TWIN BUSCH GmbH

Technical changes for purposes of a technical advancement as well as deviation in colour, errors and printing mistakes are reserved.

page 7 of 45

3. Installation

3.1 Before Installation

3.1.1 Needed tools and equipment

Appropriate lifting equipment

Hydraulic oil HLP 32

Hammer drill

Set of spanners (17, 19, 22) sockets, screw drivers and Allen keys

Hammer, pliers

3.1.2 Check list - Attachment 1 (Pack list)

Unpack all parts and check that nothing is missing or damaged using the attachment 1 as a reference.

Should anything be missing or damaged do not hesitate to contact us, should any parts be missing or damaged and the lift

is assembled, we will take no responsibility for damage or injury.

3.1.3 Ground condition

The lift should be mounted on a smooth flat surface with a hardness of approximately 3000 psi, with a tolerance of 5mm

and a thickness of at least 200mm. If new concrete is laid, 28 days should be allowed for hardening.

Safety precautions before Installation

3.2.1 Check that the posts are parallel and are vertical to the floor.

3.2.2 All hydraulic, pneumatic and electrical connections should be checked for leakage and tightness before the lift is

used.

3.2.3 All screws and bolts should be checked for tightness.

3.2.4 Do not use a vehicle on the lift for the first trial.

3.3 Installation

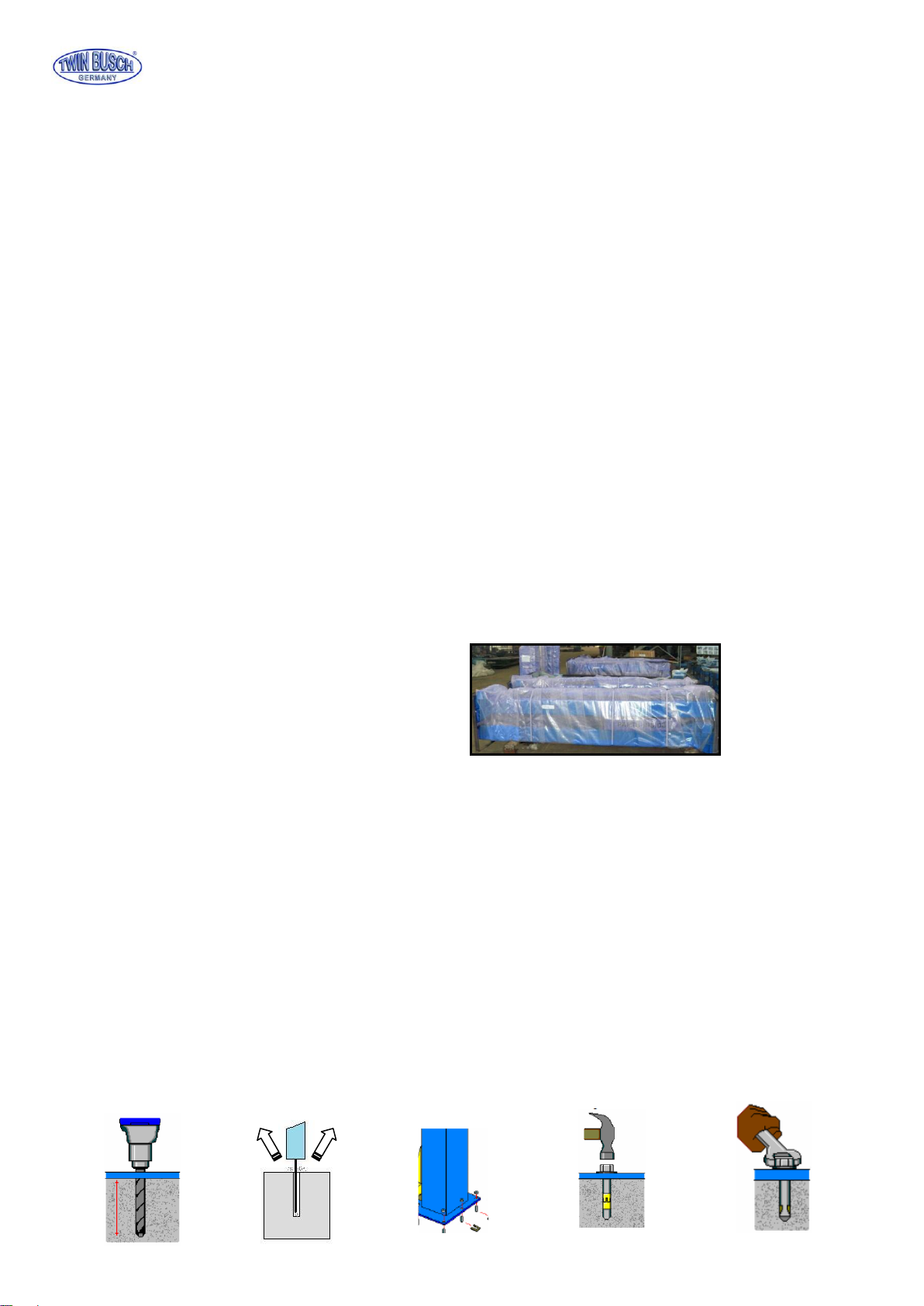

Step 1: Remove from the packing and prepare the spare parts and covers needed.

(This step is very important and the information in the diagram should be read and understood before

operating).

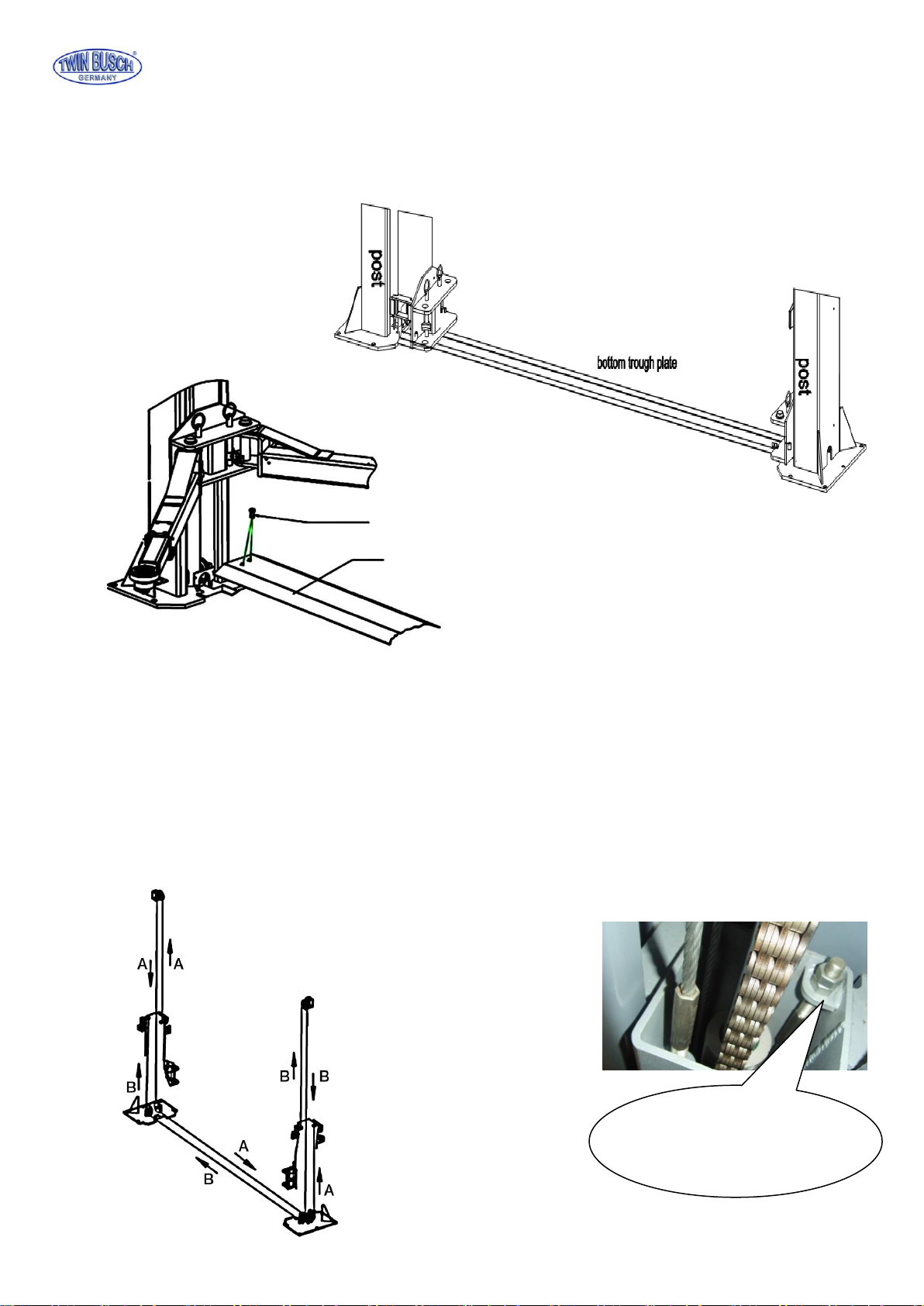

Step 2: With the aid of a forklift remove the supports between the two posts, and then remove the frame screws

Attention: Please take care that the posts cannot fall or slip as this could cause injury or damage.

Step 3: After removing the first post place a support under the other post and then remove the screws.

Step 4: Fit the post extensions and then mount the cross beam. (Make sure all bolts are tightened)

Step 5: Erect the posts, main post first and then the assistant post.

1. Drill anchor holes for each plug bolts on the ground with an electrical drill. Make sure to drill vertically.

2. After holes have been drilled, remove thoroughly the debris and dust in them and ascertain that the posts

stay upon the circle previously drew by chalk.

Step 6: 1. Drill the holes for the floor anchors making sure that the holes are vertical.

2. Remove all dust and particles and place the anchors in the holes, use a hammer to drive in the bolts.

3. Tighten to recommended torque.