SKILTEC LUXAFLEX LUMINETTE Parts list manual

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 1 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

LUMINETTE PRIVACY SHEERS

POWERVIEW MOTORISATION

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 2 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

LUMINETTE®PRIVACY SHEERS

PowerView™Motorisation

Installation •Operation •Care

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 3 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

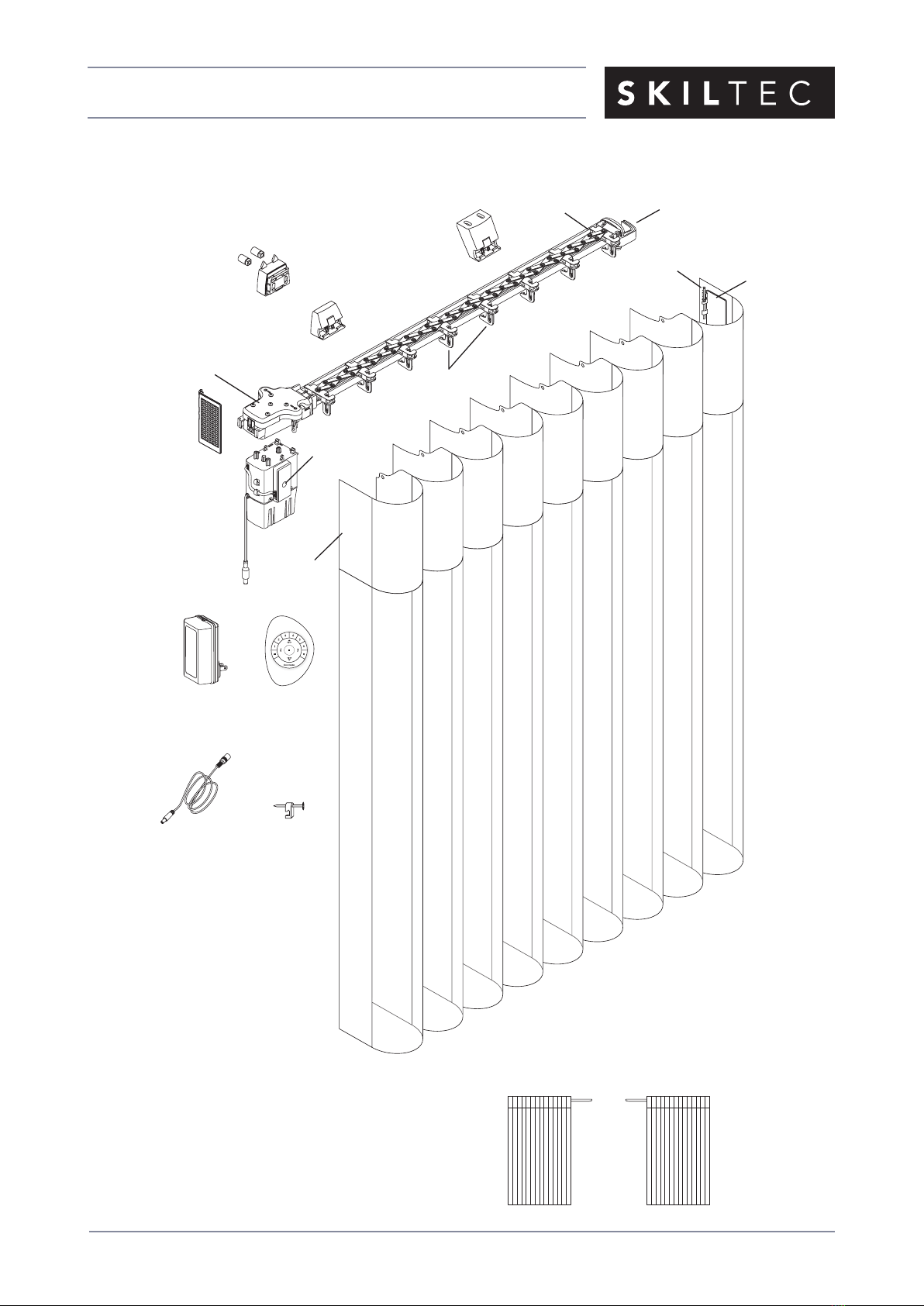

Product View

Left Stack Right Stack

SofTrak™

Headrail

Swivel

Plate

Rivet

Swivel

Arm

Left Stack Shown

Inside/Ceiling

Mount Bracket

Installation Bracket

Faceplate

DC Power

Supply

DC Power

Supply Cable

C-Clip

Modular

Motor

Assembly

Manual

Control

Button

PowerView

™

Remote

Drive Assembly

Spacer Block

with Bushings

Pinion

Clips

Swivel

Plate

End

Treatment

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 4 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

Thank you for purchasing LUXAFLEX®LUMINETTE®Privacy Sheers with PowerView™Motorisation. With

proper installation, operation, and care, your new sheers will provide years of beauty and performance.

Please thoroughly review this instruction booklet and the packing list included with your order before

beginning the installation.

Tools and Fasteners Needed

■Flat blade and Phillips screwdrivers

■Measuring tape and pencil

■Power drill, 3mm drill bit,

and 6mm hex driver

In addition, you will need fasteners designed to work with your specific mounting surface(s).

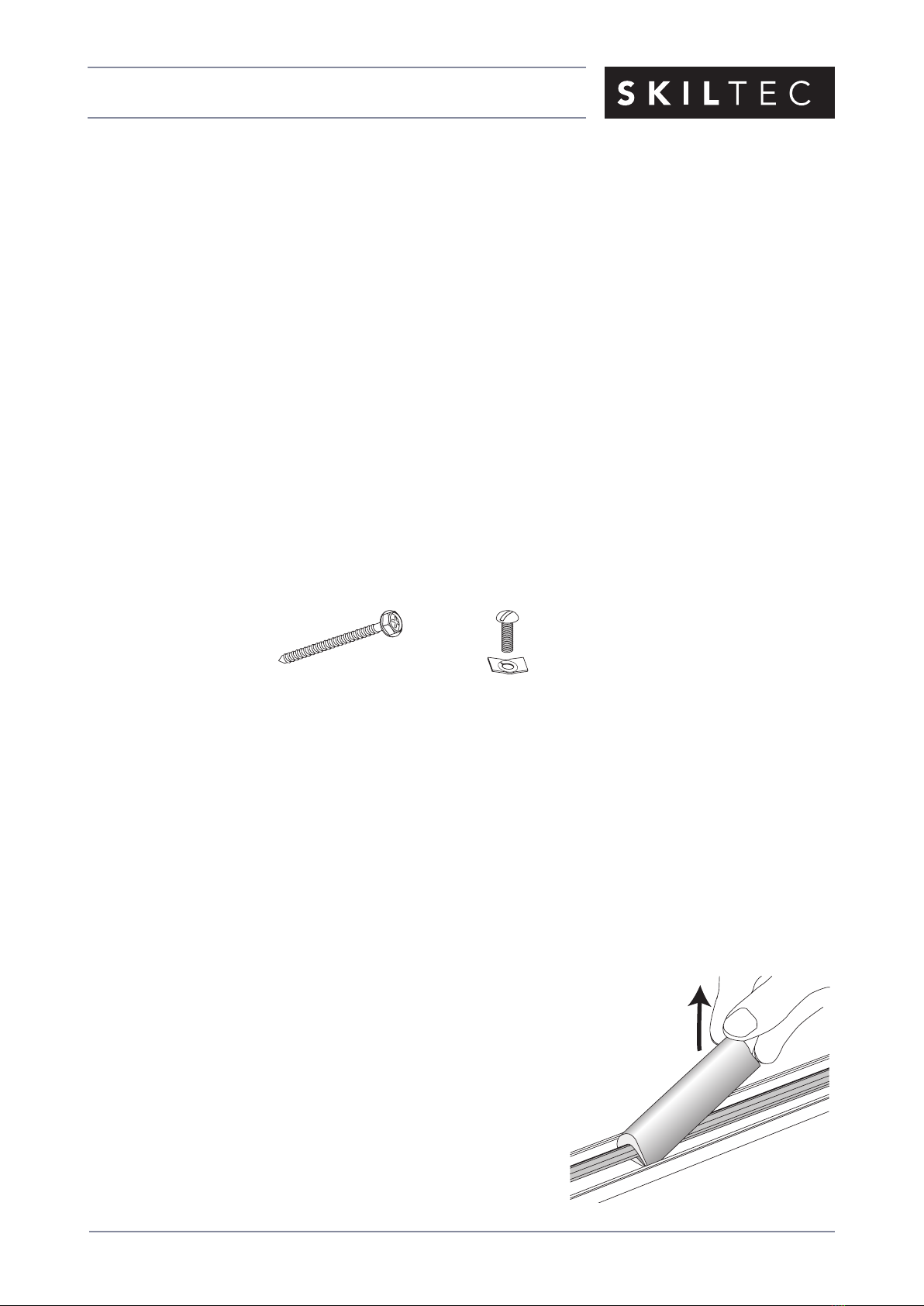

■#6 Hex Head Screws (Provided). Two 38mm screws are provided per installation bracket.

■Speed Nuts and Screws (Provided). Extension brackets come with screws and speed nuts.

■Drywall Anchors (Not Provided). Use drywall anchors when mounting into drywall.

Unpack the Components

■Make sure you have clean hands or wear disposable gloves when handling Luminette fabric. To avoid

wrinkling the fabric, do not fold it or drape it over furniture.

■One or more fabric panels may be packaged in a carton.

■The fabric panels are rolled around a cardboard tube. Do not remove the protective wrapping until

starting the “Attach the Fabric Panel(s)” step on page 16.

■Remove the SofTrak™headrail system and installation hardware from inside the carton.

■Remove the foam supports from the tilt shaft inside the

headrail. Rotate the supports in either direction until they can

be pulled off.

IMPORTANT: With wider fabrics, the SofTrak headrail may

be shipped separately.

Remove

Foam Supports

■Level (laser level is recommended)

■Needlenose pliers

■Utility knife and scissors

Speed Nut

and Screw

(Two Provided with

Each Extension Bracket)

#6 x 38mm

Hex Head Screw

(Provided)

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 5 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

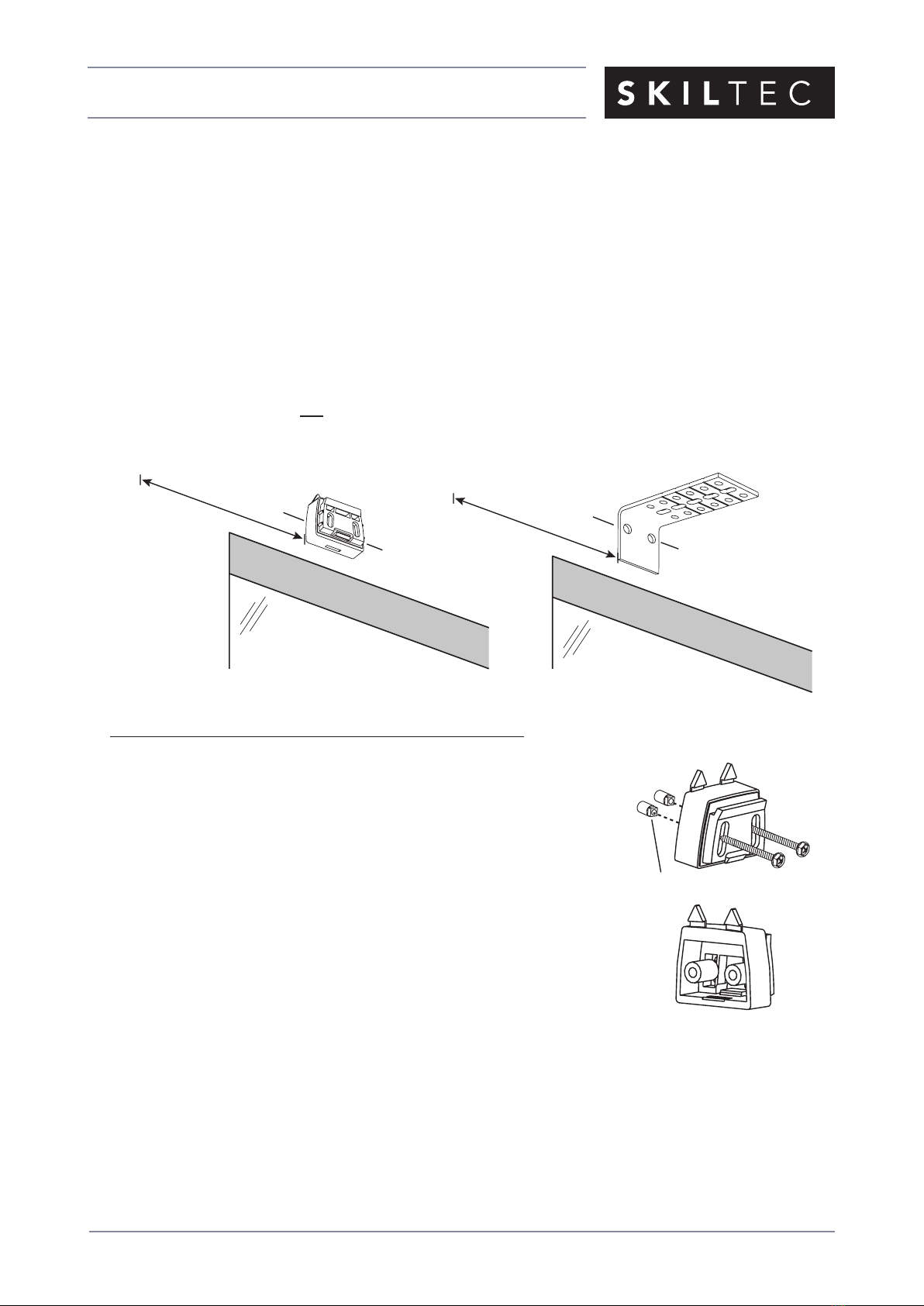

Mounting Types and Window Terminology

If the installation brackets are mounted correctly, the rest of the installation process follows easily. To

prepare for this important first step, review the mounting types and basic window terminology illustrated

below.

■For proper operation, the fabric must clear all obstructions, including window cranks, handles, and

moldings.

➤Replace protruding window cranks with T-cranks, as needed.

■Refer to the appropriate page below based on your order:

➤Reveal/Ceiling Fit — Page 4

➤Face Fit — Page 7

Collectively, the sill and

jambs are called the

“window casement.”

Molding (or Wall)

Head Jamb

Sill (or Floor)

Jamb Jamb

Reveal Fit

Sheer fits

within window

or door opening.

Face Fit

Sheer mounts

outside window

or door opening.

Recommended

Installation

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 6 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

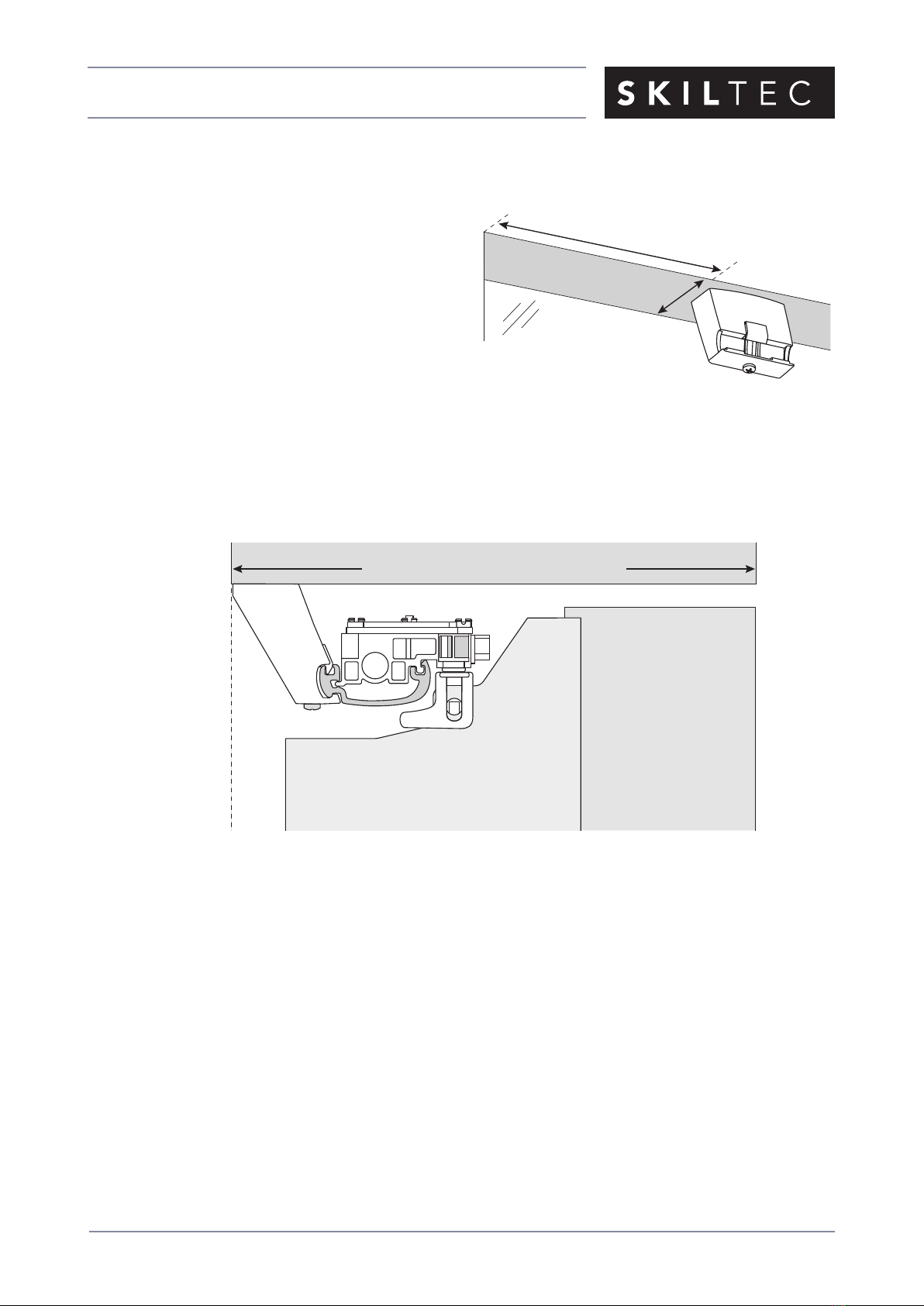

Mount the Installation Brackets — Reveal/Ceiling Fit

If you are mounting on corner or bay windows, refer to “Bracket Locations — Corner and Bay Windows” on

page 11 for specific bracket locations. Return to this page after identifying

the bracket locations.

■Your order will include the appropriate number of inside/ceiling mount installation brackets. The number

of installation brackets required varies with headrail width, as shown below.

Measure and Mark Bracket Locations

■Mark 130mm from each jamb on the mounting surface.

➤If more than two installation brackets are required (see table above), mark the locations of additional

bracket(s) spaced evenly between the two end brackets.

CAUTION: Installation brackets should be fastened into wood whenever possible. Use drywall anchors

when mounting into drywall. When attaching brackets into drywall, additional brackets may be required to

keep the headrail level after the fabric is attached.

Inside/Ceiling Mount

Installation Bracket

Headrail

Width (mm)

Brackets Required

Up to 1016 2

1017 - 1778 3

1779 - 2438 4

2439 - 3937 6

3938 - 4875 8

Top View

Bracket

Jamb

Jamb

SofTrak™Headrail

Space EvenlySpace Evenly

130mm

16mm Gap Required

Motor

130mm

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 7 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

■Mark where to drill holes for the screws.

IMPORTANT: The front edges of the brackets must align to each other.

➤Align the outside edge of the end brackets

on your marks, then mark each of the screw

holes. Center additional brackets on the marks

to mark their screw holes.

➤The minimum mounting depth required is

25mm.

➤To fully recess the fabric in the window

casement, the mounting depth required

is 160mm. See the illustration below.

Bracket Headrail

Stacked

Fabric

Vane

160mm Minimum Fully Recessed Depth

Reveal Fit

Fully Recessed Mounting Depth

Window

Side

25mm Minimum

130mm

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 8 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

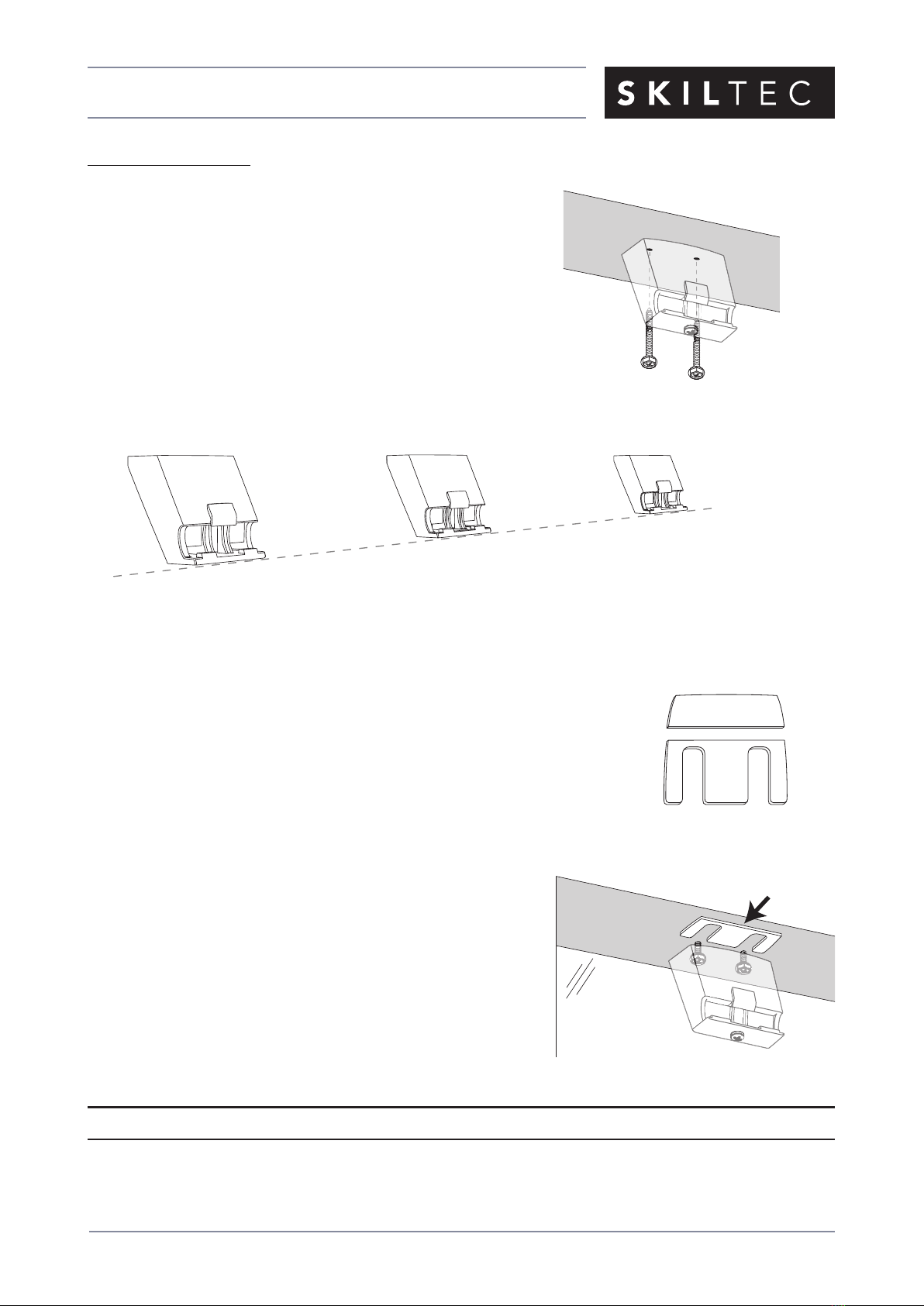

Mount the Brackets

■Drill the screw holes using a 3mm drill bit.

CAUTION: Use drywall anchors when mounting into

drywall.

■Attach the installation brackets using the screws provided.

IMPORTANT: For proper operation, the headrail must be mounted

level. Use a laser level to check that the installation brackets are

level and aligned. Shim the brackets if necessary. The brackets

may also need to be shimmed if the mounting surface is heavily

textured.

To Shim the Brackets:

■Snap off the top of the shim for use with inside/ceiling mount brackets.

■Use the shims, as needed, between the mounting

surface and the reveal/ceiling fit brackets.

Use a laser level as reference.

■To make further adjustments, you may add or remove shims by loosening

the installation bracket screws.

Proceed to “Install the SofTrak™Headrail” on page 23.

Level and

Aligned

Snap Off

Shim

Loosen

screws

to add or

remove shims.

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 9 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

Mount the Installation Brackets — Face Fit

If you are mounting on corner or bay windows, refer to “Bracket Locations — Corner and Bay Windows” on

page 11 for specific bracket locations. Return to this page after identifying the bracket locations.

■Your order will include the appropriate number of installation bracket assemblies. The number of

assemblies required varies with headrail width, as shown below.

IMPORTANT: The spacer blocks have tabs that prevent the

brackets from being mounted too close to the ceiling. If the sheer

will not be mounted at ceiling level, the tabs can be removed.

Adding Clearance

■Use spacer blocks to add additional clearance. Spacer blocks add clearance in 13mm increments.

➤One spacer block is used with the faceplate for standard installation. Three additional spacer blocks

may be added for an extra 38mm clearance.

■Use optional extension brackets to add more clearance.

➤Extension brackets can provide up to 90mm clearance.

➤Indentations are stamped into the extension brackets between each set of holes. Using the

indentations as a guide, you may cut off any unneeded length before mounting the extension

brackets. Each two-hole section is 13mm length.

Headrail

Width (mm)

Bracket Assemblies

Required

Up to 1016 2

1017 - 1778 3

1779 - 2438 4

2439 - 3937 6

3938 - 4875 8

Removable

Tabs

Faceplate

Spacer

Block

Bushings

Outside Mount

Bracket Assembly

Extension

Bracket

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 10 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

Measure and Mark Bracket Locations

■Position the SofTrak™headrail over the window or door opening at the ordered height, found on the

headrail label. Use a pencil to lightly mark each end of the headrail.

➤Alternatively, measure the width of the headrail and use that width to mark the headrail end points

over the opening.

IMPORTANT: Typically, split stack designs are centered over the opening. However, side stack designs

may be offset to one side if the fabric was intended to stack partially or completely off the window or

door opening. The intended stackback must be taken into account when marking the headrail end

points.

■Mark 130mm from each end of the headrail.

➤If more than two installation brackets are required (see table on previous page), mark the locations

of additional bracket(s) spaced evenly between the two end brackets.

CAUTION: Installation brackets should be fastened into wood whenever possible. Use drywall anchors

when mounting into drywall. When attaching brackets into drywall, additional brackets may be required to

keep the headrail level after the fabric is attached.

■Mark the bracket mounting height to allow proper floor clearance for the fabric when attached to the

headrail. This method provides a minimum of 13mm floor clearance.

➤Locate the ordered height on the headrail label.

➤Spacer Blocks: Measure the ordered height minus

6mm from the floor surface. Mark this height at each

bracket location.

➤Extension Brackets: Measure the ordered height plus

6mm from the floor surface.

Mark this height at each bracket location.

IMPORTANT: Mount the screws at the height indicated,

or higher for additional floor clearance. Be sure to clear

all floor obstructions such as carpet, vents, rugs, etc.

Floor Surface

Ordered

Height – 6mm

Ordered

Height + 6mm

Spacer

Block

Extension

Bracket

Headrail End Marks

Window Opening

Space Evenly Space Evenly

130mm 130mm

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 11 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

■Mark where to drill holes for the installation screws.

➤A minimum of 30mm flat vertical surface is required for spacer block installation and

33mm flat vertical surface is required for installation with extension brackets.

➤Align the spacer blocks or extension brackets on your height marks.

➤Align the outside edge of the end spacer blocks or extension brackets on your bracket

location marks, then mark each of the screw holes. Center any additional brackets on

the bracket location marks to mark their screw holes.

CAUTION: The rear of the spacer blocks or extension brackets must be flush against a flat

mounting surface. Do not mount blocks/brackets oncurved molding.

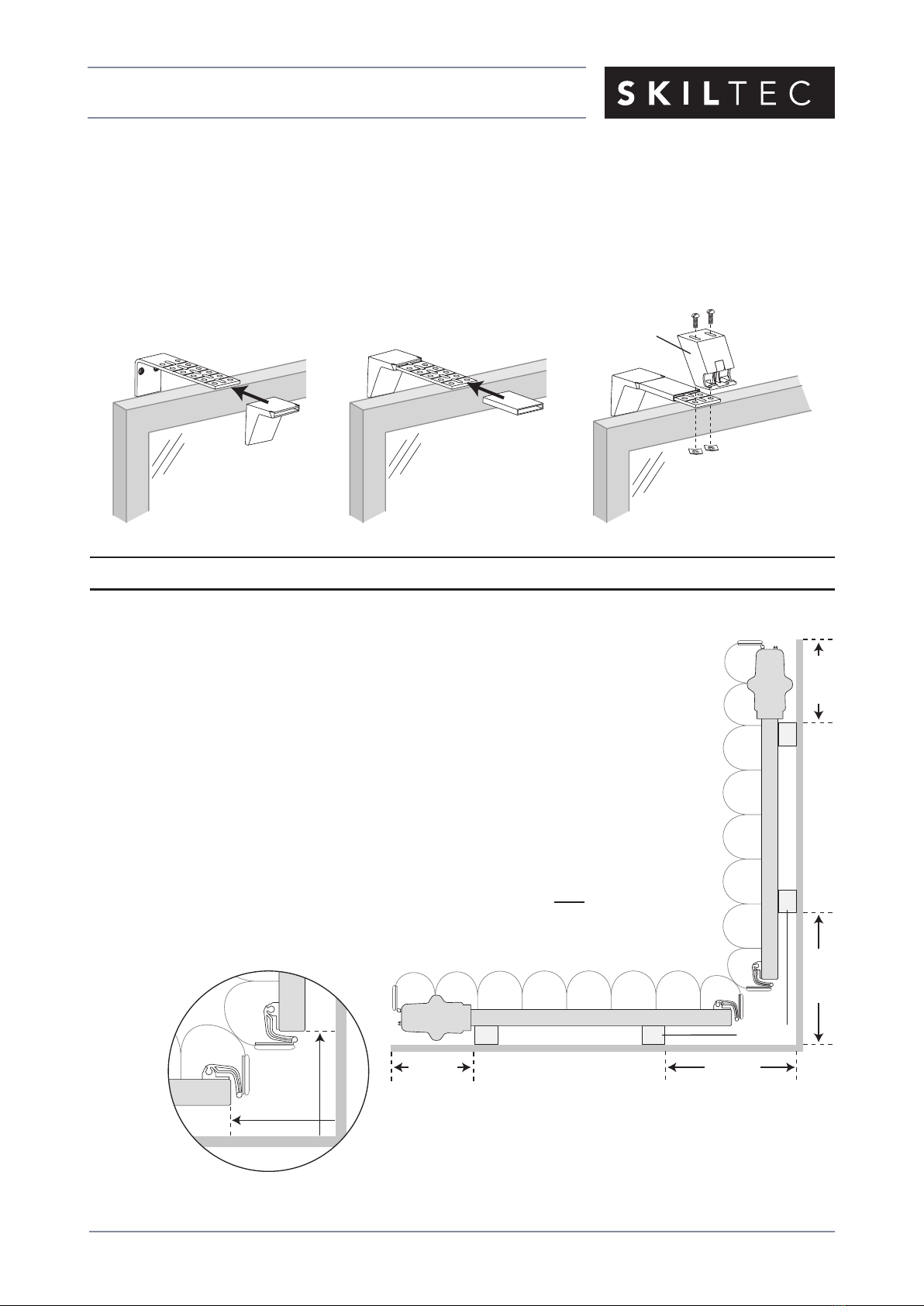

Mount the Spacer Blocks or Extension Brackets

■Drill the screw holes using a 3mm drill bit.

CAUTION: Use drywall anchors when mounting into drywall.

■Attach the spacer blocks or extension brackets using the screws

provided.

➤For the spacer block installation, first insert the square end

of the bushings into the slots in the spacer block. Insert the

screws through bushings.

IMPORTANT: With spacer blocks, place the screws in the

middle of the slots to make aligning the brackets easier.

Bushings

Bushings Inserted

130mm

Headrail

End Mark

Headrail

End Mark

Screw

Height

Mark

Screw

Height

Mark

130mm

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 12 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

➤For extension bracket installation, you may cut off any unneeded length (before mounting) at

indentations stamped into the brackets between each set of holes. Each two-hole section is 13mm

in length.

IMPORTANT: For proper operation, the SofTrak™headrail must be mounted level. Use a laser level

to check that the spacer blocks or extension brackets are level and aligned. Shim the brackets if

necessary. The brackets may also need to be shimmed if the mounting surface is heavily textured.

To Shim the Brackets:

➤Loosen the installation screws securing the spacer

block or extension bracket.

➤Insert one or more shims between the spacer block or

extension bracket and

the mounting surface. Tighten the installation screws.

Finish Bracket Assembly

Spacer Blocks

■Add any additional spacer blocks required.

IMPORTANT: A maximum of four spacer blocks can be used.

■Hook the top of the faceplate to the front spacer block and snap

it into place.

Level and Aligned

Level and Aligned

Loosen

Mounting

Screws

Insert

Shim(s)

1

2

1

2

To Shim

Installation Bracket

To Shim

Extension Bracket

Faceplate

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 13 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

200mm

Brackets

130mm

200mm 130mm

Motor

Motor

75mm

Extension

Bracket

Cover

Extension

Bracket

Extension Bracket

Base Cover

Screws

Speed Nuts

Inside/Ceiling

Mount Bracket

Extension Brackets

■Slide the base covers onto each extension bracket.

■If necessary, use scissors to trim the flat bracket cover to length. Slide a cover onto

each bracket.

■Attach inside/ceiling mount installation brackets using the screws and speed nuts provided.

Proceed to “Install the SofTrak™Headrail” on page 23.

Bracket Locations — Corner and Bay Windows

■For bracket placement, mount the spacer blocks or inside/ceiling mount

brackets 200mm from the corner.

IMPORTANT: The ends of the headrails should be located 75mm from the

corner.

➤If additional spacer blocks or extension brackets are used,

the installation brackets must be further moved away from the corner by

the amount of added clearance.

■For bay windows, treat the center sheer as a corner system on both ends of

the headrail.

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 14 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

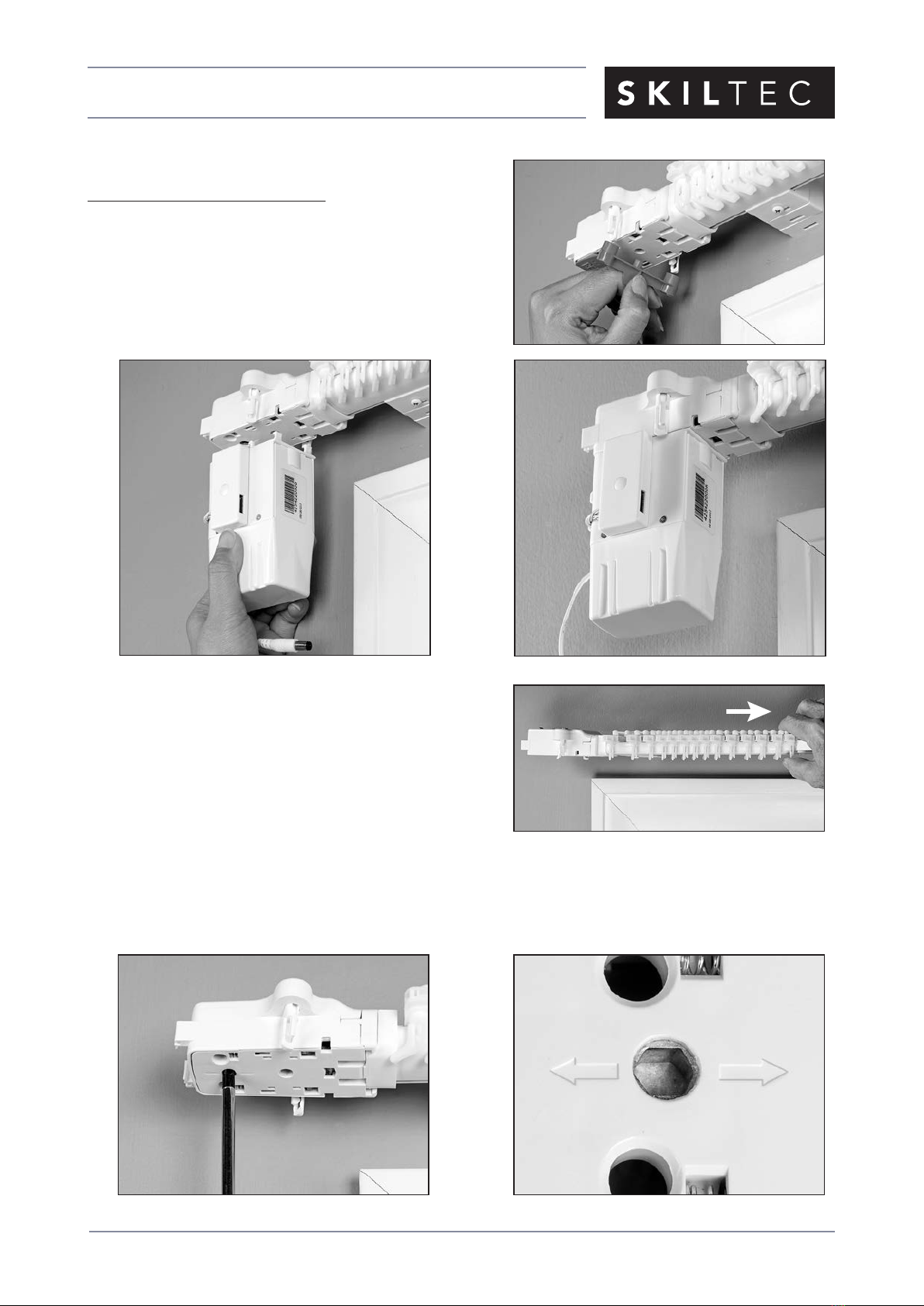

Install the SofTrak™Headrail

■Push up on the locking screws. This raises the locking tab and

makes the headrail easier to install.

■The grooves on the back of the headrail are designed to snap

into the locking tab on the faceplate and inside/ceiling mount

bracket.

➤Tilt the front of the headrail (the side with the pinion clips) up

so the top groove fits into the locking tab on each installation

bracket.

■With the top groove in place on all brackets, tilt

the headrail down so the bottom groove fits into

the bottom tabs on the installation brackets.

■Position/center the headrail and tighten the locking screws until

snug. Do not overtighten.

Reveal Fit and Wall-To-Wall Face Fit Installations

■After the SofTrak headrail is installed into the installation brackets, check the clearance at eachend and

make any necessary adjustments.

IMPORTANT: The recommended amount of clearance varies according to the control end and stack

design, as shown below.

Tilt Down

Pinion

Clip

Tighten

Tilt Up

Locking

Tab

SofTrak™

Headrail

Locking

Screw

Right Stack Design — Minimum Clearances

22mm

Non-Motor End

3mm

Left Stack Design — Minimum Clearances3mm

Non-Motor End

22mm

Motor End

Motor End

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 15 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

Side-by-Side (Abutted) Installations (Simulated Split Stack)

A simulated split stack (the fabric opens in the center)

is two side stack systems installed with the non-control

ends side-by-side.

■Adjust the SofTrak™headrails according to the

illustration for proper swivel arm operation.

IMPORTANT: Be sure to measure the spacing from

end cap to end cap, not from the swivel arms.

Non-Control

End Cap

Non-Control

End Cap

38mm

Swivel

Plates

Swivel

Arm

Swivel

Arm

RTW

Swivel

Plates

RTW Not Recommended

Proper Installation

Simulated Split Stack

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 16 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

Connect PowerView™Components

Connect the Motor Assembly

■Remove the orange cover from the drive assembly, as

shown to the right.

■Align the pins with the holes in the drive assembly, as

shown below. Press the motor

up into the drive assembly until it clicks into place.

IMPORTANT: If snapping the motor onto

the drive assembly seems difficult, grasp

the lead carrier and pull the carriers slightly

away from the motor, as shown at right.

The motor should now snap in easily.

■If you remove the motor and need to reinstall it, check the drive assembly and make sure the tilt

gear aligns with the arrows.

➤If necessary, use a screwdriver to turn the tilt gear until it is aligned.

Aligned Tilt Gear

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 17 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

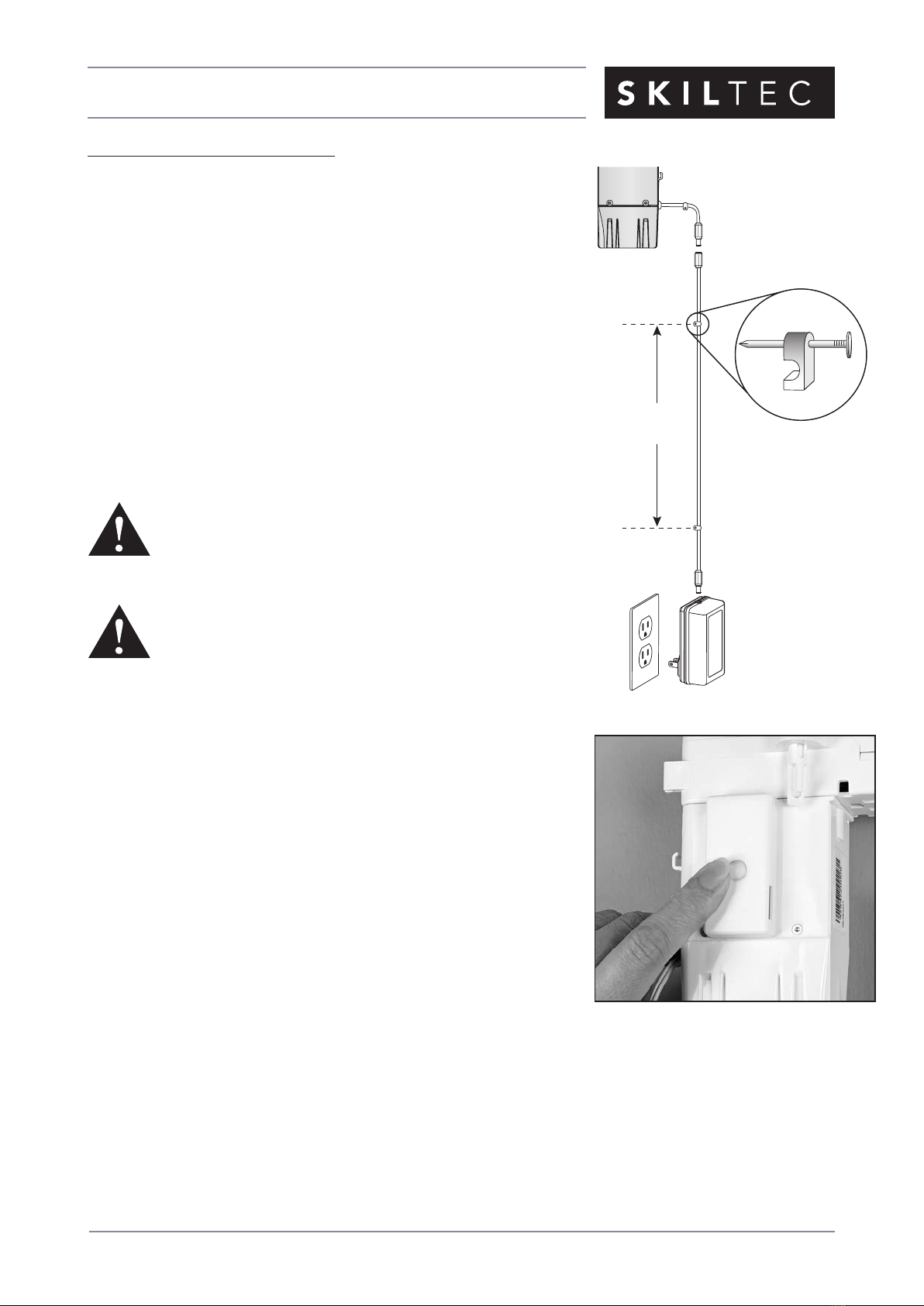

Connect the DC Power Supply

NOTE: When power is connected to the motor, a green LED inside

the manual control button housing will flash to indicate the sheer is

ready.

■Plug the power cable from the motor into the extensioncable.

■Plug the other end of the extension cable into the DC power

supply.

■Secure the extension cable using the C-clips provided. Hide the

cable behind the fabric, making sure it does not impede operation.

■Space the C-clips approximately 385mm apart along the

extension cable, as shown.

■Plug the DC power supply into the power source.

WARNING: Keep cables and small parts

out of the reach of children. They can wrap cables around

their necks and STRANGLE. They can also put small parts

in their mouths and CHOKE.

WARNING: Electric shock and/or afire hazard may occur

if not properlyinstalled.

385mm

Maximum

DC

Power

Supply

Wire Retainer

Extension Cable

Power Cable

Motor

Assembly

Test Headrail Operation

■Use the manual control button on the motor to test the operation of

the headrail, following the sequence below.

1. Press and release the button to traverse the carriers across the

full length of the headrail.

2. Press and release the button to fully rotate the pinion clips in one

direction.

3. Press and release the button to fully rotate the pinion clips in the

opposite direction.

4. Press and release the button to rotate the pinion clips to the

neutral (vanes open) position.

5. Press and release the button to traverse the carriers to the fully stacked position.

■Pressing the manual control button while the carriers are traversing or the pinion clips are

rotating will stop the action. The next button press will traverse the carriers or rotate the

pinion clips in the opposite direction.

Manual

Control

Button

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 18 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

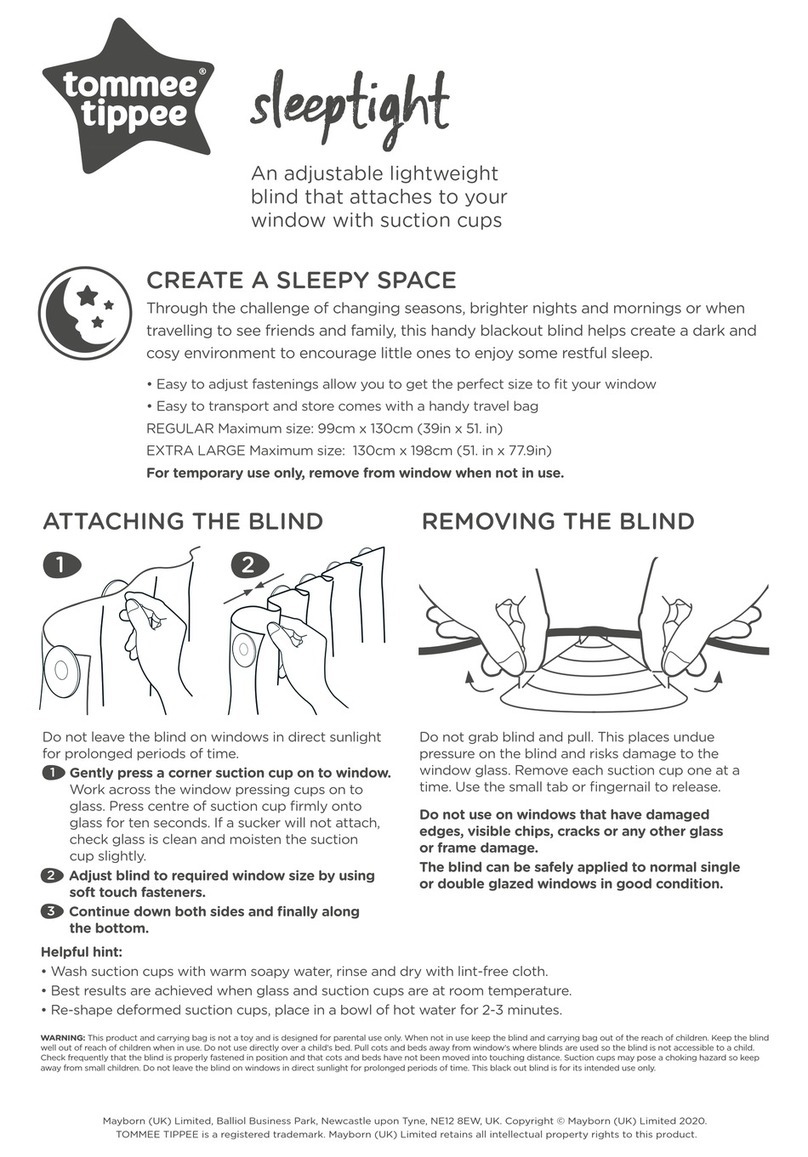

Attach the Fabric Panel(s)

Preparations

■If necessary, use the manual control button to traverse the fabric carriers to the fully stacked

position.

■Stand the tube on end on a clean surface with the valance at the top. Position the tube at the

end of the headrail where the fabric stacks.

■If the tube is too long to stand on end, carefully and safely use a utility knife to trim the tube

to an appropriate length. Do not unroll the fabric until you begin attaching the vanes to the

pinion clips.

CAUTION: Be very careful when trimming the tube to avoid damaging the fabric in any way.

■Remove the protective wrapping from the fabric.

Attach the Vanes to the Pinion Clips

■Unroll the fabric to gain enough slack to attach the first vane to the

pinion clip on the motor drive assembly.

■To attach vanes, insert the vane attachment hole into the clip until it

snaps securely in place.

➤Pull down gently on each vane to ensure that it is seated

properly.

■Unroll the fabric as you clip the rest of the vanes into the pinion

clips in sequence.

Be careful not to skip any pinion clips

orvanes.

Pinion

Clip

Installed

Vane

Tube

Fabric

Panel

STD R

Vane Attachment

Swivel

Plate

Swivel

Plate

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 19 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

Attach Swivel Plates

■The end treatments on both ends of the sheer attached with

swivel plates.

➤Swivel plates are right- and left-specific, marked by an R

or an L. The swivel plates are packaged with the product’s

hardware.

■Snap the rivet on the swivel plate into the front clip on the

control end cap. Swivel plates attached on the left will have STD

Lstamped on the top. Swivel plates attached on the right will

have STD R on the top.

■Snap the rivet on the other swivel plate onto the swivel arm (side stack) or into the front clip on the

non-control end cap (split stack). Swivel plates attached on the right will have STD R stamped on the

top. Swivel plates attached on the left will have STD L on the top.

STD RSTD L

Swivel Plate

Side Stack

Swivel Arm

Rivet

Swivel Plate

Split Stack

Rivet

Front Clip

Non-Control

End Cap

STD R

STD R

Rivet

STD L

ISSUE DATE: FEBRUARY 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: FEB 2018 APPROVED BY: S. GONZALEZ PAGE 20 OF 29

PRODUCT INFORMATION MANUAL

SECTION: 12B LUMINETTE PRIVACY SHEERS POWERVIEW MOTORISATION

Attach the End Treatment(s) to the Swivel Plate(s)

■Hold the end treatment near the swivel plate at a height where

the end vanes hang straight and the top of the end treatment is

approximately 3mm above the top of the swivel plate.

■Attach the end treatment by pressing it onto the

swivel plate.

■If the end treatment is not hanging straight, separate the swivel

plate from the end treatment and reposition it. Separate the swivel

plate by pulling up on the end treatment while holding the swivel

plate in place.

■Re-attach the end treatment. Repeat the adjustment as necessary.

Swivel

Plate

Table of contents

Other SKILTEC Window Blind manuals

Popular Window Blind manuals by other brands

Griesser

Griesser Alucolor 25 operating instructions

Graywind

Graywind 58433 instruction manual

rollease acmeda

rollease acmeda KUMO Assembly manual

Hella

Hella TOP MINI plus screen protect Operating guidelines

Guthrie Douglas

Guthrie Douglas TESS 140 instruction manual

Tommee Tippee

Tommee Tippee sleeptight quick start guide