Skytrak 6036 User manual

An Oshkosh Corporation Company

Service Manual

Models

6036, 6042, 8042,

10042 & 10054

SN 0160069719 to Present

including 0160065791, 0160065792, 0160065796,

0160065798, 0160065824, 0160065825,

0160065826, 0160069336, 0160069359,

0160069383, 0160069411, 0160069441,

0160069566, 0160069567 & 0160069568

31211015

Revised

July 31, 2017

EFFECTIVITY PAGE

6036, 6042, 8042, 10042, 10054 31211015 i

DATE REVISION DESCRIPTION

August 12, 2015 A Original Issue Of Manual

October 21, 2015 B Revise pages ii, 2-15, 2-17, 2-18, 2-20 thru 2-23, 3-49, 5-18, 7-12, 7-13, Revise pages

8-6 thru 8-29, 9-4, 9-5, Add pages 9-9, 9-13, 9-14, 9-23, 9-24, 9-27, 9-29, 9-30, Revise

page 9-31, Add pages 9-32 thru 34, 10-5, 10-7, 10-15, 10-17, 10-18.

January 04, 2017 C Revised pages 2-4 thru 2-78, 4-5, 4-8 thru 4-12, 7-8 thru 7-11, 8-6 thru 8-37, 8-43, 8-44,

9-4 thru 9-18, 9-20, 9-35 thru 9-94, 10-7

July 31, 2017 D Revised page 2-12, pages 7-9 thru 7-16, 9-43 thru 9-45

READ THIS FIRST

31211015 6036, 6042, 8042, 10042, 10054

ii

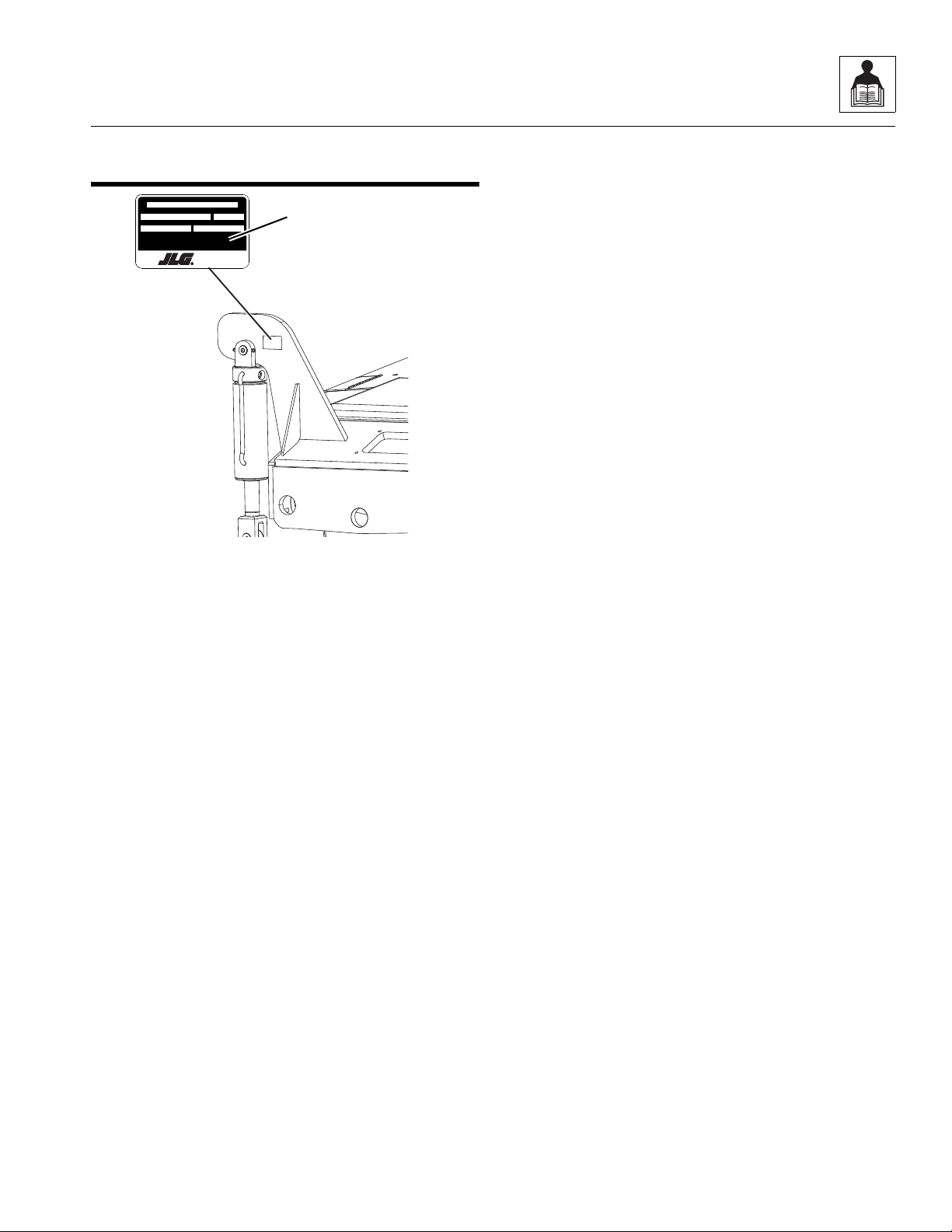

Modifications

Modifications to this machine may affect compliance with Industry Standards and/or Governmental Regulations. Any

modification must be approved by JLG.

Machine Configuration

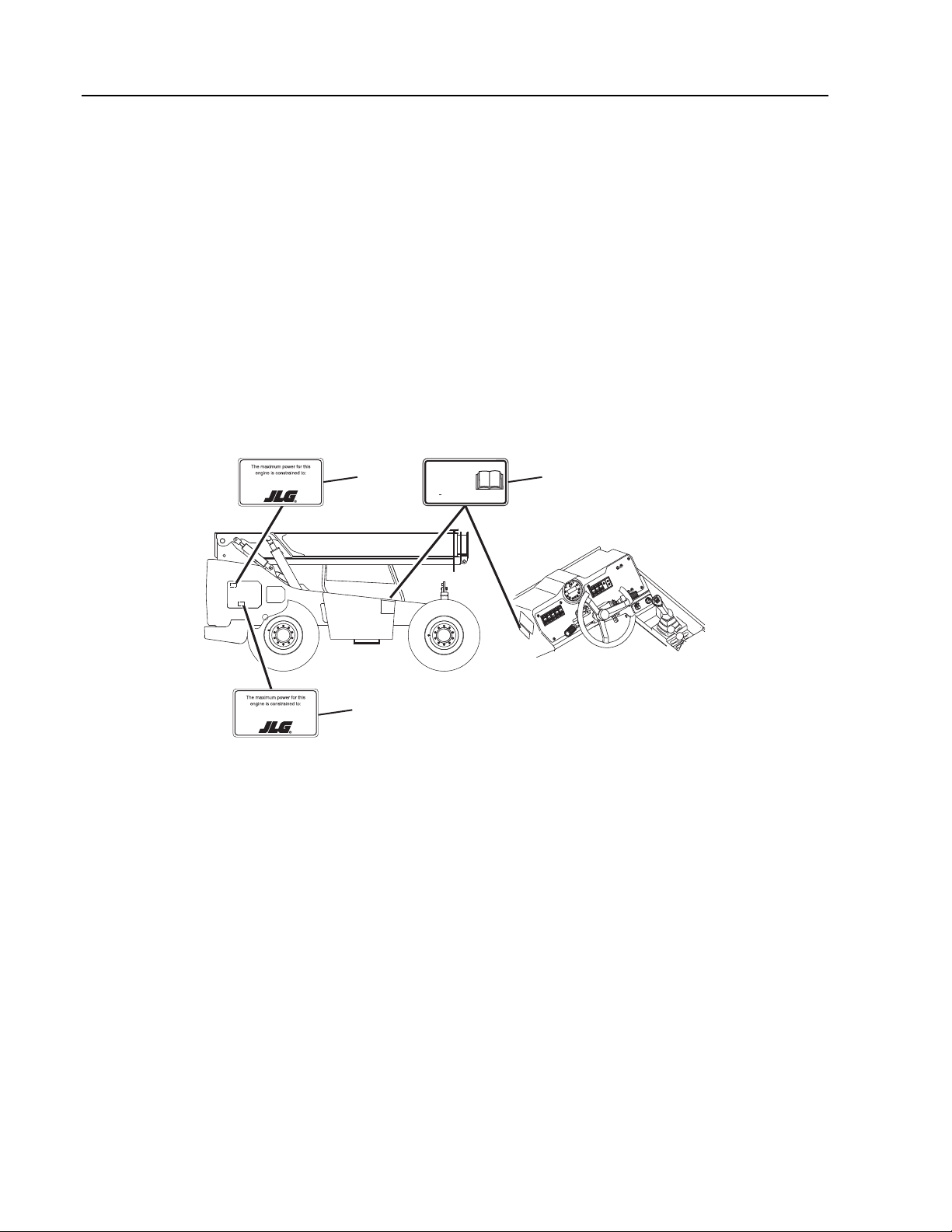

Two configurations of each machine are included in this manual. Determine if machine is equipped with Ultra Low Sulfur Fuel

Decal (1) as indicated below.

• If equipped with the Ultra Low Sulfur decal, all specific references to this machine configuration will be referred to as

Ultra Low Sulfur (ULS)from this point forward.

•Ifnot equipped with the Ultra Low Sulfur decal, all specific references to this machine configuration will be referred to as

Low Sulfur (LS) from this point forward.

Maximum engine power can be found on the decals (2) located on the inside of the side engine compartment doors.

O 5603H

ULTRA LOW

SULFUR DIESEL

FUEL ONLY

S < 15 mg/kg

1001125387 A

XXXhp (XXkW) @ XXXX RPM

XXXXXXXXXX_A

2 1

XXXhp (XXkW) @ XXXX RPM

XXXXXXXXXX_A

(8042, 10042, 10054)

(6036, 6042)

2

SECTION CONTENTS

Section Subject Page

i

6036, 6042, 8042, 10042, 10054 31211015

Section 1

Safety Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Operation & Safety Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Do Not Operate Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.6 Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.7 Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Section 2

General Information and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 Replacement Parts and Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 Fluid Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4 Fluid and Lubricant Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.5 Service and Maintenance Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.6 Lubrication Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.7 Thread Locking Compound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.8 Torque Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.9 Hydraulic Connection Assembly and Torque Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Section 3

Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 Boom System Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2 Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 Boom System - Three Section (6036, 6042, 8042 & 10042) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.4 Boom Assembly Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.5 Boom System - Four Section (10054) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.6 Boom Assembly Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.7 Boom Extend and Retract Chains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

3.8 Boom Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

3.9 Quick Coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3.10 Forks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3.11 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

Section 4

Cab and Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 Operator Cab and Covers Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Operator Cab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 Cab Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.4 Cab Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4.5 Cab Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Section Subject Page

ii 31211015 6036, 6042, 8042, 10042, 10054

Section 5

Axles, Drive Shafts, Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1 Axle, Drive Shaft and Wheel Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2 General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3 Axle Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4 Axle Assembly and Drive Shaft Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5.5 Drive Shafts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.6 Wheels and Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.7 Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

5.8 Towing a Disabled Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Section 6

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.1 Transmission Assembly Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.2 Transmission Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.3 Transmission Specifications and Maintenance Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.4 Transmission Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

6.5 Transmission Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Section 7

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.2 Engine Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.3 Specifications and Maintenance Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.4 Engine Cooling System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.5 Engine Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.6 Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.7 Engine Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-17

7.8 Air Cleaner Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

7.9 Engine Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

7.10 Isolation Coupler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Section 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8.1 Hydraulic Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.3 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

8.4 Hydraulic Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.5 Hydraulic Pressure Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

8.6 Hydraulic Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

8.7 Hydraulic System Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39

8.8 Valves and Manifolds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

8.9 Hydraulic Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-51

Section Subject Page

iii

6036, 6042, 8042, 10042, 10054 31211015

Section 9

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9.1 Electrical Component Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.3 Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.4 Fuses and Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9.5 Electrical System Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

9.6 Dielectric Grease Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

9.7 Engine Start Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

9.8 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

9.9 Charging Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

9.10 Window Wiper/Washer Windshield Wiper Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

9.11 Cab Heater and Fan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

9.12 Solenoids, Sensors and Senders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

9.13 Display Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

9.14 Dash Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

9.15 Machine Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

9.16 Analyzer Software Accessibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

9.17 Telematics Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-43

9.18 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-50

9.19 Machine Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-51

9.20 Engine Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-55

Section 10

Stabil-TRAK™ System and Boom Interlock System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10.1 Stabil-TRAK™ System Component Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

10.2 Boom Extend Interlock System Component Terminology (10054 Only) . . . . . . . . . . . . . . . . . . . . . 10-4

10.3 Stabil-TRAK™ Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

10.4 Stabil-TRAK™ Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10.5 Boom Extend Interlock System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

10.6 Boom Extend Interlock System Operation (10054 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

10.7 Stabil-TRAK™ System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

10.8 Stabil-TRAK™ Electrical Circuit Operation and Troubleshooting (6042/8042/10042) . . . . . . . . . 10-15

10.9 Stabil-TRAK™ and Boom Interlock Electrical Circuit Operation and Troubleshooting (10054) . 10-19

10.10 Boom/Outrigger Interlock System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-24

10.11 Stabil-TRAK™ Hydraulic Circuit Operation and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-26

10.12 Boom Extend System Hydraulic Circuit Operation and Troubleshooting . . . . . . . . . . . . . . . . . . . . 10-42

Section Subject Page

iv 31211015 6036, 6042, 8042, 10042, 10054

1-1

6036, 6042, 8042, 10042, 10054 31211015

Section 1

Safety Practices

Contents

PARAGRAPH TITLE PAGE

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Operation & Safety Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 Do Not Operate Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5.1 Safety Alert System and Signal Words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.6 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6.1 Personal Hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6.2 Equipment Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6.3 General Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.6.4 Operational Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.7 Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Safety Practices

1-2 31211015 6036, 6042, 8042, 10042, 10054

1.1 INTRODUCTION

This service manual provides general directions for

accomplishing service and repair procedures. Following the

procedures in this manual will help assure safety and

equipment reliability.

Read, understand and follow the information in this manual,

and obey all locally approved safety practices, procedures,

rules, codes, regulations and laws.

These instructions cannot cover all details or variations in the

equipment, procedures, or processes described, nor provide

directions for meeting every possible contingency during

operation, maintenance, or testing. When additional

information is desired consult your local authorized service

distributor.

Many factors contribute to unsafe conditions: carelessness,

fatigue, overload, inattentiveness, unfamiliarity, even drugs

and alcohol, among others. For optimal safety, encourage

everyone to think, and to act, safely.

Appropriate service methods and proper repair procedures

are essential for the safety of the individual doing the work,

for the safety of the operator, and for the safe, reliable

operation of the machine. All references to the right side, left

side, front and rear are given from the operator seat looking in

a forward direction.

Supplementary information is available from JLG in the form

of Service Bulletins, Service Campaigns, Service Training

Schools, the manufacturer website, other literature, and

through updates to the manual itself.

1.2 DISCLAIMER

All information in this manual is based on the latest product

information available at the time of publication. The

manufacturer reserves the right to make changes and

improvements to its products, and to discontinue the

manufacture of any product, at its discretion at any time

without public notice or obligation.

1.3 OPERATION & SAFETY MANUAL

The mechanic must not operate the machine until the

Operation & Safety Manual has been read and understood,

training has been accomplished and operation of the

machine has been completed under the supervision of an

experienced and qualified operator.

An Operation & Safety Manual is supplied with each machine

and must be kept in the manual holder located in the cab. In

the event that the Operation & Safety Manual is missing,

consult your local authorized service distributor before

proceeding.

1.4 DO NOT OPERATE TAGS

Place Do Not Operate Tags on the ignition key switch and the

steering wheel before attempting to perform any service or

maintenance. Remove key and disconnect battery leads.

1.5 SAFETY INFORMATION

To avoid possible death or injury, carefully read, understand

and comply with all safety messages.

In the event of an accident, know where to obtain medical

assistance and how to use a first-aid kit and fire extinguisher/

fire suppression system. Keep emergency telephone

numbers (fire department, ambulance, rescue squad/

paramedics, police department, etc.) nearby. If working

alone, check with another person routinely to help assure

personal safety.

1.5.1 Safety Alert System and Signal Words

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

DANGER

WARNING

CAUTION

Safety Practices

1-3

6036, 6042, 8042, 10042, 10054 31211015

1.6 SAFETY INSTRUCTIONS

Following are general safety statements to consider before

performing maintenance procedures on the telehandler.

Additional statements related to specific tasks and

procedures are located throughout this manual and are

listed prior to any work instructions to provide safety

information before the potential of a hazard occurs.

For all safety messages, carefully read, understand and follow

the instructions before proceeding.

1.6.1 Personal Hazards

PERSONAL SAFETY GEAR: Wear all the protective clothing

and personal safety gear necessary to perform the job safely.

This might include heavy gloves, safety glasses or goggles,

filter mask or respirator, safety shoes or a hard hat.

LIFTING: NEVER lift a heavy object without the help of at

least one assistant or a suitable sling and hoist.

1.6.2 Equipment Hazards

LIFTING OF EQUIPMENT: Before using any lifting equipment

(chains, slings, brackets, hooks, etc.), verify that it is of the

proper capacity, in good working order, and is properly

attached.

NEVER stand or otherwise become positioned under a

suspended load or under raised equipment. The load or

equipment could fall or tip.

DO NOT use a hoist, jack or jack stands only to support

equipment. Always support equipment with the proper

capacity blocks or stands properly rated for the load.

HAND TOOLS: Always use the proper tool for the job; keep

tools clean and in good working order, and use special

service tools only as recommended.

1.6.3 General Hazards

SOLVENTS: Only use approved solvents that are known to be

safe for use.

HOUSEKEEPING: Keep the work area and operator cab clean,

and remove all hazards (debris, oil, tools, etc.).

FIRST AID: Immediately clean, dress and report all injuries

(cuts, abrasions, burns, etc.), no matter how minor the injury

may seem. Know the location of a First Aid Kit, and know how

to use it.

CLEANLINESS: Wear eye protection, and clean all

components with a high-pressure or steam cleaner before

attempting service.

When removing hydraulic components, plug hose ends and

connections to prevent excess leakage and contamination.

Place a suitable catch basin beneath the machine to capture

fluid run-off.

It is good practice to avoid pressure-washing electrical/

electronic components. In the event pressure-washing the

machine is needed, ensure the machine is shut down before

pressure-washing. Should pressure-washing be utilized to

wash areas containing electrical/electronic components, it is

recommended a maximum pressure of 750 psi (52 bar) at a

minimum distance of 12 in (30,5 cm) away from these

components. If electrical/electronic components are

sprayed, spraying must not be direct and for brief time

periods to avoid heavy saturation.

Check and obey all Federal, State and/or Local regulations

regarding waste storage, disposal and recycling.

Safety Practices

1-4 31211015 6036, 6042, 8042, 10042, 10054

1.6.4 Operational Hazards

ENGINE: Stop the engine before performing any service

unless specifically instructed otherwise.

VENTILATION: Avoid prolonged engine operation in

enclosed areas without adequate ventilation.

SOFT SURFACES AND SLOPES: NEVER work on a machine

that is parked on a soft surface or slope. The machine must be

on a hard level surface, with the wheels blocked before

performing any service.

FLUID TEMPERATURE: NEVER work on a machine when the

engine, cooling or hydraulic systems are hot. Hot

components and fluids can cause severe burns. Allow

systems to cool before proceeding.

FLUID PRESSURE: Before loosening any hydraulic or diesel

fuel component, hose or tube, turn the engine OFF. Wear

heavy, protective gloves and eye protection. NEVER check

for leaks using any part of your body; use a piece of

cardboard or wood instead. If injured, seek medical attention

immediately. Diesel fluid leaking under pressure can

explode. Hydraulic fluid and diesel fuel leaking under

pressure can penetrate the skin, cause infection, gangrene

and other serious personal injury.

Engine fuel lines are pressurized. DO NOT attempt repairs

unless specific training has been completed. Refer to the

engine manufacturers’ manual for specific details

concerning the fuel system.

Relieve all pressure before disconnecting any component,

part, line or hose. Slowly loosen parts and allow release of

residual pressure before removing any part or component.

Before starting the engine or applying pressure, use

components, parts, hoses and pipes that are in good

condition, connected properly and are tightened to the

proper torque. Capture fluid in an appropriate container and

dispose of in accordance with prevailing environmental

regulations.

COOLANT SYSTEM CAP: The cooling system is under

pressure, and escaping coolant can cause severe burns and

eye injury. To prevent personal injury, NEVER remove the

radiator cap while the cooling system is hot. Wear safety

glasses. Turn the radiator cap to the first stop and allow

pressure to escape before removing the cap completely.

Failure to follow the safety practices could result in death or

serious injury.

Properly disconnect battery(s) prior to service the fuel or

hydraulic systems.

FLUID FLAMABILTITY: DO NOT service the fuel or hydraulic

systems near an open flame, sparks or smoking materials.

NEVER drain or store fluids in an open container. Engine fuel

and hydraulic fluid are flammable and can cause a fire and/or

explosion.

DO NOT mix gasoline or alcohol with diesel fuel. The mixture

can cause an explosion.

PRESSURE TESTING: When conducting any test, only use test

equipment that is correctly calibrated and in good condition.

Use the correct equipment in the proper manner, and make

changes or repairs as indicated by the test procedure to

achieve the desired result.

LEAVING MACHINE: Lower the forks or attachment to the

ground before leaving the machine.

TIRES: Always keep tires inflated to the proper pressure to

help prevent tipover. DO NOT over-inflate tires.

NEVER use mismatched tire types, sizes or ply ratings.

Always use matched sets according to machine

specifications.

MAJOR COMPONENTS: Never alter, remove, or substitute any

items such as counterweights, tires, batteries or other items

that may reduce or affect the overall weight or stability of the

machine.

BATTERY: DO NOT charge a frozen battery.Charging a frozen

battery may cause it to explode. Allow the battery to thaw

before jump-starting or connecting a battery charger.

1.7 SAFETY DECALS

Check that all safety decals are present and readable on the

machine. Refer to the Operation & Safety Manual supplied

with machine for information.

2-1

6036, 6042, 8042, 10042, 10054 31211015

Section 2

General Information and Specifications

Contents

PARAGRAPH TITLE PAGE

2.1 Replacement Parts and Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.1 Travel Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.2 Hydraulic Cylinder Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.3 Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.4 Engine Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.5 Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3 Fluid Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.4 Fluid and Lubricant Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2.5 Service and Maintenance Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5.1 Every 10 Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5.2 First 50 Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5.3 Every 50 Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5.4 First 250 Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.5.5 Every 250 Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.6 First 500 Hours or 1 Year. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.7 Every 500 Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.8 Every 750 Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.5.9 Every 1000 Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.5.10 Every 1500 Hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.5.11 Every 2000 Hours or 2 Year . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.5.12 Every 4000 Hours or 3 Years . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.6 Lubrication Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.6.1 50 Hour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.6.2 250 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.6.3 1000 Hour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.7 Thread Locking Compound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

2.8 Torque Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.8.1 SAE Fastener Torque Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.8.2 Metric Fastener Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

General Information and Specifications

2-2 31211015 6036, 6042, 8042, 10042, 10054

2.9 Hydraulic Connection Assembly and Torque Specification . . . . . . . . . . . . . . . . . . . . . . . 2-31

2.9.1 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

2.9.2 Assembly Instructions for American Standard Pipe Thread Tapered Connections 2-33

2.9.3 Assembly Instructions for British Standard Pipe Thread Tapered Connections. 2-35

2.9.4 Assembly Instructions for 37° (JIC) Flare Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2.9.5 Assembly Instructions for 45° SAE Flare Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

2.9.6 Assembly Instructions for O-Ring Face Seal (ORFS) Fittings. . . . . . . . . . . . . . . . . . . 2-40

2.9.7 Assembly Instructions for DIN 24° Flare Bite Type Fittings (MBTL and MBTS) . . 2-42

2.9.8 Assembly Instructions for Bulkhead (BH) Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

2.9.9 Assembly Instructions for O-Ring Boss (ORB) Fittings . . . . . . . . . . . . . . . . . . . . . . . . 2-48

2.9.10 Assembly Instructions for Adjustable Port End Metric Fittings . . . . . . . . . . . . . . . . 2-56

2.9.11 Assembly Instructions for Metric ISO 6149 Port Assembly Stud Ends . . . . . . . . . 2-64

2.9.12 Assembly Instructions for Adjustable Port End (BSPP) Fittings . . . . . . . . . . . . . . . . 2-66

2.9.13 Assembly Instructions for Flange Connections (FL61 and FL62) . . . . . . . . . . . . . . 2-74

2.9.14 Double Wrench Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-77

2.9.15 FFWR and TFFT Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-78

2.9.16 Adjustable Stud End Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

2.9.17 O-ring Installation (Replacement) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-78

General Information and Specifications

2-3

6036, 6042, 8042, 10042, 10054 31211015

2.1 REPLACEMENT PARTS AND WARRANTY

INFORMATION

Before ordering parts or initiating service inquiries, make

note of the machine serial number. The machine serial

number plate (1) is located as indicated in the figure.

Note: The replacement of any part on this machine with any

other than JLG authorized replacement parts can adversely

affect the performance, durability, or safety of the machine,

and will void the warranty. JLG disclaims liability for any claims

or damages, whether regarding property damage, personal

injury or death arising out of the use of unauthorized

replacement parts.

A warranty registration form must be filled out by the JLG

distributor, signed by the purchaser and returned to JLG

when the machine is sold and/or put into use.

Registration activates the warranty period and helps to

assure that warranty claims are promptly processed. To

guarantee full warranty service, verify that the distributor has

returned the business reply card of the warranty registration

form to JLG.

1001154575A

* Refer to load capacity chart for truck with attachment, and individual load ratings stamped

on forks, if equipped. Usel owest capacity of all ratings.

As released from factory this truck meets design specifications i n ANSI \ IT SDF B56.6-2011

Manufactured by

JLG Industries Inc.

McCo nnell sburg , PA

17233-9533 USA

Maximum Weight Without Attachment s (lbs/kg) Maximum Capacity (lbs/kg)*

Seri al Numb er Year OfManufacture

Model

MAQ1570

1

General Information and Specifications

2-4 31211015 6036, 6042, 8042, 10042, 10054

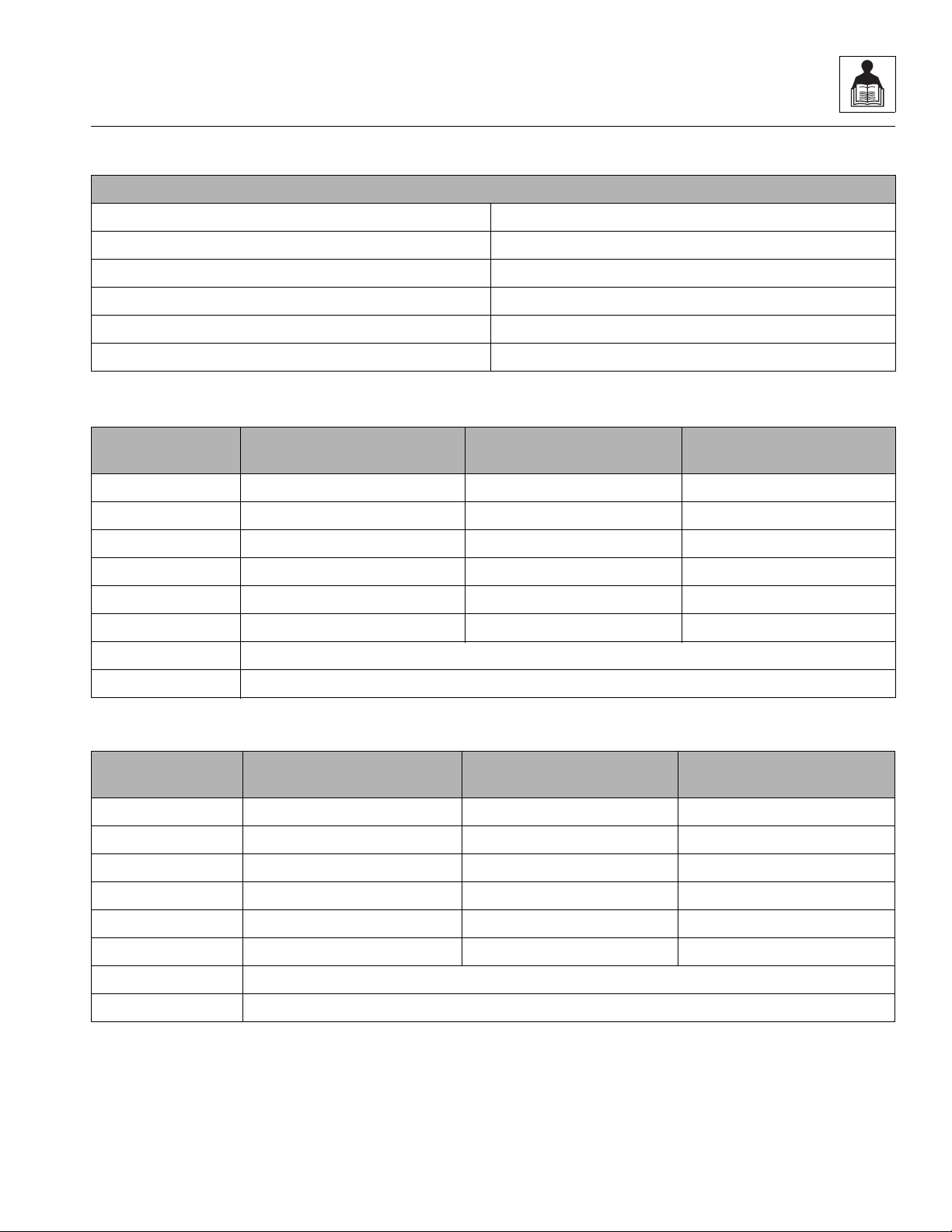

2.2 SPECIFICATIONS

2.2.1 Travel Speeds

2.2.2 Hydraulic Cylinder Performance

Note: Machine with no attachment or load, engine at full throttle, hydraulic oil above 130° F (54° C) minimum, engine at operating

temperature.

TRANSMISSION 6036 6042 8042 10042 /10054

First Gear 3.6 mph

(5,8 km/hr)

3.6 mph

(5,8 km/hr)

3.6 mph

(5,8 km/hr)

3.7 mph

(6,0 km/hr)

Second Gear 6.1 mph

(9,8 km/hr)

6.1 mph

(9,8 km/hr)

5.8 mph

(9,3 km/hr)

6.1 mph

(9,8 km/hr)

Third Gear 14.5 mph

(23,3 km/hr)

14.5 mph

(23,3 km/hr)

13.8 mph

(23 km/hr)

14.5 mph

(23,3 km/hr)

Fourth Gear 19.5 mph

(31.4 km/hr)

19 mph

(30,6 km/hr)

19.0 mph

(30,6 km/hr)

20.0 mph

(32,2 km/hr)

FUNCTION

APPROXIMATE TIMES (seconds)

6036 6042 8042 10042 10054

Boom Extend Less than 14.0 Less than 18.0 Less than 17.0 Less than 17.0 Less than 18.0

Boom Retract Less than 15.0 Less than 18.0 Less than 16.0 Less than 16.0 Less than 16.0

Boom Lift Retracted Less than 12.0 Less than 15.0 Less than 17.0 Less than 17.0 Less than 17.0

Boom Lower Retracted Less than 10.0 Less than 11.0 Less than 17.0 Less than 17.0 Less than 15.0

Attachment Tilt - Up 5 5 7.5 7.5 8

Attachment Tilt - Down 6 6 8 8 10

Frame Level Left to Right

with Boom Down 12 - 14 12.0 - 14.0 12.0 - 14.0 12.0 - 14.0 12.0 - 14.0

Frame Level Left to Right

with Boom Above 40°and

Emergency Brake

Engaged

— 23.0 - 33.0 23.0 - 33.0 23.0 - 33.0 23.0 - 33.0

Frame Level Right to Left

with Boom Down 12 - 14 12.0 - 14.0 12.0 - 14.0 12.0 - 14.0 12.0 - 14.0

Frame Level Right to Left

with Boom Above 40°and

Emergency Brake

Engaged

— 26.0 - 52.0 26.0 - 52.0 26.0 - 52.0 26.0 - 52.0

Outrigger - Left or Right,

UP or DOWN — — — 4.0 - 9.0 4.0 - 9.0

Outrigger - Left and Right,

UP or DOWN — — — 4.0 - 10.0 4.0 - 10.0

General Information and Specifications

2-5

6036, 6042, 8042, 10042, 10054 31211015

2.2.3 Electrical System

2.2.4 Engine Performance Specifications

Note: No adjustment of the throttle is required. The engine Low Idle and High Idle are controlled by the engine ECM and cannot be

adjusted without Cummins programing tools.

Battery

Type, Rating 12 BCI, Negative (-) Ground, Maintenance Free

Quantity 1

Cold Cranking Amps 3.8 Liter - 950 CCA @ 0° F (-18° C)

Reserve Capacity 205 Minutes @ 80° F (27° C)

Group/Series Group 31 - 950

Alternator 12V, 135 Amps

Description 6036 & 6042

If Equipped for ULS

6036 & 6042

If Equipped for LS

6036 & 6042

If Equipped w/ 74hp (55kW)

Engine Make/Model Cummins Turbo QSF3.8 Cummins Turbo QSF3.8 Cummins Turbo QSF3.8

Displacement 232 in3(3,8 liters) 232 in3(3,8 liters) 232 in3(3,8 liters)

Low Idle (no load) 1000 rpm 1000 rpm 1000 rpm

High Idle (no load) 2500 rpm 2500 rpm 2500 rpm

Horsepower 85 hp (63 kW) @ 2500 rpm 85 hp (63 kW) @ 2500 rpm 74 hp (55 kW) @ 2500 rpm

Peak Torque 340 lb-ft (461 Nm) @ 1400 rpm 340 lb-ft (461 Nm) @ 1400 rpm 295 lb-ft (400 Nm) @ 1300 rpm

Fuel Delivery High Pressure Common Rail (HPCR) Fuel Injection

Air Cleaner Dry Type, Replaceable Primary and Safety Elements

Description 8042, 10042 & 10054

If Equipped for ULS

8042, 10042 & 10054

If Equipped for LS

8042, 10042 & 10054

If Equipped w/ 74hp (55kW)

Engine Make/Model Cummins Turbo QSF3.8 Cummins Turbo QSF3.8 Cummins Turbo QSF3.8

Displacement 232 in3(3,8 liters) 232 in3(3,8 liters) 232 in3(3,8 liters)

Low Idle 1000 rpm 1000 rpm 1000 rpm

High Idle 2500 rpm 2500 rpm 2500 rpm

Horsepower 110 hp (82 kW) @ 2500 rpm 110 hp (82 kW) @ 2500 rpm 74 hp (55 kW) @ 2500 rpm

Peak Torque 348 lb-ft (472 Nm) @ 1500 rpm 348 lb-ft (472 Nm) @ 1500 rpm 295 lb-ft (400 Nm) @ 1300 rpm

Fuel Delivery High Pressure Common Rail (HPCR) Fuel Injection

Air Cleaner Dry Type, Replaceable Primary and Safety Elements

General Information and Specifications

2-6 31211015 6036, 6042, 8042, 10042, 10054

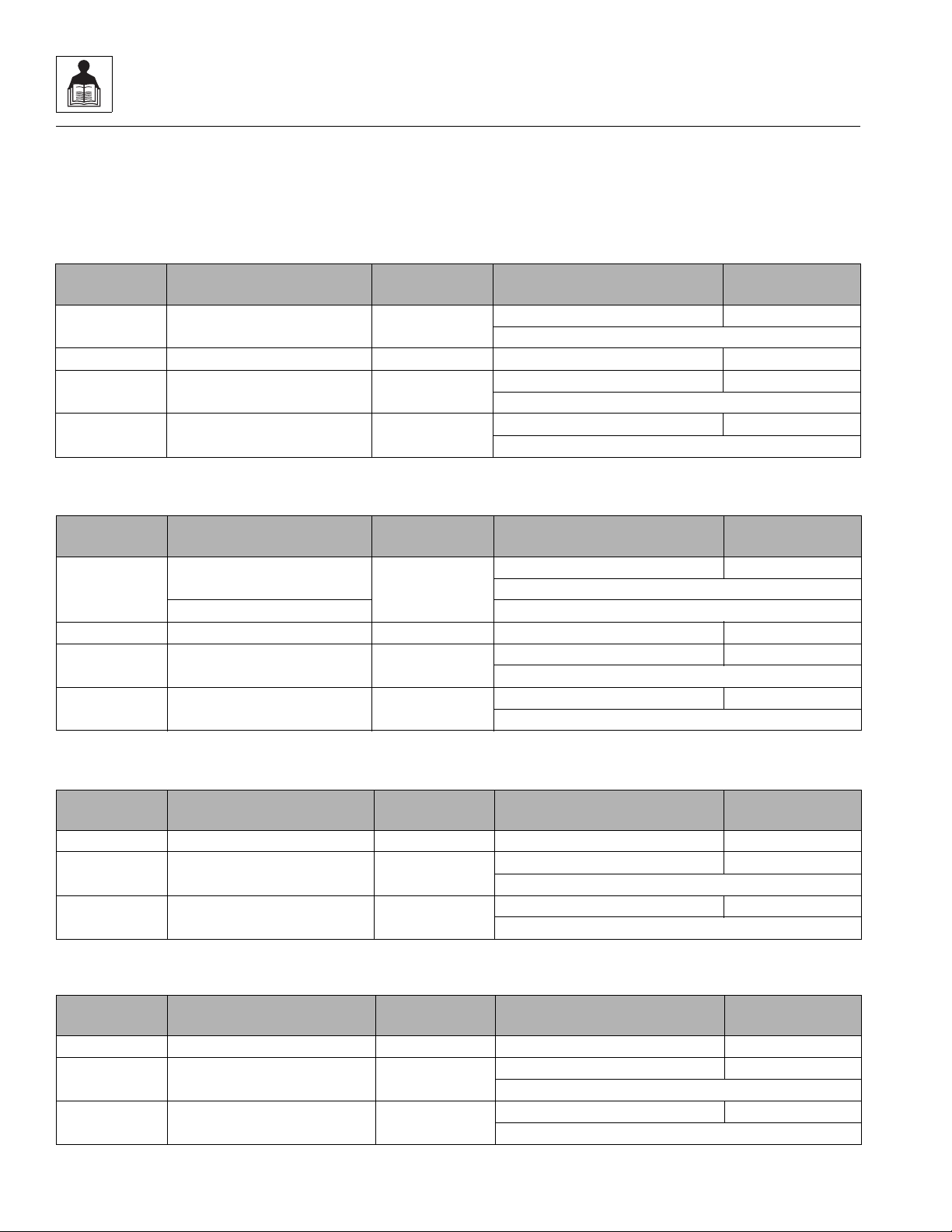

2.2.5 Tires

Note: Standard wheel lug nut torque is 350 - 400 lb-ft (474 - 542 Nm).

Note: Pressure for foam filled tires are for initial fill ONLY.

a. 6036

b. 6042

c. 8042

d. 10042 & 10054

Size Tire Type Minimum Ply/

Star Rating

Fill Type Pressure

13.0 x 24 G-2/L2 Bias Ply Traction 12 Ply Pneumatic 70 psi (4,8 bar)

Foam - Approx 542 lb (246 kg)

13.0 x 24 Solid Tires NA NA NA

15.5 x 25 G2/L-2 Bias Ply Traction 12 Ply Pneumatic 70 psi (4,8 bar)

Foam - Approx 600 lb (272 kg)

370/75x28 DuraForce 14 Ply Pneumatic 76 psi (5,2 bar)

Foam - Approx 464 lb (210 kg)

Size Tire Type Minimum Ply/

Star Rating

Fill Type Pressure

13.0 x 24 G-2/L-2 Bias Ply Traction 12 Ply

Pneumatic 70 psi (4,8 bar)

Foam - Approx 542 lb (246 kg)

TG/G-3 Bias Ply Grader Foam - Approx 542 lb (246 kg)

13.0 x 24 Solid Tires NA NA NA

15.5 x 25 G-2/L-2 Bias Ply Traction 12 Ply Pneumatic 70 psi (4,8 bar)

Foam - Approx 600 lb (272 kg)

370/75x28 DuraForce 14 Ply Pneumatic 76 psi (5,2 bar)

Foam - Approx 464 lb (210 kg)

Size Tire Type Minimum Ply/

Star Rating

Fill Type Pressure

13.0 x 24 Solid Tires NA NA NA

15.5 x 25 G-2/L-2 Bias Ply Traction 12 Ply Pneumatic 70 psi (4,8 bar)

Foam - Approx 600 lb (272 kg)

370/75x28 DuraForce 14 Ply Pneumatic 76 psi (5,2 bar)

Foam - Approx 464 lb (210 kg)

Size Tire Type Minimum Ply/

Star Rating

Fill Type Pressure

14.0 x 24 Solid Tires NA NA NA

17.50 x 25 G-2/L-2 Bias Ply Traction 12 Ply Pneumatic 70 psi (4,8 bar)

Foam - Approx 785 lb (356 kg)

400/75x28 DuraForce 14 Ply Pneumatic 76 psi (5,2 bar)

Foam - Approx 570 lb (259 kg)

General Information and Specifications

2-7

6036, 6042, 8042, 10042, 10054 31211015

2.3 FLUID SPECIFICATIONS

If Equipped for ULS

Note: *Friction Modifier may be added to axle differentials, see Section 2.4, “Fluid and Lubricant Capacities”.

**See Note on page 2-12 for details.

Compartment or System Type and Classification Viscosities

Ambient Temperature

Range

°F °C

Min Max Min Max

Engine Crankcase

API CJ-4 Plus

CES-20081

Fully Synthetic**

SAE 0W-30 -12 114 -24 45

SAE 5W-30 15 114 -10 45

SAE 10W-30 10 104 -24 40

SAE 15W-40 -40 104 -40 40

Transmission and Transfer Case

MobilFluid 424 10W-30 15 120 -10 49

MobilFluidLT 75W-80 -2015-29-10

Refer to ZF TE-ML-03 for additional fluids.

Axle Differential and Wheel End

MobilFluid 424* 10W-30 15 120 -10 49

Mobilfluid LT* 75W-80 -20 15 -29 -10

API GL4 with LS Additives

or

API GL5 with LS Additives

75W-90 -20 114 -29 45

Hydraulic System MobilFluid 424 10W-30 15 120 -10 49

Exxon Univis HVI 26 -20 120 -29 49

Boom Wear Pad Grease Extreme Pressure Grease NLGI Grade 000 -31 122 -35 50

Grease Fittings Extreme Pressure Grease

NLGI Grade 2 EP

or

NLGI Grade 3 EP

with Moly

Additive

5122-1550

Boom Chain Lubricant Gear Oil 80W-90 -40 115 -40 46

Engine Coolant Ethylene Glycol

and Water

50/50 Mix Standard

60/40 Mix Cold Weather

Fuel

EN590

ASTM D975 Grade 2-D

ASTM D975 Grade 1-D

(Maximum B5 Biodiesel)

Ultra Low Sulfur

(S <15 mg/kg)

Diesel Exhaust Fluid (DEF)

85 hp (63 kW) or 110 hp (82 kW) ISO22241-1 32.5% Urea

Brake Fluid

(SN 0160074878 to Present) Mobil ATF-D/M -20 114 -29 45

Air Conditioning Refrigerant R-134A Tetrafluoroethane

General Information and Specifications

2-8 31211015 6036, 6042, 8042, 10042, 10054

If Equipped for LS

Note: *Friction Modifier may be added to axle differentials, see Section 2.4, “Fluid and Lubricant Capacities”.

Compartment or System Type and Classification Viscosities

Ambient

Temperature Range

°F °C

Min Max Min Max

Engine Crankcase API CI-4 Multigrade

CES-20078

SAE 0W-30 -20 0 -29 -18

SAE 5W-30 -15 70 -26 21

SAE 10W-30 -9 70 -22 21

SAE 15W-40 5 120 -15 49

Transmission and Transfer Case

Mobilfluid 424 10W-30 15 120 -10 49

MobilFluid LT 75W-80 -20 15 -29 -10

Refer to ZF TE-ML-03 for additional fluids.

Axle Differential and Wheel End

MobilFluid 424 10W-30 15 120 -10 49

Mobilfluid LT* 75W-80 -20 15 -29 -10

API GL4 with LS Additives

or

API GL5 with LS Additives

75W-90 -20 114 -29 45

Hydraulic System MobilFluid 424 10W-30 15 120 -10 49

Exxon Univis HVI 26 -20 120 -29 49

Boom Wear Pad Grease Extreme Pressure Grease NLGI Grade 000 -31 122 -35 50

Grease Fittings Extreme Pressure Grease

NLGI Grade 2 EP

or

NLGI Grade 3 EP

with Moly

Additive

5122-1550

Boom Chain Lubricant Gear Oil 80W-90 -40 115 -40 46

Engine Coolant Ethylene Glycol

and Water

50/50 Mix Standard

60/40 Mix Cold Weather

Fuel

EN590

ASTM D975 Grade 2-D

ASTM D975 Grade 1-D

(Maximum B5 Biodiesel)

Low Sulfur

(S < 500 mg/kg)

Brake Fluid

(SN 0160074878 to Present) Mobil ATF-D/M -20 114 -29 45

Air Conditioning Refrigerant R-134A Tetrafluoroethane

This manual suits for next models

4

Table of contents

Other Skytrak Lifting System manuals

Popular Lifting System manuals by other brands

Plymovent

Plymovent Balancer Series user manual

Tractel Group

Tractel Group pakrol 1 Operating and maintenance instructions

SICE

SICE PT 150 E Operator's manual

Safety Clamps

Safety Clamps VL-BC Operation, maintenance, and repair manual

Monument

Monument 1043J instructions

Monzana

Monzana Deuba DBWH001 instructions

stellar labs

stellar labs 108-14-32 owner's manual

BYD

BYD ECB16 Operator's manual

Sirio Antenne

Sirio Antenne SRS1351 - I user manual

morse

morse 515M-T-114 Operator's manual

twin busch

twin busch TW 125 M Installation, operation and maintenance manual

Proactive

Proactive Protekt Take-A-Long 33400P owner's manual