Wiring the Control Panel Operations

SJE Rhombus Model 322 Three Phase Duplex control panel

operates with oat switches. When all oats are in the

open or OFF position, the panel is inactive. As the liquid

level rises and closes the STOP oat, the panel remains

inactive until the LEAD oat closes. At this point the LEAD

pump will turn ON (if the Hand-O-Auto switch is in the

AUTO mode and the power is ON). The pump will remain

ON until both the STOP and LEAD oats return to their OFF

positions. If the liquid level rises beyond both the STOP

and LEAD oats to reach the LAG oat, the lag pump will

turn ON (if the Hand-O-Auto switch is in the AUTO mode

and the power is ON). Both pumps will remain ON until the

STOP, LEAD, and LAG oats return to their OFF positions.

If the liquid level rises to reach the ALARM oat, the alarm

will be activated.

Alarm System (Indicator Light and Horn)

When an alarm condition occurs, the red light and horn will

be activated.

If the TEST/NORMAL/SILENCE switch is moved to the

SILENCE position and released, the horn will be silenced.

When the alarm condition is cleared, the alarm system is

reset.

Motor Protective Switches

Each pump circuit has motor protective switches that

provides pump disconnect, overload, and branch circuit

protection. Adjust overload to pump FLA.

Hand-O-Auto (HOA) Switches

The HOA 3-way switches control pump functions.

In HAND mode, the pump will turn ON.

OFF turns the pump OFF.

In AUTO mode, commands from the oat switches

turn each pump ON and OFF.

Motor Contactors

Motor contactors control pumps by switching electrical lines.

Transformer

The transformer converts incoming three phase power to

120V to be used for control and alarm.

Auxiliary Contact

Form C - Can be wired normally open or normally closed.

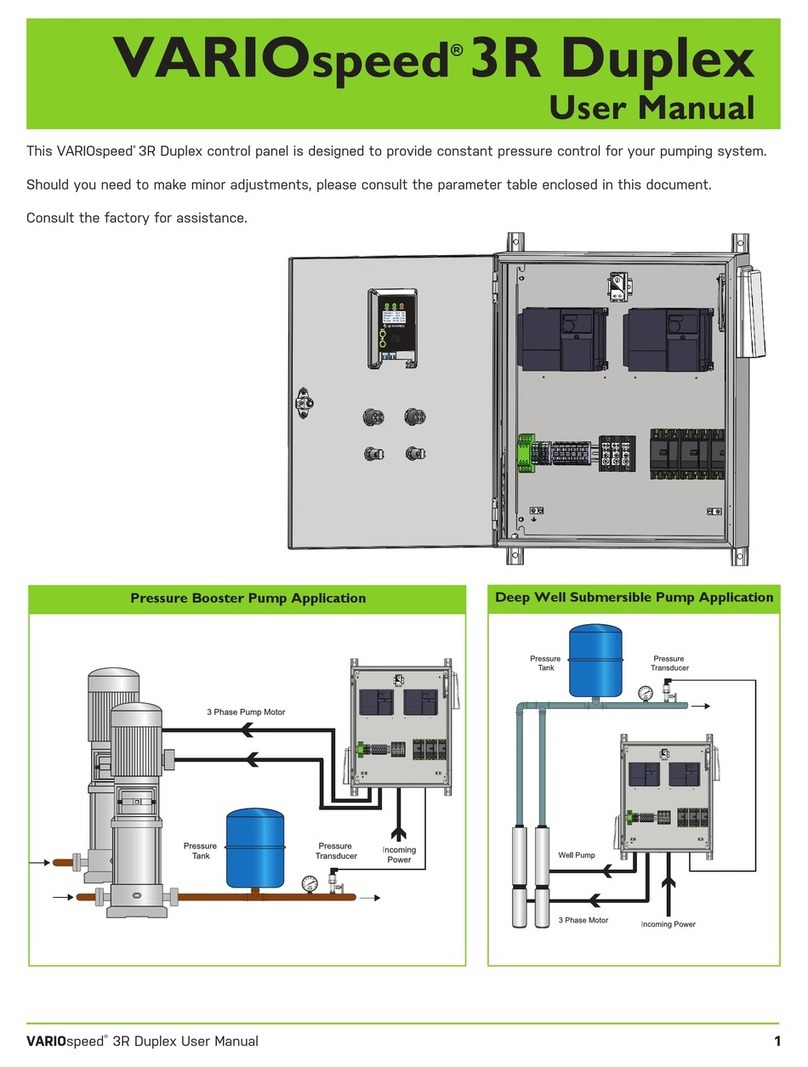

1Determine conduit entrance locations on control panel as shown.

Check local codes and schematic on the inside cover of the panel

for the number of power circuits required.

Be sure the pump power voltage and phase are the same as the

pump motor being installed.

2Connect the following wires to the proper terminal positions:

• incoming power

• pump 1

• pump 2

• oat switches

See schematic on inside cover of the control panel for details.

Technical support,

service questions:

+1-800-Rhombus

(+1-800-746-6287)

Monday - Friday

7:00 AM to 6:00 PM Central Time

?

3Verify correct operation of control panel after installation is

complete.

3

Type 4X conduit must be used to maintain a Type 4X rating of

the control panel.

Incoming

Power

Pumps

You must use conduit sealant to prevent

moisture or gases from entering the panel.

1-2 ALT 2-1

SF2

25K

5K NC

150K

125K50K

15K

LEAD / LAG

STOP LEAD LAG ALARM

PUMP 1

H

O

A

NO C N C

OFF ON

TEST TEST TEST TEST

POWER

34

12

5678910

AUX

PUMP 2

H

O

A

22650 County Highway 6

Detroit Lakes, MN 56501 USA

Tel: 218-847-1317

Web: www.sjerhombus.com

Transformer

Auxiliary Contact

Float

Switches

Typical Layout

(May vary with

options ordered).