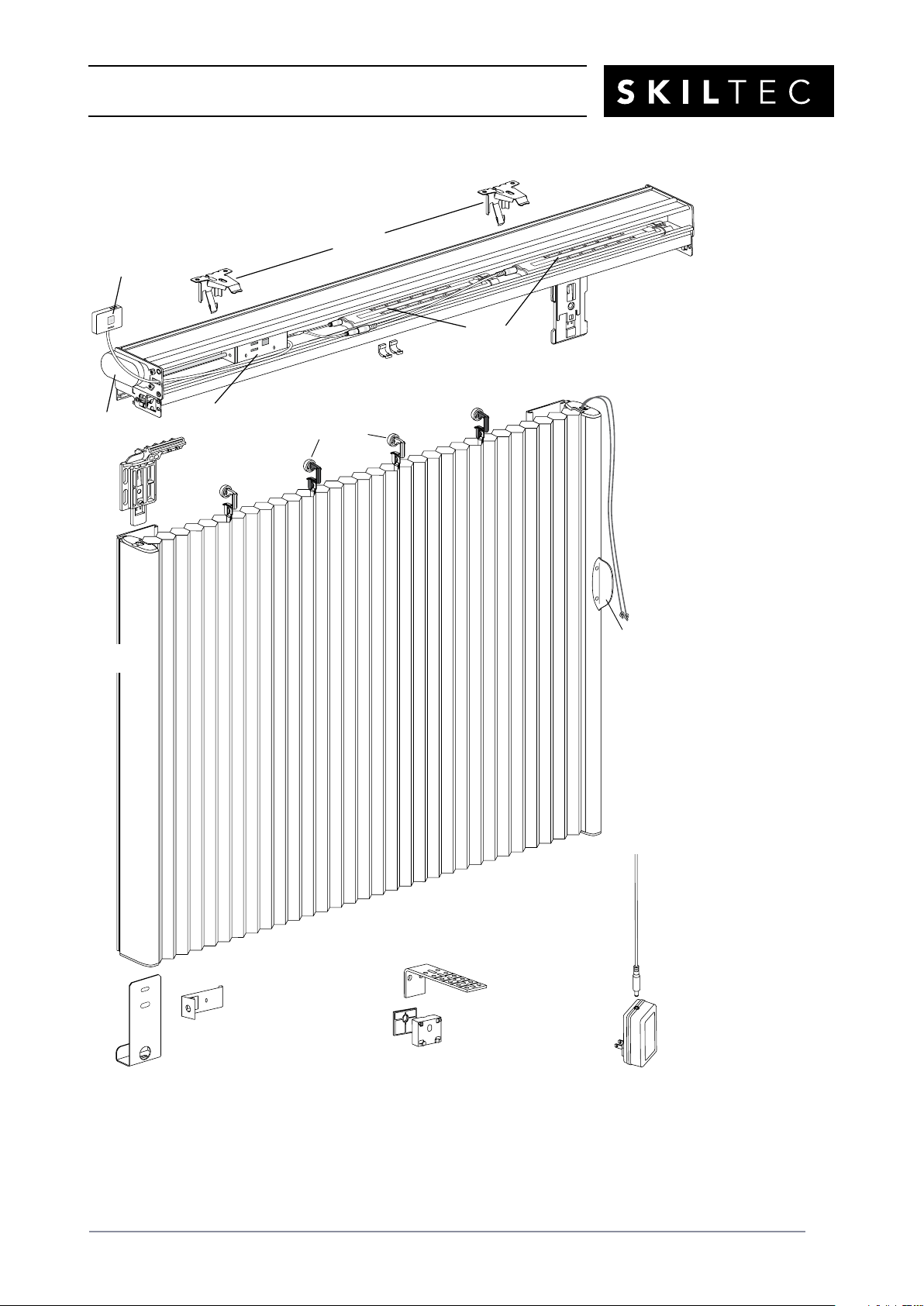

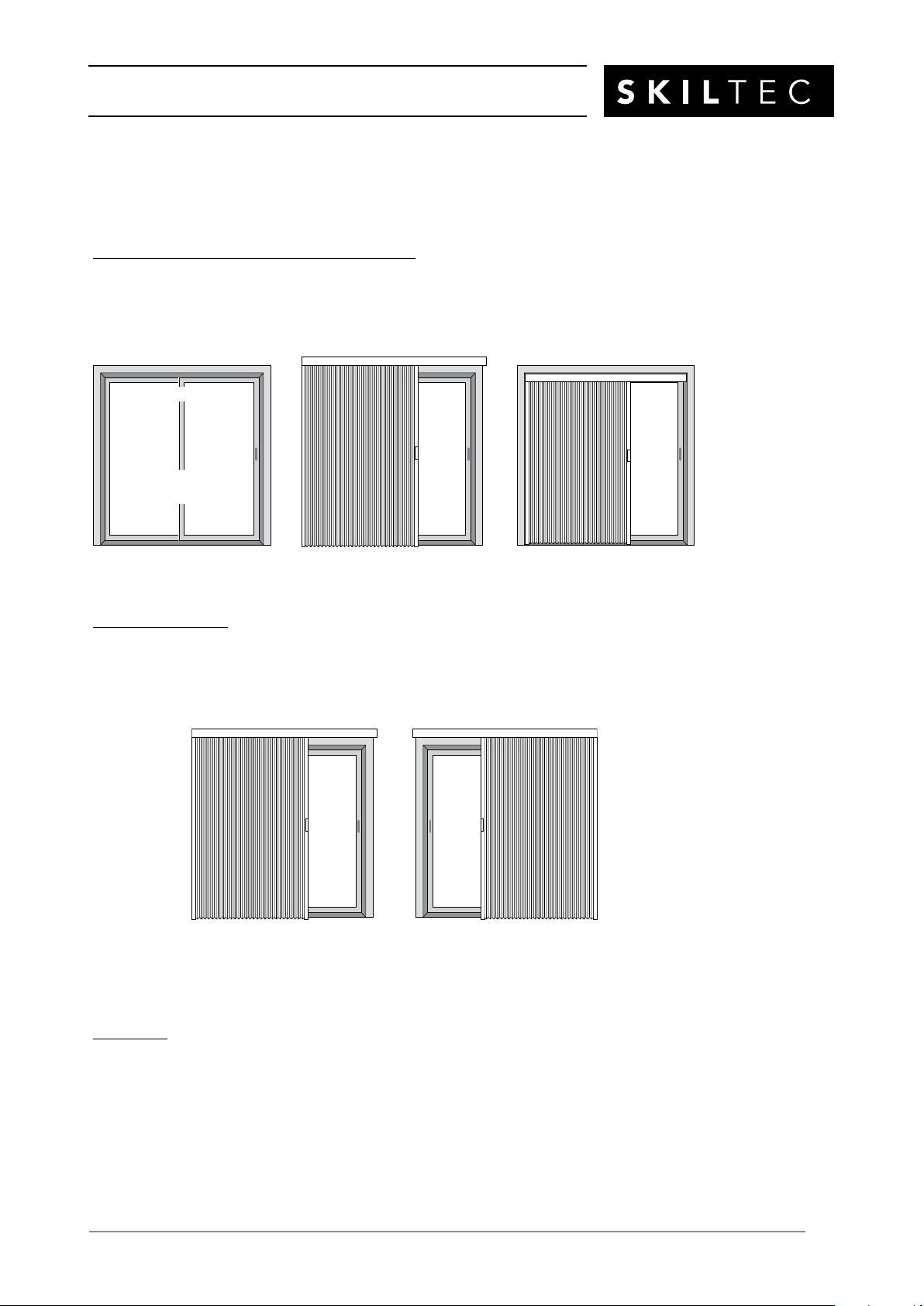

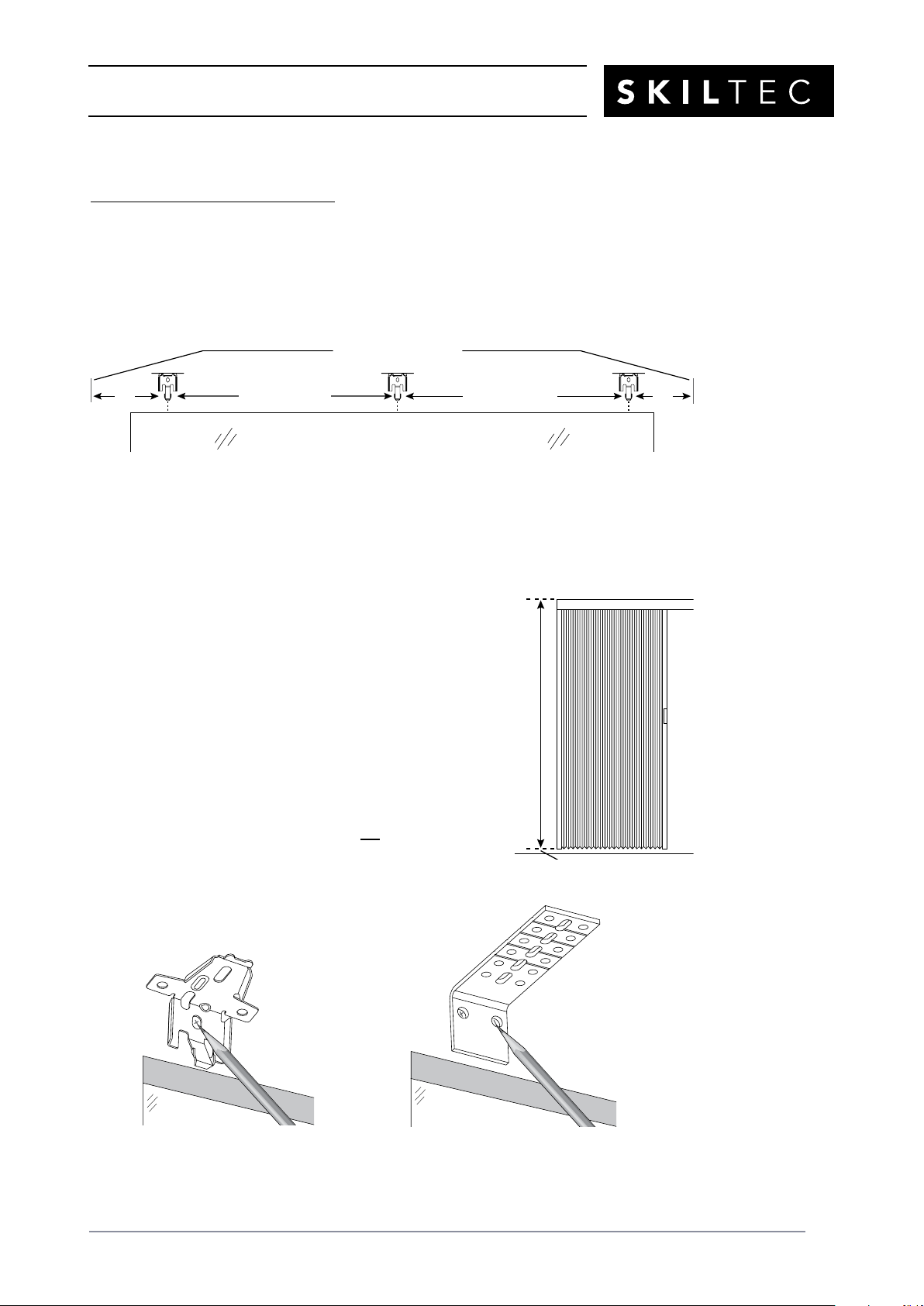

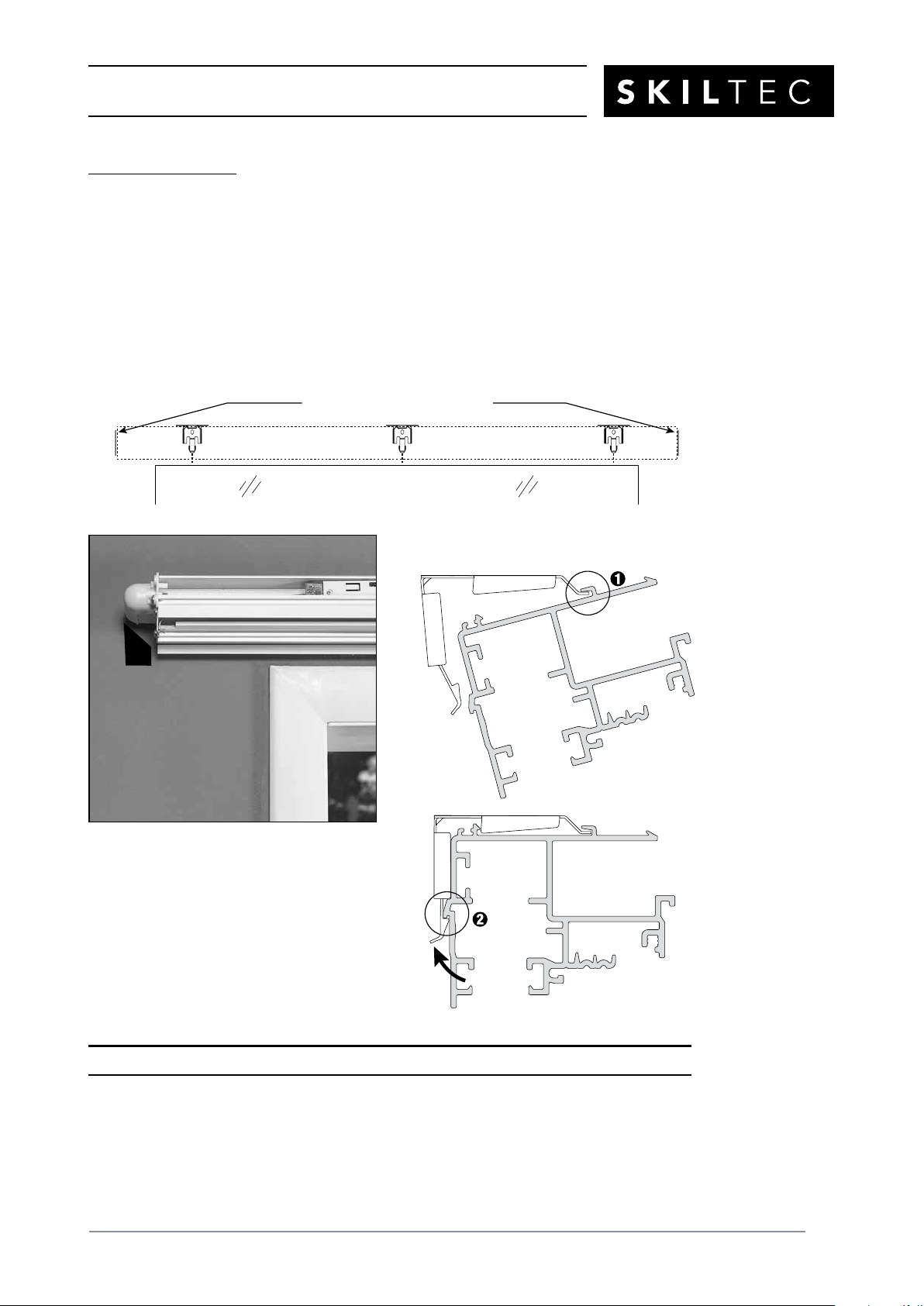

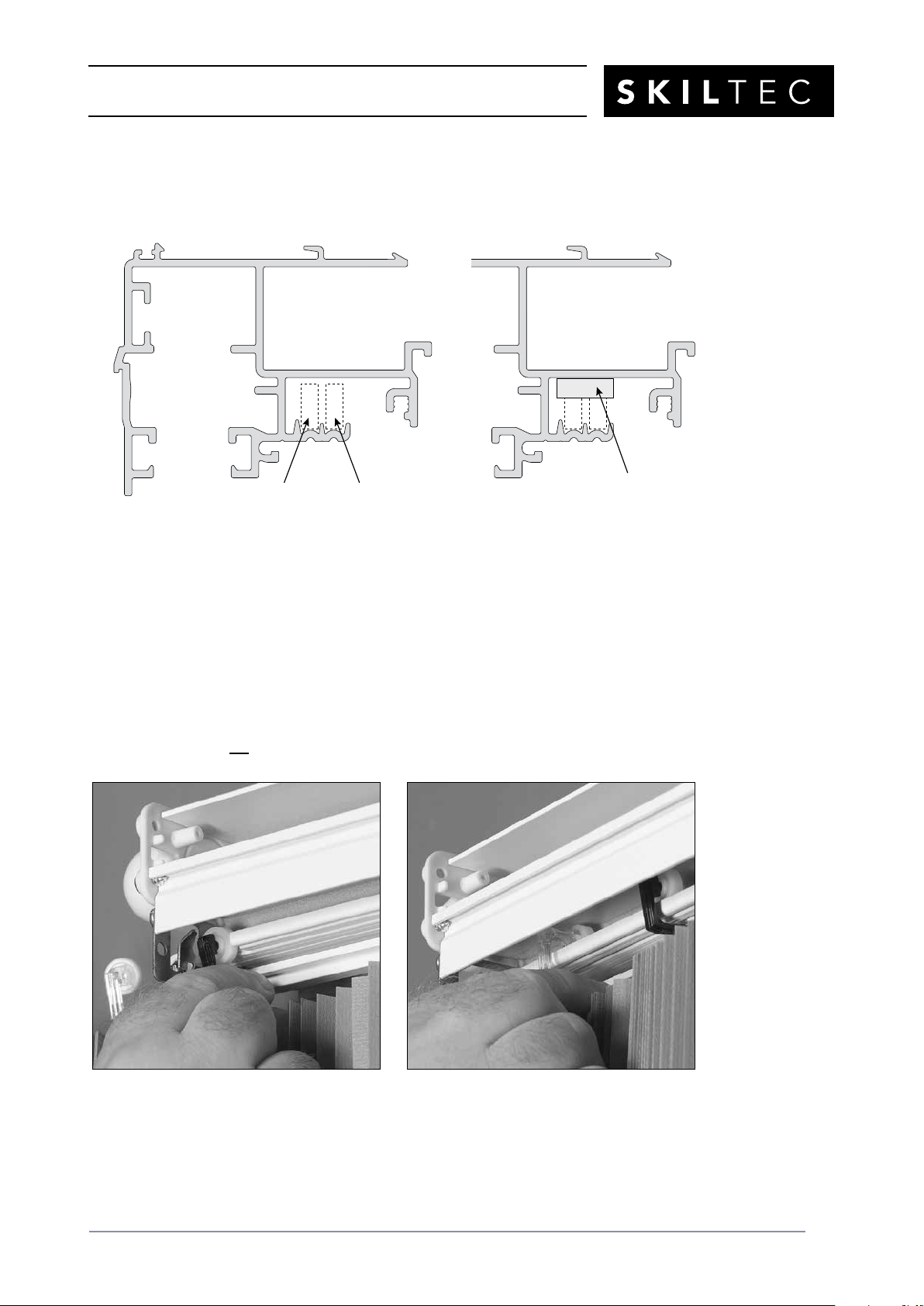

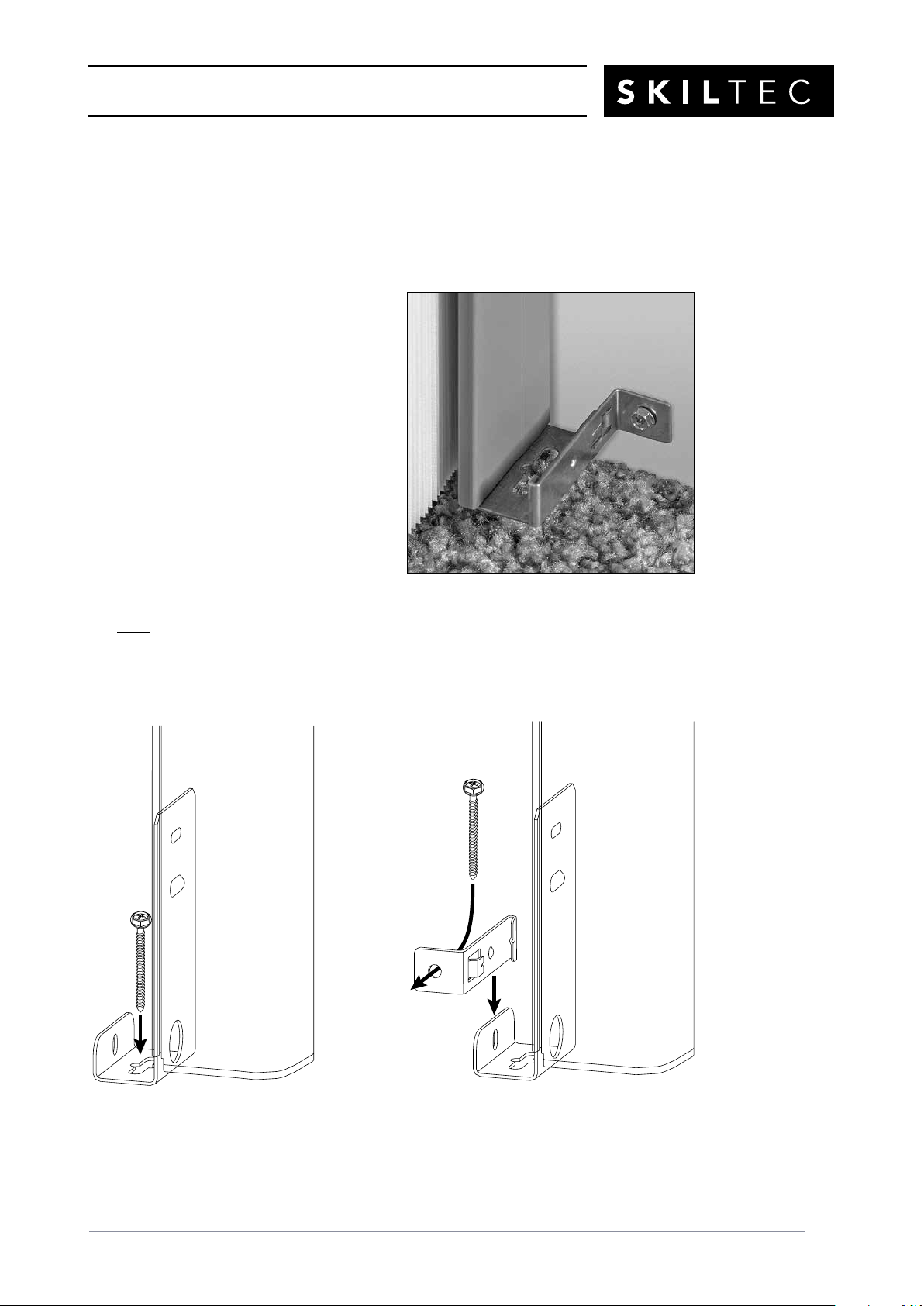

SKILTEC DUETTE VERTIGLIDE SIDE STACK DESIGNPOWERVIEW MOTORISATION... Dimensional drawing

Table of contents

Other SKILTEC Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Hillsdale Furniture

Hillsdale Furniture BAYBERRY 5791-822P manual

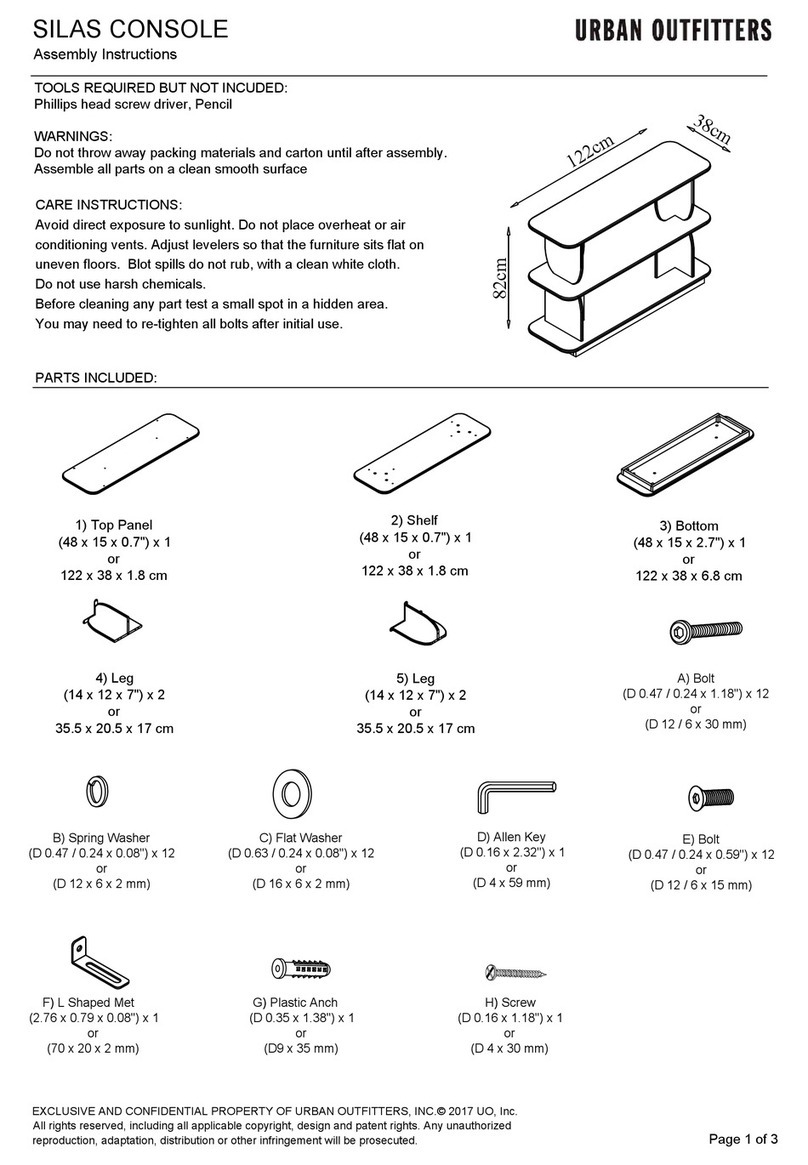

URBAN OUTFITTERS

URBAN OUTFITTERS SILAS Assembly instructions

Seville Classics

Seville Classics WEB671 Assembly instructions

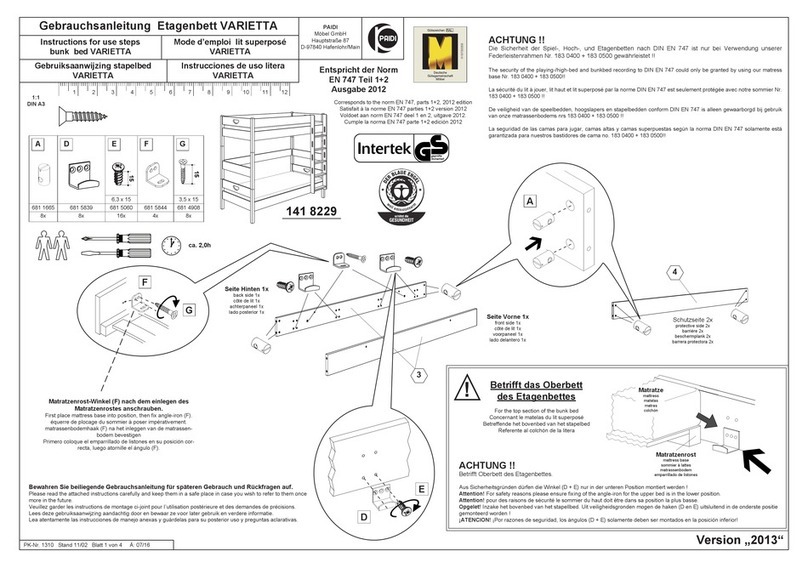

PAIDI

PAIDI VARIETTA 141 8229 Instructions for use

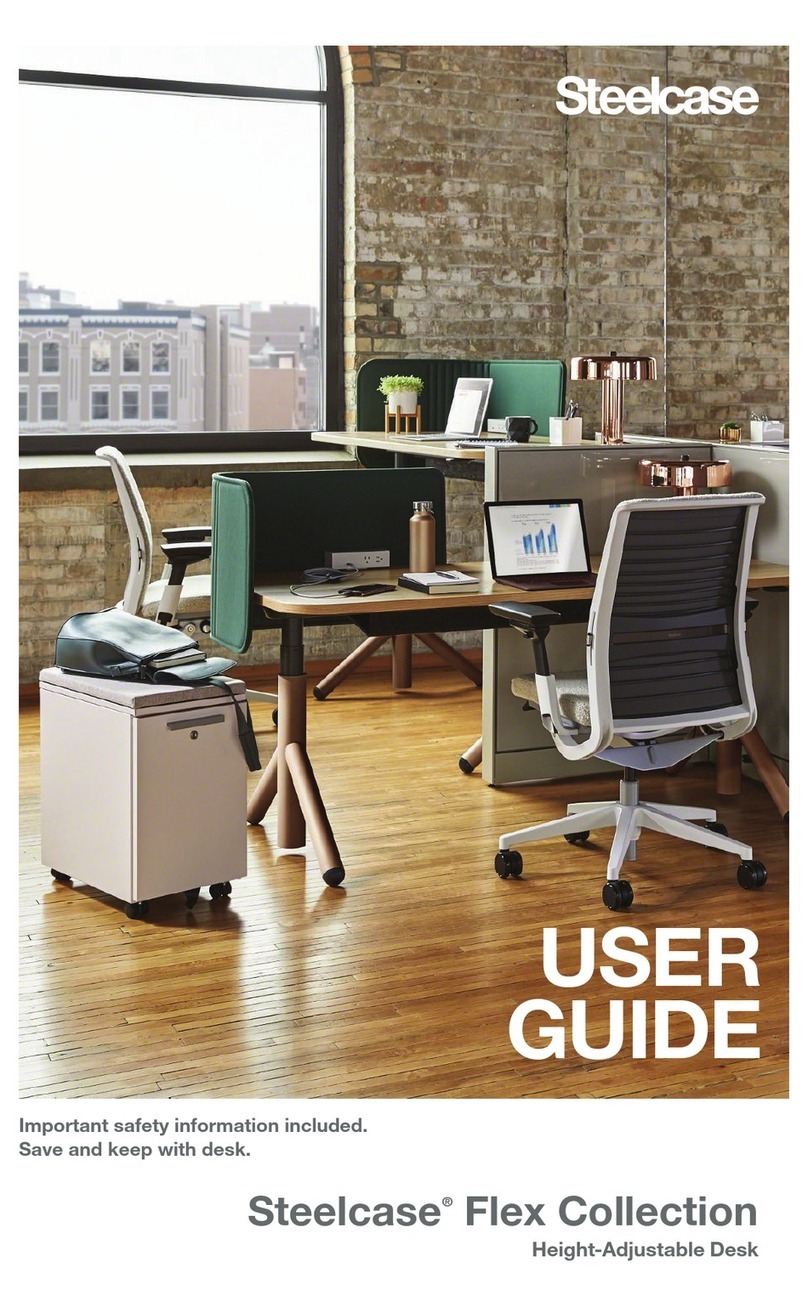

Steelcase

Steelcase Flex collection user guide

Teknik

Teknik CUBE RECEPTION CHAIR MODULAR UNIT Instruction

Furniture of America

Furniture of America Caerleon CM3474PT-3PK Assembly instructions

nbf

nbf Signature Series 67-MM3T1N61R5 operating instructions

Tot Mate

Tot Mate TM2313R Assembly instructions

SIT&MORE

SIT&MORE COOL 8241/2503 Assembly Instructions Instruction Manual

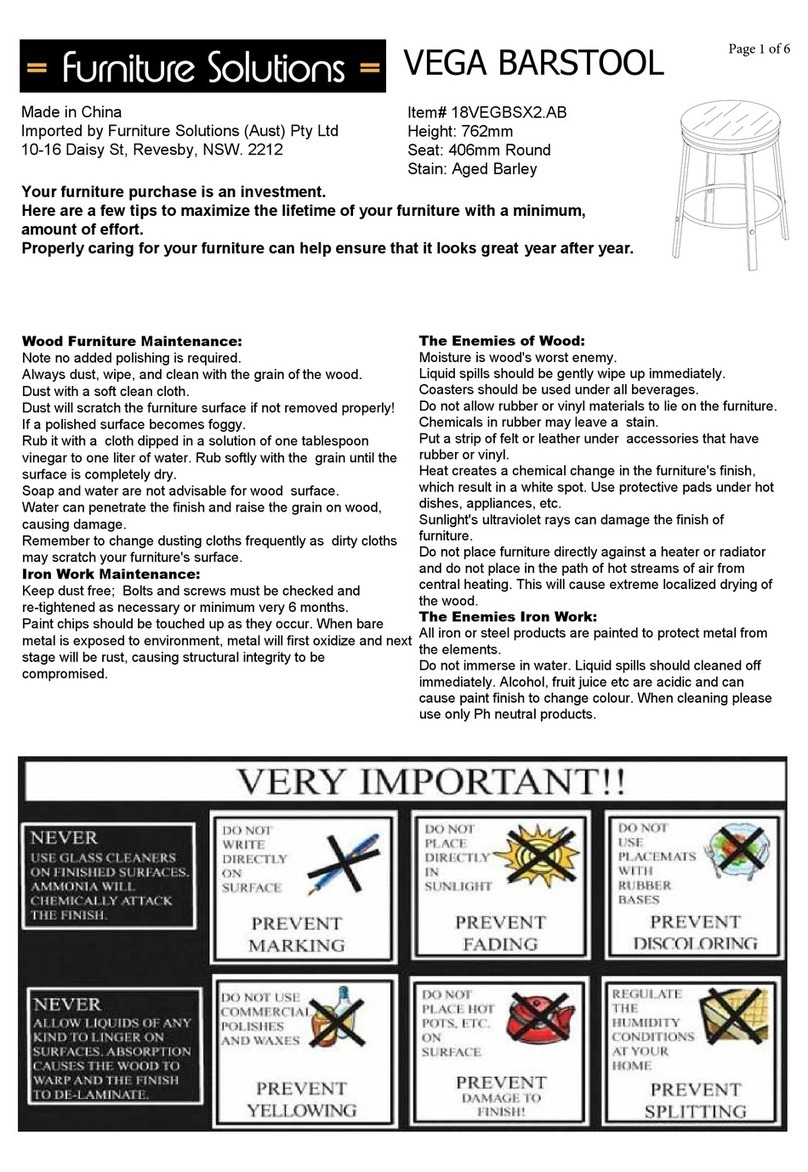

Furniture Solutions

Furniture Solutions VEGA 18VEGBSX2.AB manual

Costway

Costway HV10071 manual

VISIONARY DESIGNS

VISIONARY DESIGNS MOD-1450 Setup instructions

Royal garden

Royal garden MLOSCH201 Assembly instructions

Argos

Argos Murano 332/6138 Assembly lnstructions

Criterion

Criterion BRUNSWICK1500 Assembly & instruction manual

Hay

Hay AAT 10 instruction manual

Kangaroo

Kangaroo K9605EL Assembly instructions