Skytrak 8042 User manual

Operators and Safety Manual

Model

8042/10042

S/N 9908 & Before

8990186-006

OCTOBER 1999

ANSI

WARNING

IMPROPER OPERATION OF THIS VEHICLE CAN CAUSE INJURY OR DEATH.

BEFORE STARTING THE ENGINE, DO THE FOLLOWING:

1. READ THIS OPERATOR'S MANUAL.

2. READ ALL THE SAFETY DECALS ON THE VEHICLE.

3. CLEAR THE AREA OF OTHER PERSONS.

LEARN AND PRACTICE SAFE USE OF VEHICLE CONTROLS IN A SAFE, CLEAR AREA BEFORE YOU

OPERATE THIS VEHICLE ON A WORK SITE.

It is your responsibility to observe applicable laws and regulations and to follow manufacturer's

instructions on vehicle operation and maintenance.

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

Page 1

8042/10042 Rev. 10/99

Introduction

The Manual ..................................... 2

ReplacementParts.......................... 2

Reports............................................ 2

Disclaimer ....................................... 2

Safety Practices

Signal Words................................... 3

New or Additional Operators ........... 4

PersonalConsiderations ................. 4

OperationalConsiderations............. 7

EquipmentConsiderations ............ 11

Operation

Controls......................................... 12

Instruments/Indicators................... 19

Optional Controls .......................... 22

Walk - Around Inspection .............. 24

NormalStarting ............................. 24

Cold Starting ................................. 25

Jump Starting ................................ 27

Operating ...................................... 28

Stabil-TRAK™ System Test .......... 34

Using The Capacity Chart ............. 38

Fork Ratings.................................. 45

How To Pick, Carry

& Place a Load ............................ 47

ElevatingPersonnel ...................... 47

Using Other Attachments .............. 49

Shut - Off....................................... 50

Towing and Tie Down ................... 50

General Maintenance

Routine Equipment Checklist ........ 51

Warning Decal Locations .............. 52

Maint. Schedule and Checklist...... 53

1. Lubrication Points.................... 57

2. Air Cleaner and

Restriction Indicator............... 58

3. Engine Cooling System ........... 61

4. Engine Oil and Filter................ 63

5. Engine Fuel System ................ 65

©1999 JLG Industries, Inc.

6. Engine Fan Belt Check............ 69

7. Hydraulic Oil and Filter ............ 70

8. Transmission Oil and Filter...... 73

9. Axle Oil .................................... 75

10. Wheel End Oil ......................... 76

11. Wheels and Tires .................... 78

12. Battery(s)................................. 79

13. Fuse/CircuitBreaker

Replacement ...................... ..81

14. Boom Chains & Wear Pads .... 84

15. Emergency Boom Lowering .... 90

Specifications

Fluid and Lubricant Capacities ..... 97

Tires .............................................. 98

Engine........................................... 99

Weights ......................................... 99

Machine Dimensions .................. 100

Electrical System ........................ 100

Stability Tipping Limits ................ 101

Table Of Contents

Page 2 8042/10042 Rev. 10/99

Introduction

The Manual

This Owners/Operator’s manual provides the information

you need to correctly operate and maintain this vehicle.

IMPORTANT!

Before you operate this vehicle, read this manual com-

pletely and carefully so you will understand the safety in-

structions and the operation of the controls and safety

equipment. You must comply with all Danger, Warning,

and Caution notices. They are for your benefit.

All reference to the right side, left side, front, or rear are

given from the operator's seat looking in a forward direction.

Sky Trak International, Inc. is hereinafter referred to as Sky

Trak.

Replacement Parts

OH0280

MODEL & SERIAL

NUMBERS

IMPORTANT!

The replacement of any part on this product by anything

other than a Sky Trak authorized replacement part may

adversely affect the performance, durability, or safety of

this product and will void the warranty. Sky Trak assumes

no liability for unauthorized replacement parts which

adversely affect the performance, durability or safety of

this product.

Reports

IMPORTANT!

A Warranty Registration form must be filled out by the Sky

Trak distributor, signed by the purchaser, and returned to

Sky Trak once the product is sold and/or put into service.

This report activates the warranty period, assuring that

your claims during the warranty period will be honored and

processed expediently. To guarantee you full warranty

service, make sure your distributor has returned the

business reply card of this form to Sky Trak.

Disclaimer

Sky Trak reserves the right to make changes on and to

add improvements upon its products at any time without

public notice or obligation. Sky Trak also reserves the

right to discontinue manufacturing any product at its

discretion at any time.

For your easy reference

when ordering replacement

parts or making service in-

quiries on this machine, rec-

ord its model and serial num-

bers on the back cover of the

manual. The numbers are

stamped on the serial num-

ber plate which is located on

the front of the machine's

frame tilt cylinder tower.

Page 3

8042/10042 Rev. 10/99

Signal Word:

Is a distinctive word on safety decals and throughout this

manual that alerts the viewer to the existence and relative

degree of the hazard.

The signal word "Danger" means an extremely hazardous

situation exists on or near the

vehicle

which would result in

high probability of death or serious injury if proper precau-

tions are not taken.

The signal word “Warning” means a hazard exists on or

near the

vehicle

which can result in serious injury or death

if the proper precautions are not taken.

The signal word “Caution” is a reminder of safety practices

or directs attention to unsafe practices on or near the

vehicle

which could result in personal injury if the proper

precautions are not taken.

Danger

Warning

Caution

Safety Practices

The information in this manual does not replace any safety

rules and laws used in your area. Before operating this

telescopic handler, learn the rules and laws for your area.

Make sure the vehicle has the correct equipment according

to these rules and laws.

Your safety and the safety of others in the work area

depend significantly upon your knowledge and understand-

ing of all correct operating practices and procedures for this

vehicle.

Signal Words

This symbol means “Attention! Become Alert! Your

Safety Is Involved!” The symbol is used with the following

signal words to attract your attention to safety messages

found on safety decals and throughout this manual. The

message that follows the symbol contains important

information about Safety. To avoid possible death or

injury, carefully read and follow the messages! Be sure to

fully understand the potential causes of death or injury.

Page 4 8042/10042 Rev. 10/99

New or Additional Operators

At the time of original purchase, the purchaser of this

vehicle was instructed by the seller on its safe and correct

use. If this vehicle is to be used by an employee or is

loaned, rented or sold to someone other than the pur-

chaser, make certain that the new operator reads and

understands the Operator’s Manual and the Rough Terrain

Forklift Safety Manual that are provided with the vehicle

before operating the vehicle.

In addition, make sure that the new operator has com-

pleted a walk-around inspection of the vehicle, is familiar

with all decals and safety equipment on the vehicle, and

has demonstrated the correct use of all controls.

Personal Considerations

1. Seat Belt

Always adjust the seat and fasten the seat belt

securely before you start the engine.

2. Clothing and Safety Gear

DO NOT wear loose clothing or jewelry that can get

caught on controls or moving parts. Wear the

protective clothing and personal safety gear issued

or called for by job conditions.

MACHINE ROLL AWAY

MACHINE ROLL AWAY

can cause death or

serious injury.

ALWAYS engage

parking brake before

dismounting.

can cause death or

serious injury.

ALWAYS engage

parking brake before

dismounting.

WARNING

OG0400

3. Dismounting

DO NOT get off the vehicle until you:

• place the travel select lever in (N) Neutral,

• engage the emergency brake switch,

• lower the boom,

• ground the carriage,

• turn engine off,

• unbuckle the seat belt, and

• exit the vehicle using the hand holds.

Page 5

8042/10042 Rev. 10/99

•DO NOT use your hand to check for leaks.

Use a piece of cardboard or paper to search

for leaks. Wear gloves to protect hands from

spraying fluid.

• Hydraulic fluid can cause permanent eye

injury. Wear appropriate eye protection and

stop engine and relieve pressure before

disconnecting lines.

• If anyone is injured by or if any hydraulic fluid

is injected into the skin, obtain medical

attention immediately or gangrene may result.

D. Battery

The following WARNING is intended to supple-

ment and does not replace the warnings and

information provided on the battery by the

battery manufacturer.

4. Chemical Hazards

A. Exhaust Fumes

Fumes from the engine exhaust can cause

injury or death. If operating in an enclosed

area, provide good ventilation to replace

hazardous exhaust fumes with fresh air.

B. Explosive Fuel

Engine fuel is flammable and can cause a fire

and/or an explosion. Avoid danger by keeping

sparks, open flames and smoking materials

away from vehicle and fuel during refueling or

fuel system servicing. Know where fire extin-

guishers are kept on the work site and how to

use them.

C. Hydraulic Fluid

•DO NOT attempt to repair or tighten any

hydraulic hoses or fittings while the engine is

running or when the hydraulic system is under

pressure. Fluid in the hydraulic system is

under enough pressure that it can penetrate

the skin causing serious injury or death.

•HOT HYDRAULIC FLUID WILL CAUSE

SEVERE BURNS. Wait for fluid to cool down

before disconnecting lines.

OG0360

Page 6 8042/10042 Rev. 10/99

When jump starting the vehicle, carefully follow

instructions found under "Jump Starting" later in

this manual.

Keep sparks, flames, and lit cigarettes away

from battery at all times. Lead acid batteries

generate explosive gases. Severe chemical

burns can result from improper handling of

battery electrolyte. Wear safety glasses and

proper protective gear when handling batteries

to prevent electrolyte from coming in contact

with eyes, skin or clothing.

Battery Electrolyte First Aid

• External Contact — Flush with water.

• Eyes — Flush with water for at least 15

minutes and get medical attention

immediately!

• Internal Contact — Drink large quantities of

water. Follow with Milk of Magnesia, beaten

egg or vegetable oil. Get medical attention

immediately!

IMPORTANT: In case of internal contact, DO

NOT give fluids that would induce vomiting!

6. Lowering Boom or Falling Load Hazard

DO NOT get under a raised boom unless the boom is

blockedupsafely. Alwaysemptytheboomofanyload

and block up the boom before doing any servicing

which requires the boom to be raised.

NEVER allow anyone to walk or stand under a raised

boom. A lowering boom or falling load can result in

serious injury or death.

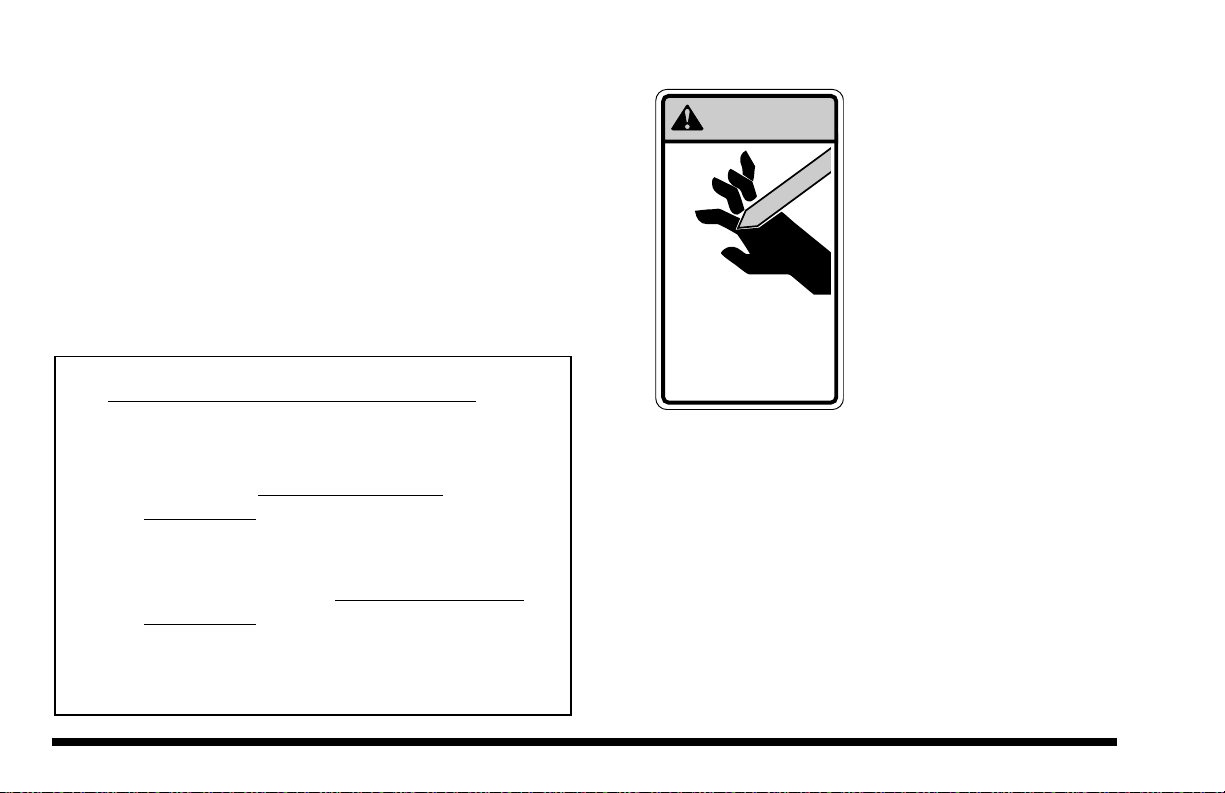

WARNING

MOVING PARTS can

cut off fingers or hands.

can

cut off fingers or hands.

Keep hands clear of

fans and belts while

engine is running.

Keep hands clear of

fans and belts while

engine is running.

OG0330

5. Moving Parts Hazard

DO NOT place limbs near

movingparts. Amputation of

any body part can result.

Turnoffengineandwaituntil

fan and belts stop moving

before servicing the vehicle.

Page 7

8042/10042 Rev. 10/99

OG0380

Prevent accidents when you move the vehicle

around the work site. Know the rules for movement

of people and vehicles on the work site. Follow the

instructions of signals and signs.

DO NOT operate the vehicle unless:

• all four tires are correctly filled with hydrofill,

• all safety equipment is in proper working condition,

• all covers and shields are in place, and

• all safety and instructional decals are in place and

readable.

(Replace all missing, illegible, or damaged decals.)

2. Clearances

Always check clearances carefully before driving

under electrical lines, bridges, etc.

3. Underground Hazards

Know the location of all underground hazards

before operating the vehicle in a new work area.

Electrical cables, gas pipes, water pipes, sewers, or

other underground objects can cause injury or

death. Contact your local underground utility

service or diggers' hotline to mark all underground

hazards.

Operational Considerations

1. Preparation and Prevention

Know the location and function of all vehicle controls.

Make sure all persons are away from the vehicle and

that the Travel Select Lever is in the "N" (Neutral)

position with the emergency brake switch engaged

before starting the engine.

Holes, obstructions, debris and other work area

hazards can cause injury or death. Always walk

around and look for these and other hazards before

operating the vehicle in a new work area.

Page 8 8042/10042 Rev. 10/99

5. Lifting Personnel

Use only an approved work platform for lifting and

lowering personnel. NEVER transport personnel in

a work platform for even the shortest distance.

Serious injury or death can occur if these rules are

not obeyed. Riders can fall and be crushed or run

over. Avoid accidents. For other specific precau-

tions, see "Elevating Personnel" later in this manual.

OG0341

OG0350

NEVER operate this vehicle in an area in which

overhead power lines, overhead or underground

cables, or power sources exist without first request-

ing that the appropriate power company or utility

company de-energize the lines or take other suitable

precautions.

4. Electrocution Hazard

Page 9

8042/10042 Rev. 10/99

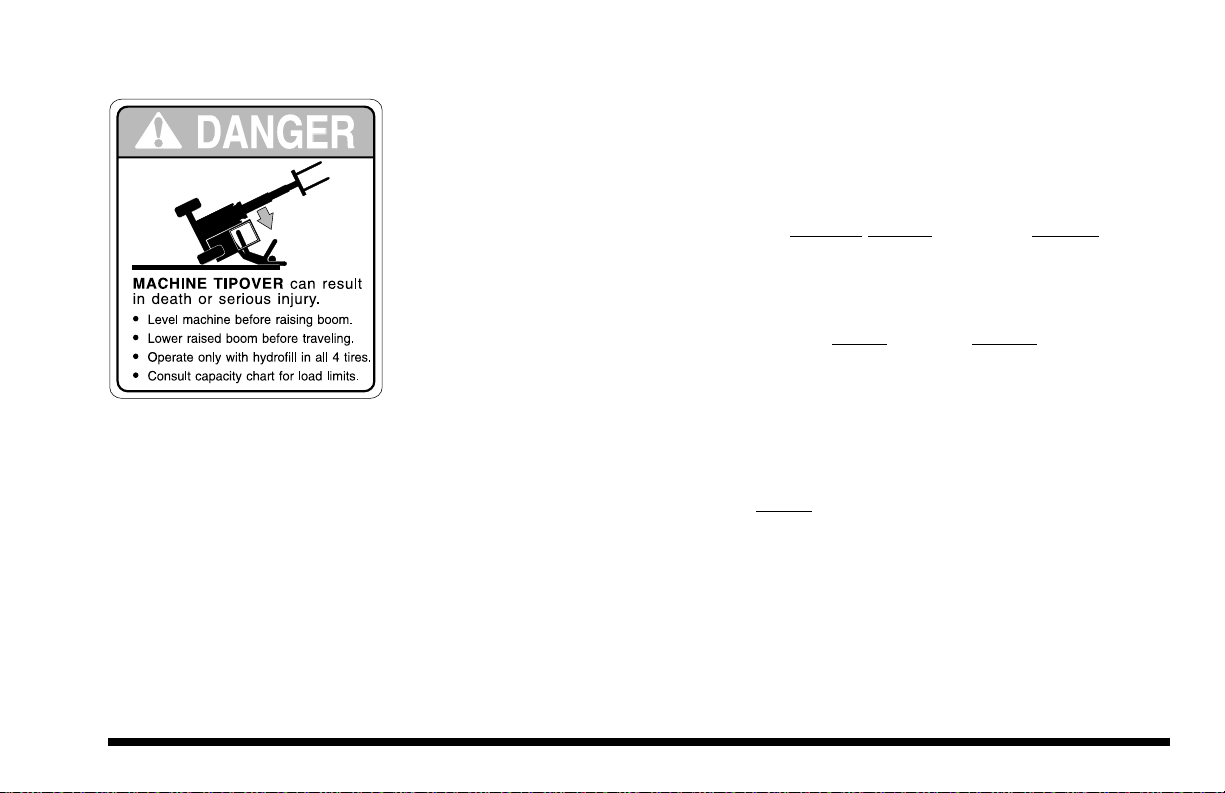

6.Tip Over Hazard ALWAYS make sure that all four tires have been

properly filled with hydrofill by a qualified tire service

center.

Traveling with the boom raised is dangerous and can

cause tipover. Keep the load as low as possible.

Travel with extreme caution and at the slowest

possible speed.

Driving across a slope is dangerous, as unexpected

changes in the slope can cause tipover. Ascend or

descend slopes slowly and with caution.

Keep the vehicle under control at all times.

Avoid jerky turns, starts, or stops. Reduce operating

speed on rough ground and slopes.

Frame tilting with the boom raised above horizontal is

dangerous. Always use the frame tilt to level the

vehicle before raising the boom above horizontal, with

or without a load. If the vehicle cannot be leveled

using the frame tilt, reposition the vehicle.

If proper operating procedures are not followed,

this vehicle will tip over. If a vehicle ever becomes

unstable and starts to tip over,

• BRACE YOURSELF and STAY WITH THE

VEHICLE.

• KEEP SEAT BELT FASTENED,

• HOLD ON FIRMLY and

• LEAN AWAY FROM THE POINT OF IMPACT.

Indecision and trying to escape from a tipping vehicle

can result in death or injury.

DO NOT exceed the

rated lift capacity of the

vehicle, as structural

damage and unstable

vehicle conditions will

result.

OG0370

Page 10 8042/10042 Rev. 10/99

7. Slopes

DO NOT park the vehicle on an incline and leave it

unattended.

• Driving across a slope is dangerous, as

unexpected changes in the slope can cause

tipover. Ascend or descend slopes slowly and

with caution.

• Ascend or descend slopes with the heavy end of

the vehicle pointing up the slope.

NOTE: The rear of the vehicle is normally consid-

ered the heavy end unless the carriage is fully

loaded. In this case the front of the vehicle is now

the heavy end.

• Unloaded vehicles should be operated on all

slopes with the carriage pointing down the slope.

• On all slopes, the load must be tilted back and

raised only as far as necessary to clear the

ground.

• When operating on a downhill slope, reduce travel

speed and downshift to a low gear to permit

compression braking by the engine and aid the

application of the service brakes.

MACHINE TIPOVER can

result in death or serious

injury.

can

result in death or serious

injury.

Always operate machine

with rear stabilizer

cylinder in place and

functioning properly.

DANGER

OH0330

DO NOT remove or unpin the rear stabilizer cylinder

from the vehicle, as unstable vehicle conditions will

result.

ALWAYS be sure the Stabil-TRAK system is

functioning properly when operating the vehicle.

Refer to “Stabil-TRAK System Test” later in this

manual for proper system function.

Page 11

8042/10042 Rev. 10/99

Equipment Considerations

ALWAYS make sure that all four tires have been

properly filled with hydrofill by a qualified tire service

center. Improper hydrofill can cause instability

which can result in tipover.

8. Falling Load Hazard

DO NOT exceed the total rated load capacity of the

specific type fork being used. Each fork is stamped

with a maximum load capacity. If capacity is ex-

ceeded, forks may break. See "Fork Ratings" later

in this manual.

DO NOT downshift at a high ground speed. You

may drop the load off of the forks due to a sudden

slowing.

9. Visual Obstruction

Dust, smoke, fog, etc. can decrease vision and

cause an accident. Always stop or slow the vehicle

until the obstruction clears and the work area is

visible again.

10. Ventilation

Sparks from the electrical system and engine

exhaust can cause an explosion. DO NOT operate

this vehicle in an area with flammable dust or

vapors, unless good ventilation has removed the

hazard.

Carbon monoxide fumes from the engine exhaust

can also cause suffocation in an enclosed area.

Good ventilation is very important when operating

this vehicle.

Warning

DO NOT modify or repair (welding, drilling, etc.) any

part of this vehicle. Modifications can weaken the

structure creating a hazard that can cause injury or

death.

Page 12 8042/10042 Rev. 10/99

Operation

Steering Wheel (See Figure 1)

Turning the steering wheel to the left or right steers the

vehicle in the corresponding direction. Any one of three

steering modes are selectable. Refer to "Steering Select

Switch."

Controls

Ignition Switch (See Figure 1)

Using the ignition switch key, the switch may be turned

clockwise from the OFF position to the RUN and START

positions. The START position is spring-loaded to return

to the RUN position and must be manually held in place

for normal starting.

Off position — The entire electrical system is shut down.

Run position — All controls and indicators are operable.

Start position — Engages starter to crank the engine

when the emergency brake switch is engaged and the

transmission is in neutral.

Accelerator Pedal (See Figure 1)

Pressing down the accelerator pedal increases travel

speed of the vehicle. The pedal is spring-loaded to

return to idle speed.

Service Brake Pedal (See Figure 1)

Pressing down the brake pedal applies the wet disc

service brakes located in the axle wheel ends. It also

activates and locks the rear axle lock system when

OH0050

STEERING WHEEL

IGNITION SWITCH

SERVICE BRAKE PEDAL

ACCELERATOR PEDAL

boom angles are greater than 40°, as long as the pedal

is depressed.

Figure 1

Page 13

8042/10042 Rev. 10/99

DANGER

MACHINE TIPOVER can result

in death or serious injury.

¥

Level machine before raising boom.

¥

Lower raised boom before traveling.

¥

Operate only with hydrofill in all 4 tires.

¥

Consult capacity chart for load limits.

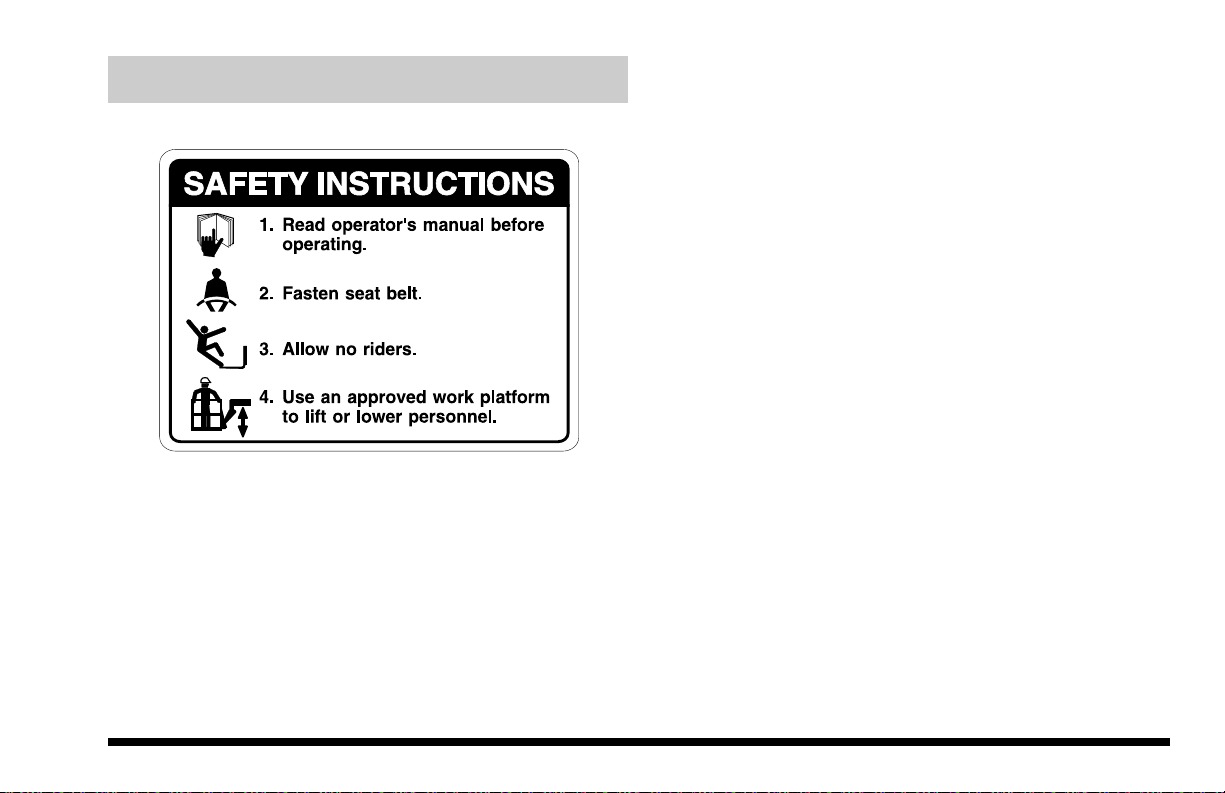

SAFETY INSTRUCTIONS

Read operator's manual before

operating.

Fasten seat belt.

Allow no riders.

Use an approved work platform

to lift or lower personnel.

1.

2.

3.

4.

LowerBoomBeforeExitingLoader

ReadOperatorsManual

FastenSeatBeltNoRiderss

WARNING

MACHINE ROLL

MACHINE ROLL

AWAY

can cause death or

can cause death or

serious injury

ous injury

.

ALWAYS

engage

parking brake before

parking brake before

dismounting.

EMERGENCY

BRAKE

P

P

CONTACTWITH ELECTRIC

POWER LINES can result in

electrocution.

Never operate this machine within

10 feet of electric power lines.

Notify the power company to

de-energize the lines before

operating forklift.

DANGER

Steering Select Switch (See Figure 2)

This switch has three positions:

Four Wheel Steer ....up position

Two Wheel Steer.....center position

Crab Steer...............down position

RefertoSteeringunder"Operating"fordetailedinformation.

EMERGENCY

BRAKE SWITCH OH0045

TRAVEL SELECT

LEVER STEERING

SELECT SWITCH

RANGE

SELECT LEVER

Travel Select Lever (See Figure 2)

The travel select lever has three positions to select

direction of travel:

F= Forward........ all the way up

N= Neutral ......... center position

R= Reverse ....... all the way down

When the travel select lever is shifted into REVERSE, the

back-up alarm will automatically sound.

NOTE: The travel select lever must be in NEUTRAL to per-

mit engine starting and when boom angles are greater than

40°, shifting into NEUTRAL locks the Stabil-TRAK system.

Figure 2

P

P

Emergency Brake Switch (See Figure 2)

The

emergency

brake switch has two positions:

Engaged ...............lift red switch cover then

push switch up

Disengaged .......... lower red switch cover

The emergency brake must be ENGAGED to permit engine

starting. Operator should use caution when engaging the

emergency brake while vehicle is moving, because the

stop will be abrupt and operator may be jolted forward unex-

pectedly. The emergency brake may be used to stop in an

emergency situation. With boom angles greater than 40°,

this switch activates and locks the Stabil-TRAK system.

OG0390

OH0780

HORN

BUTTON

Page 14 8042/10042 Rev. 10/99

Range Select Lever (See Figure 2)

The range select lever has three positions to select the

gear range:

1= Low .............. all the way down

2= Medium ........ center position

3= High.............. all the way up

Use first gear for highest torque and pulling power. Use

third gear for highest ground speed.

Boom Control Lever (See Figure 3)

The boom control lever is a joystick with variable motion

from the center to control the boom functions:

OH0170

0H0360

BOOM CONTROL

LEVER

ATTACHMENT AND

FRAME TILT

CONTROL

LEVER

Figure 3

Two boom functions can be accomplished at the same

time by moving the lever into the proper quadrant. For

example: moving the lever forward and to the left will

lower and retract the boom simultaneously.

The speed of boom movement depends on the amount

of lever movement in the corresponding direction. The

overall speed of movement depends directly upon the

speed of the engine.

Boom Raise ....... move lever backward

Boom Lower....... move lever forward

Boom Extend ..... move lever to the right

Boom Retract ..... move lever to the left

Page 15

8042/10042 Rev. 10/99

Attachment and Frame Tilt Control Lever

(See Figure 3)

The attachment and frame tilt control is a joystick with

four perpendicular motions from the center to control

two attachment functions and two frame tilt functions:

Frame Tilt Left ...............move lever to the left

Frame Tilt Right.............move lever to the right

Attachment Tilt Down ....move lever forward

Attachment Tilt Up.........move lever backward

OH0410

The attachment is self leveling and will retain any set

angle throughout boom raising, lowering, retracting or

extending operations.

OH0360

Figure 4

OUTRIGGER

CONTROL

SWITCHES

Outrigger Control Switches (std. 10042 only)

(See Figure 4)

The left and right outrigger control switches raise or

lower the corresponding outriggers.

OH0420

Raise Left Outrigger ........... lift switch up

Lower Left Outrigger........... push switch down

Raise Right Outrigger......... lift switch up

Lower Right Outrigger ........ push switch down

Page 16 8042/10042 Rev. 10/99

IMPORTANT! Outrigger equipped vehicles can be used

with the outriggers in either the raised or lowered position.

The operator must operate the vehicle within the limits

specified on the appropriate capacity chart for the

outrigger position.

Procedure for Lowering of Outriggers

Secure and proper outrigger placement is critical for

stability of the vehicle. Avoid holes or drop-offs and soft or

excessively uneven terrain. Lower outriggers just far

enough until the front of the vehicle starts to raise and

maintain a level position. Use the following procedure to

assure that both outriggers have been lowered securely.

IMPORTANT: For optimum vehicle stability, never lower

the outriggers to the point at which the tires come com-

pletely off the ground.

1. Before locating the vehicle at the lift point, observe that

the landing area for the outriggers is free of loose

material or debris and that the terrain appears to be

solid and free of holes.

2. Position the vehicle at the lift point and level the

vehicle to zero degrees (0°). If the vehicle cannot be

leveled, reposition the vehicle.

3. Lower the right outrigger until the right front tire just

starts to raise and maintains this position.

4. Lower the left outrigger until the left front tire just starts

to raise and again maintains this position.

5. Frame tilt the vehicle back to level (0°) if necessary.

Horn Button (Figure 2)

Pressing the momentary-contact horn button sounds the

vehicle horn.

Circulation Fan (Enclosed Cab Only)

(Not Pictured)

The circulation fan is only operable when the ignition

switch in is the RUN position. The fan switch is located

at the base of the fan mount.

Sliding Windows (Enclosed Cab Only)

(Not Pictured)

The sliding windows are latched with a combination slide

bar and squeeze actuated latch.

Page 17

8042/10042 Rev. 10/99

PIVOT ARM KNOB

OA0052

Figure 5

Windshield Washer/Wiper Control

(Enclosed Cab Only) (Not Pictured)

Turn the knob counterclockwise to operate the wipers at

low speed; turn the knob clockwise to operate the

wipers at high speed. Pressing the knob activates the

windshield washer for as long as it is held in. The

windshield washer fluid tank is located to the rear of the

right console (early models) or it is the front tank next to

the seat support (later models).

Rear Window Control (Enclosed Cab Only)

(See Figure 5)

Loosen the knob and slide the pivot arm in the slot to

open the rear window. Tighten the knob to secure.

Reverse the procedure to close the window.

NOTE: The rear window can be used as an emergency

exit if necessary. Unscrew the knob from the stud, raise

the pivot arm over the stud, and push the window out.

Door Latches (Enclosed Cab Only)

(Not Pictured)

There are two door latches. The outside latch is a key

lockable pull to release type. The inside latch is a push

to release type.

Roof Washer/Wiper Control

(Enclosed Cab Only) (Not Pictured)

Turn the knob clockwise to operate the wiper. Pressing

the knob activates the roof washer for as long as it is

held in. The washer fluid tank is the rear tank located

next to the seat support.

Page 18 8042/10042 Rev. 10/99

Cab Heater (Enclosed Cab Only)

(See Figure 6)

The cab heater fan is only operable when the ignition

switch is in the RUN position. The heater fan switch is

located on the left side of the seat base (Figure 6). The

switch has three positions: OFF, LO, and HI.

NOTE: During warm weather operation, close the heater

line shut-off valve, located in the heater hose connection

at the engine. (Valve is located below engine alternator.)

Seat Belt (See Figure 6)

The seat belt has a slide on each strap that is used to

tighten and loosen the strap on each side of the buckle.

To shorten, pull bottom of loop toward buckle. To

lengthen, hold slide strap, pull slide toward buckle and

readjust buckle on loop. Buckle the two straps together

to fasten. Lift the buckle latch or press the center button

to unfasten the seat belt.

Operator's Seat Adjustment (See Figure 6)

The position and suspension of the operator's seat can

be adjusted.

Suspension — Turn the knob on the front of the seat to

adjust suspension stiffness for operator weight.

Height — Height adjustment is achieved by grasping the

bottom of the seat and raising upward into one of the

three detent positions. Once the seat has reached the

highest detent position, it can be lowered by raising the

seat all the way and lowering it fully. The seat can then

be raised, one detent at a time to the desired height.

Forward/Backward — Release the lever on the left side

of the seat and slide seat forward or backward to suit.

SEAT

BELT

FORWARD/

BACKWARD

LEVER

HEATER

CONTROL

CAB HEATER

SUSPENSION

ADJUST KNOB

Figure 6 OA0071

This manual suits for next models

1

Table of contents

Other Skytrak Lifting System manuals

Popular Lifting System manuals by other brands

Adaptive Engineering

Adaptive Engineering AX Operation and maintenance manual

Amico

Amico Go Lift Portable 450 Installation and operation instructions

Jungheinrich

Jungheinrich EFG 316 operating instructions

harbor master

harbor master Premier Verical Lift instructions

GSi

GSi PNEG-1295 installation manual

XPOtool

XPOtool 30120 user manual