SKILTEC MICRO User manual

ALUMINIUM VENITIAN BLINDS

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 2 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

PRODUCT INFORMATION MANUAL

SECTION: 1 ALUMINIUM VENETIAN BLINDS

ISSUE DATE: APRIL 2015 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JANUARY 2013 APPROVED BY: M.SOMI PAGE 1 OF 13

Options & Limitations

Venetians - Micro, Slimline & 50mm Classic

16mm

MICRO

25mm

SLIMLINE/

MAGNAVIEW

25mm

TWI-NIGHTER

50mm

CLASSIC

MAXIMUM WIDTH 3100mm 3700mm 3700mm 4000mm

MINIMUM WIDTH

(See price book for

operation details)

110mm 110mm 110mm 160mm

MAXIMUM DROP 3700mm 3700mm 3700mm 3500mm

MAXIMUM AREA 7m² 9m² 9m² 12m²

MAXIMUM TAPE

SPACING 400mm 600mm 600mm 900mm

MAXIMUM END ROUT

DISTANCE 114mm 152mm 152mm 152mm

TAPE PITCH 12mm 20mm 18mm 41mm

SLAT OVERLAP 4mm 5mm 50mm 9mm

MINIMUM RECESS

DEPTH 20mm 20mm N/A

20mm

(must side fix

or back fix)

FULLY RECESSED

BOX MOUNT 50mm 50mm N/A 90mm

SHADE STACK

HEIGHT .042 x drop + 45mm .034 x drop + 45mm .036 x drop + 45mm .05 x drop + 80mm

NUMBER OF SLATS DROP - 45

12

DROP - 45

12

DROP - 45

18

DROP - 70

41

STANDARD WAND

SIZES

500mm / 750mm / 1000mm / 1500mm

Cord Control

500mm/750mm

1000mm/1500mm Worm & Gear

SLAT THICKNESS .195mm (unpainted)

.215mm (coated)

.195mm (unpainted)

.215mm (coated) .175mm (unpainted) .215mm (coated)

HEAD CHANNEL 25mm Wide

25mm High

25mm Wide

25mm High

25mm Wide

25mm High

57mm Wide

51mm High

Available with the

DUO-FLEX®option Yes Yes Yes Yes

SLAT = High Tensile # 6011 Aluminium Alloy.

PAINT = Thermosetting Polymer Coating over a Chromated Primer. Comforming to AS2728.

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 3 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

PRODUCT INFORMATION MANUAL

SECTION: 1 ALUMINIUM VENETIAN BLINDS

ISSUE DATE: APRIL 2015 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JANUARY 2013 APPROVED BY: M.SOMI PAGE 2 OF 13

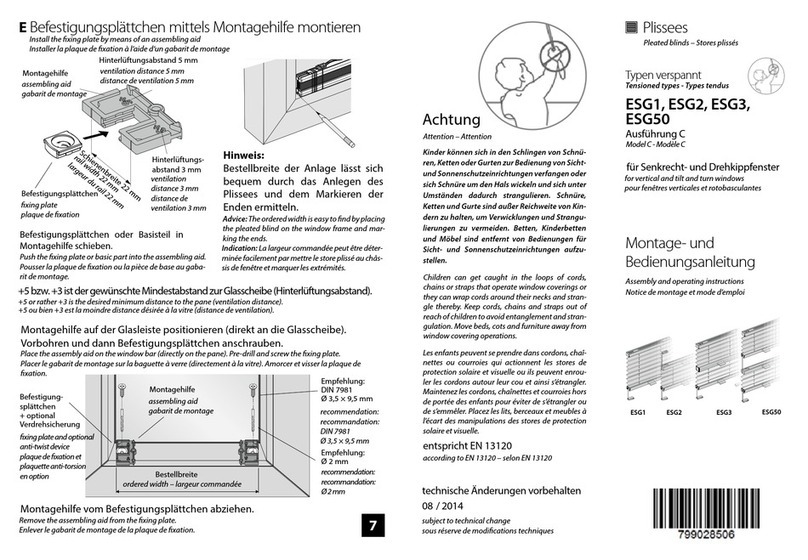

Aluminium Venetians Special Shapes

16mm and 25mm SLAT ONLY. NO SPECIAL SHAPES ONLY CUT OUTS AVAILABLE ON LIMITED

EDITION OR 50mm Venetian Blinds..

Note: Cord control side must be on shortest side of blind, as indicated by an ‘X’. Unless otherwise

indicated, blinds will tilt and raise. Blinds will only raise as far as the shortest side.

Shape

w

D

A

A

W

D

X

A

W

D

A

W

D

A

CIRCLE

SMALL CUT OUT

SLOPING BOTTOM SLOPING HEAD SLOPING HEAD & BOTTOM HALF SLOPING BOTTOM

(Tilt Operation Only)

AIR CONDITIONING

CUT OUT

CENTRE CUT OUT HEADRAIL CUT BACK

TRIANGLES ARCH

HEADRAIL SHORTER

THAN BOTTOM RAIL

A > 180mm (25mm slat)

A > 150mm (16mm slat)

A < 149mm (25mm slat)

A < 114mm (16mm slat)

A > 150mm (25mm slat)

A > 115mm (16mm slat)

A must be > 90mm

Tilt Only

A < 180mm (25mm slat)

A < 150mm (16mm slat)

Blind Price (W x D) +

Sloping surcharge

Blind Price (W x D) +

Sloping surcharge

Blind Price (W x D) +

Sloping surcharge

Blind Price (W x D) +

Sloping surcharge

Blind Price (W x D) + small

Cut Out surcharge

Blind Price (W x D) +

air conditioning surcharge

Blind Price (W x D) +

air conditioning surcharge

Blind Price (W x D) + small

Cut Out surcharge

X

Up to 45º

D

WUp to 45º

D

W

X

Up to 45º

Up to 45º

D

X

Up to 45º

W

D

X

Limitations

How to Price

Shape

How to Price

The Following Shapes Are Not Available

Shapes are not available

Cutouts

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 4 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

PRODUCT INFORMATION MANUAL

SECTION: 1 ALUMINIUM VENETIAN BLINDS

ISSUE DATE: APRIL 2015 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JANUARY 2013 APPROVED BY: M.SOMI PAGE 3 OF 13

Aluminium Venetian Blind Measuring

For 25/25 Headbox using Spring Loaded Mounting Brackets & End

Plugs

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 5 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

PRODUCT INFORMATION MANUAL

SECTION: 1 ALUMINIUM VENETIAN BLINDS

ISSUE DATE: APRIL 2015 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JANUARY 2013 APPROVED BY: M.SOMI PAGE 4 OF 13

Aluminium Venetian Blind Measuring

50mm Classic Aluminium Venetians - Spring Loaded Brackets

WIDTH -0

WIDTH -10

DROP

-10

TO

SILL

-10

ARCH

-10

TO

FLOOR

-10

WIDTH +50

60mm

WIDTH -10

DROP

-10

+120

WIDTH -10

WIDTH -5

WIDTH

-60

WIDTH

-65

FRONT EDGE +50

ON FACE

FRONT EDGE -10

FRONT EDGE -0

WIDTH -60

ON FACE

WIDTH -60

WIDTH -30

WIDTH -30

FRONT EDGE -5

FRONT EDGE -5

WIDTH -30

WIDTH -30

ARCHITRAVE & REVEAL FACE & REVEAL

CORNERS

BAYS

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 6 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

ALUMINIUM VENETIAN BLINDS

INSTALLATION OPERATION AND CARE INSTRUCTIONS

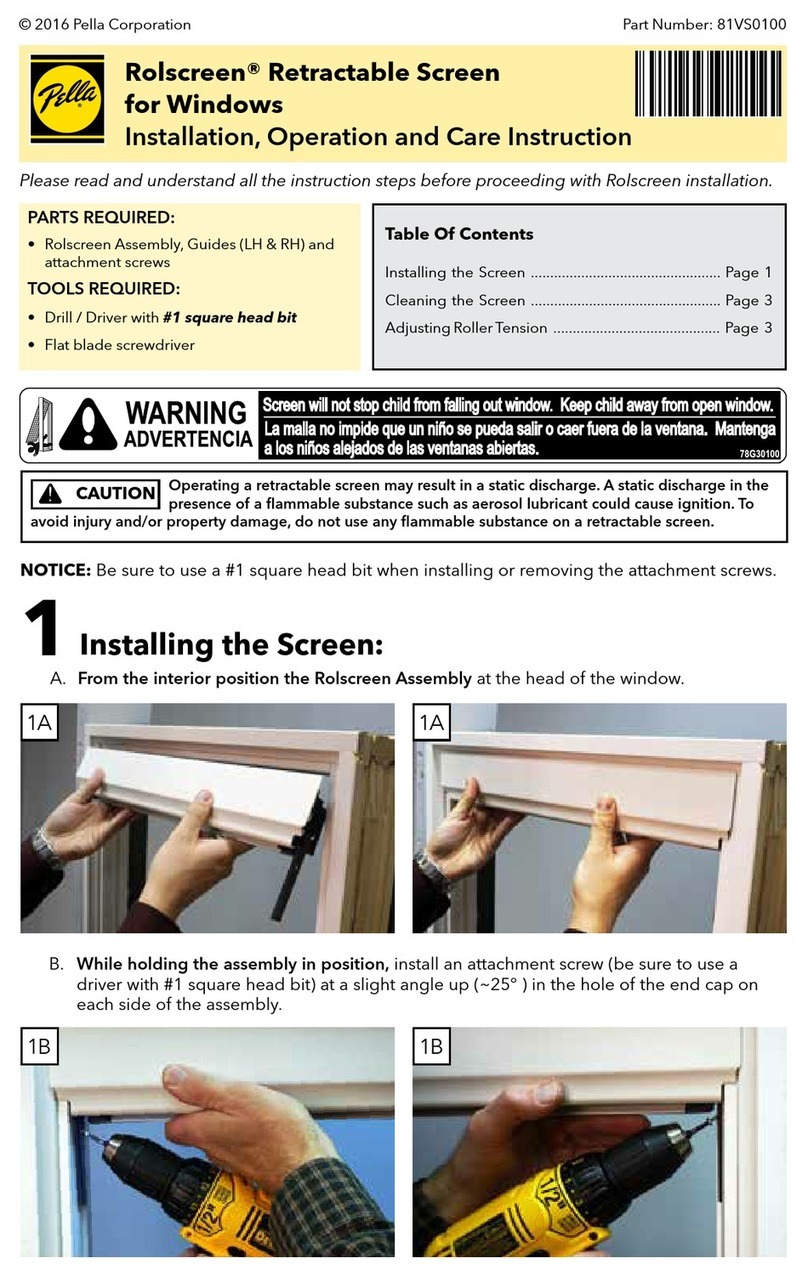

IMPORTANT: Please read these instructions all the way

through before installing.

Each Venetian Blind ordered should include:

• Spring loaded mounting brackets

(No. depends on size)

• 2 hold-down brackets

• 2 screws for each bracket (20mm x 6# Panhead)

• 2 cord cleats and screws

MATERIAL AND TOOLS

TOOLS REQUIRED

• Steel measuring tape

• Carpenter’s level

• Power or battery drill and bits

• Flat blade and Phillips head screwdrivers

• Scissors

16MM & 25MM

ALUMINIUM VENETIANS

MOUNTING THE BRACKET

The installation brackets may be Reveal

(inside the window frame) or Face

(outside the window frame) mounted. In

all cases, level mounting is critical to the

operation of the blind (use Carpenter’s

level).

SPRING LOADED

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 7 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

TILT AND LIFT SAME END TILT AND LIFT OPPOSITE END

16mm 80mm from end of headrail 55mm from end of headrail

25mm to centre of bracket. to centre of bracket.

Intermediate brackets should be spaced evenly and

as close to tape drum supports as practical.

80mm

TAPE DRUM SUPPORTS MOUNTING BRACKETS

TILTER & CORDLOCK

80MM

REVEAL FIT (INSIDE MOUNT)

Hold the Venetian inside window frame and mark position of

brackets so as not to foul tape drums. Attach the brackets with

screws provided, (1 per bracket for top fix), to the front of the

reveal, ensuring the front edges are in line and level. This is the usual

position, however you may want to fit them further back into the

reveal.

NOTE: May need to use washers or packing to ensure level.

FACE FIT (OUTSIDE MOUNT)

Hold the Venetian on the face of the window and mark position of

brackets, so as not to foul tape drums. Attach the brackets with

screws provided (2 per bracket for face fit) ensuring all brackets are in

line and level.

NOTE: Blind will close tighter if fitted level. If headbox bows poor

closure will result.

CONTROL END BRACKET LOCATION

FACE FIXING ONTO CEMENT RENDERED WALLS

Do not drill too close to edge as render may break away. Use

suitable rawl plugs in conjunction with the screws supplied.

FIXED TO CLEAR HANDLES ETC

If needing to pack out from window to clear handles, locks etc use a

full width piece of timber as this is more stable than individual pieces

and you are able to fix brackets to timber in any position.

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 8 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

17-4 Ultimate Venetian BlindVersion 3.0

mounting

01-F0433.0

01-F0431.0

1

2

01-F0636.0

OPTIONAL EXTENSION BRACKETS

INSTALL THE BLIND

SIDE GUIDING

INSTALLING THE BLIND

Simply slip the headrail onto the front

hooks of the bracket, push inwards

and twist the back of the headrail

upwards in one motion. The headrail

will snap into position.

HOLD DOWN BRACKETS (OPTIONAL)

Hold-down Brackets are used to keep the bottom of the blind

from swaying in the breeze.

They may be Reveal (inside the window frame) or Face (outside

the window frame) mounted. With the blind fully lowered, place the

hold-down brackets onto the pins of the bottom rail and mark the

hole locations. Attach the bracket with screw/s supplied (20mm

x 6# Panhead). Place the bottom rail into the brackets, open and

close the blind.

NOTE: The drop ordered on a venetian blind is measured in

the closed position from the top of the headrail to the lowest

position on the bottom rail.

END MOUNTING BRACKETS (OPTIONAL)

These brackets are used in lieu of the spring mounting brackets.

Fixing Instructions:

Add 10mm to the headrail size, this gives you the position to fit the

outside edges of the end mounting brackets. End mounting brackets

can be screwed through the top, back or side as indicated. Brackets

are marked left or right. Use 2 Panhead 20 X 6 screws per bracket. If

swivel brackets are required, locate evenly along the headrail ensuring

not to foul the tape roll supports.

Fixing the Blind:

Insert slide into the bracket which will be closest to the tilter and

cordlock. Insert headrail into end mounting brackets, then fit remaining

slide. If using swivel brackets to support the centre of the blind, ensure

lever is fully out as indicated in the diagram. After the headrail has been locked into position

by end mount brackets, close lever on swivel brackets to lock into place (see arrow).

UNIWAND

These brackets are used in lieu of Uniwand. Uniwand mechanism is suitable

for 25mm and 16mm venetains only. By moving the uniwand lever up and

down the slats are raised or lowered to the desired position. These brackets

help keep the headrail fixed while under tension when operating the blind.

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 9 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

REMOVAL OF THE BLIND

To remove, open slats and raise the blind. If the blind has three or more brackets, remove

the headrail from both ends first, leaving the centre bracket to last. Push the headrail in and

twist down at the back of the headrail to release the headbox from the hooks at the back.

Leave the headbox hanging on the front hooks. Repeat at each bracket, then lift the blind

from the bracket and take down.

WAND TILT CLUTCH (OPTIONAL)

To protect your blind from overwinding, some Aluminium Venetian Blinds come

with a clutch in the top of the wand. When too much pressure is applied the teeth

of the clutch skip over each other to prevent damage.

WAND TILT: simply rotate the wand to tilt the slats from fully

closed to any desired angle.

RAISING & LOWERING OF BLIND: to raise, tilt the slats to

the fully opened position. Remove the bottom rail from the own

brackets (if fitted). Pull the lift cord towards the centre and raise

the blind. To lock in position simply move the cord towards the

outer edge of the blind to engage the cord lock. To lower, simply

pull the cord towards the centre of the blind and lower gently.

OPERATION - 16 & 25MM VENETIAN 25MM LITERISE SPACER BLOCK

When installing LiteRise, spacer blocks are needed to be fixed for

a face fix installing.

17-3

Version 3.0Ultimate Venetian Blind

mounting

01-F0430.0

01-F0432.0

MOUNTING THE BRACKETS

OPTIONAL SPACER BLOCK

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 10 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

DUO-FLEX®OPERATING SYSTEM RAISING & LOWERING OF THE

BLIND:

1. Lower the blinds.

2. Twist the wand to operate the opening and closing of the slats.

OPERATION - DUO-FLEX® OPERATING SYSTEM

3. Twist the wand to the right to close all of the slats.

4. Twist the wand to the left to vary the opening of the slats.

5. If a different closing height or other blind desired, repeat steps

2 to 4.

CARE AND CLEANING

1. Dust can be easily brushed off at regular intervals using a

clean soft cloth, a feather duster, or a vacuum cleaner with

brush attachment.

2. To dust, tilt the slats up and then down (but not entirely

closed) to reach the entire top and bottom surfaces.

3. To vacuum, use the brush attachment and tilt slats as per

point 2 above.

4. Slats may be wiped over with warm water and a mild

detergent.

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 11 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

50MM ALUMINIUM VENETIANS

MOUNTING THE BRACKET

The installation brackets may be Reveal (inside

the window frame) or Face (outside the window

frame) mounted. In all cases, level mounting

is critical to the operation of the blind (use

Carpenter’s level).

REVEAL FIT (INSIDE MOUNT)

Hold the Venetian inside window frame and mark position of

brackets so as not to foul tape drums. Attach the brackets with

screws provided, (1 per bracket for top fix), to the front of the reveal,

ensuring the front edges are in line and level. This is the usual

position, however you may want to fit them further back into the

reveal.

NOTE: May need to use washers or packing to ensure level.

FACE FIT (OUTSIDE MOUNT)

Hold the Venetian on the face of the window and mark position of

brackets, so as not to foul tape drums. Attach the brackets with

screws provided (2 per bracket for face fit) ensuring all brackets are in

line and level.

NOTE: Blind will close tighter if fitted level. If headbox bows poor

closure will result.

FACE FIXING ONTO CEMENT RENDERED WALLS

Do not drill too close to edge as render may break away. Use

suitable rawl plugs in conjunction with the screws supplied.

FIXED TO CLEAR HANDLES ETC

If needing to pack out from window to clear handles, locks etc use a

full width piece of timber as this is more stable than individual pieces

and you are able to fix brackets to timber in any position.

REVEAL FIT BRACKET FACE FIT BRACKET

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 12 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

INSTALLING THE BLIND

Simply slip the headrail onto the front hooks of the bracket, push inwards

and twist the back of the headrail upwards in one motion. The headrail will

snap into position.

HOLD DOWN BRACKETS

Hold-down Brackets are used to keep the bottom of the blind from

swaying when mounted on doors or exposed to the wind. The

hold-down brackets are inside or outside mounted at the bottom of

the window opening. With the blind fully lowered, place the

hold-down brackets on to the pins on the end of the bottom rail

and mark mounting hole locations. Attach hold-down brackets with

screws provided. With the bottom rail attached to the hold-down

brackets, the slats may be opened or closed. Disconnect the rail

from the brackets to raise and lower the blind.

Please be aware that blind cords or chains pose a strangulation hazard for children. To

reduce the risk of strangulation this internal window covering must be installed in such

a way that a loose cord cannot form a loop 220 mm or longer at a height of less than

1600mm above floor level.

Your blind is provided with a cord cleat. It is essential that the following

installation instructions are adhered to:

• If a cleat is used to secure the cord, it must be at least 1600mm above floor level to \

prevent children from unwinding the cord from the cleat.

This pack includes the following child safety devices:

• Safety Cleat Pack – 26.228.000

• Hold Down Pin – 26.165.000

• End Cap ECI – 26.167.XXX

• Hold Down Bracket – 26.154.030

NOTE:

• These safety devices MUST be installed and used.

• Ensure the bottomrail of your blind is secured into the hold

down bracket while the blind is in the down position.

Be aware that it is possible for children to strangle in window covering cords. To

reduce the possibility of such an accident, all cords must be kept out of the reach of

children, including infants. Cord cleats are an effective way to implement this essential

precaution.

PROTECTING YOUR CHILDREN

SAFETY DEVICES

CHILD SAFETY INSTALLATION INSTRUCTIONS

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 13 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

CARE AND CLEANING

CORD TILT: Pulling on one of the single cords will tilt the slats in one direction, and

pulling the other cord will tilt the slats in the opposite direction.

RAISING & LOWERING OF BLIND: to raise, tilt the slats to the fully opened position.

Remove the bottom rail from the hold-down brackets (if fitted). Pull the lift cord towards

the centre and raise the blind. To lock in position simply move the cord towards the

outer edge of the blind to engage the cord lock. To lower, simply pull the cord towards

the centre of the blind and lower gently.

OPERATION - 50MM SLAT

Attach the cord cleats 153mm to 305mm apart at a height at least 1600mm above

floor level to prevent children from unwinding the cord from the cleat. Take into

account that a child may stand on a baby cot or other furniture in an attempt to reach

the cords. Once the cleats are attached, simply wrap the excess cord around them

after each use of the shade, as shown.

INSTALL CORD CLEATS

Cord Cleat

1.Dust can be easily brushed off at regular intervals using a clean soft cloth, a feather

duster, or a vacuum cleaner with brush attachment.

2.To dust, tilt the slats up and then down (but not entirely closed) to reach the entire top

and bottom surfaces.

3.To vacuum, use the brush attachment and tilt slats as per point 2 above.

4.Slats may be wiped over with warm water and a mild detergent.

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 14 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

PRODUCT INFORMATION MANUAL

SECTION: 1 ALUMINIUM VENETIAN BLINDS

ISSUE DATE: APRIL 2015 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JANUARY 2013 APPROVED BY: M.SOMI PAGE 13 OF 13

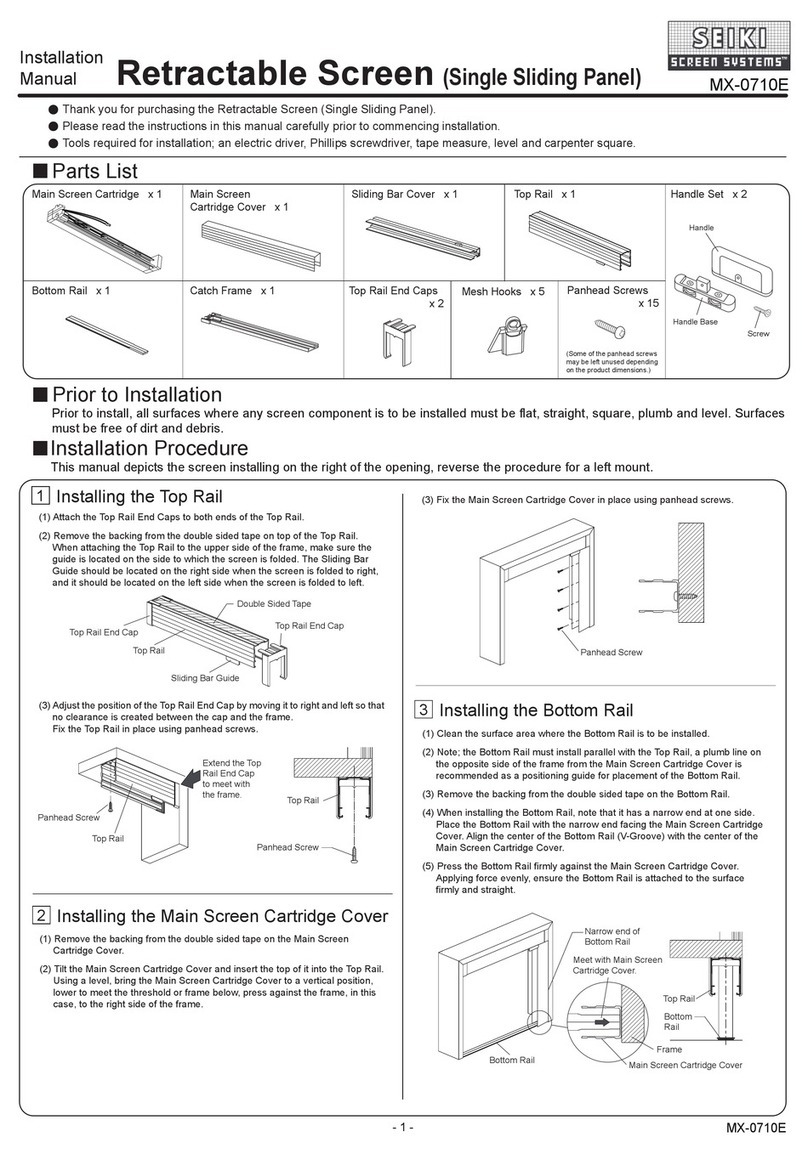

X

A

B

Shaft

Travelling Groove

Lever

5cm

YX

Calculation of Length Of Slider Shaft

Table showing shaft lengths of blinds of different heights

Formula for calculation of length of shaft

If height “B” is greater than 200cm

X= A/2+B-180cm

Y= A/2

If height “B” is less than 200cm

X=A/2+150cm

Y=A/2

Note: We require 2 height measurements to produce an order:

Height: “A” height of blind

Height “B” height from top of blind to floor

Height “X” height of shaft (Minimum 300m/Maximum 300m)

“A” Height of blinds

Sizes

cm 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 240 250

150 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

155 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

160 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

165 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

170 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

175 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

180 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

185 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

190 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

195 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

200 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140

205 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140 145 150

210 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140 145 150 155

215 75 80 85 90 95 100 105 110 115 120 125 130 135 140 145 150 155 160

220 80 85 90 95 100 105 110 115 120 125 130 135 140 145 150 155 160 165

225 85 90 95 100 105 110 115 120 125 130 135 140 145 150 155 160 165 170

230 90 95 100 105 110 115 120 125 130 135 140 145 150 155 160 165 170 175

235 95 100 105 110 115 120 125 130 135 140 145 150 155 160 165 170 175 180

240 100 105 110 115 120 125 130 135 140 145 150 155 160 165 170 175 180 185

245 105 110 115 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190

250 110 115 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195

“B” Height from top of blinds to floor

ISSUE DATE: JUNE 2018 ORIGINATOR: SKILTEC

REPLACES ISSUE DATE: JAN 2018 APPROVED BY: J.ZIVANOVIC PAGE 15 OF 15

PRODUCT INFORMATION MANUAL

SECTION: 1A ALUMINIUM VENETIAN BLINDS

The Hunter Douglas product range is continuously improving and innovative products are

always being added. With the introduction of Light Lift operation to the Aluminium Venetians

Collection, raising, lowering and tilting is now easier than ever.

With the new modern handle, simply push up to raise the blind and down to lower. Using the

same motion you can tilt the slats to any required position. This is controlled by advanced

motor gears and high quality spring mechanisms specifically designed for effortless and

precise operation. The handle is available in black, white and silver for easy colour co-

ordination with the 25mm slat range.

We understand the importance of safety in commercial applications. The patented Light Lift

design eliminates the cords providing a significant increase in safety for children and pets

whilst creating a clean, uncluttered look.

Adding innovation and Child Safe Solutions to our timeless design

Available in 25mm Slimline and Limited Edition

Light Lift size limitations: 3.6sqm, width 2000mm, drop 2000mm

This manual suits for next models

4

Table of contents

Other SKILTEC Window Blind manuals

Popular Window Blind manuals by other brands

vidaXL

vidaXL FPR-312674 Operating and safety instructions

LF

LF Style selections VR3672W quick start guide

John Lewis

John Lewis Corded roman blind kit manual

Renson

Renson Detecto Rensonmotor Nstallation instructions

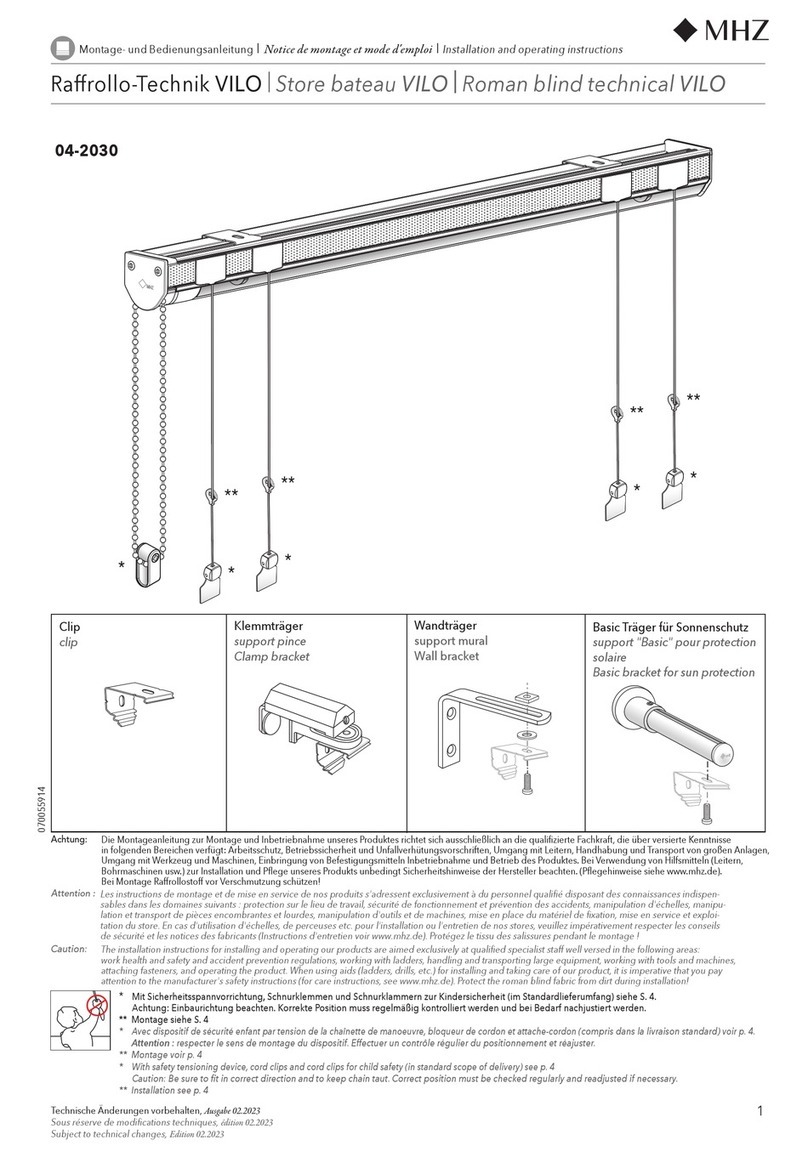

MHZ

MHZ VILO 04-2030 Installation and operating instructions

WAREMA

WAREMA WG.F.08 Instructions for use and maintenance