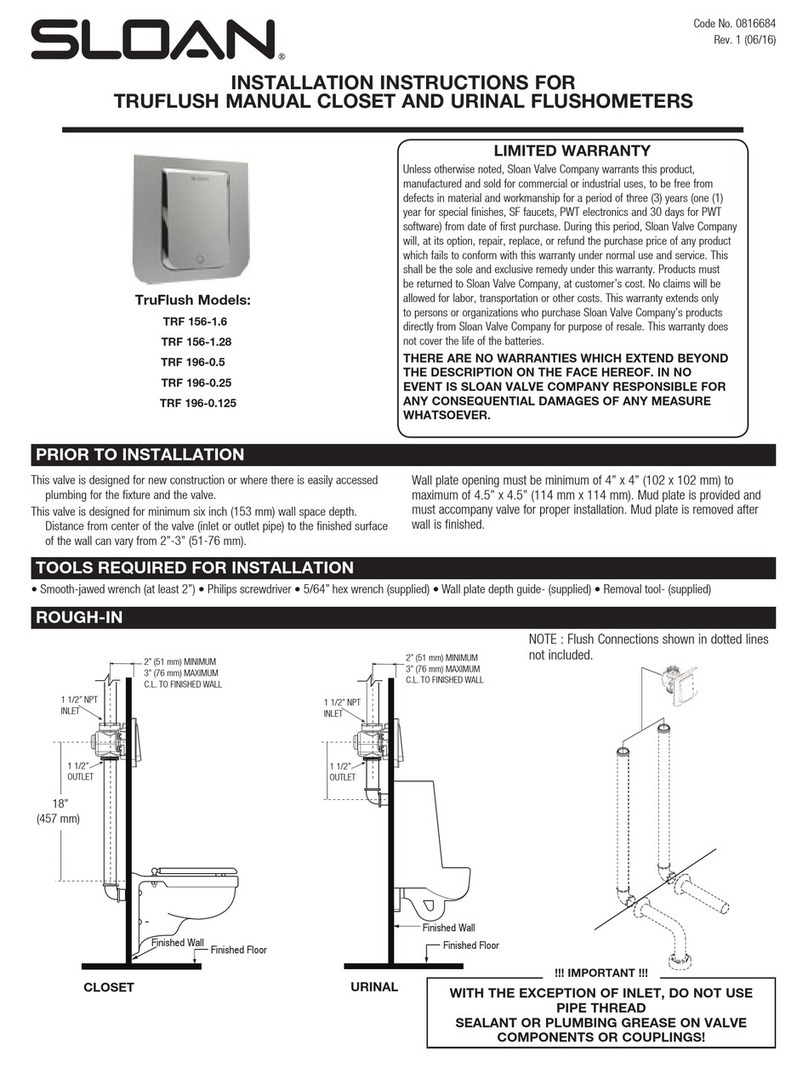

2. ADJUST CONTROL FLOW

Valve is shipped with the ow adjustment turned off.

A. Ensure activation assembly is turned fully clockwise to make sure water

is off

B. Push plunger screw in center to relieve pressure. Push in activation

assembly until fully seated.

C. Remove orange safety ring by squeezing pins together and pulling out.

D. Attach supplied screws to threaded holes in activation assembly. Pull

out activation assembly. Do not rotate to avoid turning water on!

E. Remove conical spring. Do not discard!

F. Remove piston by pulling it straight out. If unable to grip piston, remove

screw from front of activation assembly and screw into center hole of

piston.

G. Reinstall activation assembly and press until fully seated.

H. Reinstall orange safety ring securely. Safety ring will spin freely in valve

body when properly installed.

I. Using tool, (along with screwdriver or wrench, if needed), turn activation

assembly counter clockwise slowly to open ow of water to ush the lines-

careful not to overow the xture

J. Once lines are ushed clear, turn activation assembly clockwise to shut

water ow off.

K. Push button/plunger in center to relieve pressure

L. Remove orange safety ring by squeezing pins together

M.Pull out activation assembly using supplied screws. Do not rotate to

avoid turning water on!

N. Reinstall piston - insert smaller sized end rst until fully seated

O.Reinstall conical spring, small end rst, into piston.

P. Reinstall activation assembly and press until fully seated

Q. Reinstall orange safety ring securely. Safety ring will spin freely in valve

body when properly installed.

R. Using tool (along with screwdriver or wrench, if needed), turn

activation assembly slowly counterclockwise to open ow of

water

S. Push plunger screw to activate ush and adjust water ow as needed

by rotating activation assembly (clockwise to lessen ow and counter

clock wise to increase ow)

B.

H.

If supply line was ushed and is clean of debris, proceed to step R.

If supply line was not previously ushed, follow steps A-S.A.

C. D.

E.

THE FLUSHOMETER IS ENGINEERED FOR QUIET OPERATION.

EXCESSIVE WATER FLOW CREATES NOISE, WHILE TOO

LITTLE WATER FLOW MAY NOT SATISFY THE NEEDS OF THE

FIXTURE. PROPER ADJUSTMENT IS MADE WHEN PLUMBING

FIXTURE IS CLEANSED AFTER EACH FLUSH WITHOUT

SPLASHING WATER OUT FROM THE LIP AND A QUIET

FLUSHING CYCLE IS ACHIEVED.

!!! IMPORTANT !!!

THE ACTIVATION ASSEMBLY SHOULD NEVER BE OPENED TO

THE POINT WHERE THE FLOW FROM THE VALVE EXCEEDS

THE FLOW CAPABILITY OF THE FIXTURE. IN THE EVENT

OF A VALVE FAILURE, THE FIXTURE MUST BE ABLE TO

ACCOMMODATE A CONTINUOUS FLOW FROM THE VALVE.

!!! IMPORTANT !!!

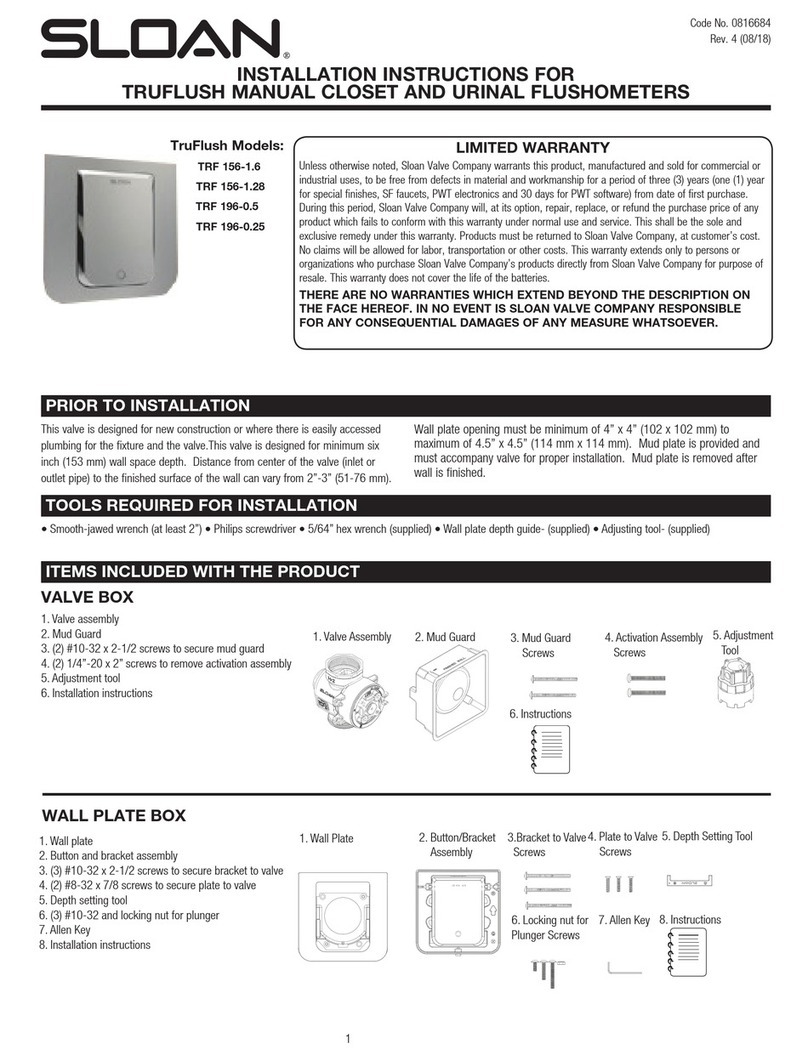

3. INSTALL BUTTON/BRACKET ASSEMBLY

A. Retrieve button/bracket assembly from box

B. Release the snap feature of the button by inserting the provided

5/64” hex key through the hole at the bottom of the face

plate while pressing at the top of the button.

C. Lift up button to 90 degrees until it locks in up position. Remove

face plate and set aside.

D. Mount black wall bracket to valve, centering wall bracket to valve.

Secure wall bracket evenly with three screws provided until bracket

ush with wall.

E. Slide wall plate over button and wall bracket and secure to

black bracket with two screws provided

F. Choose one of three plunger screws and nut provided and thread

into plunger. If Plunger starts rotating, STOP. This means the screw

has reached the bottom of the hole and overnighting the screw will

cause damage to the Plunger. Try the next shorter screw included

with the product to nish adjustment. Using depth guide provided,

adjust depth of plunger screw until screw touches depth guide (use

provided alternate length screws if necessary) and secure with nut.

G. Rotate button down until it snaps/locks into place.

H. Test ush by pushing button (make sure button is not

pushing screw when in resting position)

B. E.

1

3