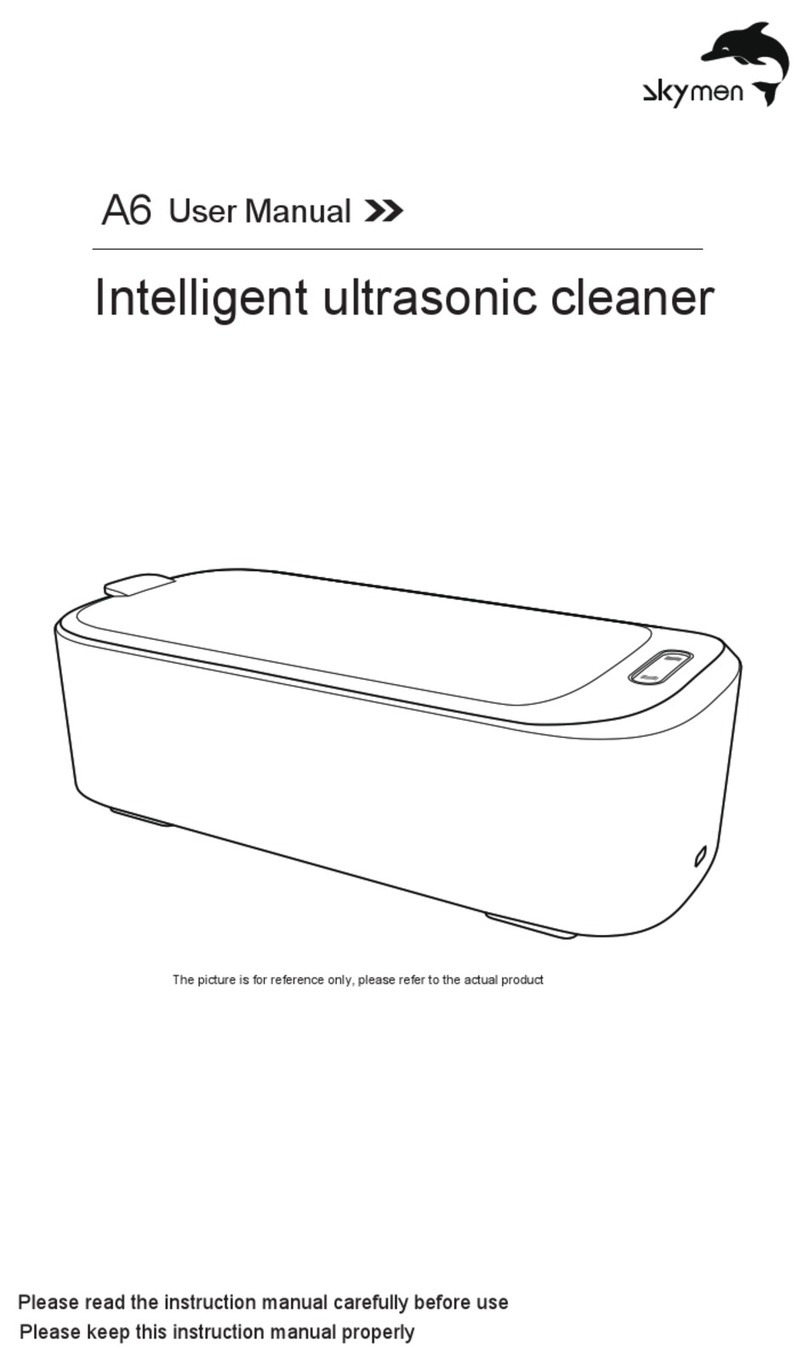

Skymen JP-009 User manual

SKY

EN

ULTRASONIC

CLEANER

SKYMEN

MANUFACTURE

Professional

manufacturer

focus

on

ultrasonic

technology

R&D

Instruction

Manual

JP-009

JP-010T

JP-010S

Application:

Electronic factory, utensil, hardware, machinery, communication, biological,

medical instrument,

glasses,

Optical, Jewelry, clock, watch, chemical,Textile

auto part, Ships, aviation,

mining

area, commercial

cleaning9

www

$Kymen

C

PREFACE

OF

USE

Thank you for purchasing

our

company's

products,this manual is mainly to explain

some

necessary precautions during installation and use. Before the operation. Please read this

manual

first,

in

order

to

fully

understand

the

operating

procedures

of

this

product,

please

keep

the

manual

for

reference

anytime.

Before

connecting

the

power,

please

confimm

wheth

er

it

is

within

the

rated

range.

Do

not

modify

this

product.

Please

note

that

The

machine

control

panel

will

be

affected

by

organic

solvents,

strong

acid,

strong

alkali

erosion

.This

product

may

cause

some

interference

to

some

electromagnetic

communication

devices,

such

as

mobile

phones,

Bluetooth,

etc.

When

installing

pls

place

it

horizontally,

do

not

cut

diagonally

to

prevent

iquid

from

flowing

out

THE

BASIC

PRINCIPLE

OF

ULTRASONIC

CLEANING

The cleaner

uses

ultrasonic

energy

(40 kHz)

in

the

form

of sound waves

to

create millions of

tiny

microscopic bubbles

in

the solution that even works its way into holes

and

hidden cavities

loosening dirt

on

all

surfaces

that

the

solution

touches.

This

action

called

cavitation,

occurs

thousands

of times per

second

to gently yet thoroughly scrub contamination

off

the article being

cleaned.

VWhen

you

lift

the

item

out

of

the

cleaner,

it's

microscopically

clean.

NOTES

BEFORE

USE

1.

Ensure

the power supply

is

in

rated range before

power

cable

is

connected.Refitting

is

strictly

prohibited!

Attention

that

the

control

panel

will

be

eroded

by

organic

solution,

strong

acid

and

strong alkali.

2.

Ensure the earth wiring

is

well

connected before starting

3.

Ensure the power key or knob

is

on the"OFF"place before starting.

4.

Do

not

operate

if

the

tank

is

empty.or

ultrasonic

generator

will

be

damaged.If

heating

isS

needed,the

water

level shouldn,t be

less

than2/3.

6.

Please

close

the

lid

to

reauce

noise and pay attention

to

water and

steam

in

case

of

burning

skin while

open

the

lid.

7.

Do

not relocate the machine when

fluid

in

the tank

in

case

of

overflow.

8.

Please

choose

the

proper

sizes

or

types

of

baskets

according

the

object

to

be

cleaned

9.

Suggest

using

water-soluble

liquid

for

bentchtop ultrasonic cleaners.

Strong

acid

or

flamma-

bility

cleaner

is

forbidden

Donot

heat

when

using

flammable

liquid

such

as

alcohol, gasoline,

etc.,

heating is

strictly

prohibited,

ultrasonic

vibration

for a

long

time

cause

temperature

of

liquid

increase, caution

fire!

10.

Do

not

use

the machine

in

severe

environment

The

place

where

humidity

is

too

high

and

The

place

where

The place

The

place

where

temperature

changes

fiercely;

The place where vibration or impact

is

strong

The place where water,

oil

or chemicals splash

IS

easy

to

produce dew,

exists corrosive

gas

or dust;

where

is

filled

with

explosive and

flammable

gas

01

www

sKymer

cn

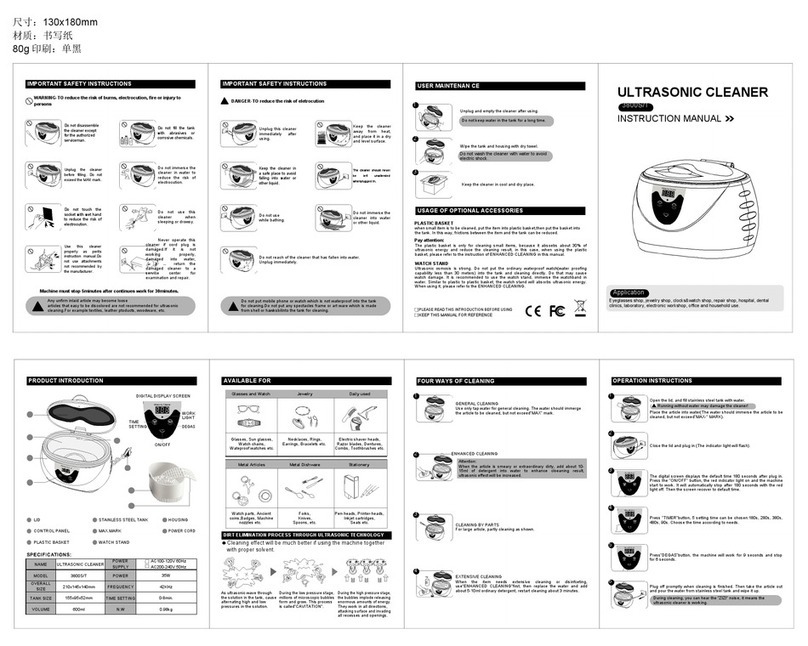

JP-009

JP-010T

Tank

Lid

Stainless

steel

body

Stainless

steel

basket

Handle

ULTRASONIC

CLEANER

Power

plug

Corner

pad

Control

board

Power switch

Fuse

(a

backup

fuse)

The

power

plug

Back

ULTRASONIC

CLEANER

SKYINENn

Heater indicator

Ultrasonic

indicator

888

Digital

display

Degas indicator

ULTRASONIC

HEAT

DEGAS

Screen

9

Ulrtasonic

ON/OFF

Degas

ON/OFF

ON/OFF

TIiME

HEAT

DEGAS

Timeset Heater

ON/OFF

02

JP-010S

Tank

Lid

Stainless steel

basket

Stainless steel

body

Power plug

Corner

pad

Control board

Power switch

Fuse

( a backup

fuse

)

The

power plug

Back

ULTRASONIC

CLEANER

Heater indicator

Ultrasonic

indicator

8888

88

88

Digital

display

Digital

display

Screen

Screen

Minuie

Second

Set

C Actual N

ON

Time+

Temp

Time

Temp+

TIME+

TIME

TIME

TIME-

Ulrtasonic

ON/OFF

Heater

ON/OFF

ONOFF

ON/OFF

-03

www.skyen

co

OPERATION

STEPS

Before

Operating

Your

Cleaner

1.

add

cleaning

liquid

Fill

the tank

with

warm

or

tap

water below the maxline

Add

required

quantity

of

cleaning solution.When using flammable

liquid

such

as

alcohol,

gasoline

and

so

on,

heating

is

strictly

forbidden!ultrasonic

vibration

for

a long time

cause

temperature

of

liquid

increase, caution

fire!

2.

open

power

Plug the cleaner into

tank back, then machine is power on.("O" is closed, and

"I"

is open)

grounded outlet. Turn on the power switch at the

Start

ultrasonic

cleaning

JP-009, JP-010T

ULTRASONIC

CLEANER

Set the

working

time,

7 setting times can be chosen: 60s, 180s, 300s, 600s.

30-

mins,

60-mins.

Touch

"ON/OFF"

button

after

set

the

time

well,

ultrasonic

light

will

be

on

and machine starts

to

work

until

the default time

is

over.

Touch

"ON/OFF"

again

if

need

to

pause when

working.

JP-0105

For the

first

Boot, time display show setting time at random, press/touch

time

key

+one

time,

"the

setting

time"

on

the

display

increase

by

1

minute

corresponding-

y

Touch

time

-

Key

to

decrease

time

seting

by

1

minute.

Touch

ON/OFF

switch

after set the

time

well,

ultrasonic indicator turns red and machine starts

Working

based

on

specified the parameters, meanwhile timer begin

to

count

down

and

stop

working

until

time shows"00:00", automatically

Heat

JP-009, JP-010T

ULTRASONIC

CLEANER

Heater

light

will

be

on

when touch

"HEAT";

heater

will

be automatically

off

when

temperature

up

to

65

C.Touch the button again

if

need pause.

JP-010S

For

the

first

boot,

the

setting

temperature

on

the

display

is

random,

and

actual

temperature

is

room

temperature.

Touch

TEMP+

once

to

increase

temperature

by

1

Touch

TEMP-

once

to

decrease

temperature

by

1C,

Temperature

display shows setting temperature and actual temperature when heater

is

Working,

the heater indicator goes

off

when actual temperature reaches setting

temperature.

DEGAS

FUNCTION

This

operation

is

applicable

to models

with

degasification.

010S

does not have

degasification

Degas

light

will

be

on

if

press"DEGAS",that

is,

ultrasonic

will

work

9

seconds,

then

pause

6

seconds

unti

the defaut

time

is

over.

04-

www.skymen.cn

Power

OFF

MECHANICAL

SERIES

Turn

the

timer

button

to

the

location

of

"OFF,

the

ultrasonic

stops

and

the

light

is

off.

Turn

the

heating

button

to

the

location

of "OFF",

the

heating stops

and

the

light

is

off.

DIGITAL

SERIES

Press

"ON/OFF" to stop

working

and

then

cut

off

the

power.

empty

out

the

liquid,

clean

the

tank

and

the

unit with

cloth

for

next

use.

APPLICATION

Full

series

standard

ultrasonic

cleaners

are

made

up

of

high

quality

stainless

steel

plate,

which

isS

corrosion

resistance

and

long

lifespan, adopt with

original

South

Korea

ultrasonic

transducer

and

advanced

adhesive

technology,

high

electro-acoustic

conversion

efficiency

and

strong

ultrasonic

power

output.

Equipped

with

automatic

constant

temperature

heating

device,

heating

range:

room

temperature-80°C

Skymen

ultrasonic

cleaner

widely

applied

to

industry

of

precision

electronics,

painting,

filter

system,

watch-clocks,

glass,

metal,

jewelry,

and

medical

instruments

deaning

etc.

Cleardirt

Industry

The

cleaning

products

materials

Integrated

circuit,

power

tube, slicon wafer

diode.

lead frame.

capillary, tray,

etc

Hards,

etching

oil,

stamping

oil,

pollshing wax. dust partides,etc

Semi-

conductor

Fingerprint.powder.cutting

oil

stamping

oil,

iron filings

polishing

materials.

wanut

powder.

polishing

wax,

resin

dust

etc

Tube

parts,

cathode

ray

tube.

printed

circuit

board,

quartz

parts

Electrical&

electronic

components,

telephone

switching

equipment,

speaker

electronic

Components,

power

meter,

LCD

glass,

core

iron parts,

computer

floppy

disk,

vido parts, hoop parts, head,

photo

die

mask,etc

machine

Bearing, sewing

machine

parts,

typewriter,

textile

machine,

optical

mechanical

device,

gas

valve,

watches,

cameras,

metal

filter

element

etc

Machine cutting oil ironfilngs

polishing

powder,

finger

print

oil.

grease,

dirt

etc.

Precision

machine

Glasses.

lens

prism.

optical lens.

filter

lens, glass device,

film,

optical Plastic,

resin,

paraffin,

finger

fiber,

etc

Optical

printing.

etc

device

Hardware

&

Bearing,

gear.bal,

metal

shaft

parts,

tools.

adjustable

valve,

and

machinery

cylinder

parts.burner.copm

pressors.

hydraulic

press.

gun

and

parts

Cutting

oil,

iron

filings.grease

polishing

powder.

finger

printing,

and

so

on

ultracentrifuge. city

water

faucet.

etc.

Iron

filings.polishing

powder

Oil,

stamping

oil,

dirt.etc.

Medical Medical instrument. denture,

etc.

instrument

Polishing

scrap

iron.oil,

black

iron shell.rust,oxidationsheli

scrao

iron,

polishing

powder

stamping

Ol dirt

etc

Electroplate

Galvanized

parts.mold

stamping parts.etc.

Poston

ning.carburetor,

flow

meter

housing.compressor

shel,

electncal

components,etc

Iron

fiings,

polishing

powder

ol

stamping

OH

dirt.etc

Car

parts

Chemical colloid

glue

and

other

Chemical

Chemical

or

artificial

fiber

nozzle

filter

protector,chemical

iber

texture

eC

Solid

material.

dust

etc

fiber

05-

www.skymen

cn

Maintenance

Regularly use high-pressure wind blown away dust

for

electrical parts Clean the tank at least

once

a

week

Troubleshooting

No

Problems

Possible

causes

Solutions

Remarks

A.Power

supply

not

connect

B.Fuse

broken

A.Check

and

plug

power

switch

B.Check the

fitted

power

supply

and

change

the

same

specification

fuse

C.Connect

fitted

cable

or

replace a

new

D.Inquiry

our

after service engineer

E.Check the broken part

and

change

it

F.Inquiry

our

after

senvice

engineer

No

Ultrasonic C.Cable short

circult

D.Transducer short

circult

E.PCB

Board

broken

F.Other

reasons

Time control A.Timer failure

2

failure

A.Replace

timer

or

digital

control

panel

B.Inquiry

our

after service engineer

B.other reasons

A.Heater

power

switch

bad

linkage

A.Check heating plug

and

connect

well.check

outlet

line

with

multimeter:if

OK

and

resistance

value

is

few

hundred

OHMs.

Suggestion

3

No

heating

B.Fuse

burn out

C.Heating

pad

burn

out

D.Digital

display

board

out

of

B.Change the same specification fuse

C.Replace

the

bad

heating

pad

if

open

circuit

D.Check

the

broken

part

and

change

it

50-60°C

control

E.Other reasons

E.Inquiry

our

after service engineer

A.Fasten the thermostat header.

Temperature

A.

Ihermostant

loosen

B.Thermostat

tube

broken

C.Digital

display

out

of

control

D.Other

reasons

B.Replace

thermostat.

C.Check the broken part and change

it.

D.Inquiry

our

after senvice engineer

control

4

failure

A.too

high

too

low

liquid

surface

A.Adjustliquid

into the best surface

B.too

high

too

low

temperature

C.Not suitable cleaning liquid

B.Adjust

temperature

into

the

most

fitted

C.Stop

and

switch

off

power

supply.replace

Suggestion

50-60C

Not

well

5

cleaning

suitable

liquid

after the previous

liquid

cool

down

D.Inquiry

our

after service engineer

D.Other reasons

A.Customer side

not

grounded

6

Electrileakage

B

Machine

not

grounded

A.To

ensure grounded

B.Check

if

machine earth

wire

loosen

Not

repairable or discarded According

to

the state related laws and designated

units for

discarded

medical

equipment

Scrap

8

Other

problems

Consult our after service: 0755-297847256

A WARNINGS

A

NO

NO

Caution

pollution

when

Donot

operate

when

tank

is

empty

Please

use

the

ground

wire correctly

Donot

use flammable

solution disposal

this

product.

-

06-

KvrmEn

www.skymen

cn

>>>>>>Product

specifications

<<<<<

Model

requency

Transducer

Capacity

(KHz)

Tank

size

tmm)

Unit

size

(mm)

Heating

power

Ultrasonic

power

(W)

Time

(M)

Temperature(

C

(Pes)

(W)

JP-009

40

1.3

150x

135x65 175x160x175 100

80

0-60

room

temp-65

1

JP-010T

40

150x135x100

175x160x210

100

0-60

room

temp-65

80

JP-010S

40

2 150x

135x

100

175x160x210

100

80

0-30 room

temp-80

-07-

ULTRASONIC

CLEANER

SKYMEN MANUFACTURE

www.skymen.cn

400

878

5188

SKYMEN

CLEANING

EQUIPMENT

SHENZHEN

C0.,

LTD.

Factory

address:Building

F12,No.110,first

Industrial

park

of

Li

Song

Lang

Guang

Ming

new

district,

Shenzhen,

China.

Fuyong

sales center:sales

center:3F,

A1

Block,

Fuhai

Technology

Park

Building,

FuYong

Steet,baoan

district,

Shenzhen,

Guangdong,

China.

Tel:

+86-0755-29784256

Fax:+86-0755-29784236

Other manuals for JP-009

1

This manual suits for next models

2

Table of contents

Other Skymen Ultrasonic Jewelry Cleaner manuals