1. Isolate the oat by disconnecting one or both of the

oat leads from the oat terminals.

2. Place one ohmmeter lead on one of the oat wires, and

the other ohmmeter lead on the other oat wire.

3. Place the ohmmeter dial to read ohms and place on

the R X 1 scale. With the oat in the “o” position, the

scale should read innity (high resistance). Replace

the oat if you do not get this reading. With the oat

in the ON position, the scale should read nearly zero

(very low resistance). Replace the oat if you do not

get this reading.

NOTE: Readings may vary depending on the length of wire

and accuracy of the measuring device.

Fuses

Check the continuity of the fuse. With power OFF, pull the

fuse out of the fuse block. With the ohmmeter on the R X 1

scale, measure resistance. A reading of innity indicates a

blown fuse and must be replaced. Replace fuse with same

type, voltage and amp rating.

Magnetic Contactor Coil

WARNING: Disconnect incoming power to panel.

Check the coil by disconnecting one of the coil leads. Mea-

sure the coil resistance by setting the ohmmeter on the

R X 1 scale. A defective coil will read zero or innity, indicat-

ing a short or opened coil respectively. Replace defective

contactor with same type.

NOTE: Readings may vary depending on the accuracy of

the measuring device.

Alarm Horn

Moving the test/nor-

mal/silence switch to

the test position or

activating the alarm

float should turn on

the alarm horn. If the

horn does not sound, replace horn with same type.

Alarm Light

Moving the test/normal/silence switch to the test position

or activating the alarm oat should turn on the alarm light.

If the light does not activate, replace with same type.

Circuit Breaker (optional)

Check each pole of the circuit breaker for proper resistance

reading using the following procedure.

WARNING: Disconnect incoming power to panel.

1. Isolate the circuit breaker by disconnecting either line

side or load side wires.

2. Place the ohmmeter leads across the corresponding

line and load terminals of each pole.

3. With the ohmmeter on the R X 1 scale and the breaker

in the OFF position, the reading should be innity (very

high resistance). With the breaker in the ON position,

the reading should be nearly zero ohms (very low re-

sistance). If the readings are not as stated, replace

the circuit breaker with one of the same ratings.

NOTE: Readings may vary slightly depending on the

accuracy of the measuring device.

Float Controls

Check the oats during their entire range of operation.

Clean, adjust, or replace damaged oats.

Checking the oat resistance - The oat resistance can

be measured to determine if the oat is operating correctly

or is defective. Use the following procedure to measure

the oat resistance.

WARNING: Disconnect incoming power to panel.

Troubleshooting

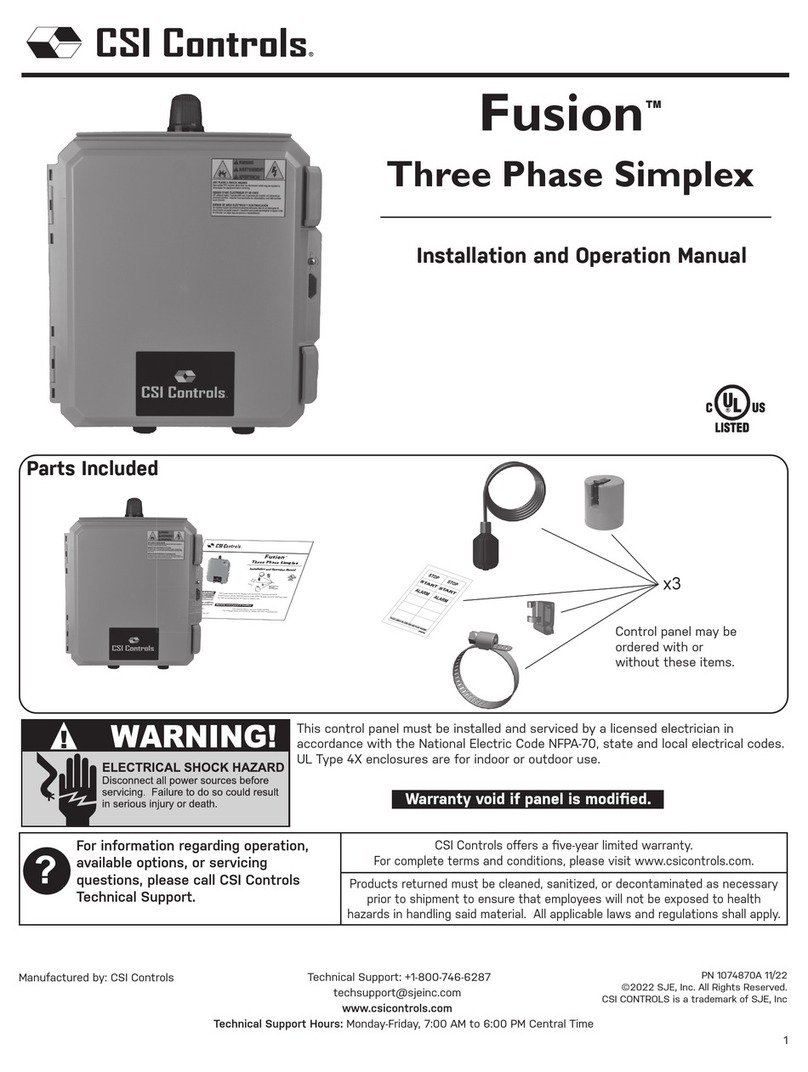

NOTICE!

Products returned must be cleaned, sanitized, or decontaminated as necessary prior to shipment to ensure that employees

will not be exposed to health hazards in handling said material. All applicable laws and regulations shall apply.

For complete terms and conditions, please visit www.sjerhombus.com.

SJE Rhombus®Five-Year Limited Warranty