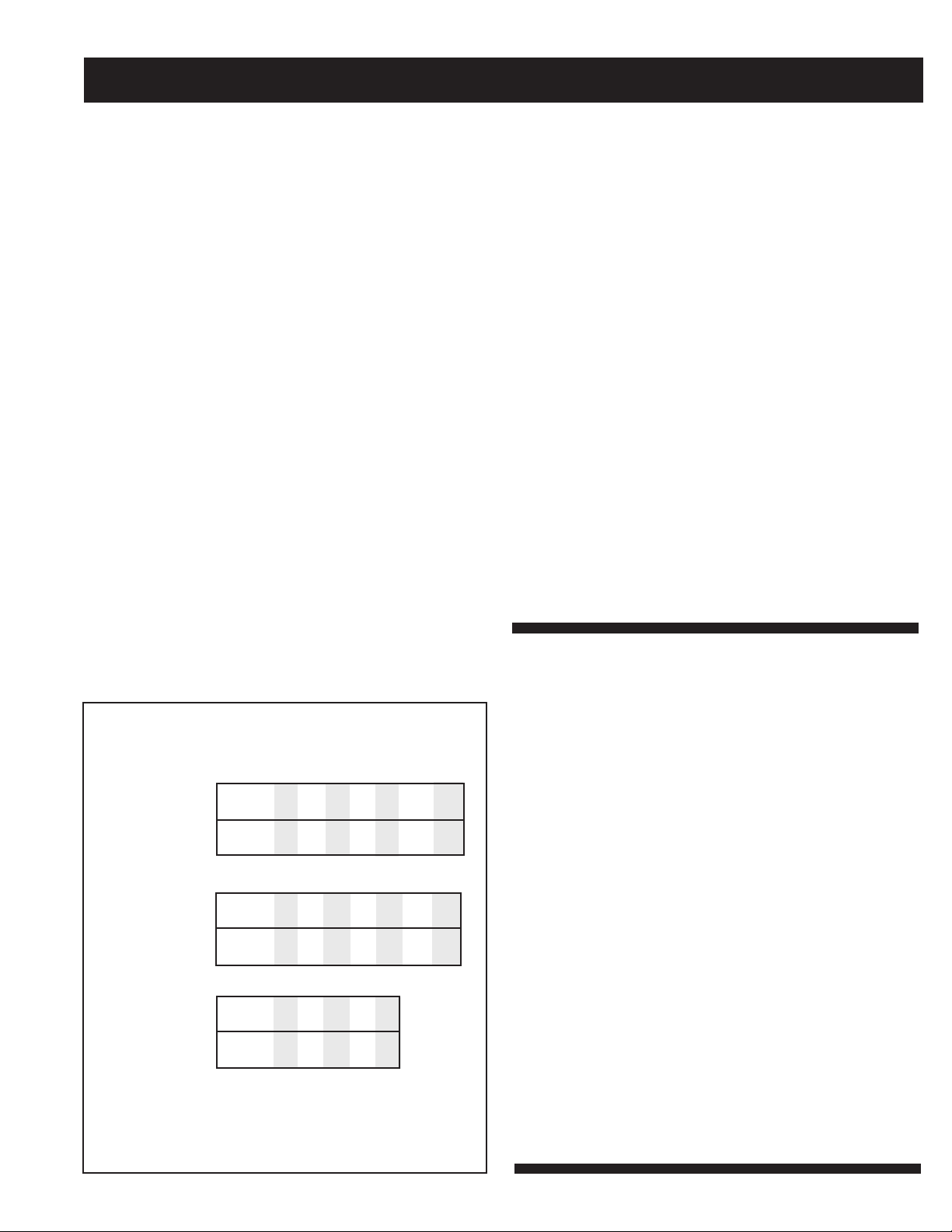

DETERMINING PUMPING RANGE

(IN INCHES)

Use only as a guide. Pumping ranges are based on testing in

non-turbulent conditions. Range may vary due to water tem-

perature and cord shape. Note: As the tether length increases,

so does the variance of the pumping range.

Super Single®

pumping range

tether

length

pumping

range

SJE

PumpMaster

Plus®

pumping range

tether

length

pumping

range

3.5 6 10 14 18 22 24

7 10 16 22 28 33

36

6.5 7.5 8.5 10 11

12.5 13.5

3.5 5 7 9 11 13 15

SJE AmpMaster™

pumping range

tether

length

pumping

range

9 13 17 21 24

5 10 14 18 22

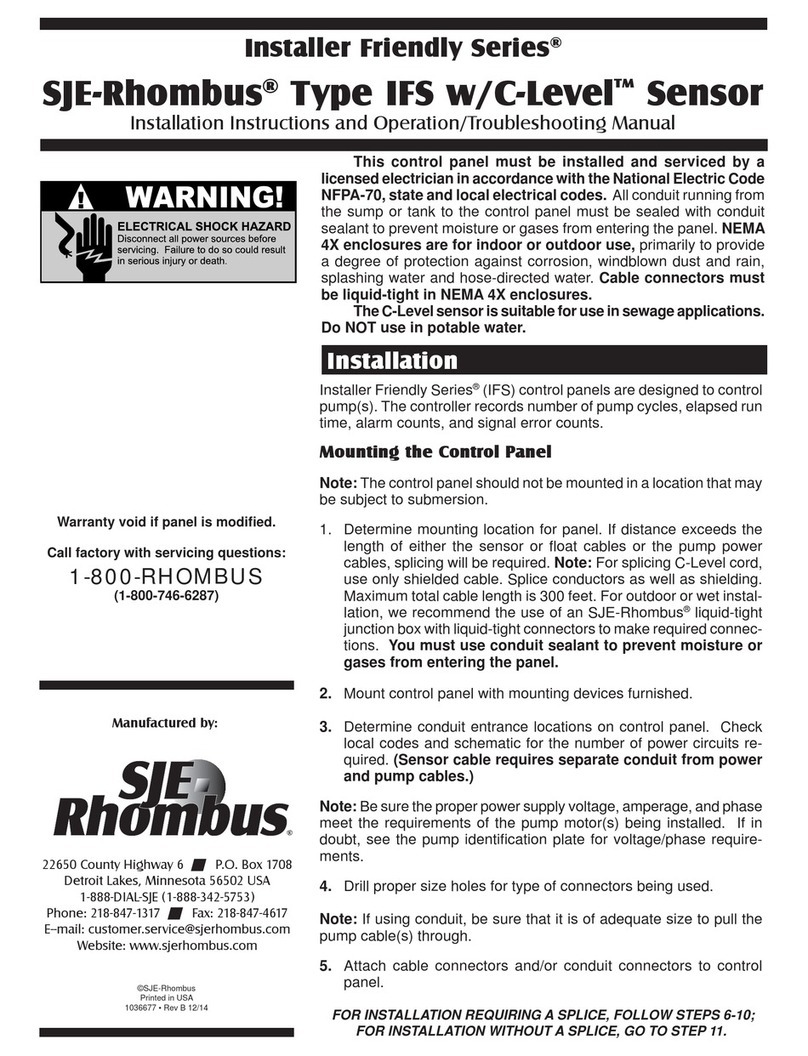

SJE Rhombus® Type 115 control panels are single

phase simplex panels designed for use with wide angle

pump switches, or an SJE Double Float™ and an alarm

switch. When all oats are open or in the OFF position,

the panel is inactive. As the liquid level changes and

closes the pump switch, the pump will start, providing

the HOA switch is in the AUTOMATIC mode and the

power is ON. If a Double Float™ is used, both oats

must be in the ON position before the pump will start.

The pump will remain ON until both oats are returned

to the OFF position. If the liquid level travels beyond

the pump switch or Double Float™ and reaches the

alarm oat, the audio/visual alarm will be activated.

The alarm horn can be silenced by moving the test/

normal/silence switch to the silence position.

Alarm System (Horn and Indicator )

When an alarm condition occurs, a red light and a horn

will be activated. If the test/normal/silence switch is

moved to the silence position, the horn will be silenced.

When the alarm condition is cleared, the alarm system

is reset. The alarm system can be tested by moving

the test/normal/silence switch to the test position.

Alarm Fuse

The alarm circuit contains a bayonett-style fuse dis-

connect. When the fuse is removed, power is cut o

and the alarm circuit is inoperable.

HOA Switch

A hand-o-automatic switch is provided for the pump.

In the hand mode, the pump will turn on unless other

safety features are employed. In the automatic mode,

the pump will turn on from commands by the oat

switches.

Pump Run Light

The run light will be ON in either the hand or the auto-

matic mode when the pump is called to run.

Circuit Breaker (optional)

The pump circuit has a thermal-magnetic circuit

breaker which provides pump disconnect and branch

circuit protection.

Dry Auxiliary Contacts (optional)

Normally Open - Contacts are open under normal con-

dictions and closed when alarm conditions is present.

Normally Closed - Contacts are closed under normal

conditions and open when alarm condition is present.

Both types automatically reset once alarm condition

is cleared.