SJE Rhombus QUEST User manual

Installation and Operating Instructions

SJE-RHOMBUS®warrants to the original consumer that this product shall

be free of manufacturing defects for two years after the date of consumer

purchase. During that time period and subject to the conditions set forth

below, SJE-RHOMBUS®will repair or replace, for the original consumer,

any component which proves to be defective due to defective materials

or workmanship of SJE-RHOMBUS®.

THIS EXPRESS WARRANTY DOES NOT APPLY TO THE MOTOR

START KIT COMPONENT. SJE-RHOMBUS®

MAKES NO WARRANTIES

OF ANY TYPE WITH RESPECT TO THE MOTOR START KIT.

ELECTRICAL WIRING AND SERVICING OF THIS PRODUCT MUST

BE PERFORMED BY A LICENSED ELECTRICIAN.

THIS WARRANTY DOES NOT APPLY: (A) to damage due to lightning

or conditions beyond the control of SJE-RHOMBUS®; (B) to defects or

malfunctions resulting from failure to properly install, operate or maintain

the unit in accordance with printed instructions provided; (C) to failures

resulting from abuse, misuse, accident, or negligence; (D) to units which

are not installed in accordance with applicable local codes, ordinances,

or accepted trade practices, and (E) to units repaired and/or modied

without prior authorization from SJE-RHOMBUS®.

Some states do not allow limitations on how long an implied warranty

lasts, so the above limitation may not apply to you. Some states do not

allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you. This warranty

gives you specic legal rights, and you may also have other rights which

vary from state to state.

TO OBTAIN WARRANTY SERVICE: The consumer shall assume all

responsibility and expense for removal, reinstallation, and freight. Any

item to be repaired or replaced under this warranty must be returned to

SJE-RHOMBUS®, or such place as designated by SJE-RHOMBUS®.

ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

ARE LIMITED TO THE DURATION OF THIS WRITTEN WARRANTY.

SJE-RHOMBUS®SHALL NOT, IN ANY MANNER, BE LIABLE FOR

ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES AS A RESULT

OF A BREACH OF THIS WRITTEN WARRANTY OR ANY IMPLIED

WARRANTY.

SJE-RHOMBUS®TWO-YEAR LIMITED WARRANTY

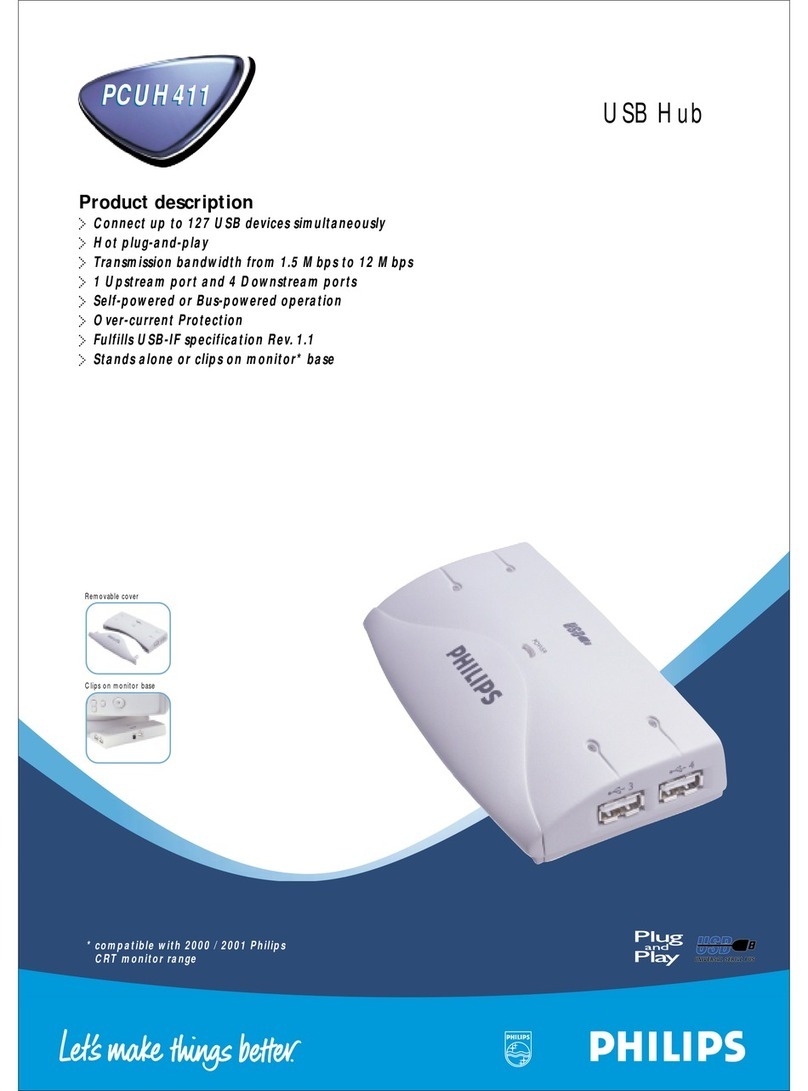

SJE-Rhombus®pump switches provide automatic control of pumps in non-potable water applications.

SPECIFICATIONS

CABLE: Flexible H07RN 1mm2 2 or 3 conductor (H05VV also available)

FLOAT HOUSING: Non-toxic corrosion resistant polyproplylene,

has IP68 protection to a water depth of 1 meter.

ELECTRICAL:

Type of Load R-M = resistance-motor load

250 VAC Rated Voltage:

Maximum Pump Running Current: 10 (8) amps

Frequency: 50/60 Hz

Microdisconnect

Number Automatic Cycles: 5E4

Function Class I or II

SJE Quest™- 2 wire - Function Class II

SJE Quest™- NO or NC with ground plate - Function Class I

SJE Quest™- SPDT Function Class II

Switch must be used with pumps that provide integral thermal overload protection. Switch is not recommended for controlling electric loads less

than 100 milliamps, 12 VAC or non-arcing electric loads. Switch should not be used as main isolating switch for power supply.

This equipment is rated to 50ºC. Approved for use in non-potable water.

SJE QUEST™

SJE QUEST™PUMP SWITCH

PREVENTATIVE MAINTENANCE

• Periodically inspect the product. Check that the cable has not become worn or that the housing has not been damaged so as to impair the protection of the

product. Replace the product immediately if any damage is found or suspected.

• H05VV cable can stiffen over time. Monitor for stiffening or cracking. Replace the product immediately if any damage is found or suspected.

• Periodically check to see that the oat is free to move and operate the switch.

• Use only SJE-Rhombus®replacement parts.

CONSTRUCTION DETAILS:

Degree Protection: IP68 1 meter 168hr

Resistance Heat Fire: Category D

Water Temp: TL50

Ambient Temp : TL50

Type of Action: 1B

Type of Construction: In-line cord control

PTI: 250

Pollution Degree: 2

SJE-Rhombus (Suzhou) Co., Ltd.

TM

SJE-Rhombus (Suzhou) Co., Ltd.

Unit B2-6, District A, Weiting Industrial Workplace, No. 9 Weixin Road, Weiting Town, Suzhou Industrial Park

Suzhou, Jiangsu Province, China

Phone: (86) 512 6507 2880

n

Fax: (86) 512 6507 2881

n

Instl. Instr. PN 1024034E

©SJE-Rhombus 03/18 ENG

ELECTRICAL SHOCK HAZARD

Disconnect power before installing or servicing this product. A

qualied service person must install and service this product

according to applicable electrical and plumbing codes. Switch

should not be used as main isolating switch for power supply.

EXPLOSION OR FIRE HAZARD

Do not use this product with ammable liquids.

Do not install in hazardous locations as dened by National

Codes or other governing body.

Failure to follow these precautions could result in serious injury or death. Replace product immediately if switch cable becomes damaged

or severed. Keep these instructions with warranty after installation. This product must be installed in accordance with local and national electric

codes, so as to prevent moisture from entering or accumulating within boxes, conduit bodies, ttings, oat housing, or cable.

For detailed specications on this product, or for the complete line of SJE-Rhombus®

panel, alarm, and switch products, visit our web site at www.sjerhombus.cn

MOUNTING THE SWITCH

WARNING: Switch has not been evaluated for

use in potable water.

WARNING: Do not install switch in direct line of

incoming liquid.

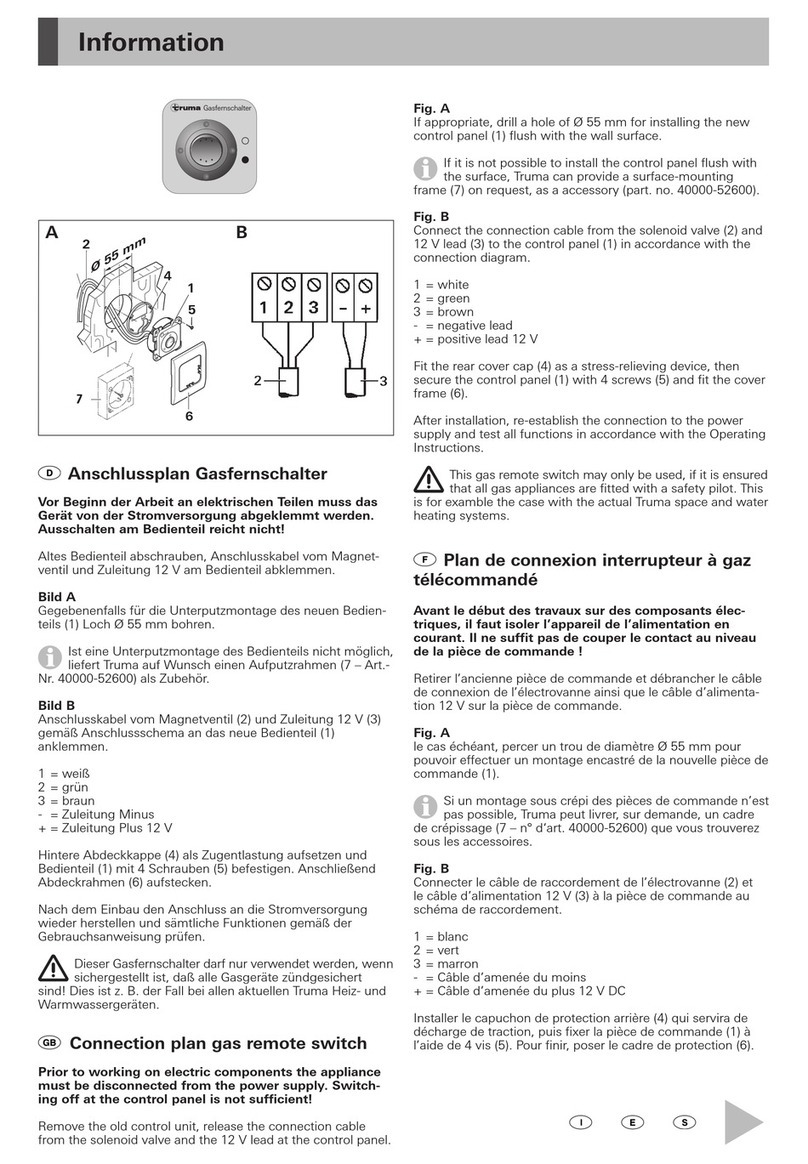

Pipe Clamp Installation (Figure A):

1. Place the cord into the clamp as shown

in Figure A.

2. Locate clamp at desired activation level

and secure the clamp to the discharge

pipe as shown in Figure A. Note: Do not

install cord under hose clamp.

3. Tighten the hose clamp using screwdriver.

Over tightening may result in damage to

the plastic clamp. Make sure the oat

cable is not allowed to touch the excess

hose clamp band during operation.

4. Wire switch as shown in Figure C.

5. Check installation. Allow system to cycle

to insure proper operation. Be sure oat

has free range of motion and does not

touch anything.

Note:All hose clamp components are made of 18-8

stainless steel material. See your SJE-Rhombus®

supplier for replacements.

Cable Weight Installation (Figure B):

1. Place the cord through cable weight as

shown in Figure B.

2. Locate cable weight at desired activation

level. Lock position of cable weight by

turning lid counter clockwise. Note: If

position adjustment is needed, push down

on lid and turn clockwise to loosen.

3. Wire switch as shown in Figure C.

4. Check installation. Allow system to cycle

to insure proper operation. Be sure oat

has free range of motion and does not

touch anything.

Figure C

125/250 VAC

NORMALLY OPEN/PUMP DOWN

125/250 VAC

NORMALLY CLOSED/PUMP UP

On SPDT models, insulate unused brown or black wires with wire nut. Wire can become electrically hot.

In 250 VAC installations, one side of the line going to the load is always HOT. This condition exists if the switch is on or off. Install double pole disconnect on all 230 VAC circuits.

SJE QUEST™SPDT ONLY SJE QUEST™

w/ground plate

SJE QUEST™

NORMALLY OPEN/NORMALLY CLOSED

125/250 VAC

Figure A

Figure B

tether

length

pumping

range

Determining Pumping Range in Centimeters

10 14 18 22 26 30

25 30 36 41 45 51

Use values published as a guide. Pumping ranges are based on

testing in non-turbulent conditions. Range may vary due to water

temperature, cord type and cord shape. Note: As the tether length

increases, so does the variance of the pumping range.

tether

length

pumping

range

Determining Pumping Range in Centimeters

9 15 23 30 38 46

23 30 45 60 75 91

Due to weight of cable, pumping range above horizontal is NOT

equal to pumping range below horizontal. Use values published

as a guide. Pumping ranges are based on testing in non-turbulent

conditions. Range may vary due to water temperature, cord type

and cord shape. Note: As the tether length increases, so does the

variance of the pumping range.

TM

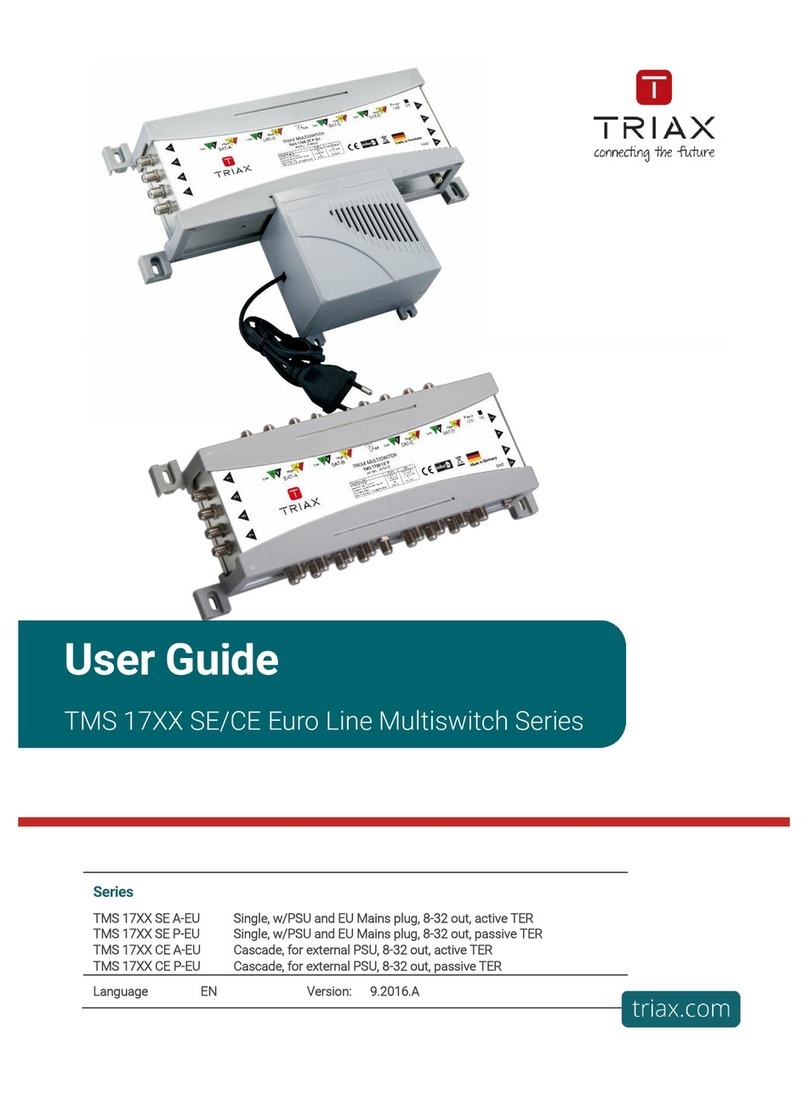

Other SJE Rhombus Switch manuals

Popular Switch manuals by other brands

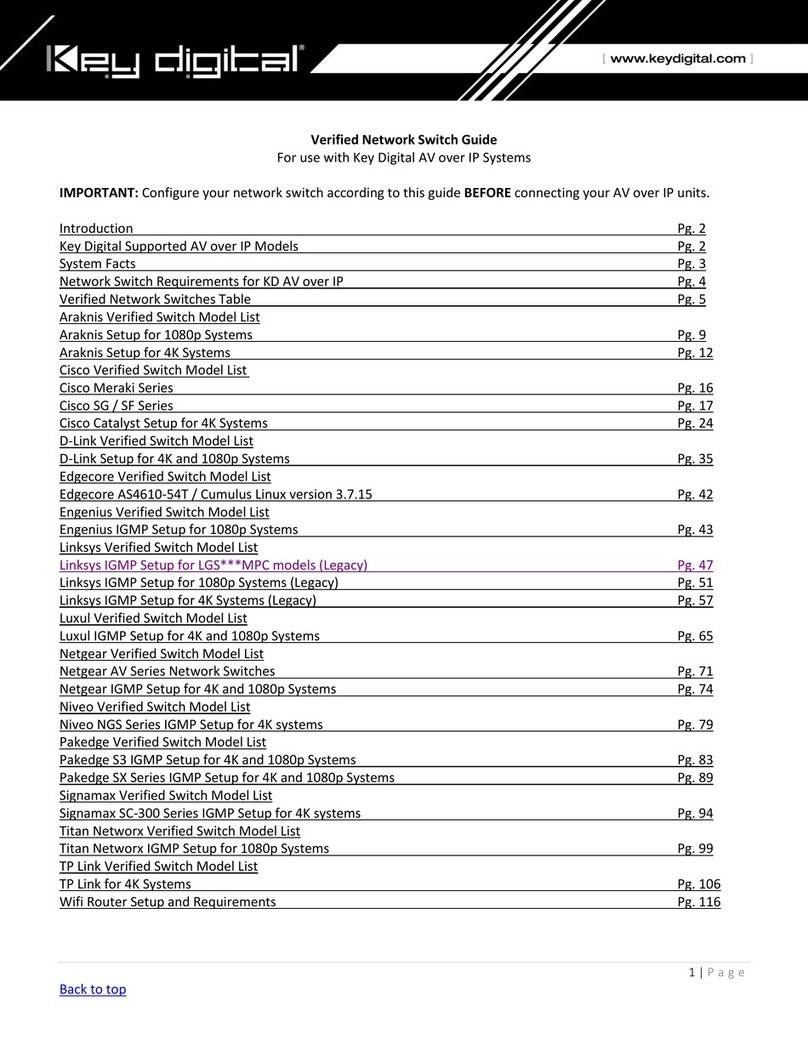

Key Digital

Key Digital KD-IP922ENC-II manual

Emos

Emos TS-EF1 quick guide

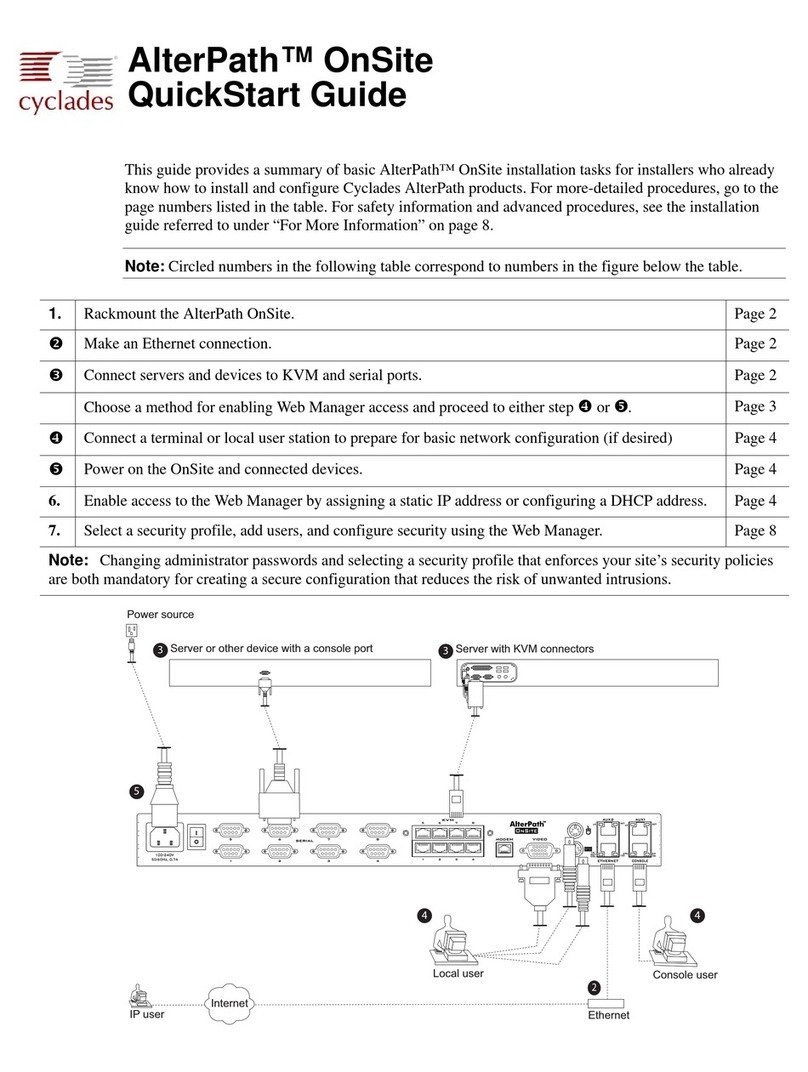

Cyclades

Cyclades AlterPath OnSite quick start guide

Rose electronics

Rose electronics MultiStation ML-2U Installation and operation manual

Kenco

Kenco KUST Series Installation & operation instructions

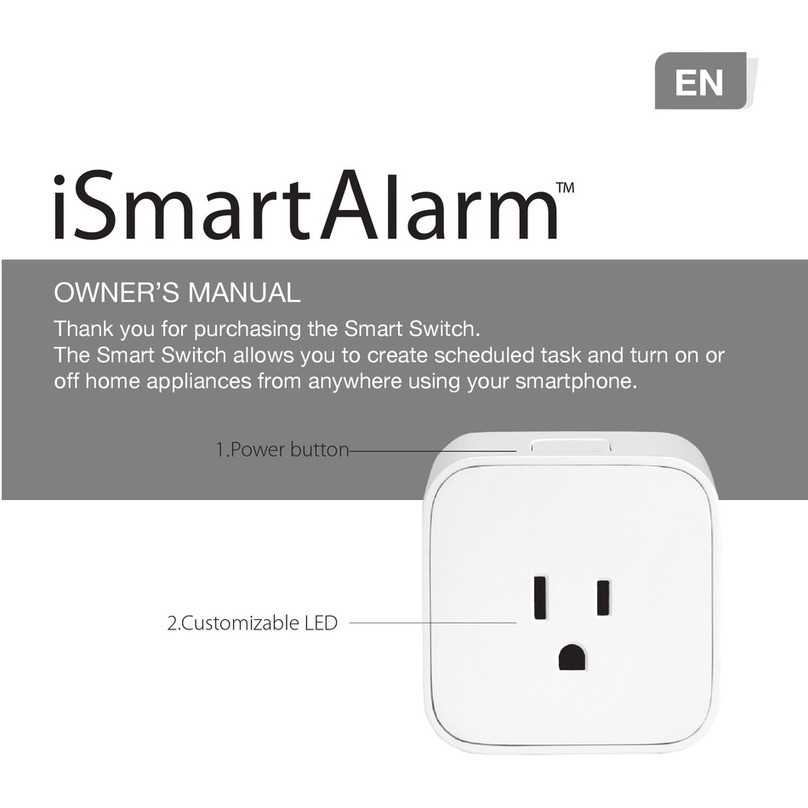

iSmartAlarm

iSmartAlarm SP3 owner's manual