SKE PL20 4KW User manual

USER MANUAL

PL20 Series Hybrid Inverter

CONTENTS

ABOUT THIS MANUAL................................................................................................................................................ 1

Purpose............................................................................................................................................................................ 1

Scope................................................................................................................................................................................ 1

IMPORTANT SAFETY INSTRUCTIONS.................................................................................................................... 1

General Precautions.......................................................................................................................................................1

Personal Precautions..................................................................................................................................................... 2

INSTALLATION...............................................................................................................................................................3

Unpacking and Inspection............................................................................................................................................. 3

Basic Configuration.........................................................................................................................................................3

Batteries............................................................................................................................................................................4

Battery Cable Size.......................................................................................................................................................... 6

DC Disconnect and Over-Current Protection............................................................................................................. 6

Battery Cable Connection..............................................................................................................................................6

AC Cable Size................................................................................................................................................................. 7

AC Connections.............................................................................................................................................................. 7

Machine panel introduction............................................................................................................................................9

OPERATION.................................................................................................................................................................. 11

Front Panel and Configuration Switch....................................................................................................................... 11

Setting Indicators.......................................................................................................................................................... 12

LCD display meaning................................................................................................................................................... 17

Table 5. display meaning............................................................................................................................................. 17

Operating Indicators..................................................................................................................................................... 18

Table 6 Fault code meaning........................................................................................................................................ 19

SPECIFICATIONS........................................................................................................................................................20

Table 7. Line Mode Specifications..............................................................................................................................20

Table 8. Invert Mode Specifications........................................................................................................................... 21

Table 9. AC Charger Mode Specifications................................................................................................................ 22

Table 10. Solar Charger Mode Specifications.......................................................................................................... 22

Table 11. General Specifications................................................................................................................................ 23

APPENDIX A.................................................................................................................................................................24

How to Select and Configure PV Panels.................................................................................................................. 24

DISPOSAL.....................................................................................................................................................................26

1

ABOUT THIS MANUAL

Purpose

The purpose of this manual is to provide explanations and procedures for installing, operating and

troubleshooting for the unit. This manual should be read carefully before installations and operations.

Please retain this manual for future reference.

Scope

This document defines the functional requirements of the unit, intended for worldwide use in electronic

processing equipment. All manuals are applicable under all operating conditions when installed in the End

Use system, unless otherwise stated.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: This chapter contains important safety and operating instructions. Read and keep

this User Guide for future reference.

General Precautions

1. Before using the unit, read all instructions and cautionary markings on:

(1) The unit (2) the batteries (3) all appropriate sections of this manual.

2. CAUTION --To reduce risk of injury, charge only deep-cycle lead acid type rechargeable batteries. Other

types of batteries may burst, causing personal injury and damage.

3. Do not expose the unit to rain, snow or liquids of any type. The unit is designed for indoor use only.

Protect the unit from splashing if used in vehicle applications.

4. Do not disassemble the unit. Take it to a qualified service center when service or repair is required.

Incorrect re-assembly may result in a risk of electric shock or fire.

5. To reduce risk of electric shock, disconnect all wiring before attempting any maintenance or cleaning.

Turning off the unit will not reduce this risk.

6. CAUTION --Battery are not already installed by the supplier only a qualified professional (e.g. service

person) may install the Inverter.

7. WARNING: WORKING IN VICINITY OF A LEAD ACID BATTERY IS DANGEROUS.

BATTERIES GENERATE EXPLOSIVE GASES DURING NORMAL OPERATION. Provide ventilation to

outdoors from the battery compartment. The battery enclosure should be designed to prevent

accumulation and concentration of hydrogen gas in “pockets” at the top of the compartment. Vent the

battery compartment from the highest point. A sloped lid can also be used to direct the flow to the vent

opening location.

8. NEVER charge a frozen battery.

9. No terminals or lugs are required for hook-up of the AC wiring. AC wiring must be no less than 10 AWG

gauge copper wire details refer to table 2. Battery cables must be rated for 35mm or higher and should be

no less than table 1. Crimped and sealed copper ring terminal lugs with a HRNB38-8 hole should be used

to connect the battery cables to the DC terminals of the unit. Soldered cable lugs are also acceptable.

10. Be extra cautious when working with metal tools on, or around batteries. The potential exists to drop a

tool and short-circuit the batteries or other electrical parts resulting in sparks that could cause an

explosion.

2

11. No AC or DC disconnects are provided as an integral part of this unit. Both AC and DC disconnects

must be provided as part of the system installation. See INSTALLATION section of this manual.

12. Fuses are provided as the over current protection of the battery supply.

13. When PV module or panel is exposed to light, it starts to supply high DC voltage, be sure to turn off DC

switch before commencing the maintenance, and make sure the cables from PV panel are properly

sealed after disconnection.

14. GROUNDING INSTRUCTIONS -This battery charger should be connected to a grounded permanent

wiring system. For most installations, the Ground Lug should be bonded to the grounding system at one

(and only one point) in the system. All installations should comply with all national and local codes and

ordinances.

15. AVOID AC output short-circuit; avoid DC input short-circuit and do not connect the mains while DC input

short-circuit

16. Warning: The maintenance information is only to service persons, If the product is used in a manner

which is not covered by the scope of warranty, the protection provided by the product may be impaired.

Personal Precautions

1. Someone should be within range of your voice to come to your aid when you work near batteries.

2. Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

3. Wear complete eye protection and clothing protection. Avoid touching eyes while working near batteries.

Wash your hands when done.

4. If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters eyes,

immediately flood eyes with running cool water for at least 15 minutes and get medical attention

immediately.

5. Baking soda neutralizes lead acid battery electrolyte. Keep a supply on hand in the area of the batteries.

6. NEVER smoke or allow a spark or flame in vicinity of a battery or generator.

7. Be extra cautious when working with metal tools on, and around batteries. Potential exists to short-circuit

the batteries or other electrical parts which may result in a spark which could cause an explosion.

8. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with

battery. Battery can produce short-circuit current high enough to weld a ring, or the like, to metal causing

severe burns.

9. If a remote or automatic generator start system is used, disable the automatic starting circuit and/or

disconnect the generator from its starting battery while servicing to prevent accidental starting during

servicing.

3

INSTALLATION

Unpacking and Inspection

Carefully unpack the inverter/charger from its shipping carton.

Verify all of items list below are present. Please call customer service if any items are missing.

The unit

1 user’s manual

Basic Configuration

PL20 Series hybrid Inverter is designed to serve as a backup power supply for AC loads. The input power of

PL20 Series hybrid Inverter comes from PV system and AC grid which not only supply power to AC loads but

also charge the battery bank when the power from AC grid or AC generator is present (also known as Line

Mode).

In the event of AC grid (or AC generator) outage, the AC loads can be alternatively powered by PV system (if

the illumination is sufficient) and battery bank.

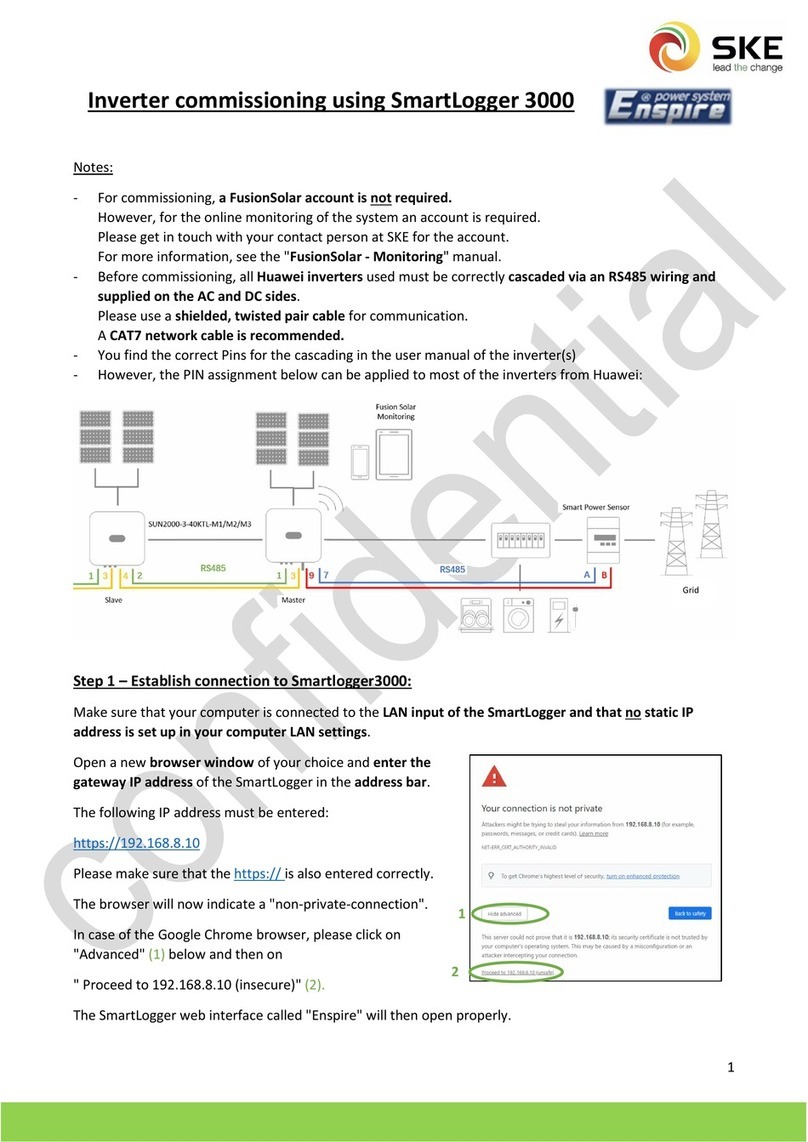

The following illustrations show basic applications for PL20 Series hybrid Inverter.

Figure 1. Typical Application of PL20 series hybrid Inverter

4

Note: Appliances like Air conditioner needs at least 3 minutes to restart in case of a power shortage occurs

in a way that the power turns off then back on again rapidly (time is required to balance the refrigerant

gas in inside circuit); so in order to protect your Air conditioner, please consult the Air conditioner

manufacturer whether they have already provided time delay function before installing. Otherwise,

Inverter will trig overload fault and shut off its output to protect your appliance but sometimes it is not

enough and your Air conditioner can be damaged internally beyond repair.

Batteries

The unit support 12volt,24volt or 48vlot battery bank. Please wiring battery correctly. Before proceeding,

ensure you have appropriate size batteries for this inverter. The unit can use flooded lead-acid, or sealed

GEL/AGM lead-acid batteries so ensure that your batteries are in one of these categories. PL20 inverter

with built-in MPPT solar controller, for the battery and solar panel connection please refer to figure 2,figure3

and figure4. If with the built-in 48 MPPT 40A solar charge controller, then please configure solar panels

more than 2350W, otherwise it can not reach the maximum charge current, if with the built-in 48 MPPT 60A

solar charge controller, then please configure solar panels more than 3500W, otherwise it can not reach

the maximum charge current.

Note: if you are using a gel battery or a deep cycle battery, please do not use ordinary lead-acid batteries for

use in solar energy systems. This is likely to damage the lead acid battery or to reach the desired

effect.

The battery must be wired to match with the DC input voltage. Recommend to use battery capacity more

than 200AH .

Figure 2. PL20 12V solar inverter system- the connection diagram of solar panel and battery

5

Figure 3. PL20 24V solar inverter system- the connection diagram of solar panel and battery

Figure 4. PL20 48V solar inverter system- the connection diagram of solar panel and battery

6

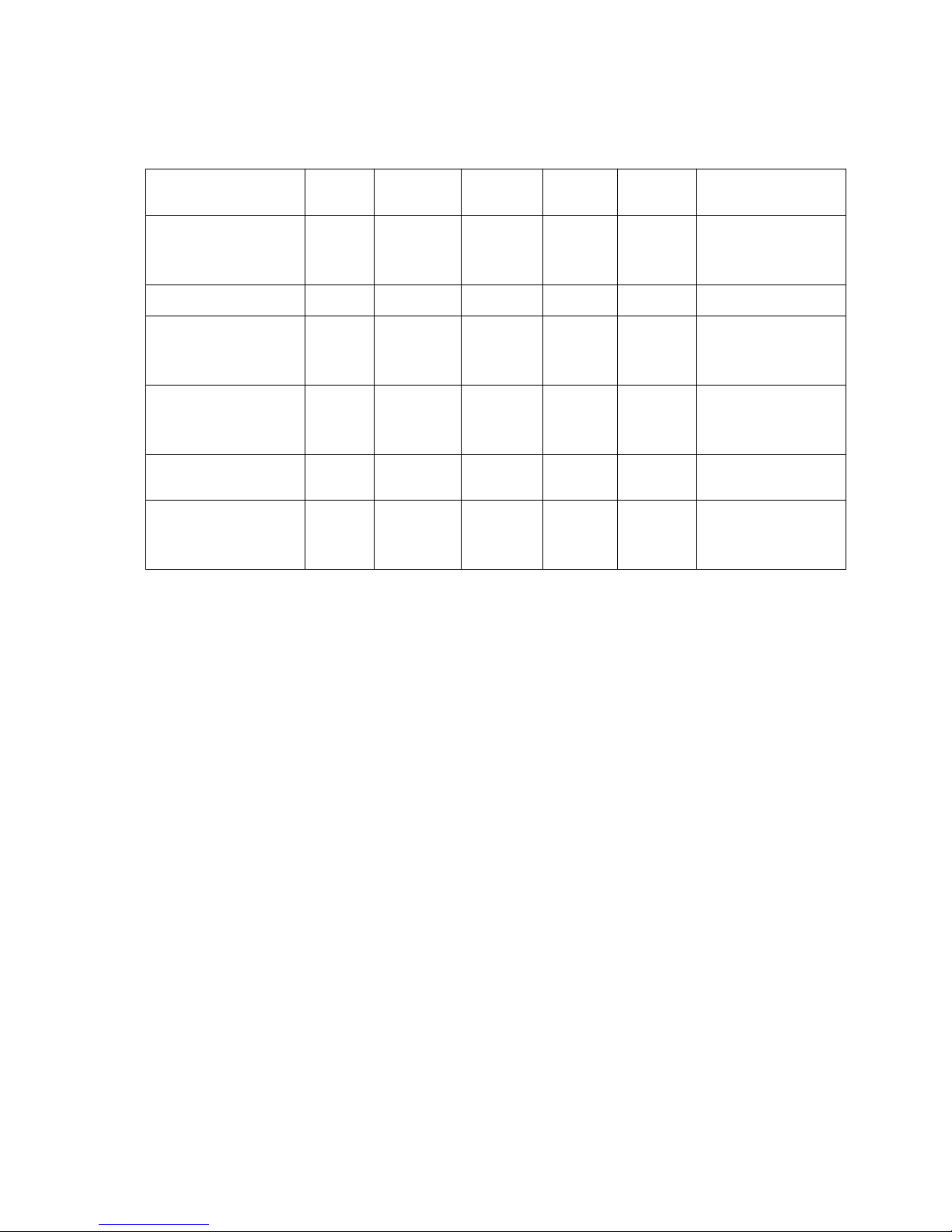

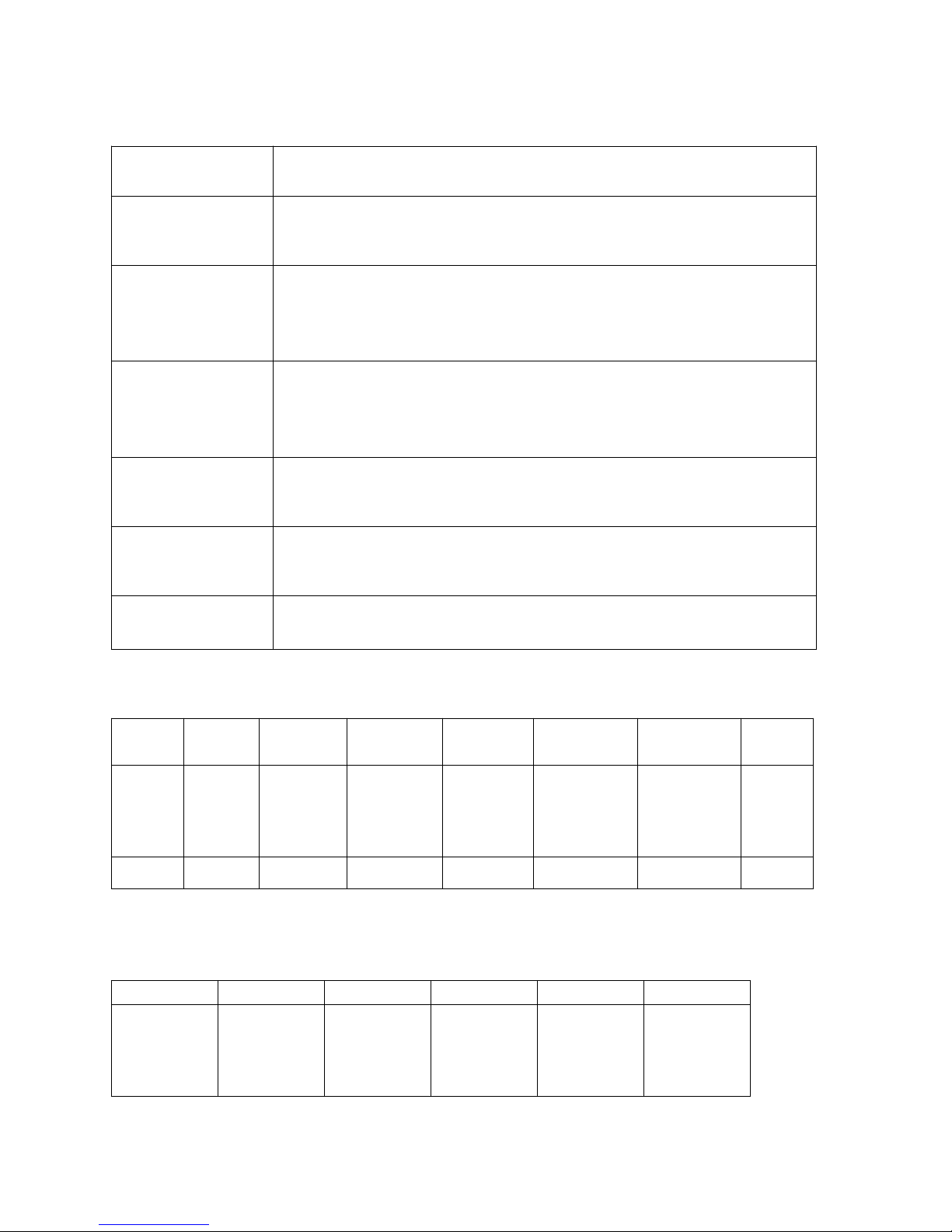

Battery Cable Size

Below table 1 you can find information for recommended battery cable and terminal.

Table 1. Recommended battery cable and terminal size

Model

Number

DC

Voltage

Typical

Amperage

Battery

Capacity

1~3 m

one-way

0.5 m

one-way

Cable Terminal

PL20 1KW

PL20 2KW

PL20 4KW

12V

24V

48V

120A

200AH

25mm2

25mm2

RNBS38-8

PL20 5KW

48V

150A

200AH

35mm2

25mm2

RNBS38-8

PL20 1.5KW

PL20 3KW

PL20 6KW

12V

24V

48V

175A

200AH

50mm2

35mm2

RNB60-8/RNBS38-8

PL20 2KW

PL20 4KW

PL20 8KW

12V

24V

48V

225A

200AH

50mm2

35mm2

RNB60-8/RNBS38-8

PL20 5KW

PL20 10KW

24V

48V

275A

200AH

75mm2

50mm2

RNB80-8/RNB60-8

PL20 3KW

PL20 6KW

PL20 12KW

12V

24V

48V

315A

200AH

75mm2

50mm2

RNB80-8/RNB60-8

DC Disconnect and Over-Current Protection

For safety and to comply with regulations, battery over-current protection and disconnect devices are

required. Fuses and disconnects must be sized to protect the DC cable size used, and must be rated for DC

operation. Do not use devices rated only for AC service – they will not function properly.

Note that some installation requirements may not require a disconnect device, although over-current

protection is still required.

Battery Cable Connection

Observe Battery Polarity! Place the ring terminal of DC cable over the bolt and directly against the unit’s

battery terminal. Tighten the M8 screw with 6-10 Nm. Do not place anything between the flat part of the

Backup System terminal and the battery cable ring terminal or overheating may occur.

DO NOT APPLY ANY TYPE OF ANTI-OXIDANT PASTE TO TERMINALS UNTIL AFTER THE BATTERY

CABLE WIRING IS TORQUED!!

WARNING: Shock Hazard

Installation must be performed with care for the high battery voltage in series.

Caution!! Do NOT place anything between battery cable ring terminals and terminals on the

inverter. The terminal screw is not designed to carry current.

Apply Anti-oxidant paste to terminals AFTER terminals have been screwed.

Verify that cable lugs are flush with the battery terminals. Tighten battery cables to terminals (6-10 Nm).

7

AC Cable Size

Before wiring the input and output of inverter, refer to table 2 for minimum recommended cable size and

torque value

Table 2. Recommended cable size and torque value for AC wire

Model Number

Typical

Amperage

AC Input

AC Output

Torque value

PL20 1KW 230Vac

10A

12AWG

14AWG

1.5~2.0 Nm

PL20 1.5KW 230Vac

12A

12AWG

14AWG

1.5~2.0 Nm

PL20 2KW 230Vac

PL20 1KW 110Vac

15A

12AWG

12AWG

1.5~2.0 Nm

PL20 3KW 230Vac

PL20 1.5KW 110Vac

20A

12AWG

12AWG

1.5~2.0 Nm

PL20 4KW 230Vac

PL20 2KW 110Vac

32A

12AWG

12AWG

1.5~2.0 Nm

PL20 5KW 230Vac

40A

12AWG

12AWG

1.5~2.0 Nm

PL20 6KW 230Vac

PL20 3KW 110Vac

50A

10AWG

12AWG

1.5~2.0 Nm

PL20 8KW 230Vac

PL20 4KW 110Vac

60A

10AWG

10 AWG

2.0~2.5 Nm

PL20 10KW 230Vac

PL20 5KW 110Vac

70A

8AWG

10 AWG

2.0~2.5 Nm

PL20 12KW 230Vac

PL20 6KW 110Vac

80A

6AWG

8AWG

2.0~2.5 Nm

AC Connections

Installation should be done by a qualified electrician. Consult local code for the proper wire sizes,

connectors and conduit requirements.

On the left of rear chassis is the AC hardwire cover. Two three-station terminal block is provided to make the

AC connections. The terminal block is used to hardwire the AC input, AC output, and ground. The National

Electrical Code requires that an external disconnect switch be used in the AC input wiring circuit. The AC

breakers in a sub panel will meet this requirement.

8

Figure 5. AC Cable Connect to unit

Step 1: Disconnect the unit from the battery by removing the battery cables. Turning off the unit before

disconnect from the battery.

Step 2: Following the wiring guide located in the AC input wiring compartment as figure 5, connect the GND

(green/yellow), Line (brown), and neutral (blue) wires from the AC input (utility, generator, etc) to

the terminal block.

Caution!! Be sure that AC source is disconnected before attempting to hardwire it to the unit.

Step 3: Connect the AC Line output wiring to the terminal marked AC Line (output), following the wiring

guide inside the compartment. Torque the wires into the terminal block.

Step 4: Lock the AC covers.

9

Machine panel introduction

Figure 6. PL201-3KW Front panel

Figure 7. PL201-3KW Back panel

Figure 8. PL204-6KW Front panel

10

Figure 9. PL204-6KW Back panel

Figure 10. PL208-12KW Front panel

Figure 11. PL208-12KW Back panel

11

OPERATION

Front Panel and Configuration Switch

Table 3. Configuration button function

Switch

Description

CONF

long press "1S" button to enter the setting interface, can be used for

selecting different contents( Voltage, frequency, charging current...)

Up SELECT

Up SELECT button can be used for selecting parameter on the function

setting mode

Down SELECT

Down SELECT button can be used for selecting parameter on the function

setting mode

ENTER

Confirm, data save function

12

LED Indicator

LED

Description

PV-LED

GREEN LED Lighting on PV normal

Battery-LED

YELLOW LED lighting on Battery normal

AC-LED

GREEN LED lighting on AC Line Mode

INV-LED

GREEN LED lighting on Battery Inverter Mode

Alarm-LED

RED LED lighting on Alarm

Setting Indicators

Table 4. Configuration option

1. Input voltage range Setting

Narrow range mode Wide range mode

NO.

Description

Selectable option

1

Input voltage setting

Wide/Normal.

2

Output voltage setting

208/220/230/240Vac.

3

Output frequency setting

50/60Hz/Automatic.

4

AC charge on, off

AC charge on/AC charge off.

5

AC Charger current setting

20A/35A/50A/70A/90A

6

DC/AC/ Intelligent mode selection

setting

DC mode priority / AC mode priority,

Intelligent mode.

7

DC conversion voltage point setting

11.0Vdc/11.5Vdc/12.0Vdc.

13

2. Output voltage Setting

208Vac/220Vac/230Vac/240Vac four kinds of output voltage can be set.

3. Output frequency Setting

50/60Hz frequency output can be adjusted, as well as the adaptive AC input frequency.

14

4. AC charger ON/OFF Setting

.5. AC Charger current Setting

Maximum rated charge current can be divided into 5 different stall for adjusting

20A charger can be adjusted into 4A/8A/12A/16A/20A

35A charger can be adjusted into 7A/14A/21/28A/35A.

50A charger can be adjusted into 10A/20A/30A/40A/50A.

70A charger can be adjusted into 14A/28A/42A/56A/70A.

90A charger can be adjusted into 18A/36A/54A/72A/90A.

15

6. DC/AC/ Intelligent mode selection setting

AC mode priority DC mode priority

7. Battery capacity setting

16

11 kinds of battery capacity settings,

65AH,80AH,100AH,150AH,200AH,250AH,300AH,400AH,500AH,600AH,800AH.

17

LCD display meaning

Table 5. display meaning

When inverter is faulty, this sign will appear.

When the inverter enter the setup interface, this flag will appear.

Battery capacity display.

Load capacity display.

Display AC input voltage and frequency, will change to the other info in every 3s.

Display AC output voltage and frequency, will change to the other info in every 3s.

Working mode and fault code.

Battery indicator:

Battery capacity segment will lighting to comply with battery voltage.

Battery

voltage

>26V

25V~26V

24V~25V

23V~24V

21.6V~23V

20V ~21.6V

<20V

ALARM

--

--

--

--

1beep/2s

continue

Load indicator:

The load indicate the load percentage comply with load VA or W (show the bigger value),the overload label will

flash when overload.

Load(±4%)

>85%

65%~85%

45%~65%

25%~45%

0%~25%

18

Operating Indicators

AC Mode:

Inverter AC mode, bypass output, mains and battery

indicator light

DC Mode:

Battery inverter mode, inverter output, the inverter

and battery indicator light

PV+DC Mode:

.PV charging battery, battery invert output, PV and

battery mode indicator light.

AC + PV mode:

.AC input and PV charging battery,indicator light.

PV Mode:

Inverter without work, PV charging battery, PV and

battery mode indicator light.

Fault Mode:

Inverter fault. fault indicator light and buzzer alarming

This manual suits for next models

9

Table of contents

Other SKE Inverter manuals