Before starting installation of the external blind, please read the following instructions.

During transportation and storage, the blind should lie horizontally in a place protected from damage

to the entire structure. The blind should not be placed on the side wall.

Any modifications or changes to the design of the external blind can only be made after consultation

with the manufacturer.Blinds should be mounted on an even surface.

Installation of external blinds should be conducted by persons competent in the area of compliance with health

and safety rules and applicable building regulations. In the case of external blinds operated

with an electric drive, the installation can only be carried out by a person with appropriate permissions

(SEP rights up to 1 kV).

Directly before installation, unpack the blind and check if there are all elements necessary

for its installation.

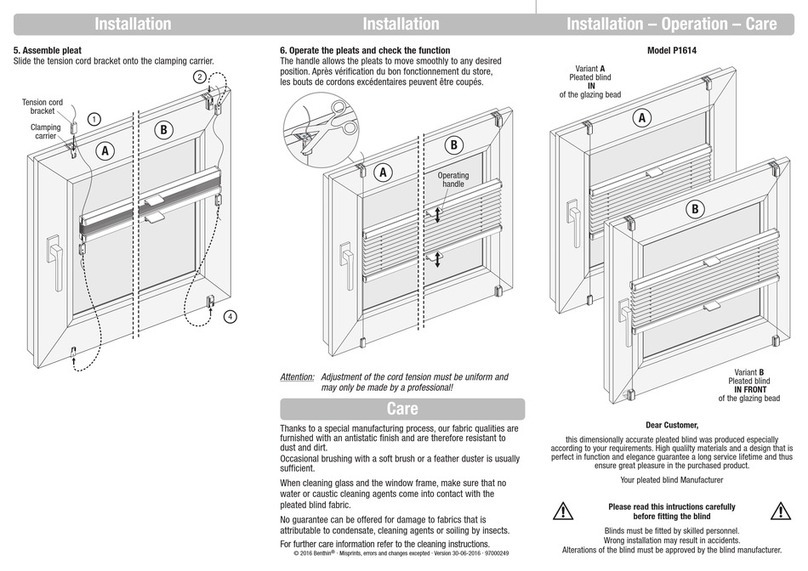

ZF3000 EXTERNAL BLIND INSTALLATION

1. Tools needed to install the external blind. The PORTOS company does not provide screws, dowels, cables for placing

the electrical installation.

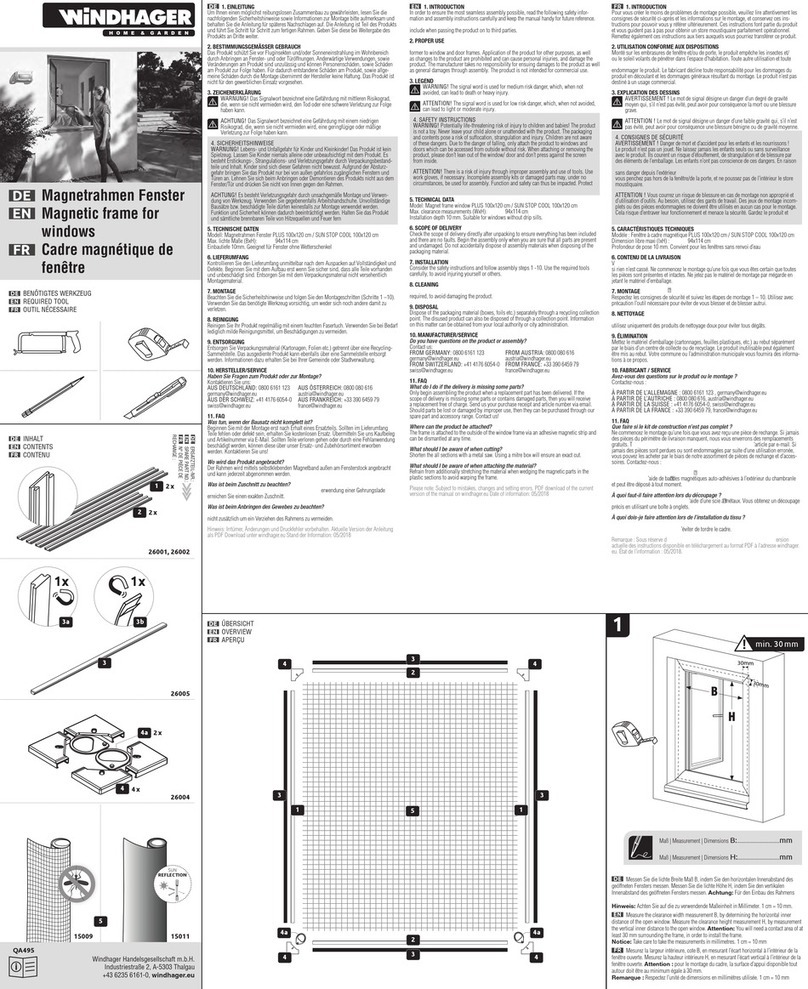

2. In the case of dimensioning, the dimension smallest from the measurements taken is the right dimension.

Dimensioning - ZF3000 external blind,

aluminium guides, installation in the window

Dimensioning - ZF3000 external blind

aluminium guides,

installation on the facade/flush-mounted

Sz = So

Wz = Wo

EXPLANATIONS TO DIMENSIONING:

Sz - blind width, So - hole width

Wz - blind height, Wo - hole height

Sz = So, Wz = Wo

So

Wo

Wz

Wp

PP

EXPLANATIONS TO DIMENSIONING:

Sz - blind width (slat width), So - hole width

Wz - blind height, Wo - hole height, Wp - package height

P - guide width (20mm), Wbo - height of the safety plate

Wz = Wo + Wp* or Wbo

INSTALLATION ON THE FACADE: Sz = So + 2 x P

FLUSH-MOUNTED: Sz = window width**

fi 8 fi 12

INSTALLATION WITH GUIDES

3

* - When adding the package height and subsequent adding a higher safety plate - the plate may enter the frame opening/hole.

** - It is recommended to take into account the installation clearance for free processing of wood elements.