25926 20 2 0 21

-

SXP35 & SXP50

Sleipner Motor AS

P.O. Box 519, Arne Svendsensgt. 6-8

N-1612 Fredrikstad, Norway

MC_0020

Contents

MC_0031

General Installation Considerations and Precautions for Electric Thrusters

• The thruster must NOT be installed in compartments that require ignition proof electric equipment. If necessary, make a separate compartment.

(NB: Ignition Protected systems are tested to be installed in areas with possible explosive gases in accordance with ISO 8846)

• When installing the thruster electro motor in small compartments, ensure the compartment is well ventilated to allow for cooling of the electro

motor.

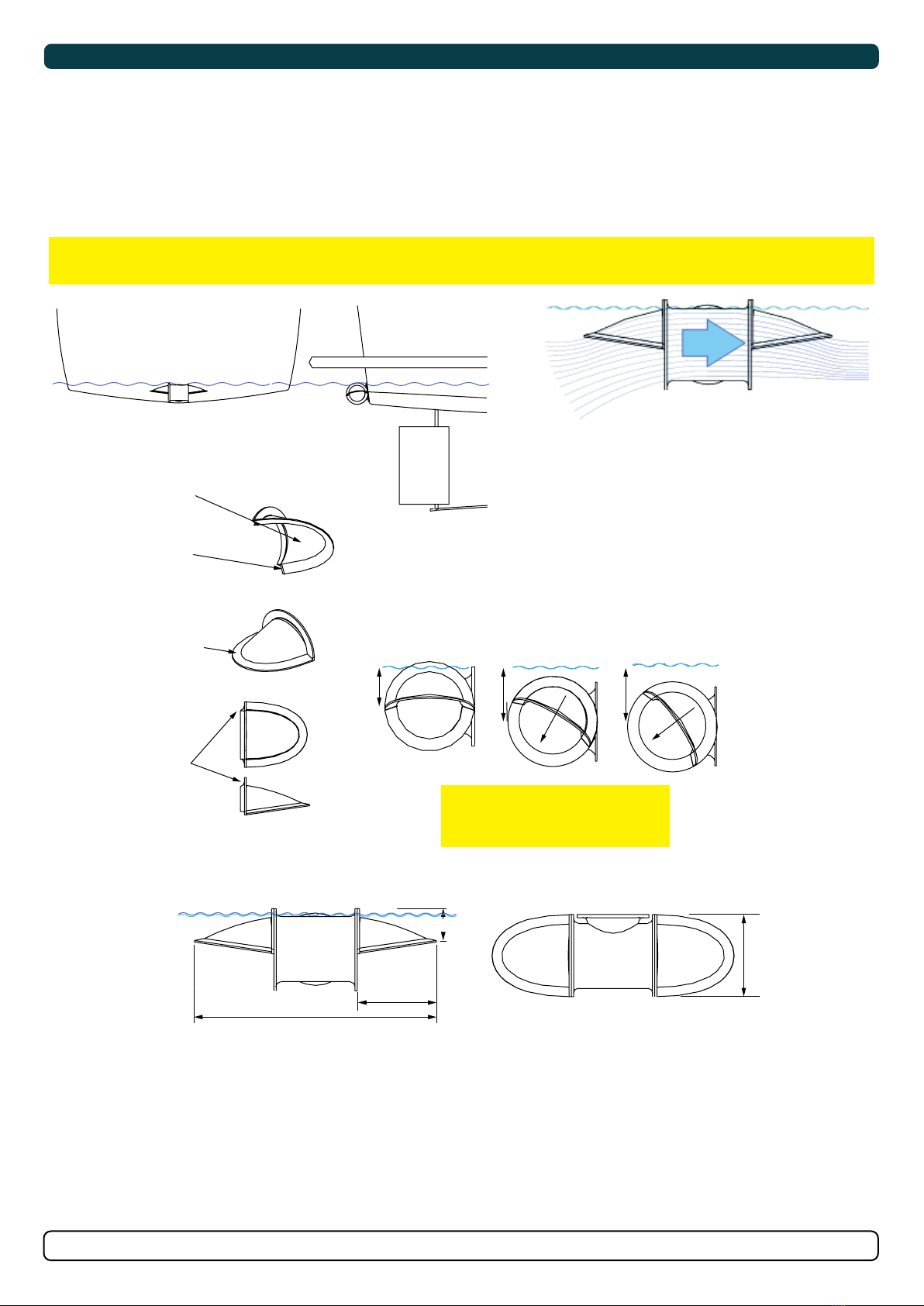

• If the height of the room you are installing the thruster is limited, the thruster can be installed horizontally or at any angle in-between.

- If the electro motor is positioned more than 30 degrees off vertical, it must be supported separately.

- Beware of keeping installation within advised measurements. No part of the propeller or gear house must be outside the tunnel.

• Do not install the thruster in a position where you need to cut a stiffener/ stringer/ support that may jeopardise the hull integrity without checking

with the boat builder this can be done safely.

• The electro motor, components and cables must be mounted so they remain dry at all times.

• We advise painting the gear house and propellers with anti-fouling. (NB: Do not paint the anodes, sealing, rubber fi ttings or propeller shafts)

• Do not fi nish the inside of the tunnel with a layer of gel-coat/ topcoat or similar. There is only room for a thin coat of primer and two layers of anti-

fouling between the tunnel and the props.

• Don’t install the electro motor close to easily flammable objects or equipment as it will reach over 100°C before the temperature switch is activated.

• Do not store items close to the thruster motor. Any loose items near the thruster motor is a potential fi re hazard and can cause undesired short-

circuiting.

• Do not lift it by internal cable connections, main terminals.

• The thruster power supply circuit must include the recommended sized fuse and a battery isolation switch.

MC_0425

General Installation Considerations and Precautions for Thrusters

• Do not install the thruster in a position where you need to cut a stiffener/ stringer/ support that may jeopardise the hull integrity without checking

with the boat builder this can be done safely.

• We advise painting the gear house and propellers with anti-fouling. (NB: Do not paint the anodes, sealing, rubber fi ttings or propeller shafts)

• Do not fi nish the inside of the tunnel with a layer of gel-coat/ topcoat or similar. There is only room for a thin coat of primer and two layers of anti-

fouling between the tunnel and the props.

• Never run the thruster out of water.

• The electro/ hydrulic motor must be handled with care. Do not place down the motor on the drive shaft.

Products

SXP50/140-12V-150MM - SXP50/140 w/Controller and PPC

SXP50/140-12V-50MM - SXP50/140 w/Controller and PPC

SXP35/140-12V-50MM - SXP35/140 w/Controller and PPC

SXP35/140-12V-150MM - SXP35/140 w/Controller and PPC

Installation Manual

Responsibility of the Installer..............................................................................................................................................................3 - 4

Thruster Measurements ........................................................................................................................................................................ 5

Thruster Specications........................................................................................................................................................................... 6

Technical Specications ........................................................................................................................................................................ 6

Control Box Technical Specications...................................................................................................................................................... 7

Positioning the Stern Thruster................................................................................................................................................................ 8

Stern Thruster Cowls/ Grids ................................................................................................................................................................... 9

Grids or Cowls Assembly...................................................................................................................................................................... 10

Tunnel Installation ................................................................................................................................................................................ 11

SX Spacer ............................................................................................................................................................................................ 12

Motor Installation .................................................................................................................................................................................. 13

Propeller Installation............................................................................................................................................................................. 14

Control Box Installation......................................................................................................................................................................... 15

Thruster Electrical Installation ....................................................................................................................................................... 16 - 17

Electrical Specications ....................................................................................................................................................................... 18

Control Panel Cable Installation .......................................................................................................................................................... 19

S-Link System Description .................................................................................................................................................................. 20

Control Panel Installation ..................................................................................................................................................................... 21

Pre-delivery Checklist .......................................................................................................................................................................... 22

Service and Support........................................................................................................................................................................... 23

Product Spare Parts and Additional Resources.............................................................................................................................. 23

Warranty Statement............................................................................................................................................................................ 23