5086-2-2018

Page 2

Contents

Please read this installation manual thoroughly, before you start

installing your Steering Power hydraulic steering kit.

Sleipner Motor AS will not take any responsibility for products that

are not installed in accordance with the instructions given in this

installation manual.

Important user precautions and procedures............................................................................................. 3

System layout, Flybridge (Twin helm) ...................................................................................................... 4

System layout, Non - Flybridge (Single helm) ......................................................................................... 5

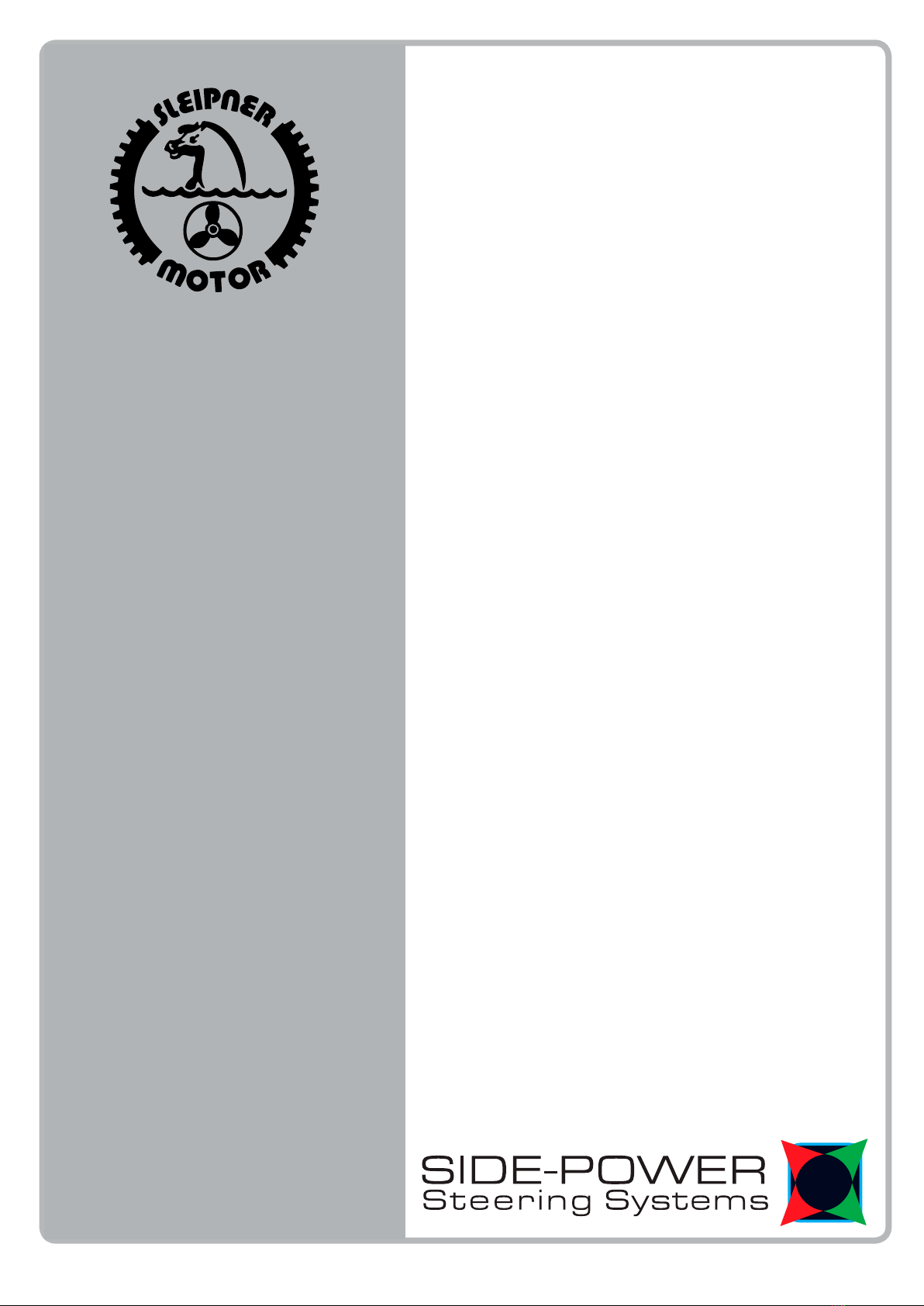

System Unit/ Servo Pump overview ......................................................................................................... 6

System Unit/ Servo Pump installation ...................................................................................................... 7

Hose installation .......................................................................................................................................

7................................................................................................................................................................

Hose connection....................................................................................................................................... 7

Power supply and signal cable connections ............................................................................................ 7

System Unit hydraulic ports...................................................................................................................... 8

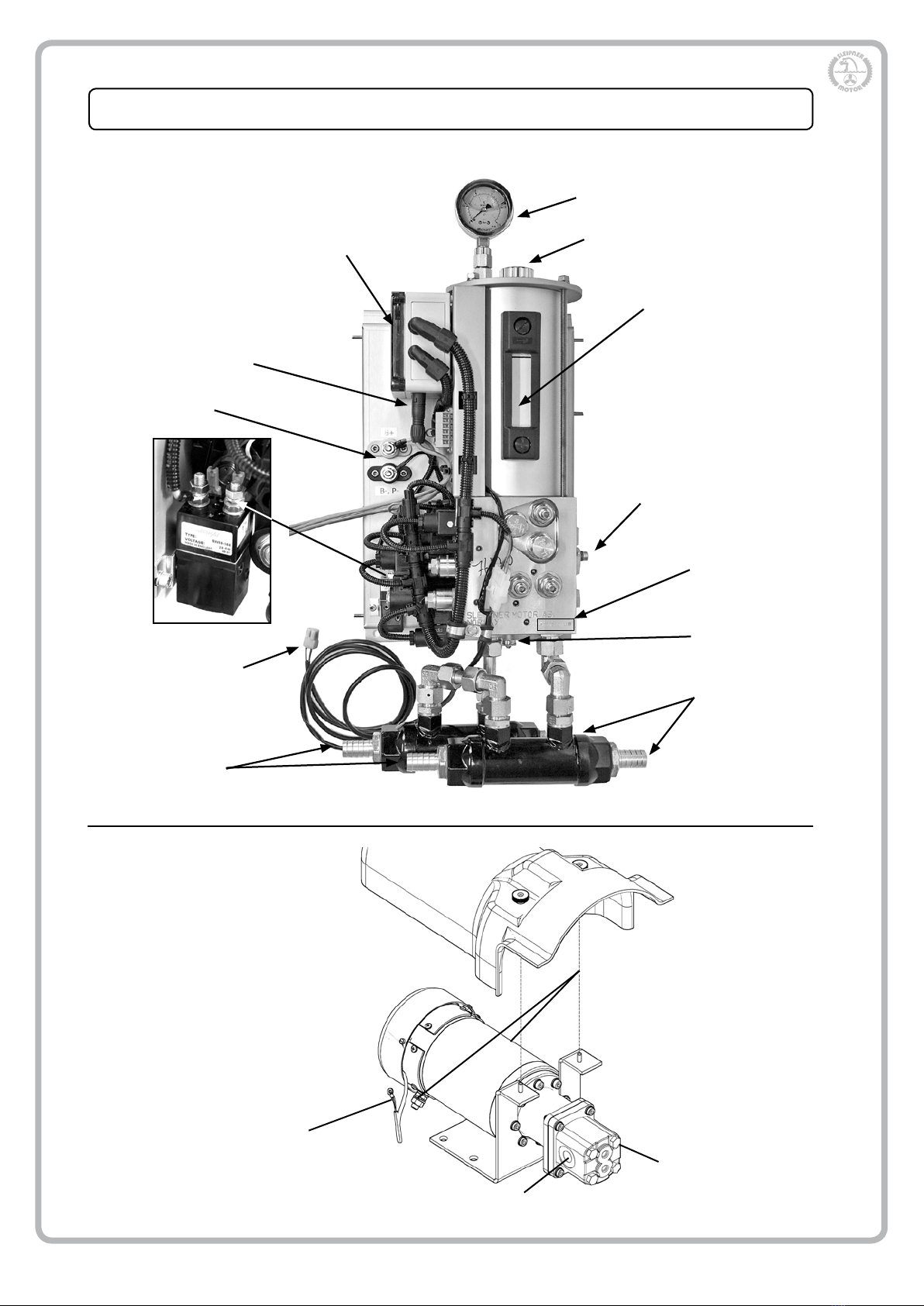

Rudder Cylinder installation...................................................................................................................... 9

Helm Pump installation, Tilt pump with hydraulic backup......................................................................... 10

Helm installation, Tilt helm without hydraulic backup.. ............................................................................. 11

Tilt Helm steering friction adjustment ....................................................................................................... 11

Helm Pumps, hydraulic connections ........................................................................................................ 12

Filling & Air purging................................................................................................................................... 13

Hydraulic system ......................................................................................................................................

14..............................................................................................................................................................

Wiring diagram, Flybridge (Twin helm)..................................................................................................... 15

Wiring diagram, Non - Flybridge (Single helm) ........................................................................................ 16

Cooling system......................................................................................................................................... 17

ECU (Electronic control unit) .................................................................................................................... 18

Important installation precautions............................................................................................................. 19

Maintenance............................................................................................................................................. 19

Spare parts............................................................................................................................................... 21

All Side-Power steering products complies with

the CE directive 94/25/EC