2

INDEX

1. Introducon ...................................................................................... 3

1.1 Safety .................................................................................................................... 3

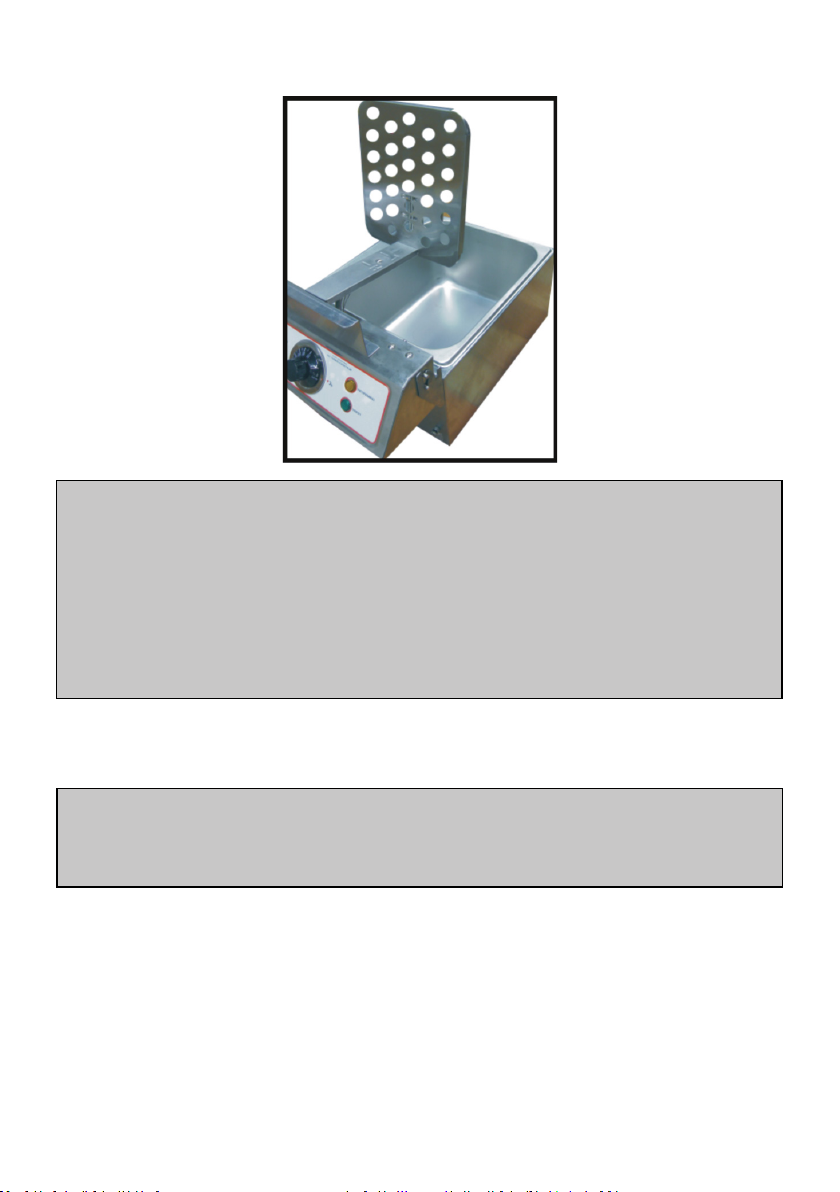

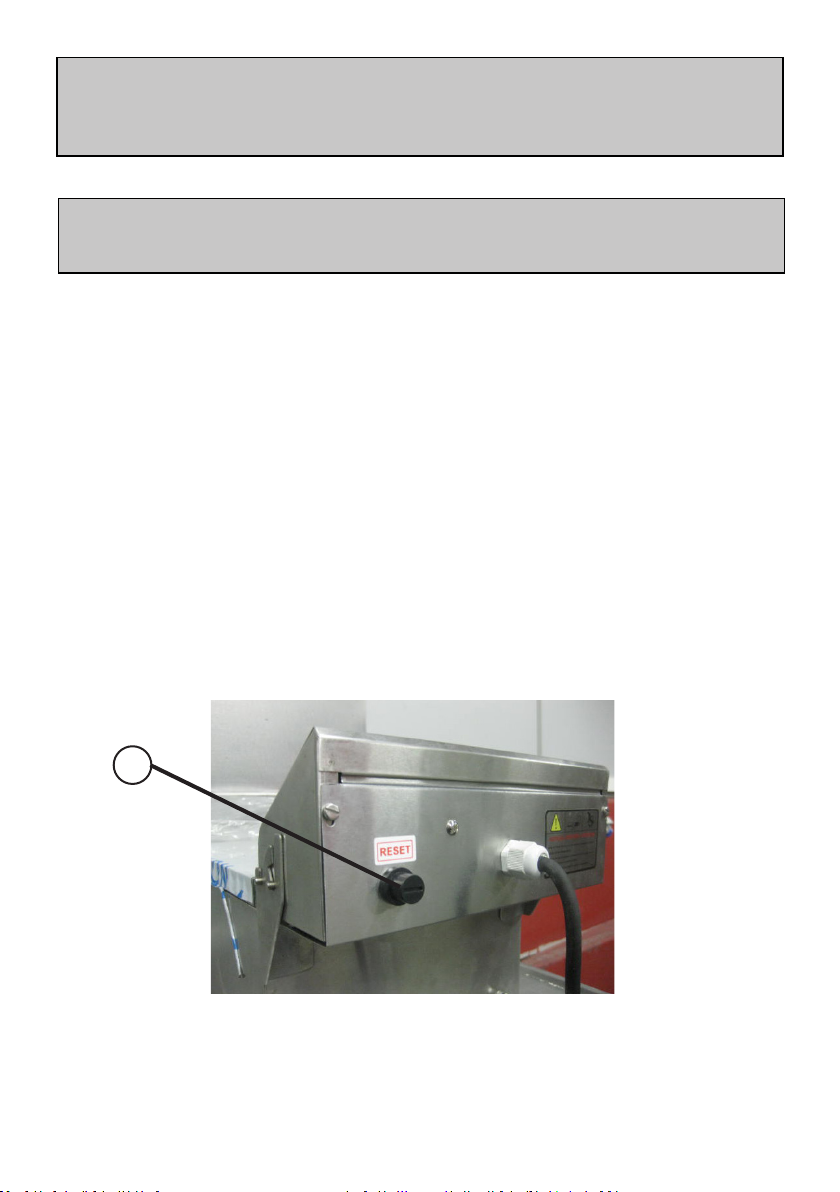

1.2 Main Components ................................................................................................ 5

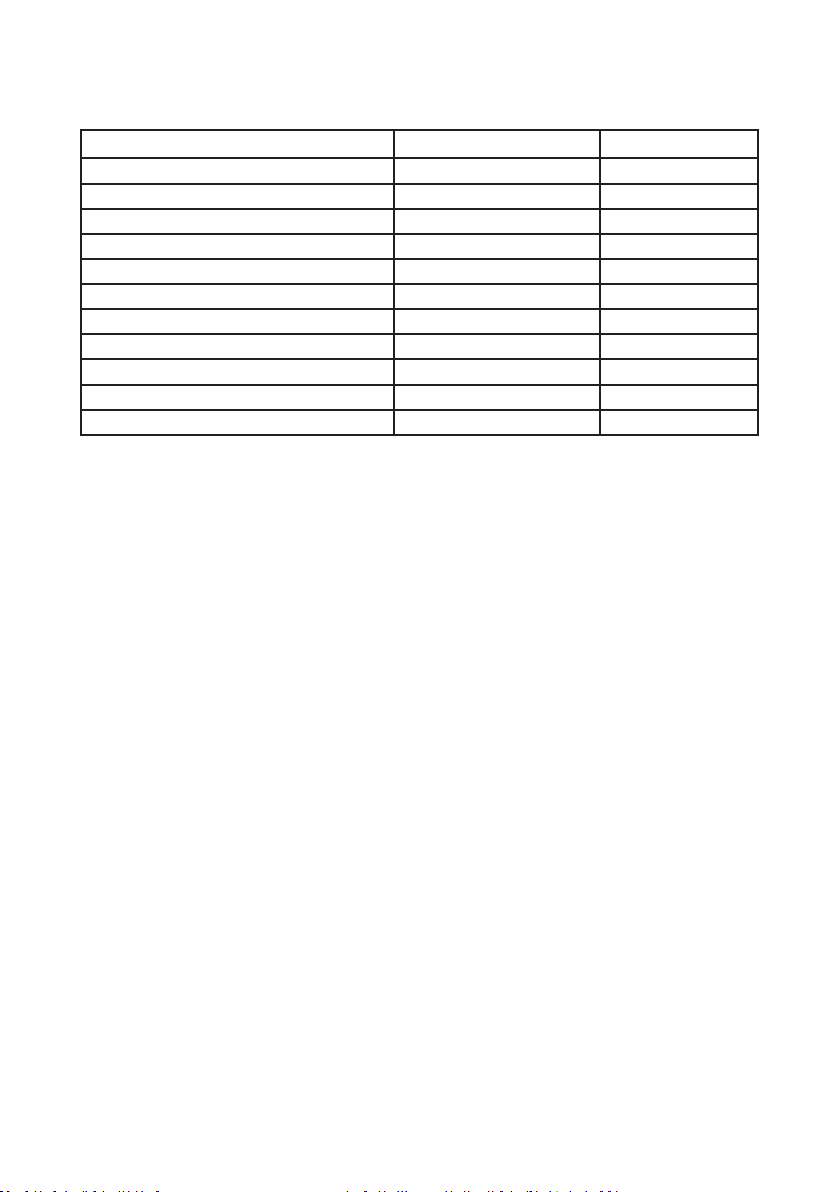

1.3 Technical Characteriscs ........................................................................................ 6

2. Installaon and Pre Operaon ........................................................... 6

2.1 Installaon ............................................................................................................ 6

2.2 Pre Operaon ........................................................................................................ 6

3. Operaon .......................................................................................... 7

3.1 Starng.................................................................................................................. 7

3.2 Cleaning................................................................................................................. 9

3.3 Cauons with Stainless Steel ................................................................................10

4. General Safety Pracces .................................................................. 11

4.1 Basic Operaon Procedures ..................................................................................11

4.2 Safety Procedures and Notes before Switching the Machine ON ...........................12

4.3 Roune Inspecon................................................................................................13

4.4 Operaon .............................................................................................................13

4.5 Aer Finishing The Work.......................................................................................13

4.6 Maintenance ........................................................................................................13

4.7 Warning................................................................................................................14

5. Analysis and Problem Solving .......................................................... 14

5.1 Problems, Causes and Soluons............................................................................14

6. Observed Norms............................................................................. 14

7. Electric Diagram............................................................................... 15